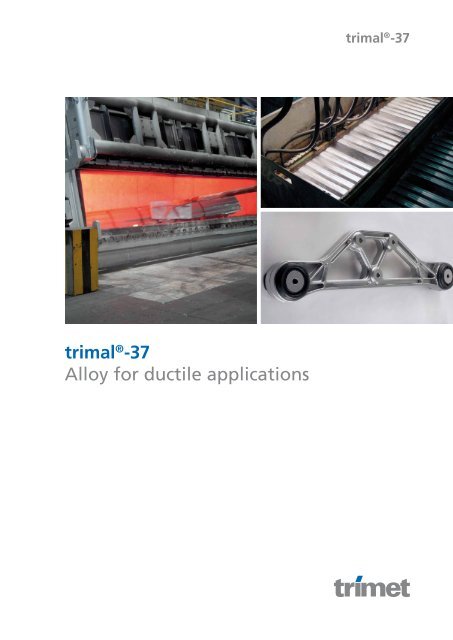

trimal®-37 Alloy for ductile applications - TRIMET Aluminium SE

trimal®-37 Alloy for ductile applications - TRIMET Aluminium SE

trimal®-37 Alloy for ductile applications - TRIMET Aluminium SE

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

trimal ® -<strong>37</strong><strong>Alloy</strong> <strong>for</strong> <strong>ductile</strong> <strong>applications</strong>trimal ® -<strong>37</strong>

trimal ® -<strong>37</strong><strong>Alloy</strong> <strong>for</strong> <strong>ductile</strong> <strong>applications</strong>trimal ® -<strong>37</strong> (AlSi9Mn) alloy was developed specially <strong>for</strong> the high pressure diecasting process. In comparison to common die cast alloys, it has excellentductility, which is evident from its high elongation and good energy absorptioncapability. As a result, trimal ® -<strong>37</strong> is particularly suited <strong>for</strong> <strong>applications</strong> that requireductility and are not intended <strong>for</strong> heat treatment.trimal ® -<strong>37</strong> has a silicon content of about 9% andis thus ideally suited <strong>for</strong> casting complicated structures.The low iron content in trimal ® -<strong>37</strong> preventsthe <strong>for</strong>mation of coarse intermetalic phases; manganeseand molybdenum prevent sticking to thedie. By modification with strontium, the structureof the eutectic silicon is so fine that it cannot beobserved under a light-optical microscope evenwith a magnification of 1000x.Copper, zircon and manganese create the necessarystrength at room temperature and providegood heat stability at higher temperatures. Thesilicon can be globulized through short annealingthat is per<strong>for</strong>med below the blister temperature,thus increasing the ductility even further. The lowmagnesium content of less than 0.08% preventsthe material from short or long-term aging.Short- and longterm heat stabilityTemper205°C - 60min.150°C - 1000hYoung’smodulusGPa6565Rp0.2MPa134135RmMPa280250Measured with a wall thickness of 2 – 3 mmThe alloy has been modified with strontiumA%1011Summarytrimal ® -<strong>37</strong> die cast alloy• has excellent cast and die-filling behavior• can be easily removed from the die• has high heat stability• has high ductility in combination withgood strength• has good corrosion resistance• is weldable with all common welding methods.Chemical composition in weight%%Min.Max.Si8,510,5Fe0,15Cu0,10,2Mn0,30,6Mg0,08Mo0,10,3%Min.Max.Zr0,10,3Zn0,07Ti0,06V0,030,10Other Balance0,15 AlMechanical propertiesThe following mechanical properties were determinedusing real parts and are considered to bereference values <strong>for</strong> the use of the alloy.TemperFOYoung’smodulusGPa65 - 7565 - 75YieldstrengthRp0.2MPa120 - 140100 - 120TensileStrengthRmMPa250 - 290200 - 240Measured with a wall thickness of 2 – 3 mmElongationA%8 - 1510 - 18HardnessHB80 - 9065 - 75CopyrightThe in<strong>for</strong>mation provided in this brochure was gathered in proper tests and is given to the best ofour knowledge and belief. However, as with all application suggestions, they are solely nonbindingreferences that are not covered by our contractual obligations (including any third-party copyrights)and <strong>for</strong> which we are not liable. The data do not constitute a guarantee <strong>for</strong> properties and do notrelease the user from his responsibility to test whether our products are suited <strong>for</strong> their intendeduse. The reproduction, translation and copying of this brochure, in whole or part, are subject to ourexpress authorization. New alloys and their technological advancements that are developed afterthe brochure has gone into print will be presented in the next issue.<strong>TRIMET</strong> <strong>Aluminium</strong> <strong>SE</strong> • <strong>Aluminium</strong>allee 1 • D-45356 EssenTel. +49 201-3660 • www.trimet.deV2 - 09/2013 - 50GB