12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

12/2012 - TOX PRESSOTECHNIK GmbH & Co.KG

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

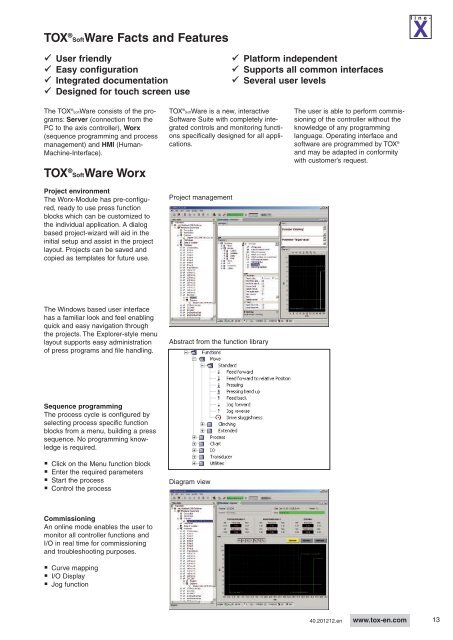

<strong>TOX</strong> ® SoftWare Facts and Featuresl i n e -Xü User friendlyü Easy configurationü Integrated documentationü Designed for touch screen useü Platform independentü Supports all common interfacesü Several user levelsThe <strong>TOX</strong> ® SoftWare consists of the programs:Server (connection from thePC to the axis controller), Worx(sequence programming and processmanagement) and HMI (Human-Machine-Interface).<strong>TOX</strong> ® SoftWare WorxProject environmentThe Worx-Module has pre-configured,ready to use press functionblocks which can be customized tothe individual application. A dialogbased project-wizard will aid in theinitial setup and assist in the projectlayout. Projects can be saved andcopied as templates for future use.<strong>TOX</strong> ® SoftWare is a new, interactiveSoftware Suite with completely integratedcontrols and monitoring functionsspecifically designed for all applications.Project managementThe user is able to perform commissioningof the controller without theknowledge of any programminglanguage. Operating interface andsoftware are programmed by <strong>TOX</strong> ®and may be adapted in conformitywith customer’s request.The Windows based user interfacehas a familiar look and feel enablingquick and easy navigation throughthe projects. The Explorer-style menulayout supports easy administrationof press programs and file handling.Abstract from the function librarySequence programmingThe process cycle is configured byselecting process specific functionblocks from a menu, building a presssequence. No programming knowledgeis required.Click on the Menu function blockEnter the required parametersStart the process<strong>Co</strong>ntrol the processDiagram view<strong>Co</strong>mmissioningAn online mode enables the user tomonitor all controller functions andI/O in real time for commissioningand troubleshooting purposes.Curve mappingI/O DisplayJog function40.20<strong>12</strong><strong>12</strong>.enwww.tox-en.com13