Low-Frequency Eddy Current Through-Bushing Inspection

Low-Frequency Eddy Current Through-Bushing Inspection

Low-Frequency Eddy Current Through-Bushing Inspection

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

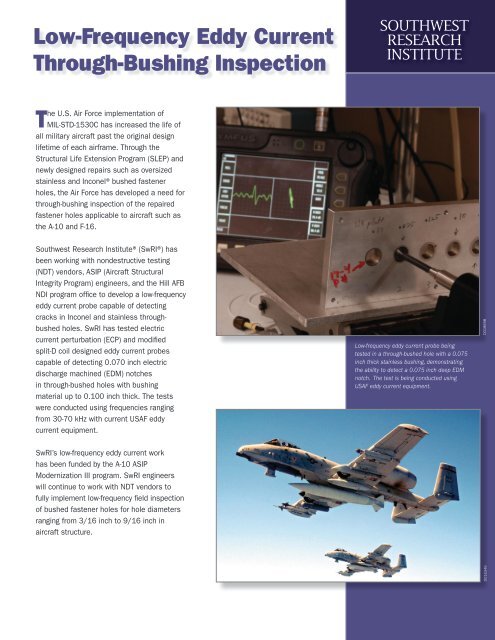

<strong>Low</strong>-<strong>Frequency</strong> <strong>Eddy</strong> <strong>Current</strong><strong>Through</strong>-<strong>Bushing</strong> <strong>Inspection</strong>The U.S. Air Force implementation ofMIL-STD-1530C has increased the life ofall military aircraft past the original designlifetime of each airframe. <strong>Through</strong> theStructural Life Extension Program (SLEP) andnewly designed repairs such as oversizedstainless and Inconel® bushed fastenerholes, the Air Force has developed a need forthrough-bushing inspection of the repairedfastener holes applicable to aircraft such asthe A-10 and F-16.Southwest Research Institute® (SwRI®) hasbeen working with nondestructive testing(NDT) vendors, ASIP (Aircraft StructuralIntegrity Program) engineers, and the Hill AFBNDI program office to develop a low-frequencyeddy current probe capable of detectingcracks in Inconel and stainless throughbushedholes. SwRI has tested electriccurrent perturbation (ECP) and modifiedsplit-D coil designed eddy current probescapable of detecting 0.070 inch electricdischarge machined (EDM) notchesin through-bushed holes with bushingmaterial up to 0.100 inch thick. The testswere conducted using frequencies rangingfrom 30-70 kHz with current USAF eddycurrent equipment.SwRI’s low-frequency eddy current workhas been funded by the A-10 ASIPModernization III program. SwRI engineerswill continue to work with NDT vendors tofully implement low-frequency field inspectionof bushed fastener holes for hole diametersranging from 3/16 inch to 9/16 inch inaircraft structure.<strong>Low</strong>-frequency eddy current probe beingtested in a through-bushed hole with a 0.075inch thick stainless bushing, demonstratingthe ability to detect a 0.075 inch deep EDMnotch. The test is being conducted usingUSAF eddy current equipment.D016346 D018698

18-1112 JCN 245076 tpSouthwest Research Institute is an independent, nonprofit, applied engineering and physical sciences research and development organization using multidisciplinary approaches toproblem solving. The Institute occupies 1,200 acres in San Antonio, Texas, and provides more than 2 million square feet of laboratories, test facilities, workshops, and offices for morethan 3,000 employees who perform contract work for industry and government clients.We welcome your inquiries.For additional information,please contact:Clinton J. ThwingStaff Engineer(210) 522-3989clinton.thwing@swri.orgSensor Systems and NDE Technology DepartmentMechanical Engineering DivisionSouthwest Research Institute6220 Culebra Road • P.O. Box 28510San Antonio, TX 78228-0510swri.orgBenefiting government,industry and the public throughinnovative science and technologyAn Equal Opportunity Employer M/F/D/VCommitted to Diversity in the Workplace