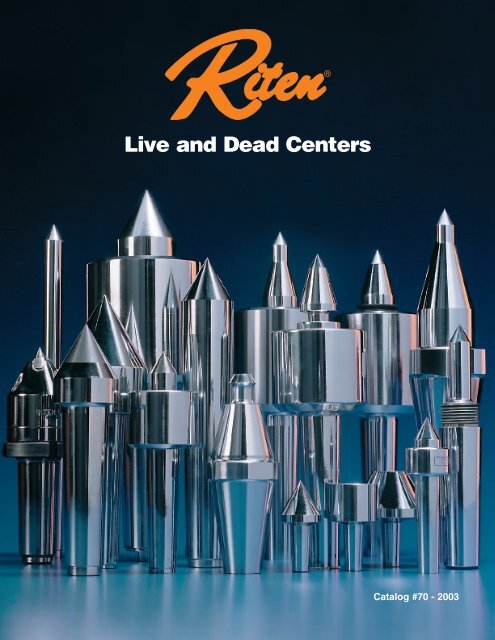

Live and Dead Centers - Discount-Tools.com

Live and Dead Centers - Discount-Tools.com

Live and Dead Centers - Discount-Tools.com

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hastings Centre Rockhounds April General Meeting MinutesMeeting called to order at 7:40 pmwith Nick Tsougrianis presiding.President: Nick Tsougrianis:noted that there was a smaller thanusual crowd tonight.Social : Brigitte Rohde: need peopleto bring goodies for Maymeeting.Showcase: Diane Bowman:want to change case to put inlapidary work. Need moreitems.Secretary: John Bowman: receivednewsletters from Surrey,Port Moody, Campbell Riverclubs, Creative Jewellers’ Guild,Outdoor Recreation Council <strong>and</strong>May Lapidary Journal.Treasurer: SueMcElgunn: reportedon balance in account.NextMeeting:Programming: Cliffwill do a program tonighton petrified charcoal fromAlberta.Thursday, June23rd, 2005History: Jackie Walker: havepictures from the show in thephoto album.Ways & Means: Ted Geernaert:have tickets for slabs onsale tonight.Rep to Centre:MichaelEdwards: Oct 2 nd willbe 50 th anniversary ofthis Centre. We willbe asked to put up a booth atthis event.Elizabeth FallsField Trips: Siggi Rohde: JadeWest trip for this Sunday is cancelled.Would like to lead a trip toBlanchard Mtn for stilpnomalene.Tentative date: June 12 th .Membership: Lillian Brooks: 31people signed in with one newmember. Brecchia is the doorprize.Page 3Del to Society: Reported onRendezvous <strong>and</strong> asked howmany going on mine tour, dinner<strong>and</strong> pancake breakfast.Reports on proposed fossilpolicy <strong>and</strong> what Society is doingabout it.M/S/C: That we donate $750to the Community Association.Meeting adjourned at 8:14 m.Up Coming Field Trips<strong>and</strong> EventsBritish ColumbiaLapidary SocietyFieldtrips 2005 WinterContinued on Page 5Rocket

CNC High RPM SprintSt<strong>and</strong>ard Point <strong>Live</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .0001.■ Coolant deflectors, no friction seal.■ Meets the rigid requirements of CNC turning.■ Points through-hardened to 61-63 Rc.■ Body heat-treated for additional strength.■ Riten full service <strong>and</strong> repair.Coolant DeflectorACEDBMORSE TAPERMax. W. P.Model Taper A B C D E RPM Weight14602 2 1 11/4 21/8 2 3/8 6000 44014603 3 1 13/8 21/8 2 3/8 6000 110014604 4 11/4 113/16 23/4 25/16 3/8 4000 210014605 5 19/16 23/8 31/8 27/16 3/8 4000 2900www.riten.<strong>com</strong>4

Quick Point <strong>Live</strong> <strong>Centers</strong>,Sets <strong>and</strong> Replacement Points■ Accuracy guaranteed to ± .00025.■ Interchangeable points reduce the need for several centers.■ Purchase individual replacement points or a <strong>com</strong>plete set.■ Special points are available upon request.■ Mounting taper of points is 1:10.■ Safe storage container provided when youpurchase a <strong>com</strong>plete set.■ Point extractor for easy removal of points is includedin the set or can be purchased separately.ACA Quick Point Set includes: one live center, one male point,one female point, one tracer point, one bull nose point, <strong>and</strong>one point extractor.QUICK POINT SETSModel Taper49502 2POINT EXTRACTORS49503 3 Model Taper49504 4 49904 2, 3, 449505 5 49905 5BCKM - Male PointCBKET - Tracer PointAADBBCCBN - Bull Nose PointFKF - Female PointKBGFAALIVE MORSE CENTER* TAPERMax. W. P.Model MT A B C D E RPM Weight49102 2 1 1/4 21/8 2 3/8 5000 10049103 3 1 1/4 21/8 2 3/8 5000 35049104 4 11/4 1/4 23/4 25/16 3/8 4000 55049105 5 19/16 1/4 31/8 27/16 3/8 4000 1400*<strong>Live</strong> Center includes male point unless otherwise specified.QUICK POINTSModel MT Style A F G K C B91031 2/3 M 1 – – 13/16 .474 61/6491032 2/3 F 11/8 1/2 7/8 13/32 .474 61/6491033 2/3 T 3/8 – – 15/16 .474 61/6491034 2/3 BN 13/4 7/8 – 13/16 .474 61/6491041 4 M 11/8 – – 15/16 .591 13/1691042 4 F 13/8 5/8 11/8 17/32 .591 13/1691043 4 T 1/2 – – 13/16 .591 13/1691044 4 BN 21/4 1 – 19/16 .591 13/1691051 5 M 11/2 – – 111/16 .867 125/6491052 5 F 11/2 3/4 11/4 11/4 .867 125/6491053 5 T 1/2 – – 2 .867 125/6491054 5 BN 23/4 11/2 – 15/8 .867 125/64www.riten.<strong>com</strong>6

ACNC Heavy-Duty <strong>Live</strong> <strong>Centers</strong>St<strong>and</strong>ard Point■ Accuracy guaranteed to ± .0002.■ May be used in conjunction with Face Drivers.■ Large workpieces in CNC applications.■ Riten full service <strong>and</strong> repair.FACEDRIVER*These CNC live centers are used to counter thehigh thrust as in face driving applications. Thesecenters are also used where workpieces mayweigh several thous<strong>and</strong> pounds. Radialpressure, thrust <strong>and</strong> rigidity requirementsdem<strong>and</strong> centers with four-bearingdesign to h<strong>and</strong>le these loads.* For detailedspecificationson Riten FaceDrivers, seethe catalogorder form onpage 42.Coolant DeflectorCEDBMORSE MORSE TAPER TAPERMax. W. P.Model MT A B C D E RPM Weight15103* 3 11/8 11/2 213/16 33/16 1/2 5000 300015164* 4 121/32 13/4 33/4 327/32 1/2 4000 480015165 5 17/8 21/4 33/4 327/32 1/2 4000 800015105 5 2 21/4 45/8 327/32 1/2 4000 1400015106 6 2 21/4 45/8 327/32 1/2 4000 14000* Stub spindle design on 3MT <strong>and</strong> 4MT.7Call: 1-800-338-0027

CNC <strong>Dead</strong> <strong>Centers</strong> – CarbideTipped■ Accuracy guaranteed to ± .0001.■ Meets the rigid requirements of CNC turning.■ Works on all CNC machines.■ Riten full service <strong>and</strong> repair.■ All stock items.ATAV2TNCarbide, Type 3 KCarbide, Type 4KNCARBIDE TIPPED, TYPE 3, MORSE TAPERModel MT T A N K V2 Threads68923 3 3/8 1/2 2 25/8 20˚ 11/8 - 1268924 4 1/2 5/8 29/32 33/32 20˚ 13/8 - 1268925 5 1/2 5/8 21/2 37/16 20˚ 15/8 - 12CARBIDE TIPPED, TYPE 4, MORSE TAPERModel MT T A N K Threads68913 3 3/4 1 15/8 23/8 11/8 - 1268914 4 1 11/4 2 229/32 13/8 - 1268915 5 11/4 13/4 21/2 321/32 17/8 - 12www.riten.<strong>com</strong>10

ySt<strong>and</strong>ard Spring Loaded <strong>and</strong>Interchangeable Bell Head<strong>Live</strong> <strong>Centers</strong>■ Accuracy to ± .0001.■ Compensates for thermal expansion.■ Low profile.Concentric Tool Corporation, now amember of the Riten workholding family,pioneered <strong>and</strong> patented the streamlinedlow profile design of high precisionspring loaded live centers. The lowprofile design has less overhang, addedload capacity, <strong>and</strong> increased rigidity.The spring loaded spindle <strong>com</strong>pensatesfor workpiece expansion or contraction.St<strong>and</strong>ardSpringLoadedInterchangeableBell Head SpringLoadedSt<strong>and</strong>ard Spring Loaded <strong>Live</strong> CenterSTANDARD SPRING LOADED LIVE CENTERType A B KKBAII .378 .88 1.38III .558 1.16 1.69IV .686 1.38 2.38V 1.075 2.00 2.88VI 1.509 2.75 3.63Bell Head Spring Loaded <strong>Live</strong> Center13Call: 1-800-338-0027

St<strong>and</strong>ard Spring Loaded <strong>Live</strong> <strong>Centers</strong>*TYPE IITYPE IIITYPE IVTYPE VTYPE VITaper Part No. Taper Part No.2 MT 171023 MT 171037 B&S 17407 9 B&S 174098 B&S 17408 8 Jarno 172086 Jarno 17206 9 Jarno 172097 Jarno 17207 1 SS 173035/8 SS 17301 1 1 /16 SS 173043/4 SS 17302 1 1 /4 SS 17305* St<strong>and</strong>ard long points availableTaper Part No.4 MT 1710410 B&S 1741011 B&S 1741110 Jarno 1721011 Jarno 1721112 Jarno 172121 1 /2 SS 17306Taper Part No.5 MT 1710512 B&S 1741213 B&S 1741314 B&S 1741414 Jarno 1721416 Jarno 172161 3 /4 SS 173072 SS 17308Taper Part No.6 MT 1710615 B&S 1741516 B&S 1741620 Jarno 1722022 Jarno 172222 1 /4 SS 173092 1 /2 SS 173103 SS 17311Bell Head Spring Loaded <strong>Live</strong> <strong>Centers</strong>TYPE IITYPE IIITYPE IVTYPE VTYPE VITaper Part No.2 MT 171227 B&S 174278 B&S 174286 Jarno 172267 Jarno 172275/8 SS 173213/4 SS 17322Taper Part No.3 MT 171239 B&S 174298 Jarno 172289 Jarno 172291 SS 173231 1 /16 SS 173241 1 /4 SS 17325Taper Part No.4 MT 1712410 B&S 1743011 B&S 1743110 Jarno 1723011 Jarno 1723112 Jarno 172321 1 /2 SS 17326Taper Part No.5 MT 1712512 B&S 1743213 B&S 1743314 B&S 1743414 Jarno 1723416 Jarno 172361 3 /4 SS 173272 SS 17328Taper Part No.6 MT 1712615 B&S 1743516 B&S 1743620 Jarno 1724022 Jarno 172422 1 /4 SS 173292 1 /2 SS 173303 SS 17331Interchangeable Bell Head AdaptersStyle 1 Style 2Style 3 Style 4Style 5 Female HeadSTYLE 1 STYLE 2 STYLE 3 STYLE 4 STYLE 5CenterType Part No. A B Part No. A B Part No. A B Part No. A B Part No. A BII 00231 0.25 1.31 00232 1.24 1.82 00233 1.75 2.33 00234 2.26 2.84 00235 0.13 0.76III 00331 0.35 1.83 00332 1.72 2.58 00333 2.46 3.32 00334 3.20 4.06 00335 0.19 1.12IV 00431 0.36 2.27 00432 2.17 3.25 00433 3.14 4.22 00434 4.11 5.19 00435 0.23 1.37V 00531 0.51 3.33 00532 3.21 4.80 00533 4.60 6.19 00534 6.06 7.65 00535 0.38 2.00VI 00631 0.61 5.08 (Contact factory for availability).www.riten.<strong>com</strong>14

Pipe Nose <strong>Live</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .00025.■ For use with pipe, tubing <strong>and</strong> thin walled piece parts.Designed for use in machining pipe, tubing <strong>and</strong> other thin wall workpieces.One center fits a wide range of sizes. For the best support <strong>and</strong>chatter-free parts, choose a center where the part will seat as close tothe large diameter as possible.AJarno,Brown & Sharpe,<strong>and</strong> Straight ShanksAvailableEKMORSE TAPERW. P.Model Taper A E K Weight65252 2 21/2 5/16 33/4 26065253 3 21/2 5/16 33/4 26065254 4 21/2 5/16 33/4 26065353 3 31/2 7/16 429/32 150065354 4 31/2 7/16 429/32 150065355 5 31/2 7/16 429/32 150065453 3 41/2 7/16 47/8 150065454 4 41/2 7/16 47/8 150065455 5 41/2 7/16 47/8 150065555 5 51/2 3/8 65/16 450065556 6 51/2 3/8 65/16 450015Call: 1-800-338-0027

Spline Rolling <strong>Live</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .00025.■ Tapered <strong>and</strong> ball bearings.■ Points are through-hardened to 61-63 Rc.■ Riten full service <strong>and</strong> repair.■ Special applications.Spline Rolling <strong>Centers</strong> are special application centers.Their design includes heavy-duty taper <strong>and</strong> rollerbearings. The heat-treated points extend the life of thecenter. Lubrication is sealed in <strong>and</strong> no additional lubricantis required.Prompt deliveries on special points including female,cupped, long point, or radius end from semi-finishedinventories. The Spline Rolling Center is available inheavy-duty design to meet difficult applications.A CEDBMORSE MORSE TAPER TAPERW. P.Model Taper A B C D E Weight46103 3 7/8 13/8 163/64 23/8 5/16 25046104 4 7/8 13/8 163/64 23/8 5/16 250CENTER EXTRACTOR46993 3 MT46994 4 MTwww.riten.<strong>com</strong>16

Econo-Tri-Bearing <strong>Live</strong> <strong>Centers</strong>St<strong>and</strong>ard Point■ Accuracy guaranteed to ± .0002.■ Three rows of bearings.■ Points are through-hardened to 61-63 Rc.■ Sealed bearings lubricated for life, protectedagainst contaminants <strong>and</strong> coolant.■ Non-repairable, trade-in available.ACEDBMORSE MORSE TAPER TAPERMax. W.P.Model Taper A B C D E RPM Weight44102 2 9/16 13/16 15/8 15/8 1/4 2500 30044103 3 13/16 1 2 115/16 1/4 2500 50044104 4 1 11/4 23/8 21/4 1/4 2500 110044105 5 1 11/4 23/8 21/4 1/4 2500 110017Call: 1-800-338-0027

Econo-Tri-Bearing <strong>Live</strong> <strong>Centers</strong>Tracer Point■ Accuracy guaranteed to ± .0002.■ Three rows of bearings.■ Points are through-hardened to 61-63 Rc.■ Sealed bearings lubricated for life, protectedagainst contaminants <strong>and</strong> coolant.■ Non-repairable, trade-in available.ACEDBMORSE MORSE TAPER TAPERMax. W. P.Model Taper A B C D E RPM Weight44902 2 3/8 11/4 15/8 15/8 1/4 2500 30044903 3 3/8 11/2 2 115/16 1/4 2500 30044904 4 1/2 2 23/8 21/4 1/4 2500 90044905 5 1/2 2 23/8 21/4 1/4 2500 900www.riten.<strong>com</strong>18

Regal <strong>Live</strong> <strong>Centers</strong>St<strong>and</strong>ard Point■ Accuracy guaranteed to ± .0001.■ Heavy-duty bearing design.■ Points are through-hardened to 61-63 Rc.■ Full-length spindle for extra rigidity.■ Double row of angular contact bearings for superiorperformance.■ Body heat-treated for additional strength.■ Riten full service <strong>and</strong> repair.ACEDBMORSE TAPERMax. W. P.Model MT A B C D E RPM Weight48602 2 1 11/4 23/8 13/4 1/4 4000 44048603 3 1 11/4 23/8 13/4 1/4 4000 110048604 4 13/8 11/2 3 131/32 3/8 4000 210048605 5 13/8 113/16 31/16 23/32 9/32 5000 280019Call: 1-800-338-0027

Regal <strong>Live</strong> <strong>Centers</strong>Long Pointn Accuracy guaranteed to ± .0001.n Heavy-duty bearing design.n Points are through-hardened to 61-63 Rc.n Full-length spindle for extra rigidity.n Double row of angular contact bearings for superiorperformance.n Body heat-treated for additional strength.n Point configuration allows for tool clearance.n Riten full service <strong>and</strong> repair.IAV2CGEDBMORSE MORSE TAPER TAPERMax. W. P.Model MT A B C D E G V2 I RPM Weight48102 2 3/8 17/8 23/8 13/4 1/4 5/8 34 121/32 4000 31048103 3 3/8 17/8 23/8 13/4 1/4 5/8 34 121/32 4000 31048104 4 1/2 27/32 3 131/32 3/8 13/16 34 2 4000 110048105 5 1/2 21/2 31/16 23/32 9/32 15/16 40 25/32 5000 1100www.riten.<strong>com</strong>20

AAdvantage <strong>Live</strong> <strong>Centers</strong>St<strong>and</strong>ard <strong>and</strong> Tracer Point■ Accuracy guaranteed to ± .0001.■ Heavy-duty, tri-bearing design.■ Points are through-hardened to 61-63 Rc.■ Full-length spindle for extra rigidity.■ Less tailstock pressure required.■ Four bearing design for superior performance.■ Body heat-treated for additional strength.■ Riten full service <strong>and</strong> repair.EDSt<strong>and</strong>ard PointBACMORSE MORSE TAPER TAPERMax. W. P.Model MT A B C D E RPM Weight51602 2 7/8 11/8 13/4 23/8 3/8 5000 88051603 3 7/8 11/8 13/4 23/8 3/8 5000 92051604 4 11/8 2 27/8 33/16 1/2 4200 220051605 5 11/8 2 27/8 33/16 1/2 4200 440051606 6 17/8 21/4 33/4 327/32 1/2 4000 6500EDTracer PointV2BCMORSE MORSE TAPER TAPERMax. W. P.Model MT A B C D E V2 RPM Weight51902 2 3/8 13/4 13/4 23/8 3/8 30˚ 5000 75051903 3 3/8 13/4 13/4 23/8 3/8 30˚ 5000 75051904 4 9/16 21/16 27/8 33/16 1/2 30˚ 4200 170051905 5 9/16 21/16 27/8 33/16 1/2 30˚ 4200 170051906 6 5/8 225/32 33/4 327/32 1/2 30˚ 4000 220021Call: 1-800-338-0027

AAdvantage <strong>Live</strong> <strong>Centers</strong>Long Point■ Accuracy guaranteed to ± .0001.■■■■■■■Heavy-duty, tri-bearing design.Points are through-hardened to 61-63 Rc.Full-length spindle for extra rigidity.Four bearing design for superior performance.Body heat-treated for additional strength.Point configuration allows for tool clearance.Riten full service <strong>and</strong> repair.IV2CEDBGMORSE MORSE TAPER TAPERMax. W. P.Model MT A B C D E G V2 I RPM Weight51102 2 3/8 2 13/4 23/8 3/8 3/4 30 111/16 5000 31051103 3 3/8 2 13/4 23/8 3/8 3/4 30 111/16 5000 31051104 4 1/2 21/2 27/8 33/16 1/2 15/16 30 23/32 4200 110051105 5 1/2 21/2 27/8 33/16 1/2 15/16 30 23/32 4200 1100www.riten.<strong>com</strong>22

AHeavy-Duty <strong>Live</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .0001.■ Four-bearing design for heavier loads.■ Riten full service <strong>and</strong> repair.■ For use where the piece part may weigh severalhundred pounds. Radial pressure <strong>and</strong> thrustrequirements dem<strong>and</strong> centers with bearing structuresthat will h<strong>and</strong>le these loads.Jarno,Brown & Sharpe,<strong>and</strong> Straight ShanksAvailableCEDBMORSE TAPERMax W. P.Model MT A B C D E RPM Weight34163 3 7/8 11/8 13/4 23/8 3/8 5000 92034164 4 11/8 2 27/8 33/16 1/2 4200 220034105 5 17/8 21/4 33/4 327/32 1/2 3200 800034106 6 2 21/4 45/8 327/32 1/2 3000 1400034107 7 2 21/4 45/8 327/32 1/2 3000 14000JARNO TAPER34220 20 2 21/4 45/8 327/32 1/2 3000 1400023Call: 1-800-338-0027

EXTRA HEAVY-DUTY <strong>Live</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .0002.■ Designed for heavy steel rolls, paper rolls, printing rolls,castings, forgings <strong>and</strong> other large parts.■ Riten full service <strong>and</strong> repair.■ For use where the piece part may weigh several thous<strong>and</strong>pounds. Radial pressure <strong>and</strong> thrust requirementsdem<strong>and</strong> centers with bearing structures thatwill h<strong>and</strong>le these loads.Jarno,Brown & Sharpe,<strong>and</strong> Straight ShanksAvailableACEDBMax W. P.Model MT A B C D E RPM Weight55103* 3 11/8 11/2 213/16 33/16 1/2 4000 300055164* 4 121/32 13/4 33/4 327/32 1/2 4000 480055105 5 2 21/4 45/8 327/32 1/2 3000 1200055106 6 25/8 21/2 69/16 53/32 19/32 3000 2250055107 7 25/8 21/2 69/16 53/32 3/4 3000 22500*Stub spindle design on 3MT <strong>and</strong> 4MTMORSE TAPERwww.riten.<strong>com</strong>24

Heavy-Duty Bull Nose <strong>Live</strong> <strong>Centers</strong>■ Large workpiece center holes.■ Large piece parts.■ Riten full service <strong>and</strong> repair.Riten Bull Nose <strong>Centers</strong> are constructed with larger bearingsto carry heavier loads. The strength <strong>and</strong> alignment of the fullysupported bull nose gives longer center life when machininglarger workpieces. The rigidity of the center preventsvibration <strong>and</strong> chatter.For best results, choose a bull nose centerthat will place the workpiece in the middle ortoward the larger end of the 60˚ angle.This will balance the weight of the parton the center <strong>and</strong> help carry theload evenly over the bearings.MORSE TAPEREKAccuracy guaranteed to ± .00015FAW. P.Model MT A F E K Weight56412 2 4 1 3/8 4 9/32 200056413 3 4 1 3/8 4 9/32 380056414 4 4 1 3/8 4 9/32 480056415 5 4 1 3/8 4 9/32 480056523 3 5 2 3/8 3 13/16 380056524 4 5 2 3/8 3 13/16 480056525 5 5 2 3/8 3 13/16 480056633 3 6 1/2 3 3/8 3 29/32 380056634 4 6 1/2 3 3/8 3 29/32 480056635 5 6 1/2 3 3/8 3 29/32 480056636 6 6 1/2 3 25/32 4 5/16 4800MORSE TAPERJarno,Brown & Sharpe,<strong>and</strong> Straight ShanksAvailableEKAccuracy guaranteed to ± .0002FAW. P.Model MT A F E K Weight56945 5 9 4 15/32 6 5/8 700056946 6 9 4 15/32 6 5/8 1200056105 5 10 1/2 5 7/16 7 7/16 700056106 6 10 1/2 5 7/16 7 7/16 1500056107 7 10 1/2 5 7/16 7 7/16 1500056126 6 12 6 7/16 7 7/16 1500056127 7 12 6 7/16 7 7/16 1500025Call: 1-800-338-0027

Super Accurate <strong>Live</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .00005.■ Compact design.■ Extended points available.■ Ideal for grinding.■ Five pounds of thrust to seat bearings.■ Riten full service <strong>and</strong> repair.The ultimate live center for grinding is provided by Riten's uniquedesign. Ideal for precision grinding applications; ± .00005.ACEW. P.Model MT A B C D E RPM Weight12102 2 3/4 13/16 11/4 3/4 3/32 1000 40012103 3 7/8 11/16 111/16 15/16 3/16 1000 100012104 4 1 1 21/8 13/16 1/4 1000 180012105 5 11/2 11/2 213/16 113/32 1/4 1000 380012106 6 21/8 21/8 43/16 21/2 5/16 1000 6000DMORSE TAPERBBROWN & SHARPE TAPERBS W. P.Model T A B C D E RPM Weight12407 7 3/4 13/16 11/4 3/4 3/32 1000 40012409 9 7/8 1 111/16 15/16 3/16 1000 100012410 10 1 1 21/8 13/16 9/16 1000 180012411 11 1 1 21/8 13/16 1/4 1000 180012412 12 11/2 11/2 213/16 113/32 5/16 1000 380012413 13 11/2 11/2 213/16 113/32 1/4 1000 3800JARNO TAPERW. P.Model JT A B C D E RPM Weight12206 6 3/4 13/16 11/4 3/4 3/32 1000 30012207 7 7/8 1 111/16 15/16 3/16 1000 80012209 9 7/8 1 111/16 15/16 3/16 1000 100012210 10 1 1 21/8 13/16 3/16 1000 180012212 12 1 1 21/8 13/16 1/4 1000 180012214 14 11/2 11/2 213/16 113/32 1/4 1000 380012216 16 11/2 11/2 213/16 113/32 3/16 1000 380012220 20 21/8 21/8 43/16 21/2 5/16 1000 6000STRAIGHT SHANKW. P.Model SS A B C D E* RPM Weight12301 1/2 1/2 9/16 11/4 3/4 21/4 1000 10012302 3/4 1/2 9/16 11/4 3/4 23/4 1000 44012303 1 7/8 1 111/16 15/16 35/8 1000 100012304 1 7/8 1 111/16 15/16 5 1000 100012305 11/4 1 1 21/8 13/16 5 1000 180012306 11/2 1 1 21/8 13/16 5 1000 180012307 13/4 1 1 21/8 13/16 7 1000 180012309 2 11/2 11/2 213/16 113/32 6 1000 3800* Straight shanks only – E dimension equals entire length of shank.www.riten.<strong>com</strong>26

Medium-Duty Super Accurate■ Accuracy guaranteed to ± .0001.■ Medium-duty for heavier cuts.■ Bigger bearings for heavier loads.■ Five pounds of thrust to seat bearings.■ Riten full service <strong>and</strong> repair.■ Extended points available.Medium-duty live centers are required where the weight of theworkpiece is several hundred pounds. These centers are builtwith larger bearings to provide the support <strong>and</strong> strength requiredto h<strong>and</strong>le heavier workpieces.ACEDB27MORSE TAPERW. P.Model MT A B C D E RPM Weight34102 2 7/8 1 111/16 11/16 3/32 1000 50034103 3 1 1 21/8 13/8 3/16 1000 120034104 4 11/2 11/2 213/16 121/32 3/16 1000 2200JARNO TAPERW. P.Model JT A B C D E RPM Weight34206 6 7/8 1 111/16 11/16 3/32 1000 40034207 7 1 1 21/8 13/8 3/16 1000 90034209 9 1 1 21/8 13/8 3/16 1000 130034210 10 11/2 11/2 213/16 121/32 5/16 1000 220034211 11 11/2 11/2 213/16 121/32 3/16 1000 220034212 12 11/2 11/2 213/16 121/32 1/4 1000 220034214 14 21/8 21/8 43/16 21/2 1/2 1000 440034216 16 21/8 21/8 43/16 21/2 5/16 1000 4400Call: 1-800-338-0027BROWN & SHARPE TAPERBS W. P.Model T A B C D E RPM Weight34407 7 7/8 1 111/16 11/16 3/32 1000 50034409 9 1 1 21/8 13/8 3/16 1000 130034410 10 11/2 11/2 213/16 121/32 3/16 1000 220034411 11 11/2 11/2 213/16 121/32 1/4 1000 220034412 12 21/8 21/8 43/16 21/2 5/16 1000 440034413 13 21/8 21/8 43/16 21/2 5/16 1000 4400STRAIGHT SHANKW. P.Model SS A B C D E* RPM Weight34303 1 1 1 21/8 13/8 35/8 1000 130034304 1 1 1 21/8 13/8 5 1000 130034305 11/4 11/2 11/2 213/16 121/32 5 1000 220034306 11/2 11/2 11/2 213/16 121/32 5 1000 220034307 13/4 11/2 11/2 213/16 121/32 7 1000 220034309 2 21/8 21/8 43/16 21/2 6 1000 4400* Straight shanks only – E dimension equals entire length of shank.

HLarge Carbide PointImperial <strong>Dead</strong> <strong>Centers</strong>Increased Centerhole Range■ Accuracy guaranteed to ± .0001.■■■Covers the widest range of center hole sizes.Eliminates the need for special centers.Also available in other tapers.Imperial Carbide <strong>Centers</strong> cover the requirements for a wide range of workpiececenter holes. They reduce costs by eliminating the need for specialdead centers.Knockout ends are hardened on carbide tipped dead centers.Applying a Moly EP632 grease on the point will reducefriction <strong>and</strong> wear.LTAEKFull <strong>Dead</strong> <strong>Centers</strong>EHalf <strong>Dead</strong> <strong>Centers</strong>KATMORSE TAPERModel Taper T* A K E69102 2 1 11/4 23/8 3/869103 3 1 11/4 23/8 3/869104 4 11/4 13/4 211/16 1/269105 5 11/4 13/4 35/16 —MORSE TAPERModel Taper T* A H L K E69502 2 1 11/4 1/8 111/16 23/8 3/869503 3 1 11/4 1/8 111/16 23/8 3/869504 4 11/4 13/4 1/4 21/4 215/16 1/269505 5 11/4 13/4 1/4 23/4 35/16 -JARNO TAPERModel Taper T* A K E69206 6 1 11/4 23/8 3/869209 9 11/4 13/4 211/16 1/269210 10 11/4 13/4 211/16 1/269214 14 11/4 13/4 31/2 —JARNO TAPERModel Taper T* A H L K E69606 6 1 11/4 1/8 17/8 23/8 3/869609 9 11/4 13/4 1/4 17/8 215/16 1/269610 10 11/4 13/4 1/4 2 215/16 1/269614 14 11/4 13/4 1/4 3 31/2 -Model Taper T* A K E69407 7 1 11/4 23/8 3/869409 9 11/4 13/4 211/16 1/269412 12 11/4 151/64 4 —* Carbide DiameterBROWN & SHARPE TAPERBROWN & SHARPE TAPERModel Taper T* A H L K E69707 7 1 11/4 1/8 17/8 23/8 3/869709 9 11/4 13/4 1/4 2 215/16 1/269712 12 11/4 151/64 1/4 31/4 4 -* Carbide Diameterwww.riten.<strong>com</strong>28

Mill Taper <strong>Dead</strong> <strong>Centers</strong>■ Accurate to ± .0001.■ Manufactured specifically for Cincinnati machines.■ Through-hardened to 61-63 Rc.■ Carbide tipped available.Nose StylesStyle 4 Style 5Style 6 Style 7Shank StylesStyle 1 Style 2Style 329Call: 1-800-338-0027

MILL TAPER DEAD CENTERS - 35 TAPERTaper Shank Nose A2=Large A=Nose C=Gage F=Blunt N=Nose Cin. RitenSize Thread Style Style Nose Dia. Dia. Line Dia. Length Part # Part #35 1/2-13 1 4 – 0.250 1.500 – 1.625 3646478 6120135 1/2-13 1 4 – 0.375 1.500 – 1.625 3646346 6120235 1/2-13 1 4 – 0.500 1.500 – 1.625 3646345 6120335 1/2-13 1 4 – 1.000 1.500 – 1.625 3646479 6120435 1/2-13 1 4 – 0.562 1.500 – 2.000 3646345L 6120535 1/2-13 1 4 – 0.250 1.500 – 2.375 6120635 1/2-13 1 4 – 0.250 1.500 – 2.750 6120735 1/2-13 1 5 – 0.812 1.500 – 2.250 6120835 1/2-13 1 5 – 1.500 1.500 – 2.625 6120935 1/2-13 1 7 – 2.000 1.500 .700 1.625 3646480 6121035 1/2-13 1 7 – 2.500 1.500 1.438 1.625 3646481 6121135 1/2-13 1 7 – 3.125 1.500 2.156 1.625 3646482 61212MILL TAPER DEAD CENTERS - 40 TAPERTaper Shank Nose A2=Large A=Nose C=Gage F=Blunt N=Nose Cin. RitenSize Thread Style Style Nose Dia. Dia. Line Dia. Length Part # Part #40 5/8-11 1 4 – 0.250 1.750 – 2.250 3646483 6130140 5/8-11 1 4 – 0.375 1.750 – 2.250 3646489 6130240 5/8-11 1 4 – 0.500 1.750 – 2.250 3646484 6130340 5/8-11 1 4 – 0.250 1.750 – 2.820 3646483L 6130440 5/8-11 1 4 – 0.500 1.750 – 2.820 3646484L 6130540 5/8-11 1 5 – 2.250 1.750 – 3.000 6130640 5/8-11 1 6 1.750 1.000 1.750 – 2.250 3646485 6130740 5/8-11 1 6 1.750 1.000 1.750 – 2.820 3646485L 6130840 5/8-11 1 6 1.500 0.500 1.750 – 2.945 4238238 6130940 5/8-11 1 6 1.500 0.250 1.750 – 3.500 6131040 5/8-11 1 7 – 2.750 1.750 1.375 1.816 3646487 6131140 5/8-11 1 7 – 3.250 1.750 2.000 1.833 3646488 6131240 5/8-11 1 7 – 2.250 1.750 0.625 1.959 3646486 6131340 5/8-11 2 6 1.250 0.250 1.750 – 2.344 622124 6131440 5/8-11 2 6 1.250 0.500 1.750 – 2.344 622105 6131540 5/8-11 2 6 1.250 0.750 1.750 – 2.344 622106 6131640 5/8-11 2 7 – 2.250 1.750 1.125 1.287 622108 6131740 5/8-11 2 7 – 2.250 1.750 0.500 1.833 622107 6131840 5/8-11 2 7 – 3.125 1.750 1.875 2.178 622109 61319MILL TAPER DEAD CENTERS - 45 TAPERTaper Shank Nose A2=Large A=Nose C=Gage F=Blunt N=Nose Cin. RitenSize Thread Style Style Nose Dia. Dia. Line Dia. Length Part # Part #45 5/8-11 3 4 – 0.625 2.250 – 2.124 3624473 6140145 5/8-11 3 4 – 0.500 2.250 – 2.500 3673534 6140245 5/8-11 3 4 – 0.750 2.250 – 2.500 3624727 6140345 5/8-11 3 4 – 1.000 2.250 – 2.500 3673535 6140445 5/8-11 3 4 – 1.250 2.250 – 3.000 3624727L 6140545 5/8-11 3 4 – 1.000 2.250 – 3.561 3674245 6140645 5/8-11 3 5 – 1.375 2.250 – 1.500 3624725 6140745 5/8-11 3 6 1.375 0.500 2.250 – 3.500 3674244 6140845 5/8-11 3 7 – 2.000 2.250 0.700 1.875 3673538 6140945 5/8-11 3 7 – 3.125 2.250 2.156 1.589 3673539 6141045 5/8-11 3 7 – 3.375 2.250 1.000 2.619 3624474 6141145 5/8-11 3 7 – 4.000 2.250 1.125 3.125 6141245 5/8-11 3 7 – 6.000 2.250 2.500 3.750 61413www.riten.<strong>com</strong>30

Long Series Full <strong>Dead</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .0001.■ Through-hardened to 61-63 Rc.■ Riten full service <strong>and</strong> repair.■ Applying a Moly EP632 grease on the point willreduce friction <strong>and</strong> wear.PAGE 36CAPKMORSE TAPERModel Taper P K C/A64502 2 53/16 25/8 .70064602 2 63/4 43/16 .70064503 3 61/4 31/16 .93864603 3 63/4 39/16 .93864504 4 73/4 311/16 1.23164604 4 81/4 43/16 1.23164505 5 91/2 45/16 1.74864605 5 10 413/16 1.74864506 6 121/2 51/4 2.49464606 6 13 53/4 2.494JARNO TAPERModel Taper P K C/A64510 10 81/2 31/2 1.25064610 10 91/4 41/4 1.25064514 14 111/2 41/2 1.75064614 14 12 5 1.750BROWN & SHARPEModel Taper P K C/A64407 7 51/4 23/8 .72064412 12 121/4 51/8 1.79731Call: 1-800-338-0027

AAPipe <strong>and</strong> Bull Nose<strong>Dead</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .0001.■ Through-hardened to 61-63 Rc.■ Riten full service <strong>and</strong> repair.■ Special “F” dimension available on bull nose.■ Quick delivery available on these items.PAGE 35FEKPipe Nose <strong>Dead</strong> CenterNENKBull Nose <strong>Dead</strong> CenterSpecial F dimensions available. Quick delivery on these items.MORSE TAPERSModel Taper A N E K66102 2 21/8 1.84 1/2 2.8466103 3 23/4 2.381 1/2 3.3866104 4 23/4 2.381 1/2 3.3866105 5 31/2 3.031 1/2 4.03JARNO TAPERSModel Taper A N E K66214 14 31/2 3.031 1/2 4.03MORSE TAPERSModel Taper A F N E K66502 2 21/8 1/2 1.407 1/2 213/3266602 2 21/8 1 .974 1/2 131/3266503 3 23/4 1/2 1.948 1/2 261/6466603 3 23/4 1 1.515 1/2 233/6466703 3 23/4 11/2 1.082 1/2 25/6466504 4 23/4 1/2 1.948 1/2 215/1666604 4 23/4 1 1.515 1/2 233/6466704 4 23/4 11/2 1.082 1/2 25/6466505 5 31/2 1 2.165 1/2 311/6466605 5 31/2 2 1.299 1/2 219/64JARNO TAPERSModel Taper A F N E K66514 14 31/2 1 2.165 1/2 311/6466614 14 31/2 2 1.299 1/2 219/64www.riten.<strong>com</strong>32

High Speed <strong>Dead</strong> <strong>Centers</strong>■ Accuracy guaranteed to ± .0001.■ Through-hardened to 61-63 Rc for extra regrinds.■ Carbide tipped dead centers are hardened only onthe knockout ends.■ Riten full service <strong>and</strong> repair.■ Applying a Moly EP632 grease on the pointwill reduce friction <strong>and</strong> wear.Style 4Style 3Style 2Style 1STYLE 1 - STEEL FULL CENTERSTYLE 2 - STEEL HALF CENTERCCDADABBPPCCH L ASTYLE 3 - CARBIDE TIPPED FULL CENTERSTYLE 4 - CARBIDE TIPPED HALF CENTERHLDADBTBTPP33Call: 1-800-338-0027

When ordering specify model # <strong>and</strong> style #,for example: 7104-Style 3.MORSE TAPERModel Taper P B C/A D •T H L7101 1 35/16 21/8 .475 .369 1/4 1/8 17102 2 43/16 29/16 .700 .572 3/8 3/16 13/87103 3 51/4 33/16 .938 .778 1/2 1/4 111/167104 4 63/4 41/16 1.231 1.020 1/2 1/4 21/47105 5 81/2 53/16 1.748 1.475 5/8 3/8 23/47106 6 111/2 71/4 2.494 2.116 7/8 1/2 31/27107 7 15 10 3.270 2.750 1 3/4 4JARNO TAPERModel Taper P B C/A D •T H L7204 6 41/2 3 .750 .600 3/8 3/16 11/87205 6 51/2 3 .750 .600 3/8 3/16 23/167206 6 6 3 .750 .600 3/8 3/16 21/27207 7 51/4 31/2 .875 .700 3/8 3/16 13/167208 8 6 4 1.000 .800 1/2 1/4 15/87209 9 63/4 41/2 1.125 .900 1/2 1/4 17/87210 10 71/2 5 1.250 1.000 1/2 1/4 27211 11 81/4 51/2 1.375 1.100 1/2 1/4 27212 12 9 6 1.500 1.200 5/8 5/16 21/47213 13 93/4 61/2 1.625 1.300 5/8 5/16 21/27214 14 101/2 7 1.750 1.400 5/8 5/16 37215 15 111/4 71/2 1.875 1.500 5/8 5/16 37216 16 12 8 2.000 1.600 3/4 3/8 37218 18 131/2 9 2.250 1.800 7/8 7/16 31/27220 20 15 10 2.500 2.000 1 1/2 47236 36 27 18 4.500 3.600 13/4 7/8 7BROWN & SHARPE TAPERModel Taper P B C/A D •T H L7405 5 31/8 2 .533 .450 1/4 1/8 15/167406 6 35/8 23/8 .599 .500 1/4 1/8 15/167407 7 43/8 27/8 .720 .600 3/8 3/16 11/87408 8 57/16 39/16 .898 .750 1/2 1/4 13/87409 9 61/2 41/4 1.078 .901 1/2 1/4 27410 10 77/8 5 1.260 1.045 1/2 1/4 21/47400 ★10 89/16 511/16 1.289 1.045 1/2 1/4 21/47411 11 95/16 515/16 1.498 1.250 5/8 5/16 21/27401 ★11 101/8 63/4 1.531 1.250 5/8 5/16 21/27412 12 111/8 71/8 1.797 1.500 5/8 3/8 31/47413 13 113/4 73/4 2.073 1.750 7/8 7/16 31/27415 15 131/2 83/4 2.615 2.250 1 1/2 47417 17 141/2 93/4 3.156 2.750 11/2 3/4 47418 18 15 101/4 3.427 3.000 11/2 3/4 41/2• Carbide diameter ★ CINN. Grinderwww.riten.<strong>com</strong>34

TFast-Trak SpecialsOrder a Riten Fast-Trak Special when you need a special center <strong>and</strong>time is of the essence. The same Riten quality in two weeks or lessat no additional charge. Additional tapers <strong>and</strong> carbide tips are availablefrom our semi-finished inventories. Call Riten at 800-338-0027with your special requirements. If you would rather fax your requirements,see pages 37 <strong>and</strong> 38.■ Two-week delivery■ Accuracy guaranteed to ± .0001.■ Other tapers available.■ Both steel <strong>and</strong> carbide centers.■ Hardened knockout ends.■ Riten full service <strong>and</strong> repair.Special CarbideBull Nose <strong>Dead</strong> <strong>Centers</strong>2-week deliverySEE DISCOUNT SCHEDULEMORSE TAPERModel MT T F N E K66901 3 13/4 3/4 0.87 1/2 1.8666902 3 2 3/4 1.08 1/2 2.0866903 3 21/2 1 1.30 1/2 2.3066904 3 23/4 1 1.52 1/2 2.51ENKF66905 4 13/4 3/4 0.87 1/2 1.8666906 4 2 3/4 1.08 1/2 2.0866907 4 21/2 1 1.30 1/2 2.3066908 4 23/4 1 1.52 1/2 2.5166909 5 13/4 3/4 0.87 1/2 2.6466910 5 2 3/4 1.08 1/2 2.0866911 5 21/2 1 1.30 1/2 2.3066912 5 23/4 1 1.52 1/2 2.5135Call: 1-800-338-0027

Fast-Trak SpecialCarbide <strong>Dead</strong> <strong>Centers</strong>2-week deliverySTYLE 3 - CARBIDE TIPPED FULL CENTERSTYLE 4 - CARBIDE TIPPED HALF CENTERCCHLDADABTBTPPWhen ordering specify model # <strong>and</strong> style #, for example: 7905-Style 3.MORSE TAPERModel Taper P B C/A D •T H L7905 3MT 51/4 33/16 0.938 0.778 3/4 1/8 111/167906 3MT 61/4 33/16 0.938 0.778 3/4 1/8 25/87907 3MT 63/4 33/16 0.938 0.778 3/4 1/8 31/87908 4MT 63/4 41/16 1.231 1.020 3/4 1/8 21/47909 4MT 63/4 41/16 1.231 1.020 1 1/8 21/47910 4MT 73/4 41/16 1.231 1.020 3/4 1/8 23/47911 4MT 73/4 41/16 1.231 1.020 1 1/8 23/47912 4MT 81/4 41/16 1.231 1.020 3/4 1/8 31/47913 4MT 81/4 41/16 1.231 1.020 1 1/8 31/47914 5MT 81/2 53/16 1.748 1.475 1 1/8 23/47915 5MT 91/2 53/16 1.748 1.475 1 1/8 33/47916 5MT 10 53/16 1.748 1.475 1 1/8 41/4JARNO TAPERModel Taper P B C/A D •T H L7926 10J 71/2 5 1.25 1.000 1 1/8 27927 10J 81/2 5 1.25 1.000 1 1/8 37928 10J 91/4 5 1.25 1.000 1 1/8 33/47929 14J 101/2 7 1.75 1.400 1 1/8 37930 14J 111/2 7 1.75 1.400 1 1/8 47931 14J 12 7 1.75 1.400 1 1/8 41/2• Carbide diameterwww.riten.<strong>com</strong>36

NOTE: This page <strong>and</strong> the following page areavailable as a PDF file on disk. Call RitenCustomer Service for a copy.SPECIALSTo order, fill in the dimensions you require <strong>and</strong> FAX or mail us a copy.Any dimension not supplied will be Riten factory st<strong>and</strong>ard.# TAPERLIVE CENTER KEYAVCA - Point DiameterG - Point to Angle (Sprint)B - Point LengthK - Gage Line to PointC - Head DiameterP - Overall LengthD - Head LengthV - Point AngleE - Gage Line to Back of HeadF - Minimum Diameter (Bull Nose <strong>and</strong> Female)EPDKB# ______ TAPER A _______ B _______ C _______E ______ F _______ G _______ V _______RPM ______ Workpiece Weight ______ Thrust ________DEAD CENTER KEYA - Point Diameter F - Minimum Diameter K - Gage Line to Point V - Point AngleB - Taper Length (Bull Nose <strong>and</strong> Female) L - Length of Cut Out V2 - Secondary AngleC - Gage Line Diameter G - Female Major Diameter N - Point Length W - Flange Outside DiameterE - Gage Line to Back of Head H - Height Above Center Line P - Overall LengthJ - Flat LengthT - Carbide Tip DiameterCNC TAILSTOCK DEAD CENTER# TAPER CA# TAPERFULL DEAD CENTERCAVVBNBKPP# ______ TAPER A _______ B _______ C ______N ______ P _______ V _______ T _______# ______ TAPER A _______ B _______ C ______K ______ P _______ V _______ T _______HALF DEAD CENTERFEMALE DEAD CENTER# TAPERC# TAPERCFGH L VAVBPBPK37# ______ TAPER B _______ C _______ H ______L ______ P _______ V _______ T _______Call: 1-800-338-0027# ______ TAPER A _______ B _______ C ______F ______ G _______ K _______ P _______ V ______

VAVSPECIALSBULL NOSE DEAD CENTERPIPE NOSE DEAD CENTER# TAPERCJF# TAPERCJAVEBPENT ______BPKT ______# ______ TAPER A _______ B _______ C ______E _____ F ______ J______ N ______ P _____ V _____MILL TAPER DEAD CENTER# MILL TAPERA# ______ TAPER A _______ B _______ C ______E ______ J _______ K _______ P _______ V ______MILL TAPER DEAD CENTER# MILL TAPERAV2VV2V# ______ TAPERJN# ______ TAPERJNA ______ J _______ N _______ V _______ V2 _____FLANGE CENTERA ______ J _______ N _______ V _______ V2 _____INTERCHANGEABLE POINT DEAD CENTER & SPECIAL POINTSBJP___DIA. DRILL THRU___C.B.x___DEEP___B.C.___PLACES___THREAD___B.C.___PLACES# TAPERC# TAPERGACVW CV2FABPKBPDEAD CENTER # _______ TAPER A _____B ______ C _______ G _______ K _______ P ______SPECIAL POINT # _______ TAPERA ______ B _______ C _______ F _______ J ______P ______ V _______ V2 ______ W ______________ DIAMETER DRILL THROUGHB ______ C _______ P _______ V _______SLEEVE WITH TANGSLEEVE# O.D.TAPER # O.D.TAPER________ C. B. X _______ DEEP________B. C. ________ PLACES# I.D.TAPER# I.D.TAPER________ THREAD________ B. C. ________ PLACESFILL IN NUMBERS ON DIAGRAM38www.riten.<strong>com</strong>

TECHNICAL INFORMATIONLIVE CENTERSThe “12” <strong>and</strong> “34” Series Super Accurate designs are ideallysuited for low RPM grinding <strong>and</strong> lathe applications. Thisdesign, unique to Riten Industries, is capable of accuraciesunder 100 millionths. These centers need at least five poundsof thrust pressure applied to seat the bearings. Super Accuratecenters are intended for use in applications where thrust pressuresare nominal <strong>and</strong> RPM's are less than 1,000.The “14”, “15”, “16” Series high-speed live centers are designedfor CNC lathes <strong>and</strong> increasingly heavy part weights. Coolantdeflectors extend the life of these accurate high-speed centers.Riten “44”, “48”, “51”, “34” Heavy-Duty <strong>and</strong> “55” Extra Heavy-Duty Series live centers are designed for both lathes <strong>and</strong>grinders. Triple row bearing designs provide robust performancewhile the “51” Advantage, “34” Heavy-Duty <strong>and</strong> “55”extra heavy-duty Series have full length spindles <strong>and</strong> biggerbearings for heavier loads.Our “46”, “49”, “65” <strong>and</strong> “56” Series are specialty centers. The“46” Series is designed for spline rolling applications. The “49”series has interchangeable points <strong>and</strong> can be used in CNCapplications where weights <strong>and</strong> RPM's are within the factorylimits of the center. The “65” Series pipe nose center isdesigned to run thin wall pipe <strong>and</strong> tubing at a wide range ofRPM's. The “56” Heavy-Duty Series bull nose center also runspipe, <strong>and</strong> very heavy parts such as rolls, castings <strong>and</strong> otherpieces with large center holes. The heavy-duty bull nose hasheavier bearings <strong>and</strong> greater rigidity than a pipe nose center.New items in this catalog include the following: The “40” Serieslight <strong>and</strong> X-light live centers for workpieces from 2 oz. to 10 lbs.,the versatile “60” Series multi-use live centers, the “17” SeriesConcentric spring loaded <strong>and</strong> bell head live centers, <strong>and</strong> the“61” Series mill taper dead centers for Cincinnati machines.SPECIALSPart Numbers: Riten specials are all stamped with a uniquepart number which aids in identifying the center. For example,a 46103-A0097 is a st<strong>and</strong>ard 46103 spline rolling live centerwith a custom spindle.In general, you can find basic information about a special byreferring to its base part number in the catalog. For instance,the taper, bearing configuration, <strong>and</strong> some tool clearances forthe 46103-A0097 are the same as the st<strong>and</strong>ard 46103.ALL CENTERSOrdering: To order a special, <strong>com</strong>plete the diagram on page37 or 38 that best describes the center you need or send a print.If you are already using a Riten st<strong>and</strong>ard that is similar to whatyou want, include that information as well. This information willhelp us select the bearing configuration best suited for yourapplication. If you don't know which live center is the correctchoice, be sure to include the RPM, workpiece weight, tailstockthrust <strong>and</strong> any other application data that will help usassist you in selecting the right center.Point Angles: To assure proper engagement of the workpiece,Riten st<strong>and</strong>ard live <strong>and</strong> dead center points have a 60degree, 15 minute included angle.Materials: Riten uses the finest bearing quality steel to manufactureits centers <strong>and</strong> <strong>com</strong>ponents. Riten live <strong>and</strong> dead centerbodies <strong>and</strong> spindles are heat-treated. This insures hardness<strong>and</strong> wear-resistant properties needed for center points. Thisalso allows for many regrindings, extending the center’s life.Bearing Life: When radial loads, axial loads <strong>and</strong> RPM aregiven for an application, the life hours of the live center can beaccurately calculated. Using a live center with more capacitythan needed is a safeguard against bearing failures due tooverload <strong>and</strong> variances of application. Weights are based on100 RPMs on 2,000 hours, using L10 life factor. If you areuncertain about an application or suspect that your workpieceweight or tailstock pressure will exceed the live center’s capabilities,call Riten for technical support.RITEN TECHNICAL SUPPORTPlease call our technical support department ifyou are not sure of the best center for yourapplication. Our customer service personnel willbe happy to help you select the correct centerto fit your needs.1-800-338-0027Or look us up on our Web site:http://www.riten.<strong>com</strong>39Call: 1-800-338-0027

Extend the Life of Your CenterNew lubricantReplace SpindleReplace Rear BearingReplace Grease SealReplace Front BearingsReturn to OriginalAccuracyOnce you select a Riten <strong>Live</strong> Center for its high degree of accuracy <strong>and</strong> dependability, we work tomaintain that quality far beyond the normal life of average live centers. We want your investment ina Riten <strong>Live</strong> Center to be a great investment.Riten Repair Program Saves You 60% of the Cost of a New Center■ Upon receipt, Riten St<strong>and</strong>ard <strong>Live</strong> <strong>Centers</strong> will be rebuilt to “Like New” condition at 40% of thecost of a new center. This is total reconditioning which includes:■ New spindle ■ New seal ■ Return to original accuracy■ New bearings ■ New lubricant ■ Approximate two-week deliveryRiten 35% Trade-in Allowance■ If a Riten St<strong>and</strong>ard <strong>Live</strong> Center is determined to be beyond practical repair, for any reason, apreferred customer trade-in allowance of 35% will be allowed toward the purchase of anequivalent new center at the time of purchase.Repairs <strong>and</strong> Allowances on Other Br<strong>and</strong>s■ Riten will repair most other manufacturers' centers or give you a trade-in allowance of up to35% on a quotation basis.Prices are subject to change without notice.www.riten.<strong>com</strong>40

Center Survey ProgramIn response to a number of customer requests,Riten has developed an in-plant survey programthat helps you gain control of live <strong>and</strong> dead centeravailability <strong>and</strong> cost.An authorized Riten representative, together withthe distributor of your choice, conducts a <strong>com</strong>pleteinventory of all centers at your plant. Theresult is a written report listing all centers foundat your location, their condition, st<strong>and</strong>ardizationsuggestions, identification of duplicates, <strong>and</strong>trade-in opportunities. This information isextremely valuable in making sure the right centersare on h<strong>and</strong>, streamlining your inventory, <strong>and</strong>cutting costs.This program is free to qualified customers. Torequest a center survey, call Riten CustomerService at 1-800-338-0027, or log on towww.riten.<strong>com</strong>. Samples of previous customersurveys can be provided on request, or can beviewed at www.riten.<strong>com</strong> under Success Stories.41Call: 1-800-338-0027

Free Face DriverCatalogFace Drivers, used in conjunction with live ordead centers, allow the <strong>com</strong>plete turning orgrinding of the entire outside diameter of aworkpiece in a single operation.This 30-page catalog contains <strong>com</strong>pleteinformation on the advantages of facedriving, <strong>and</strong> detailed specificationson Riten’s seven hydraulic designs<strong>and</strong> ten mechanical models.For your free Riten Face Driver Catalog,<strong>com</strong>plete the form below <strong>and</strong> fax this pageto 1-800-338-0717, or view the <strong>com</strong>pletecatalog at www.riten.<strong>com</strong>.NAME ____________________________________________________________________________TITLE ____________________________________________________________________________COMPANY ________________________________________________________________________ADDRESS ________________________________________________________________________CITY, STATE, ZIP ___________________________________________________________________PHONE ( _________ ) ________________________________E-MAIL _______________________________________________________________www.riten.<strong>com</strong>42

Why Riten means value in workholding products:• The industry’s largest selection of live & dead centers <strong>and</strong> face drivers• Design <strong>and</strong> production of special centers to meet specific requirements• Nationally known for supurb engineering• Same day shipping on st<strong>and</strong>ards; fast delivery on specials• Exclusive free Center Survey Program forqualified customers• Excellent repair program with generoustrade-in allowancesQuality workholding since 1933Riten Industries, Inc.1100 Lakeview Avenue ■ P.O. Box 340Washington Court House, OH 43160 USA740-335-5353 ■ FAX 740-335-4622www.riten.<strong>com</strong>Distributed by:Call: 1-800-338-0027 • FAX: 1-800-338-0717UIC #662503, FSC #3460, CAGE #05467, Harmonized Schedule B, 8466.20.1010, 8466.20.1090