A Merlin by any other name - Aero Resources Inc

A Merlin by any other name - Aero Resources Inc

A Merlin by any other name - Aero Resources Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

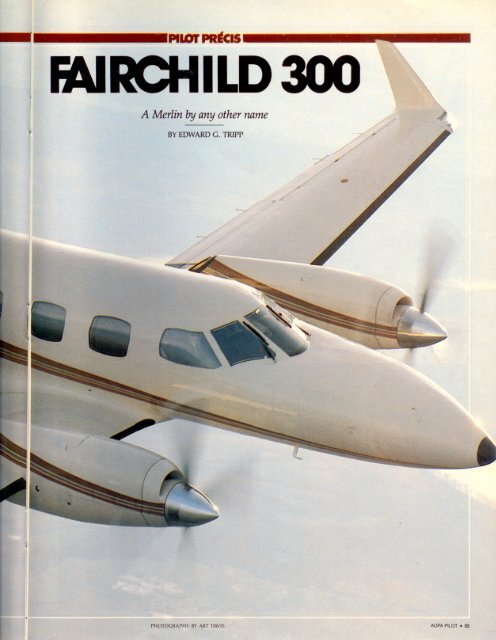

FAIA <strong>Merlin</strong> <strong>by</strong> <strong>any</strong> <strong>other</strong> <strong>name</strong>BY EDWARDG. TRIPPPHOTOGRAPHY BY ART DAVIS AOPA PilOT • 65

com;lluedThe <strong>Merlin</strong> ... (was) designed aroundour basic philosophy of matching pressurizationto the altitude performance capabilitiesof the airplane. Our aim is to fill a voidthat existed for a light transport type airplanein the six to 10 place category thatoffers high performance and pressurizedcomfort up to 30,000 feet-an airplane thatcruises between 250 and 300 miles perhour, yet still is able to use small airportswith 2,000 to 2,500 foot runways, andthat can be marketed in the $200,000 to$300,000 price category.That is a quote from remarks made<strong>by</strong> Edward J. Swearingen Jr. in January1965 to introduce the <strong>Merlin</strong>. Boththe designer and the. airplane are stillactive, even though both the man andthe product, together with the comp<strong>any</strong>he had formed, have gonethrough m<strong>any</strong> changes.Swearingen got the airplane fromfirst flight to certification in 15 monthsand made the first customer deliverythree months later. That, in the currentcycle of four-to-six year developmentcycles, is as amazing as the differencebetween the first retail price of$335,000 and the current version's$1,970,000 (both without avionics).As the accomp<strong>any</strong>ing spotter'sguide indicates, there have been almostas m<strong>any</strong> changes to the <strong>Merlin</strong> inthe ensuing 19 years as there havebeen to the value of our dollar. But thecurrent version, the Fairchild 300,shares m<strong>any</strong> common characteristicswith the first <strong>Merlin</strong>. It is a round, tubularfuselage (round is best for pressurizationaccording to the engineers)sitting on a wing; the fail-safe approachto structures is very much apart of both, as is flush riveting. Visually,the lineage is obvious.The 300 is a development of the last66. FEBRUARY 1984

model called <strong>Merlin</strong>, the mc (modeldesignation is SA227-Tf), which wasintroduced in the fall of 1980. It hadsignificant changes over previousmodels that improved operational flexibilityand utility, maintainability andoperating characteristics. It was alsothe first g'eneral aviation aircraft certificatedto Special Federal Aviation Regu-'lation (SFAR) 41. To oversimplify, thiscategory provides a way to get aroundthe ancient and arbitrary 12,500 poundmaximum takeoff or gross weight limitthat separates light aircraft from airtransport category aircraft. For operatorsof approved aircraft, it expandsoperational options, providing increasesin both payload and range. Forthe <strong>Merlin</strong>, it expanded the envelope<strong>by</strong> 730 pounds: maximum takeoffweight increased from 12,500 to 13,230(maximum ramp weight is 13,330pounds; maximum landing weight is13,230 pounds).The tradeoff for greater operationalflexibility is more stringent standardsfor structures, systems, operations andcrew qualification. Performance requirementsfor such parameters as balancedfield length and single engineclimb are more demanding. Fire protectionstandards are higher. For instance,fire detection and extinguishingsystems must be installed in theengine compartments, and fire containmentproperties must be satisfactorilydemonstrated (fire walls are stainlesssteel in the <strong>Merlin</strong> IIIC/300).Flammable fluid lines must be isolatedfrom electrical sources. Interior materialsmust meet air carrier fire resistancestandards.Any aircraft operated at weightsabove 12,500 pounds requires the pilotin command to be type rated. Initially,<strong>Merlin</strong>s that were operated underSFAR 41 required a two man crew, althoughthey now are approved for singlepilot operation.In terms of structure and systems,the <strong>Merlin</strong>s have reflected the designphilosophies of heavy transports morethan some <strong>other</strong> general aviation turboprops.In its current form, it includesa fail-safe primary structure,fail-safe structures at all critical loadpoints, multiple spar webs and <strong>other</strong>features to ensure that, in the event offailure of or damage to <strong>any</strong> critical airframeelement, structural integrity ismaintained. The airframe has a safelife of 35,000 hours. Environmentaland operational systems are dualthroughout. The electrical system employsthree buses.The horizontal stabilizer is mountedwell above the fuselage, basically acruciform tail. It is pivoted near therear spar, and the entire surface moveswith pitch trim commands throughelectrically operated dual jack screws.There are visual and aural trim indicatorsin the cockpit. The pilot and copilottrim systems are separate.The primary flight controls are actuated<strong>by</strong> directly linked push rods. Theslotted flaps are hydraulically actuatedand mechanically linked to preclude asplit flap condition.Earlier <strong>Merlin</strong>s had a relatively slow,high-drag gear extension and retractionsystem that was gradually improvedthrough several modelchanges. The mc iptroduced an improvedsystem coupled with a new enginecowl design that greatly improvedserviceability and access (the comp<strong>any</strong>claims that an engine can be disconnectedand removed in less than 30minutes without requiring rerigging afterreplacement). The new gear systemoperates more quickly. It also eliminatedthe high-drag door on the nose-AOPA PilOT • 67

COlltil/urdwheel. The gear doors close after thegear is extended, which reduces dragand keeps snow and slush from accumulatingin the gear wells.Large, four blade, advanced airfoilsection Dowty Rotol propellers werean<strong>other</strong> new feature introduced on the<strong>Merlin</strong> me.Control harmony has not been thestrongest suit of the <strong>Merlin</strong>s. Lateralcontrol required much higher forcethan pitch and yaw. This is one tradeofffor the direct, mechanical linkagethat provides the solid feel and directresponse to pilot input. Servo-actiontrim tabs were added to the mc to reducethe force. The <strong>Merlin</strong> yoke, <strong>by</strong>the way; looks like a refugee from aWorld War II bomber in terms of itsherculean size, which provides greaterleverage to the crew.The mc also featured cockpit improvements,including flap preselect,self-locking gear handle, improvedpower control friction locks and upgradedlighting.The obvious difference between themc and the 300 are the winglets. Accordingto a Fairchild spokesman, theyreduce span wise flow, therefore drag,and modestly improve climb-particularlysingle engine rate of climb-andhigh altitude cruise. They also permitlower approach speeds, which reducesthe amount of runway required forlanding.The aircraft we flew for this article,N447SA, is being used in the certificationeffort. final performance figureshave not been verified, so <strong>any</strong> improvementover the mc cannot bequantified now. Certification, originallyexpected in October, 1983, is nowexpected this month.There is a new power brake/antiskidsystem. The ailerons and controllinkage have been further changed toimprove lateral control. This includesshaping of the trailing edge of the aileronto provide aerodynamic assistanceto pilot control inputs.The 300 is to feature dual CollinsEHSI-74 electronic horizontal situationindicators, which will enable the crewto select information from various instrumentsand display it directly infront of them. When we flew N447SAthe equipment was not installed, andthe flight control system was disconnected.The aircraft was scheduled togo to Collins headquarters in CedarRapids, Iowa, for completion of theavionics system certification, including••-•68. FEBRUARY1984

the APS-80T autopilot.When certification is completed, theaircraft equipped price will be$2,409,670, including $36,000 in interiorand airframe options (it is fittedwith a continuous alchohol/water injectionsystem to improve runway andweight performance during hot andhigh conditions). Avionics options total$403,660.The 300 created quite a stir when itarrived at the ramp in Frederick, Maryland.It was flown <strong>by</strong> James R. Milner,who is a Fairchild engineering test pilot,accompanied <strong>by</strong> Phil Van Ostrand,a former AOPA employee and AOPAPilot staff member who now works forFairchild.People tend to think of it as the little<strong>Merlin</strong> because of its longer br<strong>other</strong>,the <strong>Merlin</strong> IV/Metro, which is currentlyundergoing a transformation tothe Fairchild 400. However, it is a bigairplane that can carry two cre}\' plusup to eight passengers. The cabin isnormally configured for six. Excludingthe cockpit, it is just under 17 and ahalf feet long and more than five feetwide.Typical of this category of aircraft, itwas fitted with a full set of amenities,from a Wulfsberg Flitefone, refreshmentcenter and cabinetry to a lavatorycomplete with flushing biffy.There is a large baggage compartmentaft (and there is a nose baggage bayoutside of the pressure vessel).The cockpit is high (both in headroomand distance above the ramp),wide and handsome. A distinctive featureof the 300 is the three-panel windshield.The left and right panels areelectrically heated glass. Organizationof instruments, controls and systems isgood; while the 300 is a highly complexaircraft, learning your way aboutthe cockpit is simple.Speaking of learning, Fairchild offerscrew and maintenance trainingthrough FlightSafety International at afacility co-located with the factory inSan Antonio, Texas. Initial and recurrenttraining should be consideredmandatory <strong>by</strong> <strong>any</strong> operator.Milner took a few of us on a walkaround inspection before flight thatwas a typical thorough, first flight ofthe day check. He pointed out some ofthe features that distinguish the 300,including the new shape of the trailingedge of the aileron. Access to all thepoints that need a going over, includingdropping the gear doors to checkinside the wells, is good.Start and operation of the 900 shafthorsepower (shp) Garrett TPE331-IOU503G engines is simplified <strong>by</strong> automaticstart sequencing, fuel controland Single Red Line (SRL) computers.The SRL computer senses temperaturefrom several sources, computes thecombined value against engine temperaturelimits and works to limit pilotinput from creating an overtemperaturecondition-and the attendant expense.A negative torque sensing system(NTS) is an<strong>other</strong> feature of thepowerplant. It senses differentialtorque between the engines and automaticallymoves the propeller on theaffected engine toward feather in theevent of power failure. Coupled withthe rudder boost system that automaticallyinputs yaw force toward the operatingengine, it greatly aids aircraftcontrol in the event of engine failure. Itis a no-go item.When all works as it is designed to,crew workload from start to stop islow. You are more a monitor of automatedprocesses than a link in thechain of operations.The equipped empty weight ofN447SA is 8,350 pounds. Rampweight at start, with four on board and2,000 pounds of fuel, was well belowmaximum for FAR 23 operation at approximately11,200 pounds, and 2,130pounds below the SFAR 411irnit.Milner took some time to brief meon the hydraulically actuated nosewheelsteering system before enginestart, since there are two levels of authority,one used for maneuvering intight spaces that permits greater degreeof nosewheel deflection, and the<strong>other</strong> for normal taxiing and takeoff.Steering is operated through the rudderpedals; the high authority mode isselected <strong>by</strong> actuation of a switch onthe pilot's side panel, the normalmode through a switch on the left enginecondition lever. With a little practice,ground handling is easy. The systempermits taxiing on one engine.A stability augmentation system(SAS), including an angle of attack indicatorand stick pusher, is part of thebasic equipment. It increases stickforces at low airspeed, nominally below135 KIAS, to artificially eliminatepitch sensitivity.The check list is long, as you wouldexpect for an aircraft of this type. SinceI had not flown a <strong>Merlin</strong> of <strong>any</strong> sortfor quite a while, it took a bit of time toperform the checks and get to the departureend of the runway. However,there is nothing remarkable about theprocedures or sequence.Our calculated rotation speed for theAOPA PILOT • 69

continuedweight and conditions was 100 knots,with initial climb speed at 116. Besttwin engine climb speed was 142KIAS; best single engine rate speedwas 136. Calculated runway distancerequired was 2,200 feet, accelerate/stop3,700 and accelerate/go to 50 feet4,500.To say that acceleration was fast isan understatement. There is a marvelousrush provided <strong>by</strong> 1,800 shp. I releasedthe brakes with about 60 percentpower applied and hadaccelerated through 85 knots beforethe rest of it was in. <strong>Aero</strong>dynamicsteering was available shortly afterbrake release. On the first takeoff, I rotatedtentatively, which required moreground roll, but the 300 was off andflying before my brain was.After we cleared the airport area, weSPOrrER'S GUIDEThe appearance of a Swearingen turboprop on an airport rampoften gives rise to some confusion: Is it a <strong>Merlin</strong> or a Metro? Hereis a simple way to tell the difference. <strong>Merlin</strong>s are corporate aircraft;Metros are commuter aircraft. Following is the Swearingenaircraft lineage.•NI70V<strong>Merlin</strong> IIA. In 1965, Swearingen Aircraft mated a new pressurizedfuselage to a pair of Queen Air wings to create the <strong>Merlin</strong>.Designer Edward J. Swearingen originally intended to build twoaircraft-the <strong>Merlin</strong> I with Lycoming TIGO-540 piston enginesand the <strong>Merlin</strong> II with P&W turboprops. But plans for the <strong>Merlin</strong>I were scrapped when Lycoming said the delivery of the newTIGO-540s would be delayed a year. The prototype <strong>Merlin</strong> II waspowered <strong>by</strong> 500-shp P & W PT6 turboprops. The <strong>Merlin</strong> IIA, introducedin 1966, has a 30-inch longer fuselage and is powered <strong>by</strong>578-shp PT6s. Maximum cruise is 243 knots.Swearingen Excalibur. The Excalibur, a modified BeechcraftTwin Bonanza, was introduced <strong>by</strong> Swearingen Aircraft in 1962.The airplane is powered <strong>by</strong> two 380-hp, geared, superchargedLycoming engines with low-drag cowlings. According tocomp<strong>any</strong> figures, the Excalibur's 75-percent power cruisespeed at 13,500 feet is 226 knots.<strong>Merlin</strong> lIB. The <strong>Merlin</strong> moved up the power curve in 1968when Swearingen gave the lIB 665-shp Garrett AiResearch TPE331-1-151G engines. Cruise speed increased to 256 knots. Notethe difference in engine cowlings.Swearingen Queen Air 800. In 1964, Swearingen reengined theBeechcraft Queen Air with two 400-hp, non-supercharged Lycoming10-720 eight-cylinder engines. Sixty-five-percent cruise speedat 10,000 feet is 195 knots. The Queen Air 800 still is produced <strong>by</strong>Excalibur Aviation in San Antonio, Texas.<strong>Merlin</strong> III. The first all-Swearingen <strong>Merlin</strong> is the III. It has aSwearingen-designed wing and Swearingen-designed landinggear (Twin Bonanza gear had been used originally). The <strong>Merlin</strong>Ill's major distinguishing feature is its cruciform tail. The enginecowlings for the <strong>Merlin</strong> Ill's 840-shp Garrett engines also are configureddifferently, with the air intake at the top rather than at thebottom. The <strong>Merlin</strong> III is 24-and-one-haIf inches longer than thelIB. Maximum cruise speed is 274 knots.70. FEBRUARY 1984

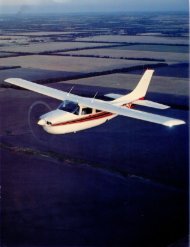

accelerated to a cruise climb speed of180 knots. Rate of climb averaged2,000 fpm up through 16,500 feet,where we leveled off to try a variety ofconfiguration changes, slow flight,missed approaches, simulated enginefailure and stalls. It is a big, stable aircraft.Control forces are high, but the300 maneuvers well. At the stall, thestick pusher wakes you up with a pronouncedyank on your arms.The only problem I had with it wascaused <strong>by</strong> the different shape of thepower levers. The left lever knob is adifferent shape and larger than theright. My lack of familiarity with theaircraft caused me regularly to applydifferential thrust. When you do thatwith all the power available, and thoselarge propellers, you know you havedone something wrong. On onebalked landing simulation, I thoughtinitially that I had lost an engine. It is,as they say, an attention grabber.After a simulated emergency descent,we went to Dulles to shoot approaches.There was a good mix oflight and heavy traffic that day that resultedin approach giving us severalrunway changes and two go-aroundsthat provided realistic demonstrationsof the 300's behavior in high-density,distracted conditions. It did well.The return to Frederick involved an<strong>other</strong>balked landing. On the secondtry, I intentionally set up an unstabilizedfinal approach at just above minimumapproach speed to see what itfelt like. On short final, with full flaps,I again applied asymmetric power. Justas I was about to call a missed approach,Milner asked with a touch ofnervousness: "Do you want a missedapproach?" At that point, I sure did.The next morning we flew a photomission with N447SA, which providedan<strong>other</strong> opportunity to sample relativelylow speed, maneuvering characteristics,do some more takeoffs andlandings and just nose around the airplanewhile Pilot creative director ArtDavis was taking static shots. My offerto take it with me the next day on abusiness trip to the West Coast was forsome reason rejected.It would have been great to havehad a chance to fly the 300 in the missionfor which it was designed: longdistance, high altitude cruising. Stillair range at maximum cruise power at26,000 feet is almost 2,200 nauticalmiles; true airspeed 275 knots. It is theright way to go cross country. 0Swearingen Metro. A 19- to 20-passenger stretched version ofthe <strong>Merlin</strong> III was introduced in 1969. The <strong>Merlin</strong> IV, a corporateversion of the Metro with luxo-interior for 11 to 15 passengers,was introduced the following year. The Metro was developed as ajoint venhue with Fairchild Hiller. In 1971, Swearingen Aircraftbecame a subsidiary of Fairchild.Fairchild 300. Introduced in 1983, replacing the <strong>Merlin</strong> I1Ie. the300's major distinguishing feature is a new pair of winglets, designedto reduce spanwise airflow and drag. Garrett 900-shp enginessupply the power. Maximum speed is 300 knots.<strong>Merlin</strong> me. The <strong>Merlin</strong> IlIA and IIIB increased in power andweight until the 12,SOO-pound weight limit for aircraft certificatedunder Federal Aviation Regulation Part 23 was reached with theI1IB.The <strong>Merlin</strong> I1IC and Metro III were certificated under a newset of standards, Special Federal Aviation Regulations Part 41,which is more stringent than FAR Part 23 but less stringent thanFAR Part 25, the regulation for transport aircraft. SFAR 41 allowsgross weights of more than 12,500 pounds, but sets higher standardsfor single-engine performance and requires certain safetyfeatures, such as engine fire extinguishers. The pilot in commandof an SFAR Part 41 certificated aircraft must have a type rating,and two pilots generally are required under these rules. (The aircraftcan be operated under FAR Part 23 if gross weight is lessthan 12,500 pounds.) Most of the differences in the <strong>Merlin</strong> I1IC arenot readily apparent to the eye. It has a maximum takeoff weightof 13,230 pounds and a maximum cruise of 300 knots.Fairchild 400. The 400, an updated <strong>Merlin</strong> IV, boasts 347-knotplusspeeds (400 mph) and is powered <strong>by</strong> two Garrett TPE 331-141,100-shp engines turning Dowty Rotol propellers. Certification isexpected in late 1985.Swearingen 5X300. The SX300 is an aluminum kit-built airplaneintended to be powered <strong>by</strong> a 300-hp Lycoming 10-540 engine.Projected cruise speed, according to Ed Swearingen, will be 239knots at 7S-percent power and 8,000 feet. First shipments arescheduled for mid-1984.-J.Jefferson MillerAOPA PILOT. 71