valvetronic engine technology - IFET College of Engineering

valvetronic engine technology - IFET College of Engineering

valvetronic engine technology - IFET College of Engineering

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

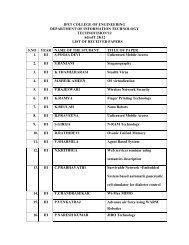

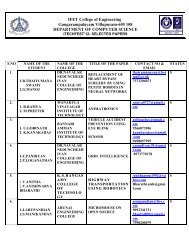

<strong>IFET</strong> COLLEGE OF ENGINEERINGDEPARTMENT OF MECHANICAL ENGINEERINGPRESENTATION ONVALVETRONIC ENGINE TECHNOLOGYPRESENTED BYS.SARAVANANIII YR MECHANICAL

VALVETRONIC ENGINE TECHNOLOGYINTRODUCTIONThe automobile has beenproviding individual mobility for morethan 100 years. This mobility is madepossible first and foremost bycombustion <strong>engine</strong>s drawing their powerfrom fossil energy carriers, which, eventoday, provide the foundation ingenerating mechanical drive power inthe automobile. The primary objectivesin developing drive systems are to curbfuel consumption and reduce CO2emissions. In an effort to meet thischallenge, the automotive industry isdeveloping suitable new <strong>engine</strong>s. Thevoluntary commitment assumed by theEuropean Automobile ManufacturersAssociation (ACEA) is to reduce thefleet emission average <strong>of</strong> all newlyintroduced cars to 140g <strong>of</strong> CO2 perkilometer by 2008 .The first objective is to minimiseemission components such ashydrocarbon, CO2 and nitrogen oxides(NOx) subject to specific limits. At thesame time, manufacturers are seeking tominimise fuel consumption and,accordingly, CO2 emissions. All <strong>of</strong> thisshould be achieved with a maximumstandard <strong>of</strong> comfort and safety on theroad. In the homologation <strong>of</strong> motorvehicles, Europe, Japan and the USapply different driving cycles todetermine emissions and fuelconsumption. However, it is theindividual customer who ultimatelydecides on his/her particular style <strong>of</strong>motoring and up to 30% <strong>of</strong> a car’s fuelconsumption depends on how it is drivenand the style <strong>of</strong> motoring that ispreferred by the driver. Clearly, thedevelopment <strong>engine</strong>er is unable toinfluence these external parameters – allthat he/she can do is change the basicfunctions and control factors in the carand its drivetrain. The amount <strong>of</strong> energyrequired for driving a vehicle also dropswith decreasing driving resistanceprovided by, for example, a reduction inroll and air resistance. To make moreefficient use <strong>of</strong> the energy in fuel, the

actual process <strong>of</strong> using energy mustreach a higher standard <strong>of</strong> efficiency.Despite modern <strong>engine</strong> <strong>technology</strong>, theprocess <strong>of</strong> on-going development has notyet come to an end. Looking at theoverall concept <strong>of</strong> a vehicle, thedevelopment <strong>engine</strong>er must thereforeoptimize the efficiency chain formed byall <strong>of</strong> the car’s individual components.For example, a car with a state-<strong>of</strong>-the-artspark-ignition <strong>engine</strong> uses only about20% <strong>of</strong> the energy consumed to actuallygenerate driving power and mobility inthe EU test cycle. This alonedemonstrates the remaining potentialEvolution <strong>of</strong> Valvetronic• the charge cycle;• friction; and• thermal losses through the walls.Optimisation in these areas indriving cycles with low loads and <strong>engine</strong>speeds provides the greatestimprovements in fuel economy. Quitegenerally, steps taken to reduce thethrottle effect have a greater potential forsaving fuel than the reduction <strong>of</strong> frictionin the drivetrain (see Figure 2.1).Precisely with this in mind, BMW haseveloped a fully variable valve drivereferred to as Valvetronic, a system<strong>of</strong>fering improvement in fuelconsumption comparable in virtually alldriving cycles to the latest spark-ignition<strong>engine</strong>s with direct fuel injection (DFI)and leanburn operation.The losses that are capable <strong>of</strong>being influenced are composed primarily<strong>of</strong> the following:• a combustion process not yet ideal;A number <strong>of</strong> other importantitems were also included in the list <strong>of</strong>objectives: • achieving dynamicperformance, fuel economy, noisemanagement and quality typical <strong>of</strong>BMW;• having a flexible concept capable <strong>of</strong>fulfilling future emissions standards;• creating a benchmark product in terms<strong>of</strong> its package, weight and cost <strong>of</strong>ownership;

• taking a modular approach in order todevelop specific <strong>engine</strong> variants;• ensuring a significant potential for ongoingdevelopment; and• providing the foundation for other<strong>engine</strong> variants, i.e. communality withfuture<strong>engine</strong>s.All <strong>of</strong> this led to the development<strong>of</strong> a fully variable valve drive system,BMW Valvetronic, helping tosignificantly reduce fuel consumptionwhile maintaining stochiometric drivingconditions with all the usual advantages.What Is Valvetronic?The Valvetronic <strong>engine</strong> is theworld's first <strong>engine</strong> without a throttlebutterfly. Valvetronic allows the <strong>engine</strong>to run without a throttle butterfly, thecylinder charge being determined underpart load as a function <strong>of</strong> the valveopeningperiod. The intake and outletcamshafts are driven by variable camadjustment, BMW’s Vanos <strong>technology</strong>.A further advantage <strong>of</strong> this concept isthat it allows worldwide use <strong>of</strong> theproven three-way catalyst for emissionsmanagement, thus meeting even thestrictest emissions standards in the US.Innovative <strong>technology</strong> wasessential in order to reach the demandingobjectives and functional requirementsdesired. However, at the same time, thisconcept demanded the utmost <strong>of</strong> theelectronic control and managementsystems in the <strong>engine</strong>.ConceptTaking nature as the role model: humanbeings also apply the ValvetronicprincipleA comparison with the humanbeing clearly explains how Valvetronicworks: Whenever we are required tomake a great effort, we human beingsbreathe in a deep and long process <strong>of</strong>ventilation. Whenever we need less air,we do not throttle the supply <strong>of</strong> air by,say, closing our nose or our mouth, butsimply breathe in a shorter, flatterprocess <strong>of</strong> ventilation. In a conventionalcombustion <strong>engine</strong> the throttle butterflyis basically comparable to a humanbeing keeping his nose or mouth at leastpartially closed. With its large valve lift(= deep, long ventilation) and shortvalve lift (= flat, short process <strong>of</strong>ventilation), Valvetronic, on the otherhand, is able to breathe in the same way

as nature – always in line with currentrequirements, without any kind <strong>of</strong>throttling effect and therefore withmaximum efficiency.Valvetronic TechnologyAccordingly, the Valvetronic<strong>engine</strong> no longer requires a throttlebutterfly, which has quite literallyrestricted the free ventilation <strong>of</strong> theinternal combustion <strong>engine</strong> ever since itsinvention. Now Valvetronic replaces thisconventional function by infinitelyvariable intake valve lift, <strong>of</strong>fering aquantum leap in <strong>technology</strong> quitecomparable to the changeover from thecarburetor to fuel injection.Its most important feature is thatit is able to save at least 10 per cent fuelthroughout the entire operating rangerelevant to the customer, with acorresponding reduction in exhaustemissions, regardless <strong>of</strong> fuel quality.And a further important point is that theefficient operation <strong>of</strong> Valvetronic doesnot require any unusual types and grades<strong>of</strong> oil possibly difficult to obtain.As a result <strong>of</strong> these particularfeatures the 85 kW/115bhp BMW 316ticompact with its top speed <strong>of</strong> 210 km/hor 125 mph consumes a mere 6.9 liters<strong>of</strong> premium fuel on 100 kilometers in theEuropean test cycle, equivalent to 40.9mpg Imp. This is a significant 0.7 litersless than the former 77 kW/105 bhpcompact and well over a liter less thanall competitors in this class.The Valvetronic system is basedconsistently on BMW’s proven double-VANOS (VANOS = variable adjustment<strong>of</strong> the camshafts), with infinite camshaftadjustment to meet specificrequirements. The additional, variablevalve lift adjusts the effective cam actionand, accordingly, the opening crosssection<strong>of</strong> the valves.This is done by a lever positionedbetween the camshaft and the intakevalves, its distance from the camshaftbeing adjusted infinitely by an additionaleccentric shaft operated by an electricmotor. Depending on the position <strong>of</strong> theValvetronic control system, the leverconverts the cam contour into a larger orsmaller valve lift, whatever may berequired.

The pistons are still running, taking airfrom the partially closed intakemanifold. The intake manifold betweenthe throttle and the combustion chamberhas a partial vacuum, resisting thesucking and pumping action <strong>of</strong> thepistons, wasting energy. Automotive<strong>engine</strong>ers refer to this phenomenon as"pumping loss". The slower the <strong>engine</strong>runs, the more the throttle butterflycloses, and the more energy is lost.WORKING OFVALVETRONIC ENGINE Working Of OrdinaryEngineIn <strong>engine</strong>s without <strong>valvetronic</strong><strong>technology</strong> fuel injection systemsmonitor the volume <strong>of</strong> air passingthrough the throttle butterfly anddetermine the corresponding amount <strong>of</strong>fuel required by the <strong>engine</strong>. The largerthe throttle butterfly opening, the moreair enters the combustion chamber.At light throttle, the throttlebutterfly partially or even nearly closes. intake valve with throttle plate. the supply <strong>of</strong> the fule/airmixture is controlled by thethrottle plate. valve lift isunchanged. Working Of Valvetronic EngineCompared with conventional twin-cam<strong>engine</strong>s with finger followers,Valvetronic employs an additional

eccentric shaft, an electric motor andseveral intermediate rocker arms, whichin turn activates the opening and closing<strong>of</strong> valves. If the rocker arms pushdeeper, the intake valves will have ahigher lift, and vice-versa. Thus,Valvetronic has the ability to get deep,long ventilation (large valve lift) andflat, short ventilation (short valve lift),depending on the demands placed on the<strong>engine</strong>. intake valve with <strong>valvetronic</strong>. the fuel/air mixture is controlled by avariable valve lift, without a throttle plate.Cylinder heads with Valvetronic use anextra set <strong>of</strong> rocker arms, calledintermediate arms (lift scaler),positioned between the valve stem andthe camshaft. These intermediate armsare able to pivot on a central point, bymeans <strong>of</strong> an extra, electronicly actuatedcamshaft. This movement alone, withoutany movement <strong>of</strong> the intake camshaft,can open or close the intake valves.The Valvetronic system is basedon BMW's established double VANOSsystem, which steplessly varies thetiming <strong>of</strong> both the inlet and exhaustcams. However, the Valvetronic systemadds variable valve lift to the inlet cam,achieved by the use <strong>of</strong> a lever positionedbetween the camshaft and the inletvalves. Valvetronic varies the timing andthe lift <strong>of</strong> the intake valves. TheValvetronic system has a conventionalintake cam, but it also uses a secondaryeccentric shaft with a series <strong>of</strong> levers androller followers, activated by a steppermotor. Based on signals formerly takenmechanically from the accelerator pedal,the stepper motor changes the phase <strong>of</strong>the eccentric cam, modifying the action<strong>of</strong> the intake valves. An additionaleccentric shaft alters the lever's distancefrom the camshaft, with the eccentric'sposition determined by a worm drivefrom an electric motor. The position <strong>of</strong>the lever converts the cam action into asmaller or larger valve lift, as requestedby the <strong>engine</strong> management system.

Intake vale lift can be altered from aminimum <strong>of</strong> 0.25mm(!) to a maximum<strong>of</strong> 9.7mm, with the electric motoradjusting the eccentric shaft in 0.3seconds.Because the intake valves nowhave the ability to move from fullyclosed to fully open positions, andeverywhere in between, the primarymeans <strong>of</strong> <strong>engine</strong> load control istransferred from the throttle plate to theintake valve train. By eliminating thethrottle plate's "bottleneck" in the intaketrack, pumping losses are reduced, fueleconomy and responsiveness areimproved. Operating Parameters Valve lift is variable between 0and 9.7 mm.Adjustment <strong>of</strong> the worm gearfrom one extreme to the othertakes 300 milliseconds. Combined with double-vanosvalve timing <strong>technology</strong>, thecamshaft angle relative to thecrankshaft can be adjusted by upto 60°.The intermediate arm is finishedto a tolerance <strong>of</strong> 0.008 mm. The cams controlling theeccentric shaft are machined totolerances <strong>of</strong> a few hundredths <strong>of</strong>a millimeter.ENGINE DESIGNASPECTS Basic <strong>engine</strong> design completelyrevisedNot only the cylinder head withBMW’s new Valvetronic <strong>technology</strong>,but also the complete four-cylinderpower unit featured in the BMW 316ti isan all-new development from the groundup. The new cross-flow cooling conceptwith its open deck crankcase reducescoolant flow resistance and thereforeallows use <strong>of</strong> a smaller water pump withjust 60 per cent <strong>of</strong> the usual poweruptake.Made <strong>of</strong> aluminum, the <strong>engine</strong>block ends exactly on the centerline <strong>of</strong>the crankshaft bearings. A ladder framebetween the crankcase and the oil sumpconnects the lower halves <strong>of</strong> the bearingbridges to form one complete unit alsoaccommodating the balance shafthousing and the two-stage oil pump.This makes the entire drive unit very

stiff and robust, minimizing anyvibration <strong>of</strong> other vehicle componentsthe driver would otherwise feel on thesteering wheel, gearshift lever andpedals, and also perceive as a kind <strong>of</strong>consistent humming noise.All ancillaries are bolted directlyto the crankcase without the ratherelaborate supports and attachmentsotherwise required – again an importantcontribution to running smoothness withvibrations reduced to a minimum. Throttle plate is not removedIt is important to note however,that the throttle plate is not removed, butrather defaults to a fully open positiononce the <strong>engine</strong> is running. The throttlewill partially close when the <strong>engine</strong> isfirst started, to create the initial vacuumneeded for certain <strong>engine</strong> functions, suchas emissions control. Once the <strong>engine</strong>reaches operating speed, a vacuum pumprun <strong>of</strong>f the passenger side exhaustcamshaft (on the N62 V8 only) providesa vacuum source, much as a diesel<strong>engine</strong> would, and the throttle plate onceagain goes to the fully open position.The throttle plate also doubles as anemergency backup, should theValvetronic system fail. In this case, the<strong>engine</strong> would enter a "limp home"program, and <strong>engine</strong> speed would onceagain be controlled by the throttle plate.ADVANTAGES ANDBENEFITS Fuel economy increasedValvetronic <strong>of</strong>fers the customerdirect, immediate benefits, with fuelconsumption and exhaust emissionsdecreasing, but dynamic performanceand the spontaneous response <strong>of</strong> the<strong>engine</strong> improving accordingly. Added tothis there is the even higher standard <strong>of</strong>running smoothness, since the valvesmove only slightly in a preciselycontrolled process.The improvement in fueleconomy ensured by this concept <strong>of</strong>throttle-free <strong>engine</strong> load management isapproximately 10 per cent in the EUcycle and at least 10 per cent under thetypical driving conditions encounteredby a customer. The basic rule is that fueleconomy versus other concepts increaseswith the driver running the vehicle at

lower loads and <strong>engine</strong> speeds. Theconsumption figures the motorist is ableto achieve in this way are comparable tothe fuel economy only a diesel <strong>engine</strong>was able to <strong>of</strong>fer just a few years ago.At the same time the new fourcylinderis even more dynamic than itspredecessor, the 316ti now acceleratingwell over a second faster to 100 km/h,achieving this important mark from astandstill in 10.9 seconds. The standingstartkilometer, in turn, comes after 31.6seconds, 1.8 seconds faster than before,and the top speed <strong>of</strong> the 316ti is now 201km/h or 125 mph, 11 km/h faster thanthe top speed <strong>of</strong> the former model.Another advantage is theunusually spontaneous response <strong>of</strong> the316ti to the gas pedal. This isattributable to the simple fact that loadcontrol, to use the technical term for"giving gas", now takes place "rightthere where the action is", that is directlyin the combustion chamber. Thiseliminates the usual time lag between theprocess <strong>of</strong> "giving gas" and the actualacceleration <strong>of</strong> the car, which used to beinevitable due to the need to fill theintake manifold between the throttlebutterfly and the combustion chamber.In this respect, Valvetronic evenoutperforms the most advanced conceptsusing individual throttle butterflies, thus<strong>of</strong>fering an unprecedented combination<strong>of</strong> spontaneous <strong>engine</strong> response andultra-fine dosage <strong>of</strong> power andperformance under low loads. Perfectly suited for all fuelgradesAnother significant advantage <strong>of</strong>Valvetronic highly beneficial to thecustomer is that a Valvetronic <strong>engine</strong><strong>of</strong>fers at least the same fuel economy as

the most advanced direct-injection petrol<strong>engine</strong>s without the same compromisesin terms <strong>of</strong> emissions. Accordingly, the316ti is able to do without the elaborateand so far hardly reliable emissionmanagement technologies still requiredtoday on a direct-injection petrol <strong>engine</strong>.And it does not require sulfur-free fuellike a direct-injection petrol <strong>engine</strong>,achieving its superior fuel economy withproven l =1 <strong>technology</strong>, which allowsthe Valvetronic <strong>engine</strong> to run on allcommercially available grades <strong>of</strong> regularpetrol. In other words, the customerenjoys all the consumption-relatedadvantages <strong>of</strong> Valvetronic also whendriving in countries without anationwide supply <strong>of</strong> sulfur-free fuel.The consumption figures for the 316tinevertheless relate to the use <strong>of</strong> premiumfuel with an octane rating <strong>of</strong> 95 RON.Together with its 63-liter (13.9 Imp gal)fuel tank, the 316ti <strong>of</strong>fers a much longerrange than its predecessor, with extraurbanfuel consumption in the EuropeanEU test cycle <strong>of</strong> just 5.3 liters for 100kilometers (53.3 Imp gals). This meansthat the driver would only have to refuelafter a very significant 1,188 kilometersor 737 miles.Other AdvantagesAnti-knock control for runningon all fuel grades between 87 and99 octane.Maintenance-free ignition systemwith individual coils. Maintenance-free valve drivewith hydraulic valve playcompensation.A Service Interval Indicator tokeep the cost <strong>of</strong> service to aminimum A two-mass flywheel formaximum running smoothnessValve drive with roller bearingsthroughout in the interest <strong>of</strong>minimum friction and fuelconsumption. Advanced catalysts near the<strong>engine</strong> in special manifold designfor minimum emissions.In Valvetronic <strong>engine</strong>s coolantflows across the head, resultingin a temperature reduction <strong>of</strong>60%.The water pump size is cut inhalf, reducing powerconsumption by 60%.The power steering fluid iswarmed quickly, reducing the

power used by the hydraulicpump.Mounting the water and powerpump on the same shaft and aheat exchanger between coolantand <strong>engine</strong> oil reduces oiltemperature by 30%.BMW has successfullycompleted this quantum leap in<strong>technology</strong>, even in the light <strong>of</strong> ademanding product developmentprocess. An important task in thisprocess is to reduce the productdevelopment period to just 30 months.This applies to all new products. Afurther objective is to reduce the amount<strong>of</strong> hardware required and provide abroad knowledge base for the newValvetronic <strong>technology</strong>, the know-howacquired in this process serving todevelop this <strong>technology</strong> to an evenhigher standard with new functions.Computer aided exercise (CAx)-basedmethods and three-dimensionalcalculations were applied consistently inthis project, ensuring successfulapplication <strong>of</strong> the new <strong>technology</strong> in thecar despite the high level <strong>of</strong> productcomplexity. This new mechatronicsystem calls for multi-parameter loadmanagement requiring the introduction<strong>of</strong> new control algorithms and new, evenmore efficient, <strong>engine</strong> management.DisadvantagesFacing such a high standard <strong>of</strong>s<strong>of</strong>tware and hardware complexity, amanufacturer obviously also runs agreater risk <strong>of</strong> making mistakes. It isessential to acquire a sufficient stock <strong>of</strong>data under all kinds <strong>of</strong> operatingconditions in order to understand howsuch a new system behaves. However,such data cannot be provided by theusual sequential test runs.All-round, general use <strong>of</strong> thelatest direct-injection <strong>technology</strong>, inturn, faces some significant drawbackssuch as costs, the need to make thecombustion process very robust and thepotentials in exhaust emissionstreatment.EXPERIMENTAL RESULTS First Working ModelThe first BMW model to enterthe market in 2001 with a largeproductionspark-ignition <strong>engine</strong>featuring fully variable Valvetronic andVanos valve control was the 316ti

Compact. In turn, the first representative<strong>of</strong> this newly developed family <strong>of</strong><strong>engine</strong>s was a four-cylinder four-valvespark-ignition power unit displacing 1.8litres, developing maximum torque <strong>of</strong>175 Newton meters (Nm) and maximumoutput <strong>of</strong> 85kW (see Figure 4). BMW’snew Valvetronic four-cylinder powerunits come with 1.8-litre and 2.0-litrecapacities.Some Experimental resultsDespite the reduction in <strong>engine</strong>size by 100 cubic centimeters, comparedwith the former generation <strong>of</strong> powerunits, torque is up from 165Nm to175Nm, with output increasing from77kW to 85kW. With displacement <strong>of</strong>the 2.0-litre <strong>engine</strong> being increased by5%, torque was up by no less than 11%from 180Nm to 200Nm, <strong>engine</strong> outputincreasing from 87kW to 105kW,resulting in specific torque <strong>of</strong>100Nm/litre and specific output <strong>of</strong>52.5kW/litre.The driver senses this enhancedperformance through the more powerfultorque curve, the car’s dynamicbehaviour on the road clearly provingthe advantages <strong>of</strong> this extra torque. Morethan 90% <strong>of</strong> the <strong>engine</strong>’s torque comesat just 2,000 revolutions per minute(rpm), with torque peaking at 3,750rpm.Engine output, in turn, remainsconsistently at its near-maximumthroughout a wide speed range.The 4.4-litre power unit developsa maximum output <strong>of</strong> 245kW with a fuelconsumption <strong>of</strong> only 10.9 litres/100km(or 25.9 miles per gallon) and alreadycomplies with the EU4 standard, whichdoes not become obligatory until 2005.The oil service intervals, in turn, havebeen extended up to 40,000km or 25,000miles.One <strong>of</strong> the most importantobjectives from the start was to reducefuel consumption. These <strong>engine</strong>s <strong>of</strong>fer aparticular enhancement <strong>of</strong> fuel economyabove all at low loads. When idling, fuelconsumption is down by approximately25% and the overall improvement in theEuropean fuel consumption test cycle is12%. The customer will also experiencethis improved economy and fuelefficiency in everyday motoring on theroad. Using the power <strong>of</strong> the <strong>engine</strong> infull, on the other hand, the driver doesnot have greater fuel efficiency than witha conventional power unit. The reasonfor this is that, under these conditions,the <strong>engine</strong> runs like a throttle butterfly

power unit with its butterfly fully open.Under normal driving conditions,however, throttle-free load managementsignificantly reduces fuel consumptionin practice.CONCLUSIONIn summary, these innovativedevelopments provide a combination <strong>of</strong>product features thus far inconceivablewith a spark-ignition <strong>engine</strong>. Theintroduction <strong>of</strong> the world’s first intakemanifold providing infinite variation inmanifold length serves to improve thetorque level, which is already very goodto begin with. A particular highlight <strong>of</strong><strong>engine</strong>s with Valvetronic loadmanagement is the significantlyimproved fuel/air mixture guaranteeingminimum fuel consumption, maximumspontaneity and optimum refinement.DFI with a stochiometric air/fuelratio provides the highest level <strong>of</strong>specific output as well as a combustionprocess helping to fulfil all exhaustemissions standards worldwide. Allround,general use <strong>of</strong> the latest directinjection<strong>technology</strong>, in turn, faces somesignificant drawbacks such as costs, theneed to make the combustion processvery robust and the potentials in exhaustemissions treatment.Valvetronic combines asignificant improvement <strong>of</strong> fuelconsumption with excellent <strong>engine</strong>response and control, allowing optimumvalve timing under all runningconditions. The result is smooth and freeoperation <strong>of</strong> the <strong>engine</strong> under part loadwith very little throttle effect. Optimisedfuel/air mixture management ensuressignificant advantages in fuel efficiencycompared with a conventional fourcylinder<strong>engine</strong>, reaching the samestandard as today’s lean-burn concepts.Since such an <strong>engine</strong> with Valvetronicdoes not require an NOx removalcatalyst, it can be used worldwide withall types and grades <strong>of</strong> fuel.REFERENCES:www.bmwworld.com/<strong>technology</strong>/<strong>valvetronic</strong>www.bmwworld.com/<strong>engine</strong>s/<strong>valvetronic</strong>www.wikipedia.org/wiki/<strong>valvetronic</strong>Internal Combustion Engines bySEMINAR TOPIC FROM ::www.edufive.com/seminartopics.html