the Folding Fusegate - Hydroplus

the Folding Fusegate - Hydroplus

the Folding Fusegate - Hydroplus

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

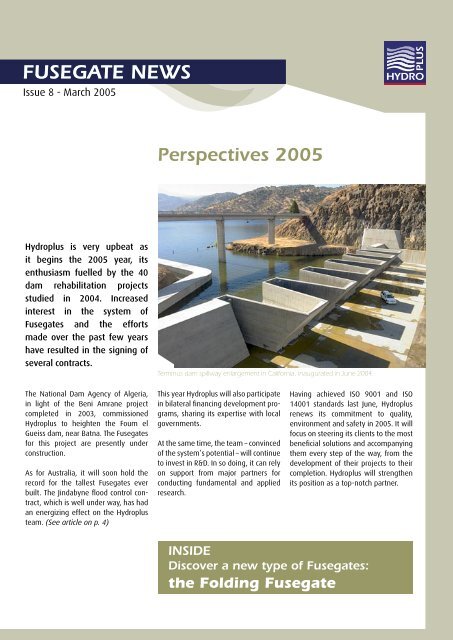

Issue 8 - March 2005Perspectives 2005<strong>Hydroplus</strong> is very upbeat asit begins <strong>the</strong> 2005 year, itsenthusiasm fuelled by <strong>the</strong> 40dam rehabilitation projectsstudied in 2004. Increasedinterest in <strong>the</strong> system of<strong>Fusegate</strong>s and <strong>the</strong> effortsmade over <strong>the</strong> past few yearshave resulted in <strong>the</strong> signing ofseveral contracts.Terminus dam spillway enlargement in California, inaugurated in June 2004.The National Dam Agency of Algeria,in light of <strong>the</strong> Beni Amrane projectcompleted in 2003, commissioned<strong>Hydroplus</strong> to heighten <strong>the</strong> Foum elGueiss dam, near Batna. The <strong>Fusegate</strong>sfor this project are presently underconstruction.As for Australia, it will soon hold <strong>the</strong>record for <strong>the</strong> tallest <strong>Fusegate</strong>s everbuilt. The Jindabyne flood control contract,which is well under way, has hadan energizing effect on <strong>the</strong> <strong>Hydroplus</strong>team. (See article on p. 4)This year <strong>Hydroplus</strong> will also participatein bilateral financing development programs,sharing its expertise with localgovernments.At <strong>the</strong> same time, <strong>the</strong> team – convincedof <strong>the</strong> system’s potential – will continueto invest in R&D. In so doing, it can relyon support from major partners forconducting fundamental and appliedresearch.Having achieved ISO 9001 and ISO14001 standards last June, <strong>Hydroplus</strong>renews its commitment to quality,environment and safety in 2005. It willfocus on steering its clients to <strong>the</strong> mostbeneficial solutions and accompanying<strong>the</strong>m every step of <strong>the</strong> way, from <strong>the</strong>development of <strong>the</strong>ir projects to <strong>the</strong>ircompletion. <strong>Hydroplus</strong> will streng<strong>the</strong>nits position as a top-notch partner.INSIDEDiscover a new type of <strong>Fusegate</strong>s:<strong>the</strong> <strong>Folding</strong> <strong>Fusegate</strong>

RESEARCH & DEVELOPMENTInitial realease of <strong>Folding</strong> <strong>Fusegate</strong>sR&D carried out by <strong>Hydroplus</strong> in cooperation with <strong>the</strong> Scientific Reasearch Institute of Energy Structures(NIIES) of Russia has borne fruit, as a new type of <strong>Fusegate</strong> has just been fine-tuned: <strong>the</strong> <strong>Folding</strong> <strong>Fusegate</strong>.This brand new, patented product functions according to <strong>the</strong> same principle as <strong>the</strong> original <strong>Fusegate</strong>system and its operation requires nei<strong>the</strong>r external energy nor human intervention.What does it look like?WELLEach element is comprised of 4 separateparts:PIER• <strong>the</strong> panel, attached to <strong>the</strong> sill of <strong>the</strong>dam by a rotating axle.• <strong>the</strong> mobile chamber, which pivots onan axel anchored to <strong>the</strong> sill on <strong>the</strong> downstreamside.UPSTREAMPANELWell WLUpstreamWLDOWNSTREAM• <strong>the</strong> supporting arm, consisting of twofolding bars. Depending on <strong>the</strong> panelsize, <strong>the</strong> arm can be reinforced with anadditional bar.CHAMBERARM• <strong>the</strong> well, linked to <strong>the</strong> chamber.How does it work?Well WLUpstreamWLUnder normal operating conditionsThe panel is raised and forms a watertightbarrier. The arm, <strong>the</strong> two bars ofwhich form almost a 180° angle, rests on<strong>the</strong> chamber and supports <strong>the</strong> panel.The <strong>Fusegate</strong> is stable and operates likean ungated spillway.In case of a major floodWhen <strong>the</strong> upstream water level reaches<strong>the</strong> inlet shaft level, water enters <strong>the</strong>well and causes an uplift pressure to developin <strong>the</strong> chamber. The mobile chamber<strong>the</strong>n rotates and pushes against <strong>the</strong>lower section of <strong>the</strong> arm. As soon as <strong>the</strong>arm angle comes to an angle greaterthan 180°, <strong>the</strong> panel falls down flat.During <strong>the</strong> floodThe panel stays flat, <strong>the</strong> chamber is backto its original position and <strong>the</strong> arm remainsbent.Once <strong>the</strong> flood is over, a winch or a jackingsystem is used to raise <strong>the</strong> panel upagain.Well WLUpstreamWL2

Testing <strong>the</strong> technologyA series of laboratory tests was conductedin Russia with <strong>the</strong> NIIES. The first modelsof <strong>Folding</strong> <strong>Fusegate</strong>s were experimentedon a hydraulic model, demonstrating<strong>the</strong>ir expected reaction according tovarious downstream water levels as wellas <strong>the</strong>ir great shock resistance.Full size <strong>Folding</strong> <strong>Fusegate</strong>sThese more than satisfactory results culminated,in July 2004, with <strong>the</strong> constructionof steel <strong>Folding</strong> <strong>Fusegate</strong>s, 1.80 mtall, which were installed at one end of<strong>the</strong> Korobrovskaya dam spillway (Russia).Artificial floods validated <strong>the</strong>ir proper operationand an observation campaign isnow underway to study <strong>the</strong>ir behaviourin icy conditions.In order to optimise <strong>the</strong> system, various spillwayconfigurations were studied, including<strong>the</strong> installation of <strong>Fusegate</strong>s between wallsparallel to <strong>the</strong> current in order to recreate <strong>the</strong>performances of a labyrinth.3<strong>Folding</strong> <strong>Fusegate</strong>s do not replace <strong>the</strong> <strong>Fusegate</strong>s currently on<strong>the</strong> market. They function according to <strong>the</strong> same principle as<strong>the</strong> original version, but <strong>the</strong>ir more elaborate design allow for aresponse that is better adapted to projects where <strong>the</strong> local hydrologyrequires frequent lowering of <strong>the</strong> <strong>Fusegate</strong>s in order toprotect <strong>the</strong> structure. With <strong>the</strong> inception of <strong>Folding</strong> <strong>Fusegate</strong>s,<strong>Hydroplus</strong> reconfirmed its commitment to R&D while demonstrating<strong>the</strong> potential and adaptability of its process.

JINDABYNE DAM – AUSTRALIASuccessful model tests runsThe challenge involving <strong>the</strong> tallest<strong>Fusegate</strong>s in <strong>the</strong> world (7.6 m high)continues. The <strong>Hydroplus</strong> team has finetunedits highly innovative concept,which allows <strong>the</strong> performance ofconventional labyrinth <strong>Fusegate</strong>s to beoptimised through a configuration that iseven more economical.Tests were conducted last fall in cooperationwith <strong>the</strong> Sogreah Laboratoryin Grenoble, France. Adjustments weremade using two hydraulic models, builtto scales of 1/20 and 1/45 respectively.The first model measured <strong>the</strong> stability of<strong>the</strong> <strong>Fusegate</strong>s under normal and downgradedworking conditions, while <strong>the</strong> secondstudied <strong>the</strong> hydraulic performanceof <strong>the</strong> spillway.The results of <strong>the</strong> tests are verysatisfactory. They highlight <strong>the</strong> potentialuses of <strong>Fusegate</strong> technology andcontribute to <strong>the</strong> progress of <strong>Hydroplus</strong>R&D initiatives.Small (above) and large (right)hydraulic models for Jindabyne Dam.The next project step will consist ofpreparing <strong>the</strong> construction drawings andenvironmental reports necessary to beginconstruction of <strong>the</strong> <strong>Fusegate</strong>s in <strong>the</strong> thirdquarter of 2005.Supported by <strong>the</strong> FASEP (<strong>the</strong> FrenchGovernment’s Private Sector Study andAid Fund), <strong>Hydroplus</strong>, in partnership withSogreah, was commissioned to conducta study to optimise <strong>the</strong> dams belongingto <strong>the</strong> Royal Irrigation Department ofThailand.The project, which is scheduled to lastover a 10-month period, will begin inMarch. Engineers will closely examineFASEP – THAILANDSolutions for meetingwater needs<strong>the</strong> possibility of raising 10 dams, selectedon <strong>the</strong> basis of technical feasibilitycriteria and <strong>the</strong> importance of <strong>the</strong> demandfor water.In so doing, <strong>Hydroplus</strong> hopes to find asuitable solution to <strong>the</strong> increasing needfor water in Thailand.<strong>Hydroplus</strong>5, cours Ferdinand-de-Lesseps92851 Rueil-Malmaison CedexFranceTel: (+33) 1 47 16 44 34Fax: (+33) 1 47 16 42 12Email: contact@hydroplus.com4