12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TOX</strong> ® -ElectricDriveElectromechanical Servo-Systemsup to 700 kN press forceline-X1

<strong>TOX</strong> ® -ElectricDriveWhen work processes require highflexibility and precision, then conventionaldrives are often no longersufficient. This calls for the use ofelectromechanical servo drives.Tailored drives adjustable from0.25 – 700 kN.From the standard drive up tothe complex special machine.Advantages <strong>TOX</strong> ® -ElectricDrive• High life expectancy and robustnessdue to the compact planetaryroller screw spindle• Future-oriented project planningand very good retooling capabilitydue to its universal applicability• Maximum energy efficiency, i.e.significantly reduced operatingcosts compared to conventionaldrives• Special executions can be easilyrealized due to the modular design• High-dynamic performance by forceand distance regulation and thepossibility of transition speed• High precision due to adaptable,regulated deflection compensation• Simple and comprehensive parametersetting, control, service, via<strong>TOX</strong> ® softWare• Can be run on most commonlyused operating systems• Utmost safety up to and includingcategory 4 as per EN 954-1,Performance level e as per EN ISO13849-1 and SIL3 as per EN/IEC62061 is possible• Stand-alone operation withoutPC/PLC is possible• The system is pre-configured andcalibrated, thus, ready for serviceplug and playTypical applicationsClinching,<strong>TOX</strong> ® -sheet metaljoiningAssembling,Press-fitting,MountingInserting,Fastener-InsertionRiveting,Crimping,FlaringPunching,Piercing<strong>Co</strong>ining,Marking,StampingClamping,Tensioning,PeeningPressing,<strong>Co</strong>mpressing,BendingScope of deliveryThe set:<strong>TOX</strong> ® -Electric Power Module<strong>TOX</strong> ® SoftWareAxis-<strong>Co</strong>ntrollerline-XCable set consisting ofmotor cable, resolver cableand force sensor cableBallastresistorMechanicalHousing with planetary roller spindle(EPMS/EPMK 005 + 010 with ballscrew), working rod, bearing, resolver,motor with reducer, DMS force transducers.<strong>Co</strong>ntroller<strong>Co</strong>mplete control unit, incl. ballastresistor and Ethernet cable.Cable setApplicable for use with cable tracks(pay attention to the minimum bendingradius).1x Motor cable, 1x resolver cable, 1xforce sensor cable, (standard length5 m, additional lengths up to 25 m insteps of 5 m are available). Cables forrobotic applications available also onrequest.<strong>TOX</strong> ® SoftWare on CD-Rom• no licence fee• can be updated• Independent of operating system• free unlimited use without additionalcost2www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

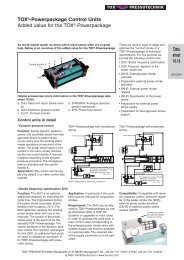

Network for modern productionProcess monitoring, operating, programming and diagnostics directly over your network.Quality dataProductionmonitoringEthernetProductiondataZone controllerStatistics<strong>TOX</strong> ® softWareLogfilePC/Laptop orIPC for servicing,parametersetting andvisualizationPLC controllerEthernetFieldbus e.g. Profibus<strong>TOX</strong> ® -ServiceThe decisive advantage• Dependable service worldwide(see brochure backside)• Remote service via Team Viewerpossible• Wide experience in various applications(general industry, automobile,medical technology, …)• <strong>TOX</strong> ® is your active partner duringthe entire project duration, from theplanning to the operation stages• Installation and process optimizationassistance• Training at the customer or in-houseat <strong>TOX</strong> ®• Calibration and repair serviceMaintenanceThe electromechanical servo systemsare designed such that only minimalmaintenance work is required.• Maintenance-free servo motors• Maintenance-free belt drive(for EPMK-/EPMR-Series)• Long lubrication intervals for thespindleFrom single components to complete machinesSystem solutions from one source. See page 18 - 19 for application examples.40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com3

The electromechanical servo driveDesign (example: EPMK 55)Anti-rotationfor spindle2 greasing points(plugged)Housing with planetaryroller spindleHousing withbelt driveEyebolt provision(both sides)Working rodMounting pilotBolt circle formounting screwsForce sensorsResolver(for distancemeasurement)ElectricalinterfacesServomotorGearbox(not withEPMK 005 + 010)Mounting instructions:The working rod should be guidedexternally in order to avoid anypotential side loads. You will find correspondingexamples in the <strong>TOX</strong> ® -Presses catalog. The connection tothe external guidance or ram guideplate must be done using a flexiblecoupling. For more information onour couplings, please see data sheet10.00 for <strong>TOX</strong> ® -Powerpackage accessories.Referencing:Generally, referencing is done usingthe internal positive stop of the servodrive. Alternatively, referencing canbe done using an external limitswitch.Greasing points/Force sensors:Special attention must be given tothe accessibility of the greasingpoints and force sensors (see EPMdata sheets).For CAD files, pleasevisit us atwww.tox-en.comPlanetary roller screwAdvantages:• <strong>Co</strong>mpact design• High life expectancy• High static capacity due to largebearing area• Highest transmission speed• Highest efficiency• Highest rigidity• High revolutionsPlanetary roller screws are designedfor high loads over millions of cyclesmaking them the best choice.Calculation of shortest possiblecycle time and estimation of lifetimeElectric motors always have the possibilityof thermal overload. Thereforewe calculate the specific load cycleand determine the minimum possiblecycle time for you. This sets the calculationfor the theoretical life time witha 90 % probability.<strong>Co</strong>nstruction of a planetary roller spindleSpindleThe data required or the calculationcan be found in your offer.We will gladly also send this onrequest.Planetary rollerSpindle nut4 www.tox-en.com 40.20<strong>12</strong><strong>12</strong>.en

l i n e -XModel overview• press force up to 700 kN• can be mounted to all <strong>TOX</strong> ® press frames (see catalog <strong>TOX</strong> ® -Presses)• can be mounted in any orientationElectromechanical servo drive withplanetary roller screw:• High speed• Highly dynamic• Precise• Long lifetime• Modular design• Precise force measuring• Integrated anti-rotationThe slim standard drive<strong>TOX</strong> ® -Electric Power Module EPMS5*, 10*, 25, 55, 100, 200 kN• Standard design• Minimum space requirementApplications:• Joining machines• Assembly machines• Special machinesThe compact drive<strong>TOX</strong> ® -Electric Power Module EPMK5*, 10*, 25, 55, 100, 200, 400, 500,700 kN• <strong>Co</strong>mpact design• Optional brake (see option)Applications:• Joining machines• Assembly machines• Special machines• Press drive for presses with thehighest safety requirements(see page 2)The robotic tongs drive<strong>TOX</strong> ® -Electric Power Module EPMR55, 100 kN• Super compact• Super light• With special flanging systemApplication:• Minimum space requirement• <strong>TOX</strong> ® robot mounted clinch unitstype TZ*EPMS/EPMK with ball screw and without gear reducer.Option:Holding brake/safety brake(Variant number 060)The EPMK drive can be additionallyequipped with a brake which is eitherbe used as a holding brake to avoid adescent of the working piston in caseof heavy tool weight or as a safetybrake which is a precondition for thehighest safety category (see page 2).How to order:EPMS 025.030.250.The maximum holding force of thebrake is at least 5 % of the correspondingnominal force. Technicaldata and dimensions incl. modelswith stronger brakes on request.Stroke [mm]Variant numberRated force kNDesign: S = standard/K = compact/R = robotic tongs driveElectric Power Module40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com5

Data sheet<strong>TOX</strong> ® -Electric Power Module EPMS 5 – 200 kNl i n e -XFor CAD files, pleasevisit us atwww.tox-en.comIJBUTRM***K***G WCØDØVLØHØFANA2A1greasing pointsforce sensorsDimensionsOrder no.Max.Nominalforce[kN] A A1 A2 B C D Ff7 G H I J K L M N R T U Vg6 WWeightapprox.kgStrokeTypeEPMS 005.030. 200 5 70 90 76 755 8xM8x16 60 50 13 25 15° 75° 25 M<strong>12</strong>x1.5 37 19 278,5 – 544 – – 16EPMS 010.030. 250 10 70 90 76 939 8xM8x16 60 50 10 30 15° 75° 20 M<strong>12</strong>x1.5 32 24 300 390 720 – – 21EPMS 025.030. 250 25 70 90 76 1047 8xM8x16 60 50 10 30 15° 75° 28,5 M22x2 48,5 24 300 390 568 18 7 25EPMS 055.030. 300 55 95 105 105.5 <strong>12</strong>18 8xM10x20 83 70 10 40 15° 75° 35 M30x2 60 34 316 456 678 26 7 43EPMS 100.030. 300 100 115 130 <strong>12</strong>2 1373 8xM<strong>12</strong>x25 98 75 15 50 15° 75° 36 M30x2 61 41 343 483 1316 26 7 72EPMS 200.030. 300 200 145 – 146 1618 8xM16x25 <strong>12</strong>5 100 18 70 15° 75° 46 M39x2 81 60 385 525 – – – 140Specifications EPMS 005.030.200 EPMS 010.030.250 EPMS 025.030.250 EPMS 055.030.300 EPMS 100.030.300 EPMS 200.030.300MechanicalRated force* push 5 kN 10 kN 25 kN 55 kN 100 kN 200 kNRated force pull 3 kN 3 kN 7.5 kN 16.5 kN 30 kN 60 kNStroke** 200 mm 250 mm 250 mm 300 mm 300 mm 300 mmMax. speed** 300 mm/s 300 mm/s 220 mm/s 200 mm/s 200 mm/s 100 mm/sMax. short-term10 % of rated forceoverloadPositional repeatability< ± 0.01 mmunder load 1)SensorsLoad cell 0.25 – 5 kN 0.5 – 10 kN 1.25 – 25 kN 2.75 – 55 kN 5 – 100 kN 10 – 200 kNAccuracy< +/- 0.5 % of rated force, pressingResolver x x x x x xResolution 0.00<strong>12</strong> mm 0.00<strong>12</strong> mm 0.0004 mm 0.0004 mm 0.0005 mm 0.0003 mmElectricalProtection classMotor/drive IP54 (as component)Mains supplysee axis controllerClimatic conditions+ 10 to + 40 °C, from 40 °C performance loss, max. 55 °C; air moisture < 75 %**, without condensation*Recommended operating range 5 – 100 %**Specials on request (colour, stroke, speed, ...)***Zero position of drive is the reference (marked) position + 3 mm1)in thermal transient conditionData sheets for spindles type EPQS can be found in the catalog for <strong>TOX</strong> ® -ElectricDrive line-Q²6www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

Data sheet<strong>TOX</strong> ® -Electric Power Module EPMK 5 – 700 kNl i n e -XOptional with brakefor category 4 safetyrequirementsFor CAD files, pleasevisit us atwww.tox-en.comJA1A2IBUTRM***K***GWØCXØDØYØVLPØHØFAgreasing pointsforce sensorsNDimensionsOrder No.Max.Nominalforce[kN] A A1 A2 B C D Ff7 G H I J K L M N P R T U Vg6 W X YStrokeTypeEPMK 005.030. 200 5 70 92 76 481 8xM8x16 60 50 13 25 15° 75° 25 M<strong>12</strong>x1.5 37 19 211 278.5 – 403 – – 24 59 16EPMK 010.030. 250 10 70 92 76 657 8xM8x16 60 50 10 30 15° 75° 20 M<strong>12</strong>x1.5 32 24 211 300 390 568 – – 24 59 22EPMK 025.030. 250 25 70 92 76 657 8xM8x16 60 50 10 30 15° 75° 28.5 M22x2 48,5 24 211 300 390 568 18 7 24 59 26EPMK 055.030. 300 55 95 <strong>12</strong>0 105.5 761 8xM10x20 83 70 10 40 15° 75° 35 M30x2 60 34 245 316 456 678 26 7 28 60 46EPMK 100.030. 300 100 115 156 <strong>12</strong>2 854 8xM<strong>12</strong>x25 98 75 15 50 15° 75° 36 M30x2 61 41 280 343 483 750 26 7 28 62 78EPMK 200.030. 300 200 145 170 146 973 8xM16x25 <strong>12</strong>5 100 18 70 15° 75° 46 M39x2 81 60 327.5 385 525 838 – – 52 94 154EPMK 400.030. 300 ±400 250 276 250 <strong>12</strong>60 8xM24x40 200 150 20 100 30° 60° 60 M64x2 <strong>12</strong>0 85 525 432 552 1074 – – 60 114 543EPMK 500.030. 300 ±500 315 330 321 1435 8xM24x48 250 200 20 <strong>12</strong>5 30° 60° 60 M64x2 <strong>12</strong>0 100 610 537 657 <strong>12</strong>43 – – 80 110 886EPMK 700.030. 300 ±700 315 330 321 1651 <strong>12</strong>xM24x48 250 200 20 150 30° 60° 60 M80x2 140 <strong>12</strong>5 610 622 742 1459 – – 80 110 1042Weightapprox.kgSpecifications EPMK 005.030.200 010.030.250 025.030.250 055.030.300 100.030.300 200.030.300 400.030.300 500.030.300 700.030.300MechanicalRated force* push 5 kN 10 kN 25 kN 55 kN 100 kN 200 kN 400 kN 500 kN 700 kNRated force pull 3 kN 3 kN 7.5 kN 16.5 kN 30 kN 60 kN 400 kN 500 kN 700 kNStroke** 200 mm 250 mm 250 mm 300 mm 300 mm 300 mm 300 mm 300 mm 300 mmMax. speed** 300 mm/s 300 mm/s 220 mm/s 200 mm/s 200 mm/s 100 mm/s 50 mm/s 50 mm/s 37.5 mm/sMax. short-term overload10 % of rated forcePositional repeatability< ± 0.01 mmunder load 1)SensorsLoad cell 0.25 – 5kNAccuracy0.5 – 10kN1.25 – 25kN*Recommended operating range 5 – 100 %**Specials on request (colour, stroke, speed, ...)***Zero position of drive is the reference (marked) position + 3 mm1)in thermal transient condition2.75 – 55kN5 – 100 kN 10 – 200kN< +/- 0.5 % of rated force, pressing20 – 400 kN or-20 – -400 kN25 – 500 kN or-25 – -500 kN35 – 700 kN or-35 – -700 kNResolver x x x x x x x x xResolution 0.00<strong>12</strong> mm 0.00<strong>12</strong> mm 0.0004 mm 0.0004 mm 0.0005 mm 0.0003 mm 0.0015 mm 0.0015 mm 0.0015 mmElectricalProtection classDrive IP54 (as component)Mains supplysee axis controllerClimatic conditions+ 10 to + 40 °C, from 40 °C performance loss, max. 55 °C; air moisture < 75 %**, without condensation40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com7

Data sheet<strong>TOX</strong> ® -Electric Power Module EPMR 55, 100 kNFor CAD files, pleasevisit us atwww.tox-en.coml i n e -XD2 D1C2C1C4XQC M***K***G WF3F4F2F1ØYØVLØJØHFC3NE2E1AA1A2A3Bgreasing pointsUTRPforce sensorsDimensionsOrder no.TypeStrokeMax.nominalforce[kN] A A1 A2 A3 B C C1 C2 C3 H7 C4 H7 D1 D2 E1 E2 F F1 ±0,02 F2 F3 F4 G H JEPMR 055.030. 100 55 95 <strong>12</strong>0 105.5 39 567 27 13 9 14 14 15 21 60 62 92.5 45 62.5 6 9 4 40 28 38EPMR 100.030. 100 100 115 144 <strong>12</strong>1.5 57 668.5 33 17.5 11 14 14 17 25 85 84 115.5 58 75.5 6 10 4 50 33 68Order no.Type Stroke K L M N P Q R T U Vg6 W X YEPMR 055.030. 100 18 M24x1.5 37 24 245 83 182 262 484 22 6 28 60EPMR 100.030. 100 17 M24x1.5 36 30 274 <strong>12</strong>0 218 298 565 22 6 28 62Weightapprox.kgSpecifications EPMR 055.030.100 EPMR 100.030.100MechanicalRated force* push 55 kN 100 kNRated force pull 16.5 kN 30 kNStroke** 100 mm 100 mmMax. speed** <strong>12</strong>0 mm/s <strong>12</strong>0 mm/sMax. short-term overload10 % of rated forcePositional repeatability under< ± 0.01 mmload 1)SensorsLoad cell 2.75 – 55 kN 5 – 100 kNAccuracy< +/- 0.5 % of rated force, pressingResolver x xResolution 0.00025 mm 0.0003 mmElectricalProtection classDrive IP54 (as component)Mains supplysee axis controllerClimatic conditions+ 10 to + 40 °C, from 40 °C performance loss, max. 55 °C;air moisture < 75 %**, without condensationThe tightly toleranced (H7) keywayson the mounting flange provide forprecise alignment of the drive withrespect to the direction of travel.The height and position of the drivecan be precisely adjusted usingspacer plates and keys.*Recommended operating range 5 – 100 %**Specials on request (colour, stroke, speed, ...)***Zero position of drive is the reference (marked) position + 3 mm1)in thermal transient condition8www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

The line-X ideal i n e -XNETWORK<strong>TOX</strong> ® softWareEthernetInterbus/ProfiNet/ProfibusRS 232/485PLC<strong>TOX</strong> ® -Axis-<strong>Co</strong>ntroller line-XStandardData busFieldbus• Ethernet TCP/IP• Profibus-DP• CanOPENOptionalInterbus, DeviceNet, ProfiNetas an alternative to Profibus.Other Fieldbus available overGateway, e.g. <strong>Co</strong>ntrolNet,Ethernet IP.Analog0 – 10 V; two available with 1 freeDigital8 inputs / 4 outputsexpandable to <strong>12</strong>8Description of controller for line-Q²can be found in the catalog for <strong>TOX</strong> ® -ElectricDrive line-Q²<strong>TOX</strong> ® -Axis-<strong>Co</strong>ntroller:the central intelligenceThe freely programmable axis controlleris a single axis controller with integratedlogic and servo amplifier. Theycontrol and monitor all functions ofthe <strong>TOX</strong> ® -ElectricDrive system.Advantages include the highly dynamicprocessing of pressing programsand fast reaction to variations in theprocess. During and after production,the process data can be taken fromthe controller for further processing ordocumentation.<strong>Co</strong>nfiguration and programmingwith the <strong>TOX</strong> ® SoftWareAll parameters, configuration and programfunctions residing inside thecontroller will be accessed with thesoftware module <strong>TOX</strong> ® -Worx in thesoftware package <strong>TOX</strong> ® softWare. The<strong>TOX</strong> ® softWare is delivered with each<strong>TOX</strong> ® -ElectricDrive. The followingsystem requirements are necessaryto access the <strong>TOX</strong> ® softWare in the axiscontroller:<strong>TOX</strong> ® softWare in the axis controller:• (Industrial) PC (Pentium III)• Recommended operating systemWindows XP or higher• Java Runtime 1.5.xCharacteristics:• Faster commissioning,Plug and Work• Extensive programming anddiagnostic functions• Parameter programming ofprocesses (online and offline)• Pre-configured and factory-calibrated• Maintenance-free• Display and monitoring of forcetravelprogressions• Graphical process analysis• Display of process results includingstatus, date and time stamp• Target position with monitoring offorce limits• Target force with monitoring ofposition limits• Window monitoring• Sequential control• Run according to PLC standardvalues- a PLC module is required for thisfunction (existing for S7, for othercontrols on request)• Deflection compensation• Abstract from the standard functionlibrary:- Force and/or travel controlledcommands- Functions for process control andprocess data recording- Graphical displays- Processing of input signals as wellas definition and setting of outputsignals- Taring and continuous monitoringof force sensors• Quality data management overEthernet and Fieldbus• <strong>Co</strong>mmissioning function withoutPLC• Input of the factory-specific calibrationvalues for force sensors• Integration of external force sensors(DMS and 0 – 10 V are possible)• Functional test of load cells• Highest safety category possible(see page 2)• Axis controller and ballast resistorcan be installed in any applicablestandard enclosure• Integrated overload functions formotor and servo amplifier• Electrical isolation betweencontroller and amplifier• 3-cable technology• Protection degree IP20• <strong>Co</strong>mpact design with direct ACsupply and integrated resolver andmotor connection• For spindle operation, includingprocess monitoring a PC is notrequired40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com9

<strong>TOX</strong> ® -Axis-<strong>Co</strong>ntroller line-Xl i n e -XPluggable axis controllerPluggable modulesPluggable I/O connectionsBasic applianceMainsconnectionCANonBOARDFieldbusmoduleEthernetTCP/IP moduleAnalog Inputs/OutputsDigital I/OMains filterMounting socketAxis controllerMotorconnectionMemorymoduleSafety moduleDiagnosticinterfaceResolverconnectionBy plugging the axis-controller to oroff the mounting base, it can bequickly connected or replaced.The plug-in system of the modulesmakes them easy to change:• Safety• Bus (communication)• IntelligenceCustomised solutions<strong>Co</strong>mplete panel in IP54. Customerspecific solutions possible on request.10www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

Functions and possibilites of line-Xl i n e -XProperties of line-X• Integrated PLC functionality,IEC 61131• Envelope curve monitoring• <strong>Co</strong>ntrolling remaining bottomthickness for clinching (qualitydimension X)• Integration of external distancesensorics• All modules are pluggable• Customized fault diagnostics arepossible• Customized functions are possible• Storage of the last 500 process datarecords• Memory for about 270 processes(for <strong>TOX</strong> ® standard workflows)• Six controllers are allocatedaccording to spindle sizes and arespecially matched to their capacityranges• Customized interfaces are generallypossibleCurrent volume of special functionlibraryProcess jumps: process calling, subprocesscalling• With process jumps it is possible todefine jumps into other processesduring and/or at the end of aprocess.Spindle data• By adding this function, you canchange the spindle data “on the fly”while the process is running. At theend of the process, the spindle datawill be reset to the default value.This gives you the possibility towork with additional force sensorson one spindle.Stopping the process• By adding this function, the processis stopped. This is useful in combinationwith the “conditional check”function.<strong>Co</strong>nditional check function (start-,target-, end condition)• Based on a selectable source (IO,Fieldbus, variable). This functiongives you the possibility to definemultiple conditional targets within aprocess.Set and evaluate integer and/or realvariables• This function is used to define aninteger and/or real variable for the“conditional check” function.General data and installation requirementsOperating conditionsCircuit type With grounded star-circuit Unlimited useIT-netFollow instructions for special measures!Standards<strong>Co</strong>nformity CE Low voltage directive (2006/95/EC)Approvals UL 508C Power <strong>Co</strong>nversion Equipment (File-No. 32659)EnclosureEnclosure type EN 60529 IP20 Not in the connecting area ofNEMA 250<strong>Co</strong>ntact protectionaccording to type 1the motor side connectors.Climatic conditionsOperation*IEC/EN 60721-3-3 EN 50178 3K3 (-10 ... +55 °C)Derating of rated output current +45 ... +55 °C: 2.5 %/°Cmax. 85 %, without condensationRelative air moisture*Attention: In case of an installation at 1000 m above sea level the reduction of the nominal current will be 5 %/1000 m.40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com11

<strong>TOX</strong> ® -Axis-<strong>Co</strong>ntroller line-Xl i n e -XMounting dimensions Mounting plate Mains filter for EPMx 10-1001560Size of the <strong>TOX</strong> ® -ElectricPower ModuleEPMx 005EPMx 010EPMx 025EPMx 055EPMx 100Dimensions a(mm)Weight(kg)90 5.3<strong>12</strong>0 8.1aSize ofthe <strong>TOX</strong> ® -ElectricPowerModuleDimensions (mm)a b b1 b2 e c1 d g mWeight(kg)EPMx 200EPMx 400206 606 556 630 294 170 585 6.5 <strong>12</strong>.5 26.5EPMx 500EPMx 700- Standard power supply: 3-phase 180 – 550 V AC (± 0 %), nominal power at 400 V AC 50/60 Hz- Dimensions of ballast resistor W/H/D: 30/60/355 mm, for EPM 200 and 400 upon request- Necessary built-in depth: 400 mmBlocks diagramUse of the <strong>TOX</strong> ® -ElectricDrive-System.Simplified diagram.line-XBallastresistorX105MMIMXI2Ethernet, programming,process dataPCStandard Interface, ProfibusMXI1Emergency switch buttonlight grille/protective doorapprox. 150 –500 msdelaySafetycategory 3MSIX4, X5E/SX3X7X105Force sensorResolverMotorServodriveEmergencyswitchundelayedEmergency switch box with adelay of approx. 150 – 500 msas per risk analysis and afterrunningtest<strong>Co</strong>ntrol, digital, PLCgreen: scope of delivery <strong>TOX</strong> ® -ElectricDrive Setred: supplied by customer<strong>12</strong>www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

<strong>TOX</strong> ® SoftWare Facts and Featuresl i n e -Xü User friendlyü Easy configurationü Integrated documentationü Designed for touch screen useü Platform independentü Supports all common interfacesü Several user levelsThe <strong>TOX</strong> ® SoftWare consists of the programs:Server (connection from thePC to the axis controller), Worx(sequence programming and processmanagement) and HMI (Human-Machine-Interface).<strong>TOX</strong> ® SoftWare WorxProject environmentThe Worx-Module has pre-configured,ready to use press functionblocks which can be customized tothe individual application. A dialogbased project-wizard will aid in theinitial setup and assist in the projectlayout. Projects can be saved andcopied as templates for future use.<strong>TOX</strong> ® SoftWare is a new, interactiveSoftware Suite with completely integratedcontrols and monitoring functionsspecifically designed for all applications.Project managementThe user is able to perform commissioningof the controller without theknowledge of any programminglanguage. Operating interface andsoftware are programmed by <strong>TOX</strong> ®and may be adapted in conformitywith customer’s request.The Windows based user interfacehas a familiar look and feel enablingquick and easy navigation throughthe projects. The Explorer-style menulayout supports easy administrationof press programs and file handling.Abstract from the function librarySequence programmingThe process cycle is configured byselecting process specific functionblocks from a menu, building a presssequence. No programming knowledgeis required.Click on the Menu function blockEnter the required parametersStart the process<strong>Co</strong>ntrol the processDiagram view<strong>Co</strong>mmissioningAn online mode enables the user tomonitor all controller functions andI/O in real time for commissioningand troubleshooting purposes.Curve mappingI/O DisplayJog function40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com13

<strong>TOX</strong> ® softWare HMI<strong>Co</strong>ntrol and visualize processesl i n e -XHMI-communication environment(HMI = Human-Machine-Interface)The <strong>TOX</strong> ® SoftWare HMI is used by the operator tocontrol and visualize the machine. The user interfaceof the software can be adapted by the operator. It isalso possible to configure the export of quality data.• Customizable user interface• Messages can be freely defined(errors, information, status, etc.)• Manual / Automatic screen• Diagnostic screen with logbook• <strong>Co</strong>unter (total, IO ,NIO, maintenance intervals)• Password protected user levels• Special screens with additional information can beintegrated (e.g. temperature indicators, travelmeasuring systems etc.)Manual operation screenCustomer specific quality data archivingQuality data managementThe <strong>TOX</strong> ® softWare provides export of quality data inExcel compatible CSV format for management of thequality data.Customer-specific solutions• During export, customer-specific data can be integratedin the export file and thus e.g. a unique piecepartnumber or a bar code can be added to thequality data.• Optionally, the export data can be linked to a customer-specificquality data archiving application (e.g. adatabase or a special export format).ArchivingThe <strong>TOX</strong> ® softWare HMI allows to save and to archive thedisplayed process curves. These curves can be displayedlater at any time, if necessary.Thus, the evaluation of the graphical process data at alater time is possible. Additionally, the archived processcurves can be exported in CSV format or as PDF file.Pressing module archiveBackup/RestoreThe <strong>TOX</strong> ® softWare provides comprehensive backup andrecovery functions.• Current project (controller parameter)• <strong>Co</strong>nfiguration settings of the <strong>TOX</strong> ® softWare HMI• <strong>Co</strong>mplete <strong>TOX</strong> ® softWare HMIWith the touch of a button the components can besaved sparately or all at once. This way, the easy recoveryof the data at any point in time is guaranteed.14www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

<strong>TOX</strong> ® softWare HMIl i n e -XProcess monitoring using the window techniqueGraphics moduleThe diagram module of the <strong>TOX</strong> ® SoftWare is used tomonitor the force/travel curve of a process by usinguser-defined windows.+ An almost unlimited number of force/travelwindows can be defined.Sequential control – expanded process administrationand simplified conversion scenarioSequence module+ Piecepart-specific parametrization at the push of abutton by selecting the desired sequence+ Maximum number of processes limited only by thehard drive capacity+ Dynamically controlled process flow with IO/NIOstatement+ Highly efficient manual workplaces thru singlecycle control possibilityProcess data export40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com15

<strong>TOX</strong> ® softWare HMI with line-Xl i n e -XMonitoringThe <strong>TOX</strong> ® SoftWare HMI collects the completeforce/travel diagrams and evaluates them with thehelp of freely programmable windows and/or envelopecurves. The values can be zoomed and displayedin different ways. SPC (Statistic Process <strong>Co</strong>ntrol)data can be archived.Clinching module with envelope curveSimple teach-in mode+ Automatic teaching of the processes and the forcelimits in the target window and the envelope+ No programming, just parameter setting+ Automatic scaling of diagramsProcess monitoring using envelope curvesThe envelope curve determines the path of theforce/travel course by two limit curves+ Full monitoring of the process between preset andtarget window, i.e. the travel/force characterisic mustnot exceed the upper and lower limits of the path+ For curves deviating from the envelope, the followingoptions can be choosen:Process will continue until target window isreachedProcess is immediately abortedClinching module process parameterClinch module for the modern sheet metaljoining technologyPrecise control of the quality dimension X (residualbottom thickness after the clinching process) with considerationof the machine deflection. Irregularities inproduction (fluctuations of sheet metal thickness, fluctuationsof surface condition…) can cause fluctuationsof the dimension X.Punch sidedeDie side<strong>Co</strong>ntroldimension "X"+ Active stabilization of variancesTechnical optimum achieved with an accuracy of±0.04 mm+ The residual bottom thickness is ensured independentof the material condition and the sheet metalcombinationPoint diameterPressing module process parameterPressing module for highly flexible pressingprocedures+ <strong>Co</strong>ckpit function due to complete parameter settingon one screen+ High precision possible, for example, by theintegration of different piecepart specific deflectionvalues in the process flow+ High repetitive accuracy, for example, by thepossible compensation of dimensional fluctuationsof piecepart lengths+ <strong>Co</strong>mplex process flows can be realized(several jump function, sub-process calling etc.)16www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

<strong>Co</strong>ntrol optionsl i n e -XIP54 enclosureFor axis controller assembly, includingfan or cooling unit. Specificationaccording to <strong>TOX</strong> ® standards. Specialmodels available on request (examplesee picture on page 10).Safety controlsAll the control variants described inthe following are type examinationtested.Basic controls:• Cycle initiation via 2-hand buttons.Both start buttons must be pressedduring the complete cycle.• Visualization over IPC with swivelarm to be mounted on pressframeOptions for basic controls:• Function: safe return stroke.The return stroke of a press takesplace automatically after completingthe press cycle. The start buttons donot have to be pressed during thereturn stroke.• Function: safe speed. The driveextends with a maximum speed of10 mm/s. The controls can beactivated with a 1-hand button orfoot pedal.<strong>Co</strong>ntrol for safety door:• Cycle initiation by 1-hand button orfoot pedal• The pressing process is only startedif the safety door is closedLight curtain controls:• Safety guard and control operationTwo operating modes are available:1. The light curtain has no controlfunction. Cycle initiation over1-hand button or foot pedal.2. The light curtain has a controlfunction. Cycle initiation after endof light curtain interruption(so-called Talot control)Special versions (on request):• Software integration of externalcomponents, e.g. sensors fortemperature, travel, etc.• Activation of additional movements,e.g. for a sliding table, rollingguards, etc.Industrial PC from <strong>TOX</strong> ® :The robust alternative to usual PC systemsTechnical dataTouchscreen17 inch TFT-LCDResolution <strong>12</strong>80 x 1024Dimensionfront panelOperating systemSoftwareRAMW: 483 mmH: 356 mmWindows XP<strong>TOX</strong> ® softWare2 GB DDR-RAMProcessor 1.6 GHz, Atom N 270Hard disk160 GB HDInterfaces4x USB, rear1x USB, front2x EthernetRS232Protection class IP65 frontsideIP20 backsideAmbient temperature 0 °C ... +40 °CPower supply24 VPanel mount version:IPC for installation in a control cabinet.Wall mount version:IPC including aluminum housing withinterface for installing the swivel armsystem type CP-L.Standard version for <strong>TOX</strong> ® safety controls:IPC including aluminum housingwith operating elements.Keyboard option:Basic keyboard and keyboardmounting. Sheetmetal mounting with keyboardand integratedmouse.Keyboard option:Professional keyboard and keyboardmounting. Membrane keyboard withintegrated mouse in aluminum housing.40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com17

l i n e -XAccessoriesGrease gun for re-greasing the <strong>TOX</strong> ® -ElectricDrive SystemsIt is a must for the long lasting operationof the drive.Order no.: ZFPGreasing intervals and amountaccording to the manual.Suitable for 400 g <strong>TOX</strong> ® -Specialgrease cartridge.400 g <strong>TOX</strong> ® -Special greasecartridgeOrder no.: ZFEAutomatic lubrication for<strong>TOX</strong> ® -Electric Power ModulePossible on request.Calibration equipment type ZKE© A.S.T. <strong>GmbH</strong>For the re-calibration of the <strong>TOX</strong> ® -Electric Power Module. The intervalfor the re-calibration should be definedby the customer.ApplicationsFrom the <strong>TOX</strong> ® building blocks to customised machinesScope of delivery:- Precision force sensor 10, 50, 100and 200 kN with connection cable(1.5 m) for digital display unit- Digital display unit (handheld)- Power supply (3 possibilities)- Batteries (3 pcs.)- USB cable via PC- USB power supply- USB cable (1.8 m)- Factory calibration report- CD-ROM with operating manualand PC software- Transport casePlanning and design of completepresses and special machines.<strong>TOX</strong> ® <strong>PRESSOTECHNIK</strong> helps yousolve your production demands withthe application of specific solutionsmade with components from ourstandard product line.Robot guided clinching tongsEPMR 55 used in <strong>TOX</strong> ® -Robotic tongs TZ for joining sheet metalEPMR 55Realization of electro-mechanic pressesof utmost safety level (see page2) and tested by the GermanEmployer’s Liability Insurance Association.Application:Metal joining with<strong>TOX</strong> ® -Round Joint(see brochure: <strong>TOX</strong> ® -Joining Systems)<strong>TOX</strong> ® -Robot tongs TZ(see brochure: <strong>TOX</strong> ® -Robot Tongs)Option:Robot couplingOption:Terminal box for startingthe compensating slideand the spray lubricationequipment, and manualinitiation for spraying alubricant on to the joiningarea, if required.18www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en

Applicationsl i n e -X<strong>TOX</strong> ® -Press series PCWith 2-column ram guide, forpressing and pulling operation,EPMK 400 with brake, protectivehood with exhaust fan, safetycontrols with function “safespeed”, stroke initiation via1-hand button or foot pedal<strong>TOX</strong> ® -Automatic stationC-frame type CEJ with CERstand, EPMR 55, <strong>TOX</strong> ® -Clinchingtools and <strong>TOX</strong> ® lube sprayequipment<strong>TOX</strong> ® -Press series MBwith 2-column ram guide, baseUUM, EPMK 55 with brake, safetycontrol with protective door and1-hand button with function “safespeed” for inching operation withopen protective door and<strong>TOX</strong> ® softWare<strong>TOX</strong> ® -Automatic stationseries CMBWith C-frame, UUM table,EPMK 100, control for automaticoperation with touch screen IPCwith <strong>TOX</strong> ® softWare<strong>TOX</strong> ® -Press series PCWith 2-column ram guide, EPMK100 with brake, protective hood withexhaust fan, safety 2-hand controls,function “safe return stroke” withoperator guarding and touch screenIPC with <strong>TOX</strong> ® softWaresee picture page 3<strong>TOX</strong> ® -Press series MAGWith 4-column ram guide,EPMK 100 with holding brake,slide table with locking cylinder,UUM of welded construction,safety control with protectivedoor and 1-hand button or footpedal, with touch screen IPCwith <strong>TOX</strong> ® softWare40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com19

Product Range<strong>TOX</strong> ® -Powerpackage<strong>TOX</strong> ® -PowerKurver<strong>TOX</strong> ® -ElectricDriveOur Worldwide Sales and Service Network<strong>TOX</strong> ® -FinePress<strong>TOX</strong> ® -Presses<strong>TOX</strong> ® -<strong>Co</strong>ntrols<strong>TOX</strong> ® -Monitoring<strong>TOX</strong> ® -Joining-Systems<strong>TOX</strong> ® -Tongs<strong>TOX</strong> ® -Punching<strong>TOX</strong> ® -<strong>Co</strong>ining<strong>TOX</strong> ® GMBH &<strong>PRESSOTECHNIK</strong>CO. <strong>KG</strong>Riedstrasse 4D-88250 WeingartenTel. +49 (0) 7 51 /5007-0Fax +49 (0) 7 51 /52391E-Mail: info@tox-de.comwww.tox-en.com<strong>TOX</strong> ® -Press-Fitting<strong>TOX</strong> ® -ProductionSystems40.20<strong>12</strong><strong>12</strong>.enSubject to technical alterations.20