12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

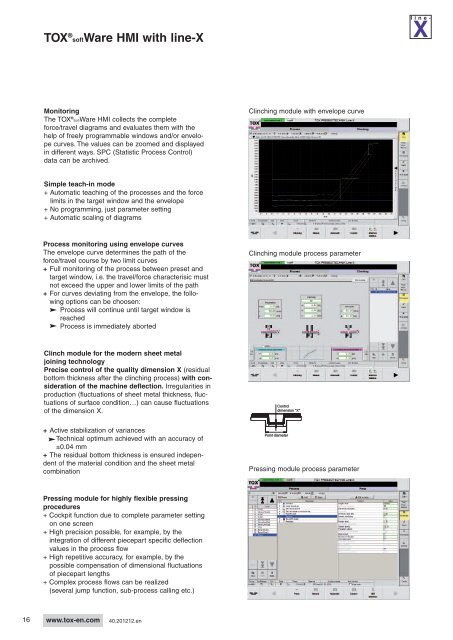

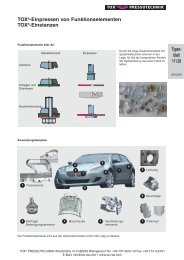

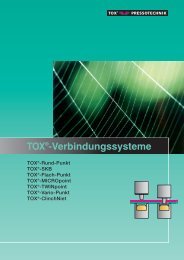

<strong>TOX</strong> ® softWare HMI with line-Xl i n e -XMonitoringThe <strong>TOX</strong> ® SoftWare HMI collects the completeforce/travel diagrams and evaluates them with thehelp of freely programmable windows and/or envelopecurves. The values can be zoomed and displayedin different ways. SPC (Statistic Process <strong>Co</strong>ntrol)data can be archived.Clinching module with envelope curveSimple teach-in mode+ Automatic teaching of the processes and the forcelimits in the target window and the envelope+ No programming, just parameter setting+ Automatic scaling of diagramsProcess monitoring using envelope curvesThe envelope curve determines the path of theforce/travel course by two limit curves+ Full monitoring of the process between preset andtarget window, i.e. the travel/force characterisic mustnot exceed the upper and lower limits of the path+ For curves deviating from the envelope, the followingoptions can be choosen:Process will continue until target window isreachedProcess is immediately abortedClinching module process parameterClinch module for the modern sheet metaljoining technologyPrecise control of the quality dimension X (residualbottom thickness after the clinching process) with considerationof the machine deflection. Irregularities inproduction (fluctuations of sheet metal thickness, fluctuationsof surface condition…) can cause fluctuationsof the dimension X.Punch sidedeDie side<strong>Co</strong>ntroldimension "X"+ Active stabilization of variancesTechnical optimum achieved with an accuracy of±0.04 mm+ The residual bottom thickness is ensured independentof the material condition and the sheet metalcombinationPoint diameterPressing module process parameterPressing module for highly flexible pressingprocedures+ <strong>Co</strong>ckpit function due to complete parameter settingon one screen+ High precision possible, for example, by theintegration of different piecepart specific deflectionvalues in the process flow+ High repetitive accuracy, for example, by thepossible compensation of dimensional fluctuationsof piecepart lengths+ <strong>Co</strong>mplex process flows can be realized(several jump function, sub-process calling etc.)16www.tox-en.com40.20<strong>12</strong><strong>12</strong>.en