Varandey oil terminal project1.81 MB - Boskalis

Varandey oil terminal project1.81 MB - Boskalis

Varandey oil terminal project1.81 MB - Boskalis

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

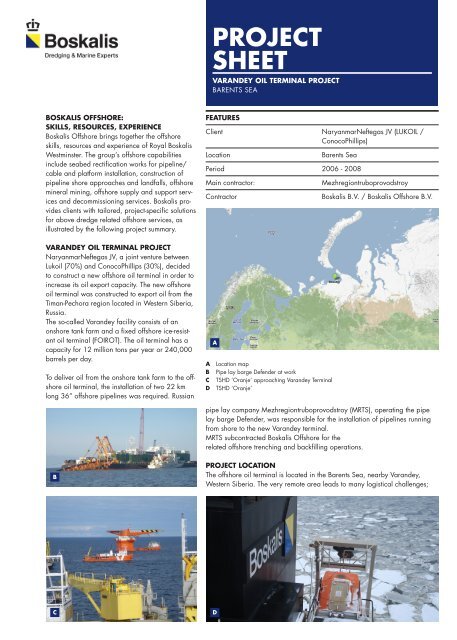

PROJECTSHEETVARANDEY OIL TERMINAL PROJECTBARENTS SEABOSKALIS OFFSHORE:SKILLS, RESOURCES, EXPERIENCE<strong>Boskalis</strong> Offshore brings together the offshoreskills, resources and experience of Royal <strong>Boskalis</strong>Westminster. The group’s offshore capabilitiesinclude seabed rectification works for pipeline/cable and platform installation, construction ofpipeline shore approaches and landfalls, offshoremineral mining, offshore supply and support servicesand decommissioning services. <strong>Boskalis</strong> providesclients with tailored, project-specific solutionsfor above dredge related offshore services, asillustrated by the following project summary.FEATURESClient NaryanmarNeftegas JV (LUKOIL /ConocoPhillips)LocationBarents SeaPeriod 2006 - 2008Main contractor:ContractorMezhregiontruboprovodstroy<strong>Boskalis</strong> B.V. / <strong>Boskalis</strong> Offshore B.V.VARANDEY OIL TERMINAL PROJECTNaryanmarNeftegas JV, a joint venture betweenLuk<strong>oil</strong> (70%) and ConocoPhillips (30%), decidedto construct a new offshore <strong>oil</strong> <strong>terminal</strong> in order toincrease its <strong>oil</strong> export capacity. The new offshore<strong>oil</strong> <strong>terminal</strong> was constructed to export <strong>oil</strong> from theTiman-Pechora region located in Western Siberia,Russia.The so-called <strong>Varandey</strong> facility consists of anonshore tank farm and a fixed offshore ice-resistant<strong>oil</strong> <strong>terminal</strong> (FOIROT). The <strong>oil</strong> <strong>terminal</strong> has acapacity for 12 million tons per year or 240,000barrels per day.To deliver <strong>oil</strong> from the onshore tank farm to the offshore<strong>oil</strong> <strong>terminal</strong>, the installation of two 22 kmlong 36” offshore pipelines was required. RussianAA Location mapB Pipe lay barge Defender at workC TSHD ‘Oranje’ approaching <strong>Varandey</strong> TerminalD TSHD ‘Oranje’pipe lay company Mezhregiontruboprovodstroy (MRTS), operating the pipelay barge Defender, was responsible for the installation of pipelines runningfrom shore to the new <strong>Varandey</strong> <strong>terminal</strong>.MRTS subcontracted <strong>Boskalis</strong> Offshore for therelated offshore trenching and backfilling operations.BPROJECT LOCATIONThe offshore <strong>oil</strong> <strong>terminal</strong> is located in the Barents Sea, nearby <strong>Varandey</strong>,Western Siberia. The very remote area leads to many logistical challenges;CD

VARANDEY OIL TERMINAL PROJECTBARENTS SEAThe information contained in this data sheet is for guidance purposes only and may be subject to changes. © <strong>Boskalis</strong>. All rights reserved.01 — 2012fuel supply, crew changes and such require carefullyplanned transports to the work site in ordernot to cause any delays. Especially since workingoffshore is only possible in the months when theBarents Sea is not ice-bound which is generallyfrom July to November.Rapidly changing weather conditions, whichinclude many short storms with wind velocities upto 10 Beaufort and outside temperatures droppingto -20°C, characterize the area.As a result of the ice conditions in the area theseabed can be exposed to ice scour, a phenomenonwhere long, narrow ditches are formed inthe seabed, due to the collision of fast ice andpack ice.TRENCH DREDGING WORKSTo protect the two pipelines from the impacts of icescour two separate, approx. 18 km long, 2.6 mdeep trenches were required, providing a minimumcover of 1.5 m top of pipe. The trenches at a maximumdredging depth of 21 m required the excavationof approximately 1,300,000 m 3 of s<strong>oil</strong>consisting of silty sand, stiff to hard clay and boulders.The material dredged from the trenches had tobe discharged at special designated disposal areas.EFG<strong>Boskalis</strong> deployed one of its bigger vessels, the 16,000 m 3 capacity trailingsuction hopper dredger (TSHD) ‘Oranje’, which was specially adjusted towork in arctic conditions. The TSHD ‘Oranje’ is a sea-going self-propelled vesselequipped with state of the art equipment, such as a dynamic positioning &dynamic tracking system and multi-beam echosounders. The vessel has twosuction pipes; for this project the dragheads were equipped with in-housedesigned clay visors to optimize the production level.TRENCH BACKFILLING WORKSUpon installation of the pipelines by MTRS’s Defender the pipeline trencheshad to be backfilled to a cover of 1.5 m top of pipe, which required approximately1,800,000 m 3 of backfill material. After locating suitable backfill materialin the area, TSHD ‘Oranje’ dredged this material and sailed back to thepipeline trench. Trench backfilling was carried out by pumping the materialreversely through the suction pipe rather than dumping by means of openingthe bottom doors. This controlled backfill process minimized material lossesand turbidity in the area.CONCLUSIONSThe conditions at the <strong>Varandey</strong> Oil Terminal Project were challenging due tothe remote location, the limited available infrastructure, the harsh environmentand difficult s<strong>oil</strong> characteristics, such as stiff to hard clay and boulders. Withthe nearest port 1,200 km away, the TSHD ‘Oranje’ had to be completely selfsufficient.After a thorough preparation, <strong>Boskalis</strong> Offshore’s first project in the RussianArctic was successfully executed and completed well in time.The first <strong>oil</strong> was shipped to Canada in June 2008.HE TSHD ‘Oranje’ at <strong>Varandey</strong> in sea iceF View on deckG View on deckH Oranje’s dragheadRoyal <strong>Boskalis</strong> Westminster N.V.PO Box 433350 AA PapendrechtThe NetherlandsT +31 78 69 69 000F +31 78 69 69 555royal@boskalis.comwww.boskalis.com