Laser Cutting System - Cincinnati Incorporated

Laser Cutting System - Cincinnati Incorporated

Laser Cutting System - Cincinnati Incorporated

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The solid heavy-duty construction of the CL-7A <strong>Laser</strong> <strong>Cutting</strong> <strong>System</strong> provides an excellent machine foundation for the resonator,<br />

beam delivery system, machine drive and motion controls. The frame is fabricated from thick steel plate with exceptional torsional<br />

stiffness to provide many years of consistent, accurate production.<br />

The CL-7A advanced design incorporates far fewer parts in the resonator, drive and control systems. Simplification of the power supply<br />

improves resonator reliability and maintainability. Fewer optics in the resonator and beam delivery system results in high reliability and<br />

lower maintenance. A reliable fiber optic bus replaces multiple wiring harnesses thus reducing susceptibility to electrical noise and<br />

improving reliability.<br />

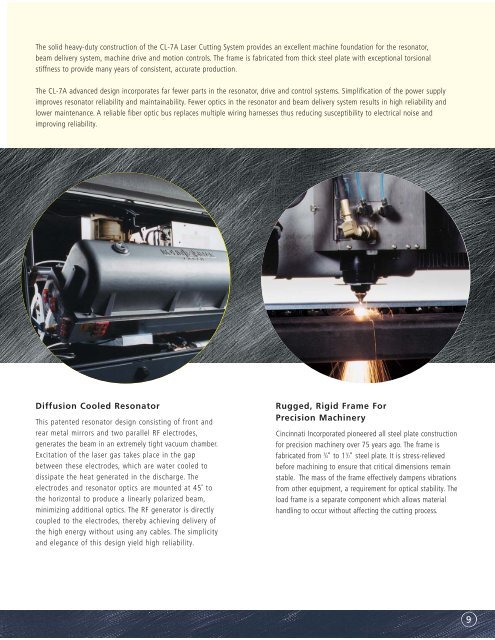

Diffusion Cooled Resonator<br />

This patented resonator design consisting of front and<br />

rear metal mirrors and two parallel RF electrodes,<br />

generates the beam in an extremely tight vacuum chamber.<br />

Excitation of the laser gas takes place in the gap<br />

between these electrodes, which are water cooled to<br />

dissipate the heat generated in the discharge. The<br />

electrodes and resonator optics are mounted at 45˚ to<br />

the horizontal to produce a linearly polarized beam,<br />

minimizing additional optics. The RF generator is directly<br />

coupled to the electrodes, thereby achieving delivery of<br />

the high energy without using any cables. The simplicity<br />

and elegance of this design yield high reliability.<br />

Rugged, Rigid Frame For<br />

Precision Machinery<br />

<strong>Cincinnati</strong> <strong>Incorporated</strong> pioneered all steel plate construction<br />

for precision machinery over 75 years ago. The frame is<br />

fabricated from 3 /4" to 1 1 /2" steel plate. It is stress-relieved<br />

before machining to ensure that critical dimensions remain<br />

stable. The mass of the frame effectively dampens vibrations<br />

from other equipment, a requirement for optical stability. The<br />

load frame is a separate component which allows material<br />

handling to occur without affecting the cutting process.<br />

9