DSC Modular Gripping Products Catalog - Pneumatic Technology, Inc

DSC Modular Gripping Products Catalog - Pneumatic Technology, Inc

DSC Modular Gripping Products Catalog - Pneumatic Technology, Inc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

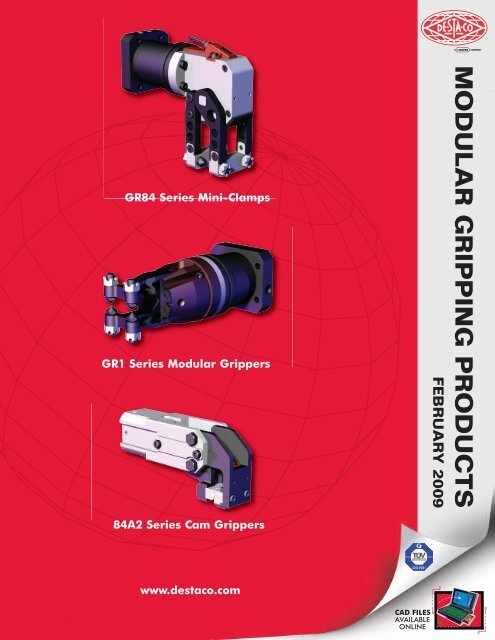

GR84 Series Mini-ClampsGR1 Series <strong>Modular</strong> GrippersMODULAR GRIPPING PRODUCTSFEBRUARY 200984A2 Series Cam Gripperswww.destaco.comCAD FILESAVAILABLEONLINE

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong><strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>IntroductionGR84 Enclosed <strong>Modular</strong> Mini-Clamp• Offers several different jaw and tip options.• Can be flange or cylinder mounted.• High clamping force and fast openingand closing action.• Locking Mechanism holds thepart if air pressure is lost• Protected from contaminates.GR1 <strong>Modular</strong> Gripper• Can be flange or cylinder mounted.• Offered in two cylinder sizes, 15 and 20 Series.• Offered with several different jaw opening andpoint options.• High clamping force and fast opening andclosing action.• Locking mechanism holds thepart if air pressure is lost.84A2 <strong>Modular</strong> CAM Style Gripper• Offered with several different jaw opening andpoint options.• High speed material movement in restricted spaces.• High clamping force and fast opening and closingaction.• Roller and cam principal, self-locking at end stopposition.• Multiple mounting and jaw opening options.• Small size, low weight.2 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini ClampTable of ContentsOrdering Information ................................Pages 6-790° Jaw Arrangement ................................Pages 8-9“9Sx” Standard Fixed Jaw ....................................Page 8“9Fx” Flange Fixed Jaw .......................................Page 8“9Ax” Standard Fixed Jaw ...................................Page 9“xx3/6/9” Preset Active Jaw Opening ..................Page 9Straight Jaw Arrangement ....................Pages 10-11“SSx” Standard Fixed Jaw ..................................Page 10“SFx” Flange Fixed Jaw......................................Page 10“SAx” Standard Fixed Jaw..................................Page 11“xx3/6/9” Preset Active Jaw Opening ................Page 11Jaw Block and Insert Options................Pages 12-15“N” Blank Jaw Block ..........................................Page 12“R” Point Insert Jaw Block ..................................Page 12“M” Block Insert Jaw Block.................................Page 12“L” Flange Point Insert Jaw Block........................Page 13“Q” Single Point Insert Jaw Block .......................Page 13“K” Adjustable Jaw Block ...................................Page 14“S/U/A” Block Inserts.........................................Page 14“P/C/S/T/U” Jaw Inserts ....................................Page 15Sensor Mounts...............................................Page 16“F1” Ø18mm Sensor Mount...............................Page 16“F2” Ø12mm Sensor Mount...............................Page 16Guard Options ..............................................Page 16“01”, “02” Face and Skid Guard.......................Page 16Cylinder Options ...........................................Page 17“Bx” Flange Base Cylinder .................................Page 17“Cx” Round Base Cylinder..................................Page 17Sensor Options..............................................Page 18Wiring Diagram of Electrical Sensing System.......Page 18Open/Closed Sensors .........................................Page 18Technical Information ............................Pages 18-21Specifications......................................................Page 18Stripping and Grip Force Charts .........................Page 19Stroke and Tip Adjustment Procedures .........Pages 20-21www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e3

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> GripperTable of ContentsOrdering Information ............................Pages 22-23Jaw Arrangement Options.....................Pages 24-31“045” 45° Angular Jaw Arrangement.................Page 24“45C” 45° Chisel Lower Jaw Arrangement .........Page 25“FCH” Fixed Chisel Jaw Arrangement ................Page 26“9DJ” 90° Drop Jaw Arrangement .....................Page 27“180” 180° Angular Jaw Arrangement..........Page 28-29“90F” 90° Fixed Lower Jaw Arrangement..........Pages 30“9FS” 90° Fixed Lower Jaw Arrangementwith Stroke Limiter Installed.............Pages 30Technical Information ...................................Page 31Grip Force Charts and Specifications...................Page 31Cylinder Options ...........................................Page 32“Bx” Flange Base Cylinder .................................Page 32“Cx” Round Base Cylinder..................................Page 32Jaw Inserts and Block Inserts ................Pages 33-35“P/C/S/U” Jaw Inserts .......................................Page 33“S30” and “D30” 30° Angle Single and DoubleSerrated Block Insert ..........................................Page 34“SOF” and “DOF” Offset Single and DoubleSerrated Block Insert ..........................................Page 34“SDB” and “DDB” Draw Bead Single and DoubleSerrated Block Insert ..........................................Page 35“SED” Extended Draw BeadSerrated Block Insert ..........................................Page 35Mounting Options ..................................Pages 36-38“MAx” Swivel Parallel Gripper Mounts ...............Page 36“MBx” Rear Swivel Gripper Mounts....................Page 37“MCx” Rear Fixed Welded Gripper Mounts .........Page 38“MD7” Rear Fixed Gripper Mounts.....................Page 38Part Present Sensor Mounts...................Pages 39-41“A04” and “P03” Sensor and Mounts ..........Page 39-41Open/Closed Sensor Option....................Page 42-43GR1-20 Series Gripper ............................Page 44-47GR1-20-Bx-180-Dxx-Mxx ...............................Page 44-474 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style GripperTable of ContentsOrdering Information ............................Pages 48-49Jaw Arrangement Options.....................Pages 50-59“...1” 72°/45°/30° Upper/Fixed Lower ................Page 50“...2” 72°/45°/30° Upper/Fixed Lower ................Page 51“...3” 72°/45°/30° Upper and Lower ..................Page 52“...4” 72°/45°/30° Upper/Fixed Lower ................Page 53“...6” 72°/45°/30° Upper/Fixed Lower ................Page 54“...7” 72°/45°/30° Upper/Fixed Lower ................Page 55“...8” 72° Upper/Fixed Lower .............................Page 56“...9” 45°/30° Upper/Fixed Lower ......................Page 57“84A2R13” 72° Upper/15° Lower ......................Page 58“84A2T13” 45° Upper/15° Lower ......................Page 59Gripper Teeth and Points ............................Pages 60Gripper Teeth, Point, and Crown Teeth................Page 60Mounting Accessories ..................................Pages 61Ø25mm and Ø1.00” Adaptor Mounts.................Page 61Sensor Accessories.......................................Pages 61Part Present and Workplace Control Sensors .......Page 61“84A2-VB000H1H2” Hi Temperature Gripperwith 72° Opening Jaw Arrangemens .................Pages 62Technical Information ...................................Page 63Grip Force and Specifications..............................Page 63www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e5

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini ClampOrdering InformationMODELSERIESCYLINDERJAW ARMJAW OPENING OPTIONSGR84 15 BE DD 9S9PATENT# 6,619,182JAW ARM OPTIONSL SR DDSINGLE ARMLEFTSINGLE ARMRIGHTDOUBLEARMFOR MINI-CLAMPMOUNTING OPTIONS,PLEASE REFER TO GR1SERIES “MOUNTINGOPTIONS” FOR STYLE OFMOUNTING AND USE THE“REPLACEMENT PART#”TO ORDER THE PREFERREDMOUNTING STYLE.(SEE PAGES 36-38)JAW ARRANGEMENT & OPENINGSTEP 1 9S X JAW ARRANGEMENT9A 9F 9S90° GRIPADJ. FLANGE90° GRIPFLANGE90° GRIPSTANDARDSA SF SSCYLINDER TYPE & PORTINGSTEP 1 B EBCYLINDER TYPECSTRAIGHTADJ. FLANGESTRAIGHTFLANGESTRAIGHTSTANDARDFLANGEBASESTEP 2 B EROUNDCYLINDERCYLINDER PORTSSTEP 2 9S 9 ACTIVE JAW OPENING3 6 9EMENGLISH (1/8 NPT)METRIC (1/8 G)30˚ PRESET 60˚ PRESET 90˚ PRESET6 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini ClampOrdering InformationINSERTS SENSORSENSINGMOUNTSQQSS E6 XXGUARDS01JAW BLOCK & INSERT OPTIONSSENSOR OPTIONSSTEP 1QQ S S ACTIVE JAW BLOCK OPTIONR L Q(SEE PAGE 18 FOR SENSOR SPECIFICATIONS)A1 = (TURCK) VDCB8 = (PEPPERL FUCHS) VDCREGULAR BLOCK FLANGE BLOCK (2) SINGLE BLOCKSN M KC8C9D1E3E4= (DE-STA-CO) VDC= (ALLEN-BRADLEY) VDC= (TURCK) AC/DC= (NAMCO) VDC= (PEPPERL FUCHS) VDCSTEP 2BLANK BLOCKQ Q S S“B” INSERT JAW(BLOCK INSERTS ONLY)FIXED JAW BLOCK OPTIONADJUSTABLE JAW(9A & SA FIXED JAW ONLY)E5E6XC= (EFECTOR) VDC= (BALUFF) VDC= COVER ONLYSTEP 3QQSSACTIVE JAW INSERT OPTIONPC U SSENSOR MOUNTSPOINTCUPURETHANESERRATEDF1F2T X Z BSTEP 4ORSELF-ADJUSTINGSERRATEDQQM MSBSSNONEFIXED JAW INSERT OPTIONS U ABLANK*BLOCKN = NON-STANDARD“B” BLOCK INSERT OPTIONS*(ACTIVE AND FIXED JAWS USE COMMON INSERTS)Ø18mm SENSOR Ø12mm SENSORXX = NO SENSOR MOUNTSGUARD OPTIONS01 02SERRATED URETHANE ALUMINUMN = NON-STANDARD(SENSING MOUNTS CAN NOT BE USED WITH (B) BLOCK OPTION INSERTS)FACE GUARD FACE + SKID GUARDXX = NO FACE GUARDwww.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e7

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“9Sx” 90° Jaw Arrangement - Standard Fixed Jaw[3.45]87.5[2.43]61.8[2.81]R71.4[5.00]127[1.45]36.9[2.63]66.7[.25]6.4[.87]22.2[1.50]38[.63]15.9[.31]7.9[.44]11.1[2.13]54[2.22]56.4Replacement Part #[2.12]53.9GR84-JFA“9Fx” 90° Jaw Arrangement - Flange Fixed Jaw[3.45]87.5[2.44]62[5.00]127[1.45]36.9[2.81]R71.4[2.63]66.7[.25]6.4[.44]11.1[.31]7.9[1.75]44.4[.63]15.9[2.13]54[2.22]56.4[2.37]60.3Replacement Part #[3.42]86.7GR84-JA-F-L (LEFT HAND)GR84-JA-F-R (RIGHT HAND)8 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“9Ax” 90° Jaw Arrangement - Adjustable Fixed Jaw[3.45]87.5[2.44]62[2.81]R71.4[5.75]146.1[2.20]56OPTION “K”JAW BLOCKSEE PAGE 10FOR DETAILS[.13]3.2[2.63][.25] [1.45]66.76.436.9[.44]11.1[2.62]66.6[3.00]76.1[3.37]85.7[4.73]120.1[.31]7.9[.63]15.9[5.00]127[2.13]54[2.56]65Replacement Part #GR84-JA-EX-L (LEFT HAND)GR84-JA-EX-R (RIGHT HAND)“xx3”, “xx6”, “xx9” 90° Jaw Arrangement - Preset Active Jaw Opening90° ACTIVE JAWOPENINGGR84-Bx-xx9[3.50] (WITH “N”R88.9JAW BLOCK)[3.06]77.7[2.71]68.94PIVOT TO CENTEROF TIP INSERT[2.81] (WITHOUTR 71.4 JAW BLOCK)60° ACTIVE JAWOPENINGGR84-Bx-xx6Replacement Part #GR84-JRA“L”FIXED LOWER JAW(STANDARD LOWER JAW SHOWN)30° ACTIVE JAWOPENINGGR84-Bx-xx3CLOSEDACTIVE JAW POSITIONCylinder Mount Length “L”Bx Flange Base 132.6 [5.22]Cx Round Base 130.8 [5.15]AVAILABLE WITH B8 AND C8www.destaco.com SENSOR OPTIONS ONLY90° ACTIVE JAW60° ACTIVE JAW30° ACTIVE JAWOPENING Sub ject to Tech nical M odi OPENINGfi cations Wi thout Notic e9

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“SSx” Straight Jaw Arrangement - Standard Fixed Jaw[2.13]54[2.22]56.4[2.44]62[4.60]116.9[3.44]87.3[2.81]R71.4[2.63]66.7[.31]7.9[.63]15.9[.44]11.1[.88]22.3[1.50]38.2[2.13]54[1.14]29[.25]6.4Replacement Part #GR84-JFA“SFx” Straight Jaw Arrangement - Flange Fixed Jaw[2.13]54.1[2.22]56.4[2.44]62[4.60]116.9[2.81]R71.3[2.63]66.7[.31]7.9[.63]15.9[3.44]87.3[1.75]44.5[2.38]60.4[3.00]76.3[.88]22.2[1.14]29[.25]6.4Replacement Part #GR84-JA-F-L (LEFT HAND)GR84-JA-F-R (RIGHT HAND)10 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“SAx” Straight Jaw Arrangement - Adjustable Fixed Jaw[2.13]54[2.56]65[5.35]136[2.81]R71.3[1.49]37.7[1.14]28.9[.31]7.990° ACTIVE[.63]JAW15.9OPENINGGR84-Bx-xx9[3.06]77.7[5.63]142.9[2.71]68.94PIVOT TO CENTER [2.19]55.6OF TIP INSERT“L”FIXED LOWER JAW(STANDARD LOWER JAW SHOWN)[.25]6.4[3.00]76.2[3.50] (WITH “N”R88.9JAW BLOCK)[.44] [2.62] [3.00]66.6 76.1[3.37]11.1 [2.81] (WITHOUT 85.7 [4.31]R 71.4 JAW BLOCK) 109.5OPTION “K”30° ACTIVEJAWJAWBLOCKOPENING SEE PAGE 10GR84-Bx-xx3 FOR DETAILSCLOSEDACTIVE JAW POSITION60° ACTIVE JAWOPENINGGR84-Bx-xx6Replacement Part #GR84-JA-EX-L (LEFT HAND)GR84-JA-EX-R (RIGHT HAND)“xx3”, “xx6”, “xx9” Straight Jaw Arrangement - Preset Active Jaw OpeningAVAILABLE WITH B8 AND C8SENSOR OPTIONS ONLY90° ACTIVE JAWOPENINGGR84-Bx-xx960° ACTIVE JAWOPENINGGR84-Bx-xx630° ACTIVE JAWOPENINGGR84-Bx-xx3[2.81] (WITHOUTR71.4 JAW BLOCK)[3.50] (WITH “N”R88.9 JAW BLOCK)Replacement Part #GR84-JRACLOSEDACTIVE JAW POSITIONFIXED LOWER JAW(STANDARD LOWER JAW SHOWN)“L”[2.71]68.94[3.06]77.7PIVOT TO CENTEROF TIP INSERTCylinder Mount Length “L”Bx Flange Base 132.6 [5.22]Cx Round Base 130.8 [5.15]www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e11

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“N” Blank Jaw Block[2.13]53.98TAP FOR M5 FASTERNER (2X)[.53]13.5Ø5.2 [.206) CLEARANCE HOLE TO SLOTCOUNTERSUNK FOR M5 FASTERNER (2X)[.14]3.6[.10]2.5TYP[1.85]46.9[1.65]41.9[1.37]34.7CENT[.44]11.11[.22]5.6Replacement Part #GR84-JB[.50]12.7[1.19]30.16[.25]6.4“R” Point Insert Jaw Block[.34]8.7A[.44]11.1[.31]7.9A[1.50]38.1.375-24 UNFTAP THRU (2X)[.19]4.8SECTION A-AReplacement Part #GR84-JB-3824“M” Block Insert Jaw BlockA[.34]8.7[.42]10.7 (2)[.77]19.5A[.59]15.0[.26]6.6 (2)[.28]7.1 (2)SECTION A-AReplacement Part #GR84-JB-BM612 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“ L” Flange Point Insert Jaw Block[2.13]54[.75]19.05[.53]13.5[1.39]35.4Replacement Part #GR84-JB-F-3824[.44]11.1[1.19]30.16[.50]12.7[1.37]34.7CENT[.34]8.7[.22]5.6[.25]6.42X .375-24 UNF-2B 19.1[.75] DEEPØ.438 C’ BORE, .188 DEEP (2)[.31]7.94[1.50]38.1Ø10.32[.41] CLEARANCETHRU TO CROSS SLOT (2)“Q” Single Point Insert Jaw Block(Offered in pairs per jaw)[.63]15.88[.53]13.5[1.19]30.12[.50]12.7[.44]11.11[.22]5.6[.25]6.4Replacement Part #GR84-JB-3824S[.34]8.7[.31]7.92X .375-24 UNF-2B 19.1[.75] DEEPØ.438 C’ BORE, .188 DEEP (2)www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e13

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“K” Adjustable Jaw Block(Can only be used with “SA” and “9A” fixed lower jaw)[.63]15.90[.31]7.94Ø.438 C’ BORE, .188 DEEP (2)2X .375-24 UNF-2B THRU ALL[1.46]37.0CENT[1.34]34.0CENT[.59]15.0CENT[1.50]38.1CENT[2.13]54.02X Ø6.6 [.26] THRU ALLØ10.7[.42] C’ BORE,7.1[.28] DEEP (2)[3.00]76.2[2.31]58.7[.70]17.9[.41]10.3[.11]2.8.000[.25]R6.4[1.25]31.8[.75]19.1[.50]12.7[.63]15.9[.25]6.42XM6X1.0 THRU ALLTHIS JAW BLOCK GR84-JB-ADJCAN ONLY BE USED ONSA AND 9A FIXED LOWER JAWReplacement Part #GR84-JB-ADJ“S”, “U”, “A” Block Inserts(Can only be used with “K” and “M” jaw blocks)[.30]7.5[.38]9.5[.39]10.0[.59]15.0[1.38]34.9M6x1.0 (2) THRU[.59]15.0“S”“U”“A”Serrated Block InsertsReplacement Part #GR84-JB-SSUrethane Block InsertsReplacement Part #GR84-JB-UPAluminum Block InsertsReplacement Part #GR84-JB-PA14 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“P”, “C”, “S”, “T”, “U” Jaw Inserts[.16]4.1[.19]4.8[.94]23.9[.38]9.5“P”Point Jaw InsertsReplacement Part #GR0107[.50]12.7HEX[.43]Ø11.0SECTION A-A3/8-24 UNF-2A[.13]Ø3.2[.36]Ø9.150°90°[.43]Ø11.0[.19]4.8[1.50]38.2[.38]9.5[.50]12.7HEX“C”Cup Jaw InsertsReplacement Part #GR01083/8-24 UNF-2A[.43]Ø11.0[.50]3/8-24 UNF-2A 12.7HEX“S”Serrated Jaw InsertsReplacement Part #GR0342[.19]4.8[1.50]38.2[.38]9.6“T”Self-AdjustingSerrated Jaw Inserts[.09] SELF2.3 ADJUSTMENT[.55]14.0[.76]19.2<strong>Inc</strong>ludes (1) GR0342 and(4) Belleville WashersPart# 329-TPR-BDA-044Self-adjusting jaw inserts require jaw blocks tohave clearance holes in place of the standard tapthread in order for the inserts to function properly.[.75]19.1CENT“U”[.16]Urethane Jaw Inserts3/8-24 UNF-2A4.0[.75]R19.1Replacement Part #GR0353[.44]R11.2[1.25]31.8[.22][.25] 5.56.4www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e15

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“F1” Ø18mm Sensor Mount(Can only be used with “K” and “M” jaw blocks)[1.53]38.9[.13]3.2[.31]R 7.94[.44]11.1[.75]19.10M18 x1.0 THRU[.16]4.00“F1”Replacement Part #CPI-PM-18[.47]R 11.9“F2” Ø12mm Sensor Mount(Can only be used with “K” and “M” jaw blocks)[1.38]34.9[.13]3.2[.75]19.10M12x1.0“F2”[.31]R 7.9[.44]11.1[.06]1.60Replacement Part #CPI-PM-12[.38]R 9.5“01”, “02” Face and Skid Guard[.84]21.3[.19]4.7“01”[.95]24.1[1.32]33.5FACE GUARD“02”2X Ø4.2 [.165] THRU ALLCOUNTERSINK FOR M4 FHCS[.55]14.1[.11]2.8FACE AND SKID GUARD45°[2.55]64.7[.59]14.9Replacement Part #GR84-JFG16 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini Clamp“Bx” Flange Base CylinderOPEN GRIPPER PORTCLOSED GRIPPER PORT[2.50]63.5[1.38]34.9[.63]15.9[3.24]82.3[.26]6.6Replacement Part #GR84-CYL-B[2.44]Ø62[2.81]71.4[2.25]57.2150 SERIES“RJM” REARGRIPPERMOUNTSURFACEØ38.1[Ø1.50”]BORECYLINDER[.27]Ø6.7150 SERIES“GPC” GRIPPERPARALLEL CLAMPLOCK GROOVEASTROKETRAVELCYLINDER PORTSE =1/8” NPT (ENGLISH)M =1/8” G (METRIC)PATENT# 6,619,182CLOSED GRIPPER PORT(OPTIONAL FORLARGER AIR FITTINGS)MINI CLAMP/GRIPPERHEAD MOUNTINGSURFACEJAWOPENING30° 60° 90°STROKE “A” 21.3 [.84] 32.8 [1.29] 42.9 [1.69]“Cx” Round Base Cylinder[2.44]Ø61.9[.56]14.2[3.18]80.8Ø38.1[Ø1.50”]BORECYLINDER[.26]6.6RETRACTEDPOSITION[2.44]62Replacement Part #GR84-CYL-COPENGRIPPERPORTCLOSEDGRIPPERPORTCYLINDER PORTSE =1/8” NPT (ENGLISH)M =1/8” G (METRIC)150 SERIES“GPC” GRIPPERPARALLEL CLAMPLOCK GROOVEASTROKETRAVELMINI CLAMP/GRIPPERHEAD MOUNTINGSURFACEJAWOPENING30° 60° 90°PATENT# 6,619,182STROKE “A” 21.3 [.84] 32.8 [1.29] 42.9 [1.69]www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e17

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini ClampTechnical InformationWiring diagram of electrical sensing system“A1”PNP Pin Configuration+DC VoltageS01Unclamped1 4 Load2 312NPN Pin Configuration+3 42 1“C8”LoadS02ClampedA1A2Open/Closed Sensor Options:“A1” (Turck) Replacement Part# “8EA-054-1”+”GR84-SB” .10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast(Fasterners required for “A1” replacement: (2) M5x0.5 10mm FHCS, (1) M4 x 0.7 20mm SHCS)“B8” (Pepperl Fuchs) Replacement Part# “8EA-031-1” .......10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast“C8” (DE-STA-CO Brand) .......................................................10...30 VDC 150mA, PNP, 4-Pin, M8, Pico“C9” (Allen-Bradley) Replacement Part# “8EA-1006-1”......10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast“D1” (Turck) Replacement Part# “8EA-1002-1”........................20...250 AC/DC 150mA, 5-Pin, ½-20, Mini“E3” (Namco) Replacement Part# “8EA-1007-1” ............................10...30 VDC 150mA, NPN, 4-Pin, M12“E4” (Pepperl Fuchs) Replacement Part# “8EA-1010-1” .....10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast“E5” (Efector) Replacement Part# “8EA-1012-1” ................10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast“E6” (Baluff) Replacement Part# “8EA-1019-1”..................10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast“XC” Cover Only Replacement Part# “GR84-SC”.........................................................No Sensor SuppliedSpecificationsWeight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2 lb [1.5 kg]Grip Range (Standard and Flange with Jaw Inserts) . . . . . . . . . . . . . . . . . . . . .0 to 0.31” [0mm - 8mm]Arm Position Tolerance: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±0.33°Arm Lateral Tolerance: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±0.3mmCycle Speed @ 60 psi: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.6 Sec (Open/Closed)Displacement Per Cycle @ 60psi: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.0 in3Max Air Consumption @ 100 cycles/min: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 ft3/minReliability:Mean Time Between Failure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5 Million CyclesMean Time To Repair: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Minutes300Grip Force (in lbs.)28026024022020018040 50 60 70 80 90Supply Pressure (in psi)18 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini ClampTechnical InformationThe GR84 Mini-Clamp utilizes a self-locking linkage system. If the air is lost while fullyclosed, the mini-clamp will continue to hold the part. The amount of air required to achievethe high gripping forces is greater than pressure to release or open the mini-clamp. If thereis a slight drop of pressure during the opening cycle, the mini-clamp will still release thepart. Other self locking systems can jam and require more air to release the part than itwould need to grip it.AAAACCAPANEL APANELCInline Strip ForcePANELAAGrip Force DDCLateral Strip ForceBBPANELOpening ForceDBBPANELBBPANELDPANELBPANELSingle Jaw Arm StylesDouble Jaw Arm StylesPRESSURE2.8 bar[40 psi]3.4 bar[50 psi]4.1 bar[60 psi]4.8 bar[70 psi]5.5 bar[80 psi]6.2 bar[90 psi]“A”Inline StripForce31.8 kg[70 lb]34.0 kg[75 lb]36.3 kg[80 lb]38.6 kg[85 lb]40.8 kg[90 lb]43.1 kg[95 lb]“B”Lateral StripForce31.8 kg[70 lb]34.0 kg[75 lb]36.3 kg[80 lb]38.6 kg[85 lb]40.8 kg[90 lb]43.1 kg[95 lb]“C”<strong>Gripping</strong>Force86.2 kg[190 lb]93.0 kg[205 lb]102.1 kg[225 lb]108.9 kg[240 lb]117.9 kg[260 lb]131.5 kg[290 lb]“D”Force toOpen294.8 kg[650 lb]294.8 kg[650 lb]294.8 kg[650 lb]294.8 kg[650 lb]294.8 kg[650 lb]294.8 kg[650 lb]PRESSURE2.8 bar[40 psi]3.4 bar[50 psi]4.1 bar[60 psi]4.8 bar[70 psi]5.5 bar[80 psi]6.2 bar[90 psi]“A”Inline StripForce34.0 kg[75 lb]36.3 kg[80 lb]38.6 kg[85 lb]40.8 kg[90 lb]43.1 kg[95 lb]45.4 kg[100 lb]“B”Lateral StripForce34.0 kg[75 lb]36.3 kg[80 lb]38.6 kg[85 lb]40.8 kg[90 lb]43.1 kg[95 lb]45.4 kg[100 lb]“C”<strong>Gripping</strong>Force86.2 kg[190 lb]93.0 kg[205 lb]102.1 kg[225 lb]108.9 kg[240 lb]117.9 kg[260 lb]131.5 kg[290 lb]“D”Force toOpen589.4 kg[1300 lb]589.4 kg[1300 lb]589.4 kg[1300 lb]589.4 kg[1300 lb]589.4 kg[1300 lb]589.4 kg[1300 lb]www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e19

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini-ClampJaw Opening AdjustmentThe GR84 <strong>Modular</strong> Mini-Clamp offers a featureallowing the jaw opening angle to be changed inthe field.The GR84 <strong>Modular</strong> Mini-Clamp is ordered with apreset jaw opening angle. Follow the instructionsbelow to change the jaw opening angle.Retaining BoltWith the jaws in the closed position and the air off,loosen and remove Retaining Bolt.Stroke Adjustment BlockRetaining BoltThread retaining bolt into the bottom of the StrokeAdjustment Block.Use Retaining Bolt to remove the Stroke Adjustment Block.There are holes in the Stroke AdjustmentBlock designating three different jawopening angles.90° Opening30° Opening 60° OpeningPosition the Stroke Adjustment Block so the RetainingBolt hole aligns with the desired jaw opening hole.30° Opening 60° Opening90° OpeningReplace and tighten Retaining Bolt to secure the strokeadjustment block in the new position.Once the mechanical adjustment is complete, the sensormust be relocated to detect the new target location.20 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR84 <strong>Modular</strong> Mini-ClampJaw Insert AdjustmentAll Jaw Inserts can be adjusted for different sheet metalthicknesses. The Jaw Insert is threaded into the Jaw Block.The Jam Nut is used to secure the Jaw Insert into place.(This procedure can be used for boththe GR84 Mini-Clamp and GR1 Grippers)Jam Nut• Loosen jam nuts to allow jaw inserts to be adjusted.• Adjust jaw inserts fully toward jaw blocks.• Adjust jaw inserts on the fixed jaw toward panel toestablish panel location.• Hold fixed jaw inserts in place and tighten jam nuts.Jaw Insert“S” Jaw Insert(Shown)Jaw Block“R” Jaw Block(Shown)Active JawFixed Jaw• With panel in position, and clamp in closed position,adjust the jaw inserts on the active jaw. (Make sure to closethe clamp by air pressure and not by hand.)• Turn the jaw inserts by hand until they make contact withthe panel and can no longer turn.• Open the clamp and continue to turn the active jawInserts (1) turn further toward the part. This ensures therewill be a tight grip on the panel.• Hold active jaw inserts in place and tighten jam nuts.Block Insert AdjustmentBlock Insert height can be adjusted by placing a differentthickness Shim(s) between the Jaw Block and Block Insert.M6 FastenersShimJaw Block“M” Jaw Block(Shown)Block Insert“S” Block Insert(Shown)Manual Lock OverrideThe GR84 <strong>Modular</strong> Mini-Clamp’s manual lock overrideenables the gripper to be release from the closed position.This lock override eliminates the need to cycle air to themini-clamp in order to open the jaws, if the part needs tobe removed.• With the air off, using a 3mm hex wrench, rotate theRelease Screw approximately 15° clockwise.• Once unlocked, the Mini-Clamp Jaws can be manuallyopened.Release Screwwww.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e21

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> GripperOrdering InformationMODELSERIESCYLINDERJAW OPENING ARRANGEMENTGR1 15 BE 045CYLINDER TYPE & PORTINGSTEP 1 B ECYLINDER TYPEBCSTEP 2 B ECYLINDERPORTSEENGLISH (1/8 NPT)FLANGEBASEROUNDCYLINDERM METRIC (1/8 G)JAW ARRANGEMENT OPTIONSPATENT#S 6,619,182 , 6,988,696 , 6,361,095045 45C FCH 9DJ45˚ ANGULAR 45˚ CHISEL 45˚ FIXED CHISEL90F9FS 18090˚ DROP JAW90˚ FIXED LOWER90˚ FIXED LOWERLIMITED STROKE180˚ ANGULAR22 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> GripperOrdering InformationINSERTS MOUNTS PART PRESENTDPP MXX XXXOPEN/CLOSEDXXXPOINTS & TIP INSERT OPTIONSORBLOCK INSERT OPTIONSSTEP 1 DPPPOINT TIP OPTIONX =OMITDDBDOFD30SDDOUBLEDRAW BEADDOUBLEOFFSETDOUBLE30° ANGLESDBSOFS30SINGLE POINTDOUBLE POINTSTEP 2 DPPUPPER TIP INSERT OPTIONX =OMITSINGLEDRAW BEADSINGLEOFFSETSINGLE30° ANGLEPC U SSEDPOINTSTEP 3 DPPCUP URETHANE SERRATEDLOWER TIP INSERT OPTION X =OMITSINGLEEXTENDEDDRAW BEADMOUNT OPTIONSSTEP 1 M X X MOUNT TYPE X =OMITA B C D? ? ?(FASTENERSNOT INCLUDED)PARALLEL SWIVEL MOUNT REAR SWIVEL CLAMP MOUNT REAR FIXED WELDED STYLEMOUNT BALL SIZES AVAILABLEMOUNT BALL SIZES AVAILABLEMOUNT ROD SIZES AVAILABLE1 2 3 41 2 3 41 3 5 6REAR FIXED CLAMP MOUNTMOUNT SIZES AVAILABLE7STEP 2 MXXMOUNT BALL/ROD SIZEX= OMITwww.destaco.com1 = 1.00” W/METRIC FASTENERS 2 = 1.25” W/METRIC FASTENERS 3 = 25MM METRIC FASTENERS4 = 30MM BODYBUILDER/METRIC 5 = 1.50” (TYPE C ONLY) 6 = 40MM (TYPE C ONLY)7A04XXX= M1514 (TYPE D ONLY)= TURCK (4-PIN)PART PRESENT(SEE PAGE 40 FOR SENSOR SPECIFICATIONS)= NO SENSORP03= P & F (4-PIN)Sub ject to Tech nical M odi fi cations Wi thout Notic eT04OPEN/CLOSED(SEE PAGE 42 FOR SENSOR SPECIFICATIONS)XXX= INTERNAL SENSOR= NO SENSOR23

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“045” 45° Angular Jaw Arrangement - Single and Double InsertSINGLE INSERT OPTION5/16-24 UNF-2A[.54]13.7[2.44]Ø61.9DOUBLE INSERT OPTION[3.32]84.4[1.45]36.85/16-24 UNF-2A X2[1.13]28.6[2.31]58.7PATENT# 6,361,095[3.33]84.5[1.45]36.9FULL OPENINGJAW POSITIONLIMITED OPENINGJAW POSITION[.34]8.6[2.62]66.4[3.38]85.8[1.48]37.5[.25]6.4[1.88]47.6[2.38]60.3[1.70]43.3[2.27]R57.6[.68]17.2Fig. 1 Fig. 2For Limited Stroke Option1. Loosen fasteners securing gripper body from cylinder.2. Pull gripper body away so fasteners clear the spacer.3. Rotate Spacer 90° (Fig. 2).4. Reattach gripper body to cylinder and tighten fasteners.24 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“45C” 45° Chisel Lower Jaw Arrangement - Single and Double InsertSINGLE POINT OPTION5/16-24 UNF-2A[.54]13.7[2.44]Ø61.9[3.32]84.4[1.45]36.8DOUBLE POINT OPTION5/16-24 UNF-2A X2[1.13]28.6[1.62]41.2[2.31]58.7PATENT# 6,361,095[3.32]84.4[1.45]36.8FULL OPENINGJAW POSITIONLIMITED OPENINGJAW POSITION[3.57]90.8[2.27]R 57.6[.28]7.0[1.47]37.4[2.35]59.7[2.77]70.3[.68]17.2[.25]6.4[.50]12.7[3.76]95.5[2.33]R 59.2Fig. 1 Fig. 2For Limited Stroke Option1. Loosen fasteners securing gripper body from cylinder.2. Pull gripper body away so fasteners clear the spacer.3. Rotate Spacer 90° (Fig. 2).4. Reattach gripper body to cylinder and tighten fasteners.www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e25

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“FCH” Fixed Chisel Jaw Arrangement - Single and Double InsertSINGLE INSERT OPTION5/16-24 UNF-2A[.54]13.7[2.31]58.7DOUBLE INSERT OPTION[3.33]84.6[1.45]36.8[.71]17.95/16-24 UNF-2A X2[1.13]28.6[2.31]58.7PATENT# 6,361,095FULL OPENINGJAW POSITIONLIMITED OPENINGJAW POSITION[3.33]84.6[1.45]36.8[2.34]R59.5[.28]7.0[1.30]33.0[1.65]41.9[1.36]34.6[2.34]59.5[1.72]43.7[.25]6.4[2.38]60.3[1.70]43.2[1.89]47.9[1.13]28.6[1.62]41.2Fig. 1 Fig. 2For Limited Stroke Option1. Loosen fasteners securing gripper body from cylinder.2. Pull gripper body away so fasteners clear the spacer.3. Rotate Spacer 90° (Fig. 2).4. Reattach gripper body to cylinder and tighten fasteners.26 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“9DJ” 90° Drop Jaw Arrangement - Single and Double InsertSINGLE INSERT OPTION[1.50]38.1[2.31]58.7DOUBLE INSERT OPTION[2.08]53.0[.55]14.05/16-24 UNF-2A[1.22]30.9[2.44]61.9[.73]18.5[1.63]41.3[2.31]58.7PATENT# 6,361,095FULL JAW OPENINGPOSITION (97°)LIMITED JAW OPENINGPOSITION (62°)[2.23]R56.7[3.26] [3.58]82.8 90.8[.72]18.3[.25]6.4[.56]14.3[2.56]65.1[1.98]50.4[1.02]25.95/16-24UNF-2A X2[1.13]28.6[2.44]61.9[.56]14.3Fig. 1 Fig. 2For Limited Stroke Option1. Loosen fasteners securing gripper body from cylinder.2. Pull gripper body away so fasteners clear the spacer.3. Rotate Spacer 90° (Fig. 2).4. Reattach gripper body to cylinder and tighten fasteners.www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e27

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“180” 180° Angular Jaw Arrangement - Double Insert[1.13]28.6[2.44]Ø61.9[2.88]73.0[1.40]35.65/16-24 UNF-2A X2FULL OPENINGJAW POSITION[4.04]R 102.7[.65]16.6[2.06]52.3[6.14]156.0[1.53]38.9[2.50]63.5[1.78]45.1[1.69]42.8Limited Stroke Ring is NOT Availble28 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“180” 180° Angular Jaw Arrangement - Single Insert5/16-24 UNF-2A[.50]12.7[2.44]61.9[2.89]73.3[1.40]35.6FULL OPENINGJAW POSITION45°[2.06]52.3[6.14]156.1[2.50]63.5[1.06]26.9[1.65]41.9[.82]20.9[.75]19.1[.75]19.1[2.56]65.1SINGLE INSERT OPTION WITH TIP RISERSFOR TIP BLOCK INSERTS[.65]16.6Tip Risers for Block InsertsReplacement Part #GR0314-TRwww.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e29

114.9[1.25]31.8<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper[.81]20.6“90F” and “9FS” Fixed Lower Jaw Arrangement - Double Insert5/16-24 UNF-2ADOUBLE INSERT OPTION[.56]14.3[1.13]28.6[2.44]Ø61.9“90F”Full Arm Opening[4.27]108.6[1.40]35.65/16-24 UNF-2A X2“90F” OPENINGJAW POSITION (50°)“9FS” OPENINGJAW POSITION (25°)[3.85]R97.8[.82]20.9[.33]8.3[.34]8.6[3.16]80.2[3.93]99.9[1.28]32.4[2.88]73.0[1.78]45.1[.50]12.7[1.69]42.8Limited Stroke Ring is NOT Availble“9FS”Limited Arm Opening(Stroke Limiter Installed)30 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> GripperGrip Force and Technical Information045/45C/FCHGrip Force (lbf)70060050040030020010006070 80 90Supply Pressure (psi)9DJ“045” 45° Angular450400350300250200150Weight:10050Weight:1 kg [2.2 lb]01 kg [2.2 lb]60 70 80 90Grip Range:Grip Range:0”- 0.125” [0 - 3mm] Supply 0”- Pressure 0.063” (psi) [0 - 1mm]Grip Force (lbf)“45C” 45° Chisel“FCH” 45° Fixed ChiselWeight:1 kg [2.2 lb]Grip Range:0”- 0.063” [0 - 1mm]090F/9FS 045/45C/FCH9DJGrip Force (lbf)700210 450190 600 400350170 500300150 400 250130300 200110 150200100 90100 70 505006070 70 80 80 80 90 90 90Supply Pressure (psi)180 9DJ“9DJ” 90° Drop Jaw400400350350300300250250200200150Weight:100501 kg [2.2 lb]0Grip Range:6070 80 900”- 0.125” [0 - 3mm]Supply Pressure (psi)Grip Force (lbf)09090F/9FS 9DJ 180Grip Force (lbf)210 400 450190 350400350170 300300150 250250130 200200110 150150100 9070505006070 70 80 80 9090Supply Pressure (psi)180 (20 SERIES)“90F” 90° FIxed Lower“9FS” 90° Fixed Lowerwith Limited Stroke40035030025020015010050Weight:0Weight:1.1 kg [2.6 lb]6070 1.1 80 kg [2.6 90lb]Grip Range:Supply Grip Range:Pressure (psi)0”- 0.125” [0 - 3mm] 0”- 0.125” [0 - 3mm]Grip Force (lbf)90180(20 SERIES)Grip Force (lbf)www.destaco.com4003503002502001501005006070 80 90Supply Pressure (psi)180 (20 SERIES)400180 (20 SERIES)“180” 180° Angular Technical Infomation(for all GR1 Gripper Jaw Styles)Grip Force (lbf)400350300Air Requirements:250Recommended operationg Pressure:2002-6 bar [30-90 psi]150Ports: 1/8” BSPP [1/8” NPT]10050Air flow controls recommended for0maximum lifeWeight:60 70 80 90Operating Temperature:1.2 kg [2.7 lb] Supply Pressure 0° (psi) - 93°C [32° - 200°F]Grip Range:0”- 0.125” [0 - 3mm]Sub ject to Tech nical M odi fi cations Wi thout Notic e31

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“Bx” Flange Base CylinderOPEN GRIPPER PORTCLOSED GRIPPER PORT[2.50]63.5[1.38]34.9[.63]15.9[2.62]66.4[.26]6.6[2.44]Ø62[2.81]71.4[2.25]57.2[.27]Ø6.7150 SERIES“RJM” REARGRIPPERMOUNTSURFACEØ38.1[Ø1.50”]BORECYLINDER150 SERIES“GPC” GRIPPERPARALLEL CLAMPLOCK GROOVE[1.01]25.7STROKETRAVELCYLINDER PORTSE =1/8” NPT (ENGLISH)M =1/8” G (METRIC)CLOSED GRIPPER PORT(OPTIONAL FORLARGER AIR FITTINGS)GRIPPER HEADMOUNTINGSURFACEReplacement Part #GR1-CYL-BPATENT# 6,619,182“Cx” Round Base Cylinder[2.44]Ø61.9[.56]14.2[2.55]64.7Ø38.1[Ø1.50”]BORECYLINDER[.26]6.6RETRACTEDPOSITION[2.44]62OPENGRIPPERPORTCLOSEDGRIPPERPORTCYLINDER PORTSE =1/8” NPT (ENGLISH)M =1/8” G (METRIC)PATENT# 6,619,182150 SERIES“GPC” GRIPPERPARALLEL CLAMPLOCK GROOVE[1.01]25.7STROKETRAVELMINI CLAMP/GRIPPERHEAD MOUNTINGSURFACEReplacement Part #GR1-CYL-C32 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“P”, “C”, “S”, “U” Jaw Inserts[.38]9.5HEX[.13].13[.34]Ø8.6SECTION A-A5/16-24 UNF-2A[.13]Ø3.2[.13]3.3[.69]17.5[.31]Ø7.950°[.28]7.1100°“P”Point Jaw InsertsReplacement Part #GR0304[.34]Ø8.6[.13]3.3[1.09]27.7[.28]7.1[.375]9.5HEX“C”Cup Jaw InsertsReplacement Part #GR03055/16-24 UNF-2A[.38]5/16-24 UNF-2A 9.5HEX“S”Serrated Jaw InsertsReplacement Part #GR0341[.34]Ø8.6[.13]3.3[1.09]27.7[.28]7.1[.55]14.0[.76]19.2[.09] SELF2.3[.56]ADJUSTMENT14.3[.13]“U”Urethane Jaw InsertsCENT3.2[.625]5/16-24 UNF-2A R15.9Replacement Part #GR0338[.34]R8.6[1.25]31.8[.19][.32] 4.88.1www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e33

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“S30” and “D30” 30° Angle Serrated Block Inserts[.75]19.1[.75]19.1[1.53]38.930°[1.86]47.3[1.22]31.0[1.22]31.0“S30”[.75]19.1“D30”[.75]19.1[1.53]38.9[.75]19.1[.77]19.4[1.53]38.930°Single [1.86] Upper/Lower [1.22]30° 47.3 Angle Insert 31.0Block[.22]5.5 Replacement 1.86 [1.20] Part #47.3GR1-INS-SD30S 30.5[1.22]31.0[1.20]30.5Double Upper/Lower30° Angle Insert BlockReplacement Part #GR1-INS-D30S“SOF” and “DOF” Offset Serrated Block Inserts[.75]19.1[.77]19.4[1.53]38.9“SOF”Single UpperOffset Insert Block30°[.75]19.130°[.22]5.5 1.86[.51] 47.313.0[.22]5.5[.39]9.9[.51]30° 13.0[.22]5.5[1.86]47.3[1.86]47.3[.22]5.5[1.20]30.5[1.10]28.1[1.10]28.1[1.86]47.3[.39] Single Lower9.9 Offset Insert Block[.77]19.5[.77]19.5[1.20]30.5[1.10]28.1[1.10]28.1[1.18]30.0Double UpperOffset Insert Block[1.53]38.9[1.53]38.9[.75]Replacement Part # 19.1 Replacement [.39] Part # Replacement Part # Replacement Part #9.9GR1-INS-SDUOS [1.81] GR1-INS-SDLOSGR1-INS-DUOSGR1-INS-DLOS46.0[.77]19.534 Subjec 30° t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om[.77]19.5“DOF”Double LowerOffset Insert Block

[.22]5.5<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>[.75]19.11.8647.3[1.20]30.5[.75]19.1[1.20]30.5[1.53]38.930°[1.86]47.3GR1 Series <strong>Modular</strong> Gripper“SDB” and “DDB” Draw Bead Serrated Block Inserts[1.22]31.0[1.22]31.030°[.77]19.5[1.53]38.9[.75]19.1[.51]13.0[.22]5.5[1.86]47.3[1.10]28.1[.77]19.4[1.10]28.1[1.53]38.9“SDB”[.75]19.1[.39]9.9 [.22]5.530°1.8647.3[1.20]30.5“DDB”[.77]19.5[1.20]30.5Single UpperDraw Bead Insert BlockReplacement Part #GR1-INS-SDDB30°[.22]5.5[1.86]47.3[.39][.51]9.9[1.81] Single 13.0LowerDraw 46.0 Bead Insert [1.86] Block [1.10]47.3 28.1Replacement [.22] Part #GR1-INS-SDLOS5.5[.39]9.9[.75]19.1[1.18]30.0 [.77]19.5Double UpperDraw Bead Insert Block [1.10]28.1Replacement Part #GR1-INS-DDB[1.53]38.9Double LowerDraw Bead Insert BlockReplacement Part #GR1-INS-DLOS“SED” Extended Draw Bead Serrated Block Inserts30°[.77]19.5[.22]5.5[1.86]47.3[1.18]30.0[1.81]46.0[.39]9.9“SED”www.destaco.comUpper ExtendedDraw Bead Insert BlockReplacement Part #GR1-INS-SDDB-3Sub ject to Tech nical M odi fi cations Wi thout Notic eLower ExtendedDraw Bead Insert BlockReplacement Part #GR1-INS-SDLOS-335

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“MAx” Swivel Parallel Gripper MountsPATENT# 6,988,696SWIVELROTATION25° 25°M8 SHCS[.75]19.1[1.00]25.4DE-STA-COGR1 15 SERIES GRIPPER& GR84 HEAVY DUTYMINI-CLAMP[5.88]149.2[5.67]144.1LENGTH FOR “MA2”/“MA4”MOUNTING OPTIONSLENGTH FOR “MA1”/“MA3”MOUNTING OPTIONS[1.22]R31.1Snap-In BallSpecial patented design allowsuser to replace ball withoutdisassemby[3.00]76.2“X”BALL/ROD SIZE[2.50]63.5Mounting Option Rod/Ball “X” Replacement Part#MA1 Ø1.00” CPI-GPC-150-100S-DCMA2 Ø1.25” CPI-GPC-150-125S-DCMA3 Ø25mm CPI-GPC-150-25MS-DCMA4* 30mm BB CPI-GPC-150-30BBS-DC*”MA4” and “MB4” Mounts to the 30mm BodyBuilderoctagonal extruded aluminum boom. For more informationon this octagonal boom, please refer to the BodyBuilderRobotic End Effector Systems <strong>Catalog</strong>.36 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

34.9[1.38]34.9M6 X 1.0<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>[2.25]57.2[2.25]57.2M6 X 1.0GR1 Series <strong>Modular</strong> Gripper“MB1” and “MB3” Rear Swivel Gripper Mount[.88]22.2PATENT# 6,988,696SWIVELROTATIONSWIVELROTATION25°25°[2.31]25°25°58.7[2.31]58.7[.88] M8 SHCS22.2M8 SHCS[1.50]38.1[.97]24.6 [1.50]38.1[.97]24.6GR1 15 SERIES GRIPPER &GR84 HEAVY DUTY MINI-CLAMPGR1 15 SERIES GRIPPER &GR84 HEAVY DUTY MINI-CLAMP[1.41]35.7[2.81]71.4[1.41]35.7[2.81]71.4[1.00]25.4[2.00]50.8[2.50]63.5[2.50]63.5[2.00]50.8[1.00]25.4 “X”BALL/ROD SIZE“X”BALL/ROD SIZEM8 SHCSM8 SHCSMounting Option Rod/Ball “X” Replacement Part#MB1 Ø1.00” CPI-RJM-150-100SMB3 Ø25mm CPI-RJM-150-25S“MB2” and “MB4” Rear Swivel Gri[pper MountPATENT# 6,988,696SWIVELROTATIONSWIVELROTATION25°25°25°25°[1.50]38.1[1.50]38.1GR1 15 SERIES GRIPPER &GR84 HEAVY DUTY MINI-CLAMPGR1 15 SERIES GRIPPER &GR84 HEAVY DUTY MINI-CLAMP[1.41]35.7[2.81]71.4[1.41]35.7[2.81]71.4[1.25]31.8[2.50]63.5[2.50]63.5[1.25]31.8 “X”BALL/ROD SIZE“X”BALL/ROD SIZE Mounting Option Rod/Ball “X” Replacement Part#MB2 Ø1.25” CPI-RJM-150-125SMB4* 30mm BB CPI-RJM-150-30BBSSnap-In BallSpecial patenteddesign allowsuser to replaceball withoutdisassemby“MBx” Rear Swivel Gripper MountGripper Mounting Pattern[1.38]34.9PATENT# 6,988,696www.destaco.com[2.25]57.2Sub ject to Tech nical M odi fi cations Wi thout Notic eM6 X 1.037

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“MCx” Rear Fixed Welded Mount[.47]12.0[11.75]298.5[2.81]71.4[2.25]57.2[.47]12.0[11.75]298.5[2.81]71.4[1.38]"X"[2.25]35.157.2[2.50]63.5[.28]Ø7.1[1.38]"X" 35.1Mounting Option Rod “X” Replacement Part#MC1 Ø1.00” CPI-RJM-150-100MC3 Ø25mm CPI-RJM-150-25[.28]MC5 Ø1.50” CPI-RJM-150-150Ø7.1MC6 [3.50] Ø40mm CPI-RJM-150-4089.0[2.50]63.5“MD7” Rear Fixed Clamp Mount[3.50]89.0[.47]12.0[2.36]60.0[3.00]76.2[2.25]57.2M10 SHCS“X”[.47]12.0[2.36]60.0[1.73]44.0M10 SHCS[1.26]32.0[3.00]76.2[2.25]57.2[1.38]35.0 “X”[1.88]47.6[2.89]73.5[1.73]44.0[2.52]64.0M8 x 1.25THREAD (4X)[1.26]32.0[2.13]54.0[1.06]27.0M6 X 1.0THREAD [1.38] (4X) [1.88]35.0 47.6[2.89]73.5[2.52]64.0M8 x 1.25THREAD (4X)[2.13]54.0[1.06]27.0M6 X 1.0THREAD (4X)Mounting Option Rod/Ball “X” Replacement Part#MD7 Ø1.00” M151438 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper18mm Swivel Proximity Sensor Mount[.75]Ø19.1[.63]R 15.9[1.00]25.4POS. 1[5.63]142.9POS. 2M8 SHCS[3.25]82.6POS. 1 = NON ROTATING MOUNTINGPOS. 2 = 360° ROTATIONAL MOUNTING[.50]12.7M6 SHCS[.56]14.3[2.76]70.1[2.45]Ø62.1[5.26]133.5[2.25]57.2[1.63]41.3[6.25]158.8360°POS. 2: 360° ROTATION OPTIONALONG ONE AXISReplacement Part#CPI-GPM-15-18www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e39

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“A04” and “P03” Sensor Options“A04” (Turck) Replacement Part# “Bi 5-Q08-VP6X2-0.2M-RS4.4T” ....10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast“P03” (P & F) Replacement Part# “NBB5-F104M-E2-C-200MM-V1” ...10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast(Sensors include “GR0326” Proximity Switch Mount when ordered with GR1-15 Series.)Proximity Switch Mount for “A04” and “P03” Sensor Options[1.13]28.6[.51]13[.22]5.7[.97]24.6[.34]8.7[1.43]36.3[.84]21.4[1.19]30.2#5-40TAP[1.27]32.3[1.34]34.1Replacement Part#GR0326[.32] [2.81]Ø8.271.3[.38]9.5[1.47]37.3[2.42]61.3[.97]24.6[.53]13.5[.78]19.7[.76]19.3[.50]12.7[.56]14.3Barrel Style Proximity Switch Mount[1.28]32.6[1.26]32[1.50]38.1Replacement Part#GR1-15-PM-31[2.32]58.8[.50]12.7[.70]17.7[.56]14.3[1.33]33.9[.11]2.840 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>[1.13]28.6[.50]R 12.7[1.69]42.812[.17]R 4.3M18 x 1.0GR1 SeriesTHRU<strong>Modular</strong> GripperØ18mm and Ø12mm Inline Proximity Switch Mount[1.72]43.7[.13]3.2[1.72]43.7[2.63][.13]66.8 3.2[.13]3.2[1.13]28.6[.17][1.72] R 4.343.7[.94]23.9[.50]R 12.7M18 x 1.0[.13]THRU3.2[1.69]42.8[.50]12.7[1.13]28.6[.17]R 4.3[.94]23.9[1.13]28.6[.17]R 4.3 x 2[.79]19.9[1.69][.50] 42.8R 12.7[.22]5.6[.47] M12 x 1.0 M18 x 1.0[2.63] R 11.9 THRU[.13] THRU66.83.2[1[1.13]28.6[.17][1.13] R 4.328.6[.94]23.9[1.72]43.7[.13]3.2[1.69]Replacement[.94]Part# 42.823.9 [.50]CPI-PM-15D-18 R 12.7[.17][1.72] R 4.343.7M18 x 1.0THRU[1.69][.50] 42.8R 12.7[2.63] M12 x 1.066.8[.13]THRU3.2[.13]3.2[.50]12.7[1.13]28.6[2.50]63.5[.79]19.9Replacement [1.13] Part#[.17] CPI-PM-15D-12 28.6[.50][.75]R 4.3 x 212.719.1[.47] M18 x 1.0R 11.9 THRU[.17]R 4.3 x 2[2.50]63.5[.38]R 9.5[.22]5.6[.13]3.2[.13]3.2Ø18mm and Ø12mm Offset Proximity Switch MountM12 x 1.0THRU.69]2.8[.50]12.7[1.13]28.6[.17]R 4.3[.94]23.9[1.13]28.6[.17]R 4.3 x 2[.79]19.9[1.69][.50] 42.8R 12.7[.47]R 11.9 M12 x 1.0THRU[.22]5.6M18 x 1.0THRU[.50]12.7[1.13]28.6[.17]R 4.3 x 2[.75]19.1[.38]R 9.5[.13]3.2[.13]3.2M12 x 1.0THRU[2.50]63.5.69]2.8www.destaco.com[.50]12.7[.13]Replacement [1.13] Part#3.2Replacement Part#28.6CPI-PM-15S-18 [.75]CPI-PM-15S-1219.1 [.13]3.2Sub ject to Tech nical M odi fi cations Wi thout Notic e41

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“T04” Open/Closed Sensor OptionThis sensor option can only be used at full stroke.[2.17]55.1[1.90]48.2[2.61]66.2[1.31]33.3[1.01]25.7[2.85]72.3[.98]24.8[1.55]39.5[1.85]47.0[.84]21.4Replacement Part#CPI-GR1-15-TK-DC-T04This Sensor Part Numberis used on the followingGR1 Gripper Styles“T04”This sensor option is used in conjuction with aspecial gripper body used in place of the standardgripper body in order for the sensor to functionproperly.“T04” Proximity Switch Wiring2 13 4PIN 1) BROWN: POSITIVE POWERPIN 2) BLACK: SIGNAL FOR GRIPPER CLOSEDPIN 3) BLUE: NEGATIVE POWERPIN 4) BLACK: SIGNAL FOR GRIPPER OPEN3 amps, 250 volts, VDC4-Pin Euro Micro Connector42 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1 Series <strong>Modular</strong> Gripper“T04” Sensor Open/Closed Target PositionCLOSED POSITIONOPEN POSITIONSENSORTARGET 1SENSORTARGET 2JAW PIVOTJAW SLIDESENSORTARGET 1PIVOTJAW PIVOTSENSORTARGET 1JAW PIVOTJAW SLIDESENSORTARGET 1SENSORTARGET 2SENSORJAW SLIDETARGET 2“045” 45° Angular “45C” 45° Chisel “FCH” 45° Fixed Chisel “9DJ” 90° Drop JawPIVOTJAW PIVOTRT 1JAW PIVOTSENSORTARGET 2JAW SLIDE SENSORTARGET 1JAW SLIDEJAW PIVOTSENSORTARGET 2SENSORTARGET 1CLOSED POSITIONOPEN POSITION21JAW JAW PIVOT PIVOTSENSORTARGET 2SENSORTARGET 1JAW SLIDEJAW JAW PIVOT PIVOTJAW SLIDESENSORSENSORTARGET 2TARGET 12JAW PIVOTJAW SLIDEJAW PIVOTSENSORTARGET 2J“90F” 90° FIxed Lower“9FS” 90° Fixed Lowerwith Limited Stroke“180” 180° Angularwww.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e43

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1-20 Series <strong>Modular</strong> GripperOrdering InformationCYLINDER INSERTS MOUNTSOPEN/CLOSEDGR1 - 20 - BE - 180 - Dxx - Mxx - (BLANK)CYLINDER TYPE & PORTINGPOINTS & TIP INSERT OPTIONSSTEP 1 B ECYLINDER PORTINGSTEP 2 DPPUPPER TIP INSERT OPTIONX =OMITEENGLISH (1/8 NPT)PC U SMMETRIC (1/8 G)OPEN/CLOSED SENSING(SEE PAGE 42 FOR SENSOR SPECIFICATIONS)B04 = INTERNAL SENSOR(LEAVE BLANK TO OMIT)POINTSTEP 3 DPPCUPURETHANELOWER TIP INSERT OPTIONSERRATEDX =OMITFOR TIP INSERT DIMENSIONS AND REPLACEMENT PART#S,PLEASE REFER TO GR84 MINI CLAMP TIP INSERT OPTIONS.MOUNT OPTIONSSTEP 1 MXXMOUNT TYPEX=OMITSTEP 2 MXXMOUNT BALL/ROD SIZEACD1= 1.00” ROD/BALL MOUNT (A & C ONLY)3= 25MM ROD/BALL MOUNT (A & C ONLY)7= M-1514 (D OPTION ONLY)PARALLELSWIVEL MOUNTREAR FIXEDWELDED STYLEREAR FIXEDCLAMP MOUNTX= OMIT44 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1-20 Series <strong>Modular</strong> Gripper“180” 180° Angular Jaw Arrangement - Double InsertCLOSED GRIPPER PORTOPEN GRIPPER PORTGRIPPER PORTSE =1/8” NPT (ENGLISH)M =1/8” G (METRIC)[1.50]38.1[3.13]79.4200 SERIES“GPC” GRIPPERPARALLEL CLAMPLOCK GROOVE[4.06]103.2[1.92]48.74X .375-24 UNF-2B 19.1[.75] DEEP[5.41]R137.5[2.25]57.2Ø50.8[Ø2.00”]BORECYLINDER[2.58]65.6[8.29]210.5[2.09]53.0[.84]21.3[3.08]78.2FULL OPENINGJAW POSITION[2.42]61.4[7.35]186.7[3.00]76.2[1.88]47.6REARMOUNTINGPATTERN[.34](4) Ø8.6[9.77]248.1CLOSED GRIPPER PORT(OPTIONAL FORLARGER AIR FITTINGS)[3.00]76.2[3.75]95.3www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e45

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>GR1-20 Series <strong>Modular</strong> Gripper“MAx” Swivel Parallel Gripper MountsPATENT# 6,988,696M8 SHCS[.75]19.1[1.00]25.425° 25°[1.57]R39.9SWIVELROTATION[6.31]160.3Snap-In BallSpecial patented design allowsuser to replace ball withoutdisassembyUSE WITHDE-STA-COGR1 20 SERIESGRIPPERS[3.75]95.3X[2.75]69.9Mounting Option Rod/Ball “X” Replacement Part#MA1 Ø1.00” CPI-GPC-200-100S-DCMA3 Ø25mm CPI-GPC-200-25MS-DC“MCx” Rear Fixed Welded Mount[.50]12.7[11.75]298.5[3.75]95.3[3.00]76.2[3.00]76.2[1.88]47.6[.98]Ø25.0(4) [.34]Ø8.6Mounting Option Rod/Ball “X” Replacement Part#MC1 Ø1.00” CPI-RJM-200-100MC3 Ø25mm CPI-RJM-200-2546 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

"X" 35.1 63.5<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>[.28]Ø7.1GR1-20 Series <strong>Modular</strong> Gripper“MD7” Rear Fixed Clamp Mount[3.50]89.0[.47]12.0[2.36]60.009DJGrip Force (lbf)45040035030025020015010050060[1.26]32.070 80 90[3.00]76.2[2.25]57.2M10 SHCS“X”[1.38]35.0[1.88]47.6[2.89]73.5[1.73]44.0[2.52]64.0180Supply Pressure (psi)M8 x 1.25THREAD (4X)[2.13]54.0[1.06]27.0M6 X 1.0THREAD (4X)90Grip Force (lbf)4003503002502001501005006070 80 90Supply Pressure (psi)Mounting Option Rod/Ball “X” Replacement Part#MD7 Ø1.00” M1514Technical Information180 (20 SERIES)“180” 180° Angular Technical InfomationGrip Force (lbf)4003503002502001501005006070 80 90Supply Pressure (psi)Weight:2.4 kg [5.4 lb]Grip Range:0”- 0.125” [0 - 3mm]Air Requirements:Recommended operationg Pressure:2-6 bar [30-90 psi]Ports: 1/8” BSPP [1/8” NPT]Air flow controls recommended formaximum lifeOperating Temperature:0° - 93°C [32° - 200°F]www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e47

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style GripperOrdering InformationMODELOPENINGPORTINGJAW ARRANGEMENT84A2 - V 1TO ORDER BASE GRIPPERWITHOUT SENSORS, MOUNTS, OR TEETH:ADD (7) ZEROS TO END OF BASE MODELNUMBER TO COMPLETE GRIPPER ORDERCODE. (e.g. 84A2-V10000000)JAW OPENINGPORTING-YX1 A V72° JAWOPENING45° JAWOPENING30° JAWOPENING(2) M5 PORTS(2) SIDES(1) 1/8 NPT(2) SIDES(2) 1/8 G(1) SIDEJAW ARRANGEMENT OPTIONS1 2 3 4672°/45°/30° Upper 72°/45˚/30° Upper 72°/45˚/30° Both 72°/45˚/30° Upper72°/45˚/30° Upper7 872°/45˚/30° Upper72° Upper945°/30° Only (Lower)FOR “DROP JAW” ARRANGEMENTS:84A2R(x)3 (72° UPPER/15° LOWER) AND84A2T(x)3 (45° UPPER/15° LOWER)PLEASE SEE PAGES 58-59.FOR “HI TEMPERATURE” GRIPPER:84A2-VB000H1H2 (72° OPENING)PLEASE SEE PAGE 62.48 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style GripperOrdering InformationPART PRESENTMOUNTSLOWER TEETHUPPER TEETHD4JBABAPART PRESENT SENSOR OPTIONS (TO OMIT: USE “00”)D4D58MA-149-1(ORDERED SEPARATELY)PART PRESENT SENSOR(3MM SENSING DISTANCE FOR84A2-1(1/8) AND 84A2-V(1/8))3-WIRE, OPEN WIREWORK PLACE CONTROLSENSORVDC, M12, 4-PINCABLE SUPPORTFOR “D4” SENSOR(MOUNTED ON LOWERSIDE OF GRIPPER)MULTIPLE SENSOR PACKAGEGP (1) D4 + (1) D5GK (2) D5MOUNT OPTIONS (TO OMIT: USE “0”)JZØ25MM ADAPTOR MOUNTØ1.00” ADAPTOR MOUNTGRIPPER TEETH AND POINTS (TO OMIT: USE “00” IN BOTH, UPPER AND LOWER)BA BB PH8SB-039-1(ORDEREDSEPARATELY)GRIPPERTEETHHARDENEDSTEELGRIPPERTEETHSOFT STEELGRIPPERPOINTHARDENEDSTEELSHIMSFOR GRIPPERTEETH(DIMENSIONS:10x10x1MM)CROWN TEETH (TO OMIT: USE “00” IN BOTH, UPPER AND LOWER)(FOR DEFORMATION-FREE PART TRANSFER)UPPER CROWN TEETHLOWER CROWN TEETHSL SM SN SP SKCROWN TEETHHARDENED STEELCROWN TEETHHARDENED STEELCROWN TEETHHARDENED STEELCROWN TEETHHARDENED STEELCROWN TEETHHARDENED STEELwww.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e49

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“(-/Y/X)(1/A)(1)” 72°/45°/30° Upper/Fixed Lower Jaw Arrangement[1.34]34.0[1.34]34.0[1.57]40.0[1.57]40.0[1.57]40.0[1.57]40.0“P”“P”[.55]14.0[.55]14.0(4) M5 TAP6MM DEEP(4) M5 TAP6MM DEEP[.79]20.1[.79]20.1[.26]6.5[.26]6.5[1.50]38.0[1.50]38.0[2.17]55.0[2.17]55.0[1.75]44.5[1.75]44.5[4.46]113.3[4.46]113.3[5.66]143.8[5.66]143.8(2) M4 TAP9MM DEEP(2) M4 TAP9MM DEEP[.39]10.0[.39]10.0(2) Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU(2) Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU[1.15]29.2[1.15]29.2[1.82]R 46.2[1.82]R 46.2 [.65]16.5[.65]16.5[.81]20.5[.81]20.5[2.05]52.0[2.05]52.0[1.11]28.1[1.11]28.1[1.57]40.0[1.57]40.0[1.90]48.3[1.90]48.3“(-/Y/X)(V)(1)” 72°/45°/30° Upper/Fixed Lower Jaw Arrangement[.63](Y)45°[.51] (-)72°16.0“P” 13.0[.63](Y)45°[.51] (-)72°(X)30°16.0“P” 13.0[1.18](X)30°[1.97] 30.0[1.18][1.54][3.18]50.0[1.97] 30.039.080.7[1.54][3.18]50.039.080.7[.63]16.0(4) M5 TAP[.63]6MM DEEP16.0(4) M5 TAP“P” = AIR PORTING6MM DEEP[.30](3) M3 TAP7.5 [.74] 1 “P” = M5 = AIR PORTINGTHRU [.30](3) M3 TAP18.8 2 PORTS / 2 SIDES7.5THRU[.74] 1 M5A = 1/818.8 2 PORTS NPTSIDES1 PORTS / 2 SIDES[1.15] A = 1/8 NPT29.2 V = 1/81 PORTS G / 2 SIDES[1.15] 2 PORTS / 1 SIDES29.2 V = 1/8 G2 PORTS / 1 SIDES[1.20] (2) [.24]30.5 Ø8.0 [.24] C’BORE 3MM DEEP[1.20] Ø4.5 (2) [.24] [.18] THRU30.5 Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRUGRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHT50 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>“P”“P”84A2 Series Cam Style Gripper“(-/Y/X)(1/A)(2)” 72°/45°/30° Upper/Fixed Lower Jaw Arrangement[.55]14.0[.55]14.0[.26]6.5[.26]6.5(2) M4 TAP9MM DEEP(2) M4 TAP9MM DEEP[1.11]28.1[1.11]28.1[2.05]52.0[2.05]52.0[1.57][1.50]40.038.0[1.34] [1.57][1.50](4) M5 TAP34.0 40.038.06MM DEEP[2.17][1.34]55.0(4) M5 TAP34.0 6MM DEEP[2.17](4) M5 TAP55.0[.79]6MM DEEP20.1(4) M5 TAP[3.08][.79]6MM DEEP78.3[.30] 20.1[3.08]7.5[1.75]78.3[.30]44.57.5[1.75][2.34] [.30][.74]44.5[1.63] R 59.4 7.5 [.74]18.841.5[2.34] [.30] 18.7[.74][1.63] R 59.4 7.5 [1.15] [.74]18.841.518.7 29.2[1.15]“(-/Y/X)(V)(2)”[.63][.51] 72°/45°/30° Upper/Fixed Lower Jaw 29.2 Arrangement“P”16.013.0[.63][.51]“P”(-)72°16.0[1.18]13.0[1.97] 30.0(-)72°50.0 [1.18](Y)45°[3.48][1.97] 30.0(Y)45° (X)30° 88.350.0[3.48][.63][1.18](X)30° 88.316.030.0[.63][1.18][.39][1.15] (4) 16.0 Ø8.0 [.24] C’BORE 3MM DEEP30.0[.63]10.029.2 Ø4.5 [.18] THRU16.0 [.81] [.39](2) [1.15] (4)M3 TAPØ8.0 [.24] C’BORE 3MM DEEP [.63] 20.5 10.0THRU 29.2 Ø4.5 [.18] THRU16.0 [.81](2) M3 TAP20.5“P” = AIR PORTINGTHRU1 “P” = M5 = AIR PORTING2 PORTS / 2 SIDESA 1 = M5 1/8 NPT12 PORTS / 2 SIDES[4.46]V A = G113.321 1/8 PORTS NPT/ 12 SIDES[4.46][5.68]V = 1/8 G113.3144.32 PORTS / 1 SIDES[5.68]144.3GRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHTwww.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e51

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“(-/Y/X)(1/A)(3)” 72°/45°/30° Upper and Lower Jaw Arrangement[.26]6.5[.26] “P”6.5“P”(2) M4 TAP9MM DEEP(2) M4 TAP9MM DEEP(4) [.24]Ø8.0 [.24] C’BORE 3MM DEEP(4) Ø4.5 [.24] [.18] THRUØ8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU[.74] [2.05]18.7 52.0[.55][.74] [2.05]14.018.7 52.0[.55] [1.50]14.0[.91]38.0[1.50]23.0[1.57][.91]38.040.023.0[1.82][1.57][1.34]R 46.240.0 (4) M5 TAP[1.57]34.0[1.82]6MM DEEP [2.17]40.0[1.34] (4) M5 TAP 55.0R 46.2[1.57]34.0 6MM DEEP [2.17]40.055.0[.79][.81][2.23]20.120.556.6[.79][.81][2.23]20.120.556.6(4) M5 TAP[1.75]44.5[.67][1.11] 6MM DEEP(4) M5 TAP[1.75]17.028.144.5[.67][1.11] 6MM DEEP17.028.1“(-/Y/X)(V)(3)” 72°/45°/30° Upper and Lower Jaw Arrangement[.51](Y)45°[.63]13.0(-)72°“P”16.0[.51](Y)45° (X)30°[.63]“P” 13.0(-)72°16.0[1.18](X)30°[1.97] 30.0[1.18][1.65]50.0[1.97] 30.042.0[3.62][1.65] 92.050.042.0[3.62][.63]92.0[.39][.74] 16.010.018.7 [.63][.39][.74] 16.0[5.66]10.018.7 [.19]143.84.7[5.66][.19]143.8“P” = AIR PORTING4.7[.37]19.3“P” = M5 = AIR PORTING2 PORTS / 2 SIDES[.37]1 M59.3 A = 1/8 NPT21 PORTS / 2 SIDESA 1/8 NPTV =11/8PORTSG2 SIDES[1.20]2 PORTS / 1 SIDES[4.46]30.5V = 1/8 G113.3[1.20]2 PORTS / 1 SIDES[4.46]30.5113.3GRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHT52 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>[1.34][1.34] 34.034.0[1.57][1.57] 40.040.0[1.57][1.57] 40.040.0[.63][.63] 16.016.0[1.97][1.97] 50.050.0[.63][.63] 16.0(4) M5 TAP16.0(4) M5 6MM TAP DEEP6MM DEEP[.26][.26] 6.56.5 “P”“P”[.55][.55] 14.014.0(4) M5 TAP(4) 6MM M5 DEEP TAP6MM DEEP[.79][.79] 20.120.1“P”“P”[1.18][1.18] 30.030.0[1.50][1.50] 38.038.0[2.17][2.17] 55.055.0[1.75][1.75] 44.544.5[.51][.51] 13.013.0[4.46][4.46] 113.3113.3(2) M4 TAP(2) M4 9MM TAP DEEP9MM DEEP[5.66][5.66] 143.8143.8(-)72°(-)72°[.39][.39] 10.010.084A2 Series Cam Style Gripper“(-/Y/X)(1/A)(4)” Jaw Arrangement(2) [.24](2) Ø8.0 [.24] [.24] C’BORE 3MM DEEPØ8.0 Ø4.5 [.24] [.18] C’BORE THRU 3MM DEEPØ4.5 [.18] THRU[.16][.91][.16] 4.2[.91] 23.0 [.41] 4.223.0 [.41] 10.4[1.82] 10.4[1.82] R 46.2R 46.2 [.65][.65] 16.516.5[.81][.81] 20.520.5(Y)45°(Y)45°(X)30°(X)30°[1.54][1.54] 39.039.0[.37][.37] 9.49.4[2.05][2.05] 52.052.0[3.18][3.18] 80.780.7[.37][.37] 9.49.4[1.90][1.90] 48.348.3“(-/Y/X)(V)(4)” Jaw Arrangement“P” = AIR PORTING“P” = AIR PORTING1 = M51 = M5 2 PORTS / 2 SIDESA = 21/8 PORTS NPT / 2 SIDESA = 1/8 1 PORTS NPT / 2 SIDESV = 1/8 PORTS G / 2 SIDESV = 1/8 2 PORTS G / 1 SIDES2 PORTS / 1 SIDESGRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHTwww.destaco.com[.91][.91] 23.023.0Sub ject to Tech nical M odi fi cations Wi thout Notic eØ8.0 [.24] C’BORE 3MM DEEPØ8.0 Ø4.5 [.24] [.18] C’BORE THRU 3MM DEEPØ4.5 [.18] THRU53

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“(-/Y/X)(1/A)(6)” 72°/45°/30° Upper/Fixed Lower Jaw Arrangement“P”[.26]6.5(2) M4 TAP9MM DEEP[.91]23.0(2) [.24]Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU[2.05]52.0[1.34]34.0[.55]14.0(4) M5 TAP6MM DEEP[1.50]38.0[2.17]55.0[.41][.16]10.44.2[1.82]R 46.2[.65]16.5[1.57]40.0[.79]20.1[.81]20.5[1.90]48.3[1.57]40.0[1.75]44.5[5.66]143.8[.39]10.0“(-/Y/X)(V)(6)” 72°/45°/30° Upper/Fixed Lower Jaw Arrangement[.63]16.0“P”[.51]13.0(-)72°(Y)45°(X)30°[1.97]50.0[1.18]30.0[1.54]39.0[3.18]80.7(4) M5 TAP6MM DEEP[.63]16.0[4.46]113.3[.37]9.4“P” = AIR PORTING1 = M52 PORTS / 2 SIDESA = 1/8 NPT1 PORTS / 2 SIDESV = 1/8 G2 PORTS / 1 SIDESGRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHT[.61]15.5Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU54 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“(-/Y/X)(1/A)(7)” 72°/45°/30° Upper/Fixed Lower Jaw Arrangement[.26]6.5“P”(2) M4 TAP9MM DEEP(2) Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU[1.15][2.05]29.252.0[1.34]34.0[.55]14.0(4) M5 TAP6MM DEEP[1.50]38.0[2.17]55.0[4.46]113.3[1.82]R 46.2[.74]18.7[1.57]40.0[.79]20.1[1.44][1.59]36.540.5[2.61]66.3[1.57]40.0[1.75]44.5[.39]10.0[1.15]29.2“(-/Y/X)(V)(7)” 72°/45°/30° Upper/Fixed Lower Jaw Arrangement[.63]16.0“P”[.51]13.0(-)72°(Y)45°(X)30°[1.97]50.0[1.18]30.0[3.31][2.32] 84.059.0[.63]16.0(4) M5 TAP6MM DEEP[5.66]143.8“P” = AIR PORTING(2) M3 TAPTHRU[.30]7.5[.74]18.81 = M52 PORTS / 2 SIDESA = 1/8 NPT1 PORTS / 2 SIDESV = 1/8 G2 PORTS / 1 SIDESGRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHTwww.destaco.com[1.20]30.5Sub ject to Tech nical M odi fi cations Wi thout Notic e(2)Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU55

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“(-)(1/A)(8)” 72° Upper/Fixed Lower Jaw Arrangement[1.34][1.34]34.034.0(2) M4 TAP[.26] (2)9MMM4 TAP[.26]DEEP6.59MM DEEP6.5“P”“P”[.55][.55]14.014.0 1.501.5038.038.0[4.46][4.46]113.3113.3(4) M5 TAP(4)6MMM5DEEPTAP6MM DEEP[1.15][1.15]29.229.2[2.17][.65][2.17]55.0[.65]16.555.016.5(2) Ø8.0 [.24] C’BORE 3MM DEEP(2)Ø4.5Ø8.0[.18][.24]THRUC’BORE 3MM DEEPØ4.5 [.18] THRU[2.56][2.56]65.0R 65.0[2.05][2.05]52.052.0[.74][.74]18.718.7[1.57] [1.90].79[.81][1.90][1.57] .7940.0 20.1[.81]20.548.3 48.340.0 20.120.5[1.57][1.57]40.040.0[1.75][1.75]44.544.5[.39][.39]10.010.0[1.15][1.15]29.229.2“(-)(V)(8)” 72° Upper/Fixed Lower Jaw Arrangement[.63][.63]16.016.0[1.97][1.97]50.050.0(-)72°(-)72°[.51][.51]“P” 13.0“P” 13.0[3.27][1.18] [3.27][1.18] 83.030.083.030.0[1.54][1.54]39.039.0[.63][.63]16.0(4) M5 TAP 16.0(4) M56MMTAPDEEP6MM DEEP[6.45][6.45]163.8163.8(2) M3 TAP(2) M3THRUTAPTHRU[.30][.30]7.57.5[.74][.74]18.818.8“P” AIR PORTING“P” = AIR PORTING1 = M5 M5PORTS SIDES2 PORTS / 2 SIDES1/8 NPTA = 1/8 PORTS NPTSIDES1 PORTS / 2 SIDES1/8 V = 1/8 PORTS GSIDES2 PORTS / 1 SIDESGRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHT[1.99][1.99]50.550.5(2) [.24](2) [.24]Ø8.0 [.24] C’BORE 3MM DEEPØ8.0Ø4.5[.24][.18]C’BORETHRU3MM DEEPØ4.5 [.18] THRU56 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“(Y/X)(1/A)(9)” 45°/30° Lower/Fixed Upper Jaw Arrangement“P”[.26]6.5(2) M4 TAP9MM DEEP[.39]10.0[1.57]40.0[1.34]34.0[1.15]29.3[.55]14.0[1.50]38.0(4) M5 TAP[2.17]6MM DEEP55.0[1.57][.79]40.020.1[1.75]44.5(2) Ø8.0 [.24] C’BORE 6MM DEEPØ4.5 [.18] THRU[1.83]R 46.6[.63]16.0[.78][1.15][2.05]19.829.252.0[1.02]26.0(2) M3 TAPTHRU[.81]20.5[2.46][2.54]62.564.5[.30]7.5(2) Ø8.0 [.24] C’BORE3MM DEEPØ4.5 [.18] THRU[.74]18.7[.74]18.8“(Y/X)(V)(9)” 45°/30° Lower/Fixed Upper Jaw Arrangement[.63]16.0“P”[.51]13.0[.63]16.0[.39]10.0[1.97]50.0[.63]16.0[1.18]30.0[.98]25.0[2.69][2.95]68.475.0(4) M5 TAP6MM DEEP(Y)45°(X)30°[1.54]39.0[.39]10.0GRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHTwww.destaco.com[4.46]113.3[5.48]139.3Sub ject to Tech nical M odi fi cations Wi thout Notic e“P” = AIR PORTING1 = M52 PORTS / 2 SIDESA = 1/8 NPT1 PORTS / 2 SIDESV = 1/8 G2 PORTS / 1 SIDES57

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“84A2R(1/A)(3)” Drop Jaw Gripper with 72° Opening[1.57][1.57] 40.040.0[1.34][1.34] 34.034.0“P”“P”[.55][.55] 14.014.0[.63][.63] 16.0 (4) M5 TAP16.0 (4) 6MM M5 DEEP TAP6MM DEEP[1.57] [.79][1.57] 40.0 [.79] 20.140.0 20.1[.63][.63] 16.016.0[.26][.26] 6.56.5[1.50][1.50] 38.038.0[2.17][2.17] 55.055.0[1.75][1.75] 44.544.5(2) M4 TAP (4) Ø8.0 [.24] C’BORE 3MM DEEP(2) M4 9MM TAPDEEP(4) Ø4.5 Ø8.0 [.18] [.24] THRU C’BORE 3MM DEEP9MM DEEP Ø4.5 [.18] THRU[.74] [2.05][.74] 18.7 [2.05] 52.018.7 52.0[.91][4.46] [.91] 23.0[4.46] 113.3 23.0113.3[1.82][1.82] R 46.2R 46.2 [.67][.67] 17.017.0[.81][.81] 20.520.5[.39][.39] 10.010.0[.74][.74] 18.718.7[2.23][2.23] 56.656.6[1.11][1.11] 28.128.1“84A2R(V)(3)” Drop Jaw Gripper with 72° Opening[.51](4) M5 TAP 72°“P” [.51] 13.0(4) M5 6MM TAPDEEP72°“P” 13.06MM DEEP[1.18][1.97] [1.18] 30.0[1.97] 50.0 30.050.0[1.65][1.65] 42.042.0[3.18][3.18] 80.780.7[1.11][1.11] 28.128.115°15°[5.66][5.66] 143.8143.8[1.20][1.20] 30.530.5[1.11][1.11] 28.128.1“P” = AIR PORTING“P” = AIR PORTING1 = M51 = M5 2 PORTS / 2 SIDESA = 21/8 PORTS NPT / 2 SIDESA = 1/8 1 PORTS NPT / 2 SIDESV = 11/8 PORTS G / 2 SIDESV = 1/8 2 PORTS G / 1 SIDES2 PORTS / 1 SIDESGRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHTADD SENSORS, MOUNTS, AND TEETH TO END OF BASE MODEL NUMBER TOCOMPLETE GRIPPER ORDER CODE. (e.g. 84A2RV3D4JBABA)58 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“84A2T(1/A)(3)” Drop Jaw Gripper with 45° Opening[1.57]40.0[1.57]40.0[.63]16.0[.63]16.0[1.57]40.0[1.57]40.0[.63]16.0[.63]16.0[.26]6.5[.26]“P” 6.5“P”[.55]14.0[.55]14.0(4) M5 TAP6MM DEEP(4) M5 TAP6MM DEEP [.79]20.1[.79]20.1[1.50]38.0[1.50]38.0[1.75]44.5[1.75]44.5(2) M4 TAP9MM DEEP(2) M4 TAP9MM DEEP[.91][4.46] [.91]23.0113.3[4.46] 23.0[1.82]113.3R 46.2[1.82]R 46.2[.67]17.0[.67]17.0[.39]10.0[.39]10.0(4) Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU(4) Ø8.0 [.24] C’BORE 3MM DEEPØ4.5 [.18] THRU[.74] [2.05]18.7 52.0[.74] [2.05]18.7 52.0[.81]20.5[.81]20.5[.74]18.7[.74]18.7[1.11]28.1[1.11]28.1[2.23]56.6[2.23]56.6“84A2T(V)(3)” Drop Jaw Gripper with 45° Opening(4) M5 TAP [.51]“P” 13.06MM DEEP45°(4) M5 TAP [.51]“P” 13.06MM DEEP45°[1.18][1.97] 30.0[2.89][1.18][1.65]50.073.3[1.97] 30.042.0 [2.89][1.65]50.073.342.0[1.11]28.1[1.11]28.1[2.17]55.0[2.17]55.0[5.66]143.8[5.66]143.815°15°[1.20]30.5[1.20]30.5[1.11]28.1[1.11]28.1“P” = AIR PORTING1 “P” = M5 = AIR PORTING1 2 PORTS / 2 SIDESA = M521 1/8 PORTSPORTS NPT / 2 SIDESSIDESA = 1/8 NPTV = 1/8 PORTS G / 2 SIDES2 PORTS / 1 SIDESV = 1/8 G2 PORTS / 1 SIDESGRIPPER TEETH AND PANEL THICKNESSMUST EQUAL 20.5MM TOTAL HEIGHTIT MAY BE NECESSARY TO USE SHIMS ORTO GRIND TEETH TO ACHIEVE THIS HEIGHTwww.destaco.comADD SENSORS, MOUNTS, AND TEETH TO END OF BASE MODEL NUMBER TOCOMPLETE GRIPPER ORDER CODE. (e.g. 84A2RV3D4JBABA)Sub ject to Tech nical M odi fi cations Wi thout Notic e59

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“BA”, “BB”, “PH” Gripper Teeth, Point, and Crown Teeth[.39]M4 X X 0.6[.39]10.0M4 X 6MM 0.6DEEP[.39]10.06MM DEEPM4 X 0.6 10.06MM DEEP[.39][.39]9.9[.39]9.9 “BA”[.39]9.9[.39]9.9[.39]9.99.9Gripper Teeth(Hardened Steel)Replacement Part#8JZ-027M4 X X 0.6M4 X 6MM 0.6DEEP6MM DEEPM4 X 0.66MM DEEP90°M4 X X 0.6M4 X 6MM 0.6DEEP6MM DEEPM4 X 0.66MM DEEP“Sx” Upper Crown Teeth[.39][.39]10.0[.39]10.010.090°90°[.39][.39]10.0[.39]10.010.0[.39][.39]9.9[.39]9.9[.39]9.9[.39]9.9[.39]9.99.9“BB”Gripper Teeth(Hardened Steel)Replacement Part#8JZ-028“PH”Gripper Point[.39](Hardened Steel)[.39]9.9Replacement Part#[.39]9.9[.39]8JZ-0299.9[.39] 9.9[.39]9.99.9“SK” Lower Crown Teeth[.26][.26]6.5[.26]6.56.5[.39][.39]10.0[.39]10.010.0[1.14][1.14]29.0[1.14]29.029.0“A”“A”“A”“B”“B”“B”M4 X X 0.6M4 X 6MM 0.6DEEP6MM DEEPCrown M4 Replacement X 0.6MATERIAL“A” “B”Teeth 6MM Part# DEEPTHICKNESS“SL” 8JZ-037 10.3 [.41] 9.7 [.38] 0.5 - 0.8MM“SM” 8JZ-038 10.1 [.40] 9.5 [.37] 0.9 - 1.2MM“SN” 8JZ-039 9.9 [.39] 9.3 [.37] 1.3 - 1.6MM“SP” 8JZ-040 9.6 [.38] 9.0 [.30] 1.7 - 2.1MM45°45°45°[.20][.20]5.0[.20]5.05.0[.39][.39]10.0[.39]10.010.0[.39][.39]10.0[.39]10.010.0[1.14][1.14]29.0[1.14]29.029.0M4 X X 0.6M4 X 6MM 0.6DEEP (2X)6MM DEEP (2X)M4 X 0.66MM DEEP (2X)[.67][.67]17.0[.67]17.017.0[.30] [.67][.67][.30] 7.717.0[.67][.30] 7.717.017.07.7[.39][.39]9.9[.39]9.99.9Replacement Part#8JZ-03660 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“J”, “Z” Adaptor Mounts[1.34]34.1[.20]5.0[.20]5.0[.79]20.0[.79]20.0[1.34][.20] 34.1[1.34] 5.034.1[.79][1.75]20.044.5[1.75]44.5[1.75]44.5[1.65]42.0[2.17]55.0[1.65]42.0“D”[1.18][2.17][1.65]30.0 55.042.0[2.17]55.0[2.30] [.22][.59]58.5 5.5 “D”[1.18][1.08] 15.030.027.5“D”[1.18][2.30]30.0Adaptor Mount [.22][.59]Replacement Part# “D” Weight58.5 5.5[1.08] 15.0[2.30] J[.22]8MA-166-1 Ø25.0mm27.5[.98”] 74.9g [.59] [.17 lb]58.5 5.5[1.08] 15.0Z 8MA-168-1 Ø25.4mm 27.5 [1.00”] 75.3g [.17 lb]“D4”, “D5” Sensors“D4” (Turck) Replacement Part# “8EA-075-2”....................................................Open Wire (3 Wires, No Connector)“D5” (Turck) Replacement Part# “8EA-087-1”...................................10...30 VDC 150mA, PNP, 4-Pin, M12, Eurofast“D4”[.33]8.5[.33]8.5[.96]24.5[.96]24.5[.33]8.5[.33]8.5www.destaco.com[.33]8.5[.96][.59]24.515.0[.33]8.5[.59]15.0[.39]10.0[.39]10.0[.91]23.0[.91]23.0[.59]Part Present Sensor[.24] “D5”15.0Replacement Ø6.0 Part# C’BORE 4MM DEEP[.39]10.08EA-075-2 [.14][.24] Ø3.5 THRUØ6.0 C’BORE 4MM DEEP[.24]Ø6.0 C’BORE [.14] 4MM DEEPØ3.5 THRU [.12][.14]3.0Ø3.5 THRU[.91]23.0[.12]3.0[.12]3.0[.28]7.0[.28]7.0[.28]7.0[.28]7.0[.28]7.0[.79]20.0[.79]20.0[.28]7.0[.02].5[.02].5[.79]20.0[.39]10.0[.39]10.0[1.16]29.5Sub ject to Tech nical M odi fi cations Wi thout Notic e[.02].5Workplace Control SensorReplacement Part#[.28]8EA-087-1 7.0 ADJUSTMENT[.28]7.0 ADJUSTMENT[.31][.28]7.97.0 ADJUSTMENT[.39]10.0[1.16]29.5[1.16]29.5[.31]7.9[.31]7.9[.24]6.1[.24]6.1[.33]8.3[.33]8.3[.24]6.1[.33]8.361

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style Gripper“84A2-VB000H1H2” Hi Temperature Gripper with 72° OpeningGripper teeth can beadjusted by shims fordifferent materialthicknesses.Ceramic Gripper TeethPrevent gripper arms fromheat conductionAll cylinder seals are made of viton.Lubricated with high-temperaturegrease.Can handle sheet metaltemperatures higher than 800° C.Stainless Steel ShieldingPlatesProtects gripper mechanicsfrom heat.(2) 1/8 G(2) M4 TAP9MM DEEP[1.11]28.2[1.57]40.0[1.99]50.6[4.46]113.3[1.57]40.0[.63]16.0[.51]13.0[1.18]30.0(4) M5 TAP6MM DEEP[.74]18.8[1.97]50.0[.79]20.1[3.51][3.12] 89.379.3[3.19]81.0[1.15]29.2[1.57]40.0[.63]16.0(4) M5 TAP6MM DEEP[1.75]44.5[2.17]55.0[5.94]150.8[2.20]56.0[2.63]R 66.9[.74]18.862 Subjec t to Techn ical Modifica ti on s With ou t Notice www.destaco.c om

<strong>Modular</strong> <strong>Gripping</strong> <strong>Products</strong>84A2 Series Cam Style GripperTechnical InformationModel Number84A2(x)(x1)84A2(x)(x2)84A2(x)(x3)84A2(x)(x4)84A2(x)(x6)84A2(x)(x7)84A2(x)(x8)84A2(x)(x9)84A2R(x)(x3)84A2T(x)(x3)84A2-VB000H1H2Clamp Force@ 5 bar [70 psi]580 N[130 lbf]360 N[81 lbf]270N[60 lbf]580 N[130 lbf]580 N[130 lbf]580 N[130 lbf]340 N[76 lbf]580 N[130 lbf]270N[60 lbf]270N[60 lbf]360 N[81 lbf]84A2 Series Cam Style GripperOpening Angle72°/45°/30° UpperFixed Lower72°/45°/30° UpperFixed Lower72°/45°/30°Upper and Lower72°/45°/30°Upper/Fixed Lower72°/45°/30° UpperFixed Lower72°/45°/30° UpperFixed Lower72° UpperFixed Lower45°/30° LowerFixed UpperAir Consumptionper minute@ 5 bar [70 psi]0.3 Liters [18 in 3 ]0.4 Liters [24 in 3 ]0.3 Liters [18 in 3 ]0.3 Liters [18 in 3 ]0.3 Liters [18 in 3 ]0.3 Liters [18 in 3 ]0.3 Liters [18 in 3 ]0.3 Liters [18 in 3 ]72°Upper/15° Lower 0.3 Liters [18 in 3 ]72°Upper/15° Lower 0.3 Liters [18 in 3 ]72° UpperFixed Lower0.4 Liters [24 in 3 ]Weight0.60 kg[1.3 lb]0.65 kg[1.4 lb]0.60 kg[1.3 lb]0.50 kg[1.1 lb]0.50 kg[1.1 lb]0.60 kg[1.3 lb]0.65 kg[1.4 lb]0.65 kg[1.4 lb]0.60 kg[1.3 lb]0.60 kg[1.3 lb]0.65 kg[1.4 lb]SpecificationsMaximum Operating Pressure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 bar [85 PSI]Temperature Range: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-20°C to 80°C [-4°F to 176°F]Maximum Operating Temperature (84A2-VB000H1H2) : . . . . . . . . . . . . . . . . . . . . . . . . .210°C [410°F]Cycle Speed @ 60 psi: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.2 Sec (Open/Closed)www.destaco.comSub ject to Tech nical M odi fi cations Wi thout Notic e63

PRECISELY POSITIONING OUR CUSTOMERS FOR PRODUCTIVITY.Workholding• Widest variety of workholding products• High durability and reliability• Flexible solutions for all applications• Custom products for unique requirementsAutomation• Broad range of engineered automation products• Complementary products for modular integration• Unmatched accuracy, reliability and performance• Unparalleled global sales, service and engineering supportNORTH AMERICADE-STA-CO HeadquartersAuburn Hills, MichiganTel: 1.248.836.6700Marketing: marketing@destaco.comAuburn Hills, MichiganTel: 1.888.DESTACOCustomer Service: cs-workholding@destaco.comWheeling, IllinoisTel: 1.800.645.5207Customer Service: camco@destaco.comMonroe, ConnecticutTel: 1.888.DESTACOCustomer Service: cs-automation@destaco.comCharlevoix, MichiganTel: 1.888.DESTACOCustomer Service: cs-automotive@destaco.comSOUTH AMERICABrazilTel: 0800-124070Customer Service: samerica@destaco.comDE-STA-CO GLOBAL LOCATIONSASIAThailandTel: +66-2-326-0812Customer Service: info@destaco.comChinaTel: Customer Service: china@destaco.comIndiaTel: +91-80-41123421-426Customer Service: india@destaco.comEUROPEGermanyTel: +49-6171-705-0Customer Service: europe@destaco.comFranceTel: +33-1-3996-5000Customer Service: france@destaco.comUKTel: +44-1902-797980Customer Service: uk@destaco.comSpainTel: +34-936361680Customer Service: spain@destaco.comNetherlandsTel: +31-297285332Customer Service: benelux@destaco.comP r e c i s e l y p o s i t i o n i n g o u r c u s t o m e r s f o r p r o d u c t i v i t y.© Copyright, 2009 DE-STA-CO.All rights with regards to logos, layout, photos and text,including all artwork, rest with DE-STA-CO.All photomechanical or other reproductions can only bemade with our expressed permission.1025 Doris RoadAuburn Hills, MI 48326Fax: (248) 836-6740Technical Support E-mail:tech-automotive@destaco.comwww.destaco.com<strong>DSC</strong>_MGP-C_0109_0.0K