Download (0.1 MB) - Prolyte Group

Download (0.1 MB) - Prolyte Group

Download (0.1 MB) - Prolyte Group

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

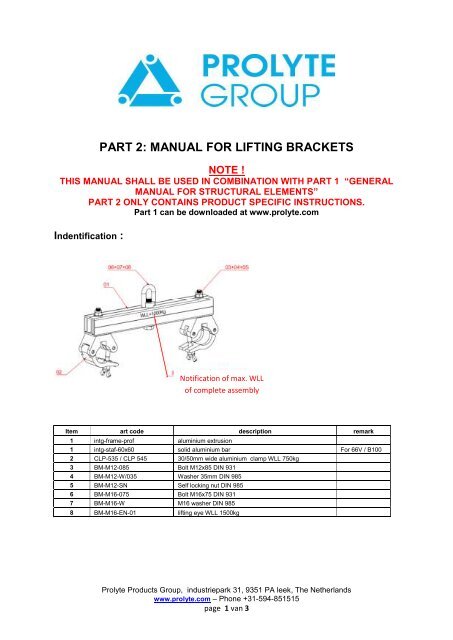

PART 2: MANUAL FOR LIFTING BRACKETSNOTE !THIS MANUAL SHALL BE USED IN CO<strong>MB</strong>INATION WITH PART 1 “GENERALMANUAL FOR STRUCTURAL ELEMENTS”PART 2 ONLY CONTAINS PRODUCT SPECIFIC INSTRUCTIONS.Part 1 can be downloaded at www.prolyte.comIndentification :Notification of max. WLLof complete assemblyItem art code description remark1 intg-frame-prof aluminium extrusion1 intg-staf-60x60 solid aluminium bar For 66V / B1002 CLP-535 / CLP 545 30/50mm wide aluminium clamp WLL 750kg3 BM-M12-085 Bolt M12x85 DIN 9314 BM-M12-W/035 Washer 35mm DIN 9855 BM-M12-SN Self locking nut DIN 9856 BM-M16-075 Bolt M16x75 DIN 9317 BM-M16-W M16 washer DIN 9858 BM-M16-EN-01 lifting eye WLL 1500kg<strong>Prolyte</strong> Products <strong>Group</strong>, industriepark 31, 9351 PA leek, The Netherlandswww.prolyte.com – Phone +31-594-851515page 1 van 3

Use :Lifting brackets shall be used to lift or suspend trusses with corresponding centre-to-centre distancesof truss main chords.Depending on local regulations the WLL shall be adjusted when used to move loads above peopleLifting brackets shall be positioned in the node point of the webbing of the truss. If this is not possiblethe following max. truss loading can be applied.X/H30D/V and X/H40D/V truss > full load on truss is allowed when positioned within 100mm from anode point.S36R/V, S52F/V/SV, S66R/V, > max 2000kg per support point is allowed when positioned within100mm from a node point.Make sure all bolts are tightened.In case of suspended from a steel wire make sure item 6 (bolt for lifting eye) is secured againstunintended loosening.Lifting brackets can be used up-side-down .The lifting eye can be mounted between the clamps. In order to do so, uptight the bolt, replace thebolt up-side-down and re- connect the lifting eye. Secure lifting eye against unintended loosening bydamaging the bolt wire thread or drilling a hole and putting a split pin in.Never exceed the max. WLL as embossed on the aluminium extrusion (item 1).<strong>Prolyte</strong> Products <strong>Group</strong>, industriepark 31, 9351 PA leek, The Netherlandswww.prolyte.com – Phone +31-594-851515page 2 van 3

Warning ! :lifting brackets shall only be used in a vertical line with its suspension !Warning ! :In case of questions contact your local dealer or <strong>Prolyte</strong><strong>Prolyte</strong> Products <strong>Group</strong>, industriepark 31, 9351 PA leek, The Netherlandswww.prolyte.com – Phone +31-594-851515page 3 van 3