Untitled - Aero Resources Inc

Untitled - Aero Resources Inc

Untitled - Aero Resources Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

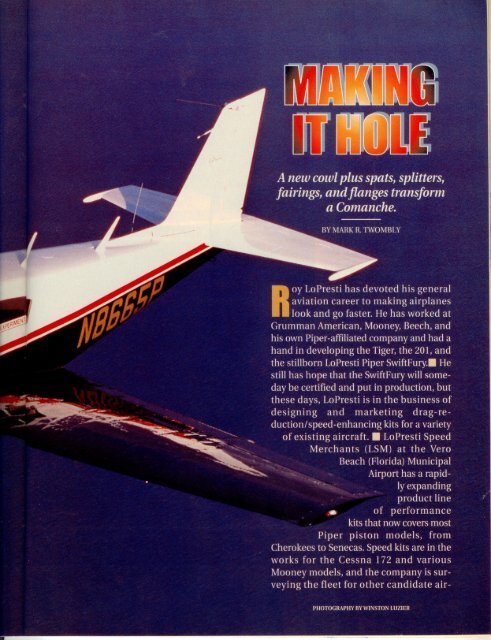

planes. "We want to become the premiermodifier of piston singles andtwins," LoPresti declares.Current LSM mods include newengine cowlings, main landing gearfairings, flap hinge fairings, and flapand aileron gap seals. A chart on oneof the company's brochures for its socalledMach I kits (all of the previouslymentioned mods except for the enginecow\) breaks down the effects of eachof the drag reduction devices bymodel. For example, installing flaphinge fairings ("splitters") on a PA-28140 Cherokee increases speed 2.5miles per hour (about 2.2 knots). Addflap seals and enjoy another 2.5mph-5 mph (4.3 knots) total. AnArrow modified with splitters, flap gap"feel seals," and main gear fairings("spats," which smooth airflow overthe retracted but slightly exposedmain landing gear wheels and tires)will pick up 10 mph (8.7 knots),according to LSM.The company's major modificationis a new fiberglass engine cowldesigned to significantly reduce coolingdrag and, nearly as important inLSM's opinion, look good while doingit. New cowls currently are available•Once a Comancheowner sees and flieshis GTO, he's goingto realize it's awhole new airplane.for the Piper PA-30 Twin Comancheand PA-24 Comanche (l80, 250, 260,and 2608 models). Next in line for thecowling treatment are the PA-32Cherokee Six/Lance/Saratoga and thePA-28R Arrow series.LSM's expectations for the cowl arehigh-a 15-mph (13-knot) gain in topspeed for the Comanche and 8 mph (7knots) for the Twin Comanche. (Thestock "tiger shark" cowling on theTwin Comanche is more aerodynamicallyefficient than the stock Comanchecowl.)The company has taken all of itsmagic-flap hinge fairings, aileronand flap gap seals, main gear fairings,and the cowl-and installed it on aComanche 260. In characteristic fashion,LoPresti has given the tricked-outairplane a fast new name: the GTO60 • MAY 1994•

(Gran Turismo Omologato, as in Ferrari,not Pontiac; LoPresti prefers thenobility of the prancing horse-hedrives a Ferrari-to the tire-smoking,in-your-face attitude of the GeneralMotors muscle car; if it were otherwise,he probably would be flying aComanche 400).The LSM cowl gives the 1965Comanche a contemporary look,much like Piper's new firewall-forwardtreatment for the Saratoga andSeneca. The Piper and LSM cowls lookvery similar but were developed independently.In fact, cowls featuringthose distinctive circular, protrudingcooling inlets have been used on otherdesigns-Ed Swearingen's SX-300 andLance Neibauer's Lancair kitplanes,for example.LSM arrived at the specific shape anddimensions of the circular inletsthrough trial-and-error flight testing.Experimental cowls were coated withdyes that, in flight, revealed areas ofhigh- and low-efficiency airflow into thecooling inlets. LSM didn't start out withcircular inlets, but that's where it arrivedafter testing a variety of other shapes.The cowl also has a refined shape forthe induction air inlet below the spinner.As with the cooling inlets, themouth of the induction air scoop iscloser to the propeller than on thestock cowl to capture more of the energyof the prop blast. The air then travelsdown an expanding duct to furtherpressurize it. Beech took the sameapproach several years ago with theKing Air, extending the air intake on thePT6 cowl to just behind the propellerdisk. Beech calls it the "pitot cowl."Each side of the new cowl is hinged.Unscrew a half-dozen cam locks oneach side, and you can then lift thecowl to reveal the engine and accessories.Although the hinged panels donot extend as far down the sides of thecowl as on the standard Comanchecowl, it's still possible to get a socketon the lower set of spark plugs withoutremoving the lower cowl. The nosebowlalso can be removed withouttaking off the entire cowl.New baffling is installed as part ofthe cowling change, and the oil cooleris relocated from below the engine tobehind it.The cowl also features longer nosewheeldoors that completely enclosethe nose gear when it is retracted. Onthe stock airplane, the short nosewheeldoor is connected to and actuated byAOPA PILOT· 61

the gear. Initially, it worked the sameon the LSM cowl. Then it was discoveredthat in flight, the gear was beingsucked down by low-pressure air flowingover the nose-gear door. That ledto a design change in which the nosegeardoor has its own extend/retractactuation system. A firewall-mountedelectric motor drives a series of rodsthat open and close the door insequence with the gear. The doormotor is activated by the gear handleswitch, but a'separate gear door handlemust be pulled before releasing theemergency gear extension system.The stock Comanche does not havea cowl flap. Cooling air exits the enginecompartment from behind the nosewheel.Because that area is covered bythe long nosewheel door, theLSM cowl has a cowl flap. It'son the left side of the cowland looks monstrously largebut only because we're usedto cowl flaps beingunder the nose.hiddenThe GTO includes all LSMmods except aileron seals.Tests with the seals installedshowed a degradation of stallcharacteristics. Aileron sealsare offered for other Pipermodels, principally toimprove roll response. Allfairings and seals are made offiberglass and attached with•LSM'splastic surgeryenables the airplane togo a heck of a lot faster.New nosewheel doors necessitatedaddition of cowl flap (above). Flange onprop boosts induction air pressure.rivets and sealant. A Teflon strip isattached with adhesive to flap andaileron seals to reduce frictionbetween the sealaileron surface.and the flap orWhen I visited LSM, the GTO stillwore an "Experimental" stickerbecause of the unusual propeller. TheHartzell three-blade prop has a uniqueplanform with swept leading edgesand a small trailing edge flange oneach blade near the hub. The flange issupposed to give the air an extra pushas it enters the induction scoop. Thispoor man's turbo system sounds plausibleenough to a lay gearhead, butLSM has done it one better: The propis synchronized with the induction systemto ensure that the superchargedair travels through the inductionsystem to the cylinderintake valve with the least lossof energy. Synchronization isachieved by the timing positionof the prop, the locationof the induction inlet, and thelength of the induction systemducting.If all this sounds like anengineering sleight of hand,well, LoPresti won't claim tohave applied NASA testingtools and methods to verifythe theory. But he does contendthat precise measurementsof average manifold62 • MAY 1994

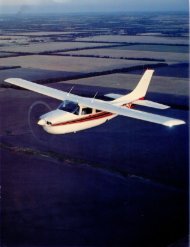

pressure show about a I-inch increaseat typical cruise speeds from the specialprop. The tuned prop, spinner,and induction system package adds5.5 mph (4.8 kts) to the Comanche'sspeed, according to LSM.LSM is developing the special propin partnership with Hartzell, and anSTC is expected sometime this summer.What does all of LSM's plasticsurgery do to a Comanche besidesmake it look like a current productionairplane? Based on what I observed, itenables it to go one heck of a lot faster.Curt LoPresti, LSM's chief designerand test pilot, and I, plus about 90 gallonsof gas, departed Vero BeachMunicipal and climbed at 110 KIAS.The 5-degree pitch attitude afforded anadequate view over the nose and a 900foot-per-minute rate of climb at loweraltitudes. Cylinder head temperaturesduring the climb appeared to be about350 degrees, judging by the InsightGEM EGT/CHT display. The headscooled as ambient air temperaturedecreased during the climb to altitude.The engine in the GTO is exceptionallysmooth for a 540-cubic-inchLycoming, perhaps due in part to theexperimental three-blade prop. Theonly changes to the cockpit related tothe LSM mods are the addition of ared emergency nose-gear-door releasehandle and a T-handle to open andclose the cowl flap.I sampled a couple of cruise altitudesand power settings. At 8,500 feet,full throttle (22 inches), and 2,500 rpm,with the mixture leaned to 50 degreesrich of peak (about 15.5 gallons perhour), the airspeed indicator stabilizedat 148 KIAS/ 170 mph. Backing off to2,400 rpm scrubbed a couple of knotsoff the speed. At 6,500 feet, full throttle(23.5 inches), and 2,400 rpm, I waslooking at 151 KlAS/174 mph.Back on the ground, we fed the datato Jim LoPresti's computer (LSM is afamily affair; along with Curt and Jim, athird LoPresti son, David, is involvedwith the company, as is Roy LoPresti'swife, Peggy), and it crunched out someimpressive true airspeeds: 171.5knots/ 197.6 mph at the higher altitude,and 170.4 knots/196.3 mph down lower.The LoPrestis tactfully pointed out thatthe speeds I recorded were a tad underthe numbers they had been seeing andwere not corrected for standard conditions.So be it, I said; what I saw is what Igot. Even so, these speeds representhealthy increases over a stock 260-hpComanche and in fact are typical of a300-hp Bonanza. Higher speeds on thesame horsepower mean an increase inrange and endurance on the same fuelcapacity, too. Not bad for a 29-year-old(referring to the airplane, of course).The LSM cowl does have a few drawbacks,in my opinion. The cowl flap isunsightly given its location, and the cowlflap actuator handle in the cockpit possiblycould bang against the right frontMOONEY MUSClEGiven his past affiliationwith Mooney Aircraft, itshould come as no surprisethat LoPresti hasplans to modify a Mooney.At the time of our visit tothe LSM shop at VeraBeach, the finishing toucheswere being put on a260-hp Lycoming 10-540powered Mooney 231. Theconversion will mean 50more non-turbochargedhorsepower for the 231.LSM's computer analysispredicts the airplanewill fly at 187 to 191 knotsat non-oxygen altitudes,largely due to a more efficientcowling being designed,according toLoPresti.

I ----------.--------pressure show about a I-inch increaseat typical cruise speeds from the specialprop. The tuned prop, spinner,and induction system package adds5.5 mph (4.8 kts) to the Comanche'sspeed, according to LSM.LSM is developing the special propin partnership with Hartzell, and anSTCis expected sometime this summer.What does all of LSM's plasticsurgery do to a Comanche besidesmake it look like a current productionairplane? Based on what I observed, itenables it to go one heck of a lot faster.Curt LoPresti, LSM's chief designerand test pilot, and I, plus about 90 gallonsof gas, departed Vero BeachMunicipal and climbed at 110 KIAS.The 5-degree pitch attitude afforded anadequate view over the nose and a 900foot-per-minute rate of climb at loweraltitudes. Cylinder head temperaturesduring the climb appeared to be about350 degrees, judging by the InsightGEM EGT/CHT display. The headscooled as ambient air temperaturedecreased during the climb to altitude.The engine in the GTO is exceptionallysmooth for a 540-cubic-inchLycoming, perhaps due in part to theexperimental three-blade prop. Theonly changes to the cockpit related tothe LSM mods are the addition of ared emergency nose-gear-door releasehandle and a T-handle to open andclose the cowl flap.I sampled a couple of cruise altitudesand power settings. At 8,500 feet,full throttle (22 inches), and 2,500 rpm,with the mixture leaned to 50 degreesrich of peak (about 15.5 gallons perhour), the airspeed indicator stabilizedat 148 KIAS/ 170 mph. Backing off to2,400 rpm scrubbed a couple of knotsoff the speed. At 6,500 feet, full throttle(23.5 inches), and 2,400 rpm, I waslooking at 151 KIAS/174 mph.Back on the ground, we fed the datato Jim LoPresti's computer (LSM is afamily affair; along with Curt and Jim, athird LoPresti son, David, is involvedwith the company, as is Roy LoPresti'swife, Peggy), and it crunched out someimpressive true airspeeds: 171.5knots/197.6 mph at the higher altitude,and 170.4 knots/ 196.3 mph down lower.The LoPrestis tactfully pointed out thatthe speeds I recorded were a tad underthe numbers they had been seeing andwere not corrected for standard conditions.So be it, I said; what I saw is what 1got. Even so, these speeds representhealthy increases over a stock 260-hpComanche and in fact are typical of a300-hp Bonanza. Higher speeds on thesame horsepower mean an increase inrange and endurance on the same fuelcapacity, too. Not bad for a 29-year-old(referring to the airplane, of course).The LSM cowl does have a few drawbacks,in my opinion. The cowl flap isunsightly given its location, and the cowlflap actuator handle in the cockpit possiblycould bang against the right frontpassenger's knees. The separate nosegear-doorsequencing system complicatesthe emergency gear extension system,and the cowl weighs an estimated10pounds more than the stock cowl.The cost of the GTO mods, withoutconsidering installation expense, is$10,900 for the cowl (not including a$1,400 credit for exchanging the stockcowl and spinner); $695 for the maingear fairings; $795 for the flap hingefairings; and $695 for the flap gapseals. Aileron gap seals for other Pipermodels are $395 uninstalled. Modificationkits are sold through dealers forinstallation in the field.The Hartzell prop, hub, and spinnerwill be about $7,500, according to LSM.It takes about a week to install thenew cowl, according to LSM,because ofchanges to the baffling, induction system,oil cooler, cowl flap, and gear doors.In the end, LSM's performancepackage for the Comanche probablywill prove more expensive to customersthan the cost of the hardwareand installation. Once a Comancheowner sees and flies his GTO, he'sgoing to realize it's a whole new airplane.You simply can't fly aroundwith old paint on a new airplane. Andthose scratchy, analog radios? Gottacome out to make room for the digitalflip-flop displays and GPS, so you canobserve those faster groundspeeds.And how about that fading, threadbareinterior. ... 0MOONEY MUSCLEGiven his past affiliationwith Mooney Aircraft, itshould come as no surprisethat LoPresti hasplans to modify a Mooney.At the time of our visit tothe LSMshop at VeroBeach, the finishing toucheswere being put on a260-hp Lycoming 10-540powered Mooney 231. Theconversion will mean 50more non-turbochargedhorsepower for the 231.LSM's computer analysispredicts the airplanewill fly at 187 to 191 knotsat non-oxygen altitudes,largely due to a more efficientcowling being designed,according toLoPresti.