Laser Cutting System - Cincinnati Incorporated

Laser Cutting System - Cincinnati Incorporated

Laser Cutting System - Cincinnati Incorporated

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

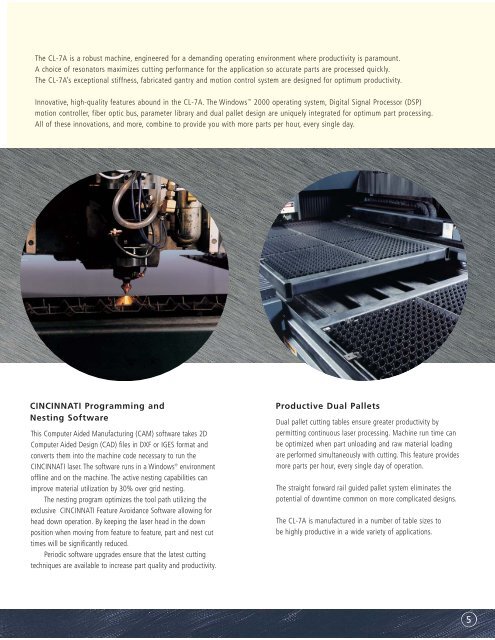

The CL-7A is a robust machine, engineered for a demanding operating environment where productivity is paramount.<br />

A choice of resonators maximizes cutting performance for the application so accurate parts are processed quickly.<br />

The CL-7A’s exceptional stiffness, fabricated gantry and motion control system are designed for optimum productivity.<br />

Innovative, high-quality features abound in the CL-7A. The Windows 2000 operating system, Digital Signal Processor (DSP)<br />

motion controller, fiber optic bus, parameter library and dual pallet design are uniquely integrated for optimum part processing.<br />

All of these innovations, and more, combine to provide you with more parts per hour, every single day.<br />

CINCINNATI Programming and<br />

Nesting Software<br />

This Computer Aided Manufacturing (CAM) software takes 2D<br />

Computer Aided Design (CAD) files in DXF or IGES format and<br />

converts them into the machine code necessary to run the<br />

CINCINNATI laser. The software runs in a Windows ® environment<br />

offline and on the machine. The active nesting capabilities can<br />

improve material utilization by 30% over grid nesting.<br />

The nesting program optimizes the tool path utilizing the<br />

exclusive CINCINNATI Feature Avoidance Software allowing for<br />

head down operation. By keeping the laser head in the down<br />

position when moving from feature to feature, part and nest cut<br />

times will be significantly reduced.<br />

Periodic software upgrades ensure that the latest cutting<br />

techniques are available to increase part quality and productivity.<br />

Productive Dual Pallets<br />

Dual pallet cutting tables ensure greater productivity by<br />

permitting continuous laser processing. Machine run time can<br />

be optimized when part unloading and raw material loading<br />

are performed simultaneously with cutting. This feature provides<br />

more parts per hour, every single day of operation.<br />

The straight forward rail guided pallet system eliminates the<br />

potential of downtime common on more complicated designs.<br />

The CL-7A is manufactured in a number of table sizes to<br />

be highly productive in a wide variety of applications.<br />

5