Laser Cutting System - Cincinnati Incorporated

Laser Cutting System - Cincinnati Incorporated

Laser Cutting System - Cincinnati Incorporated

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

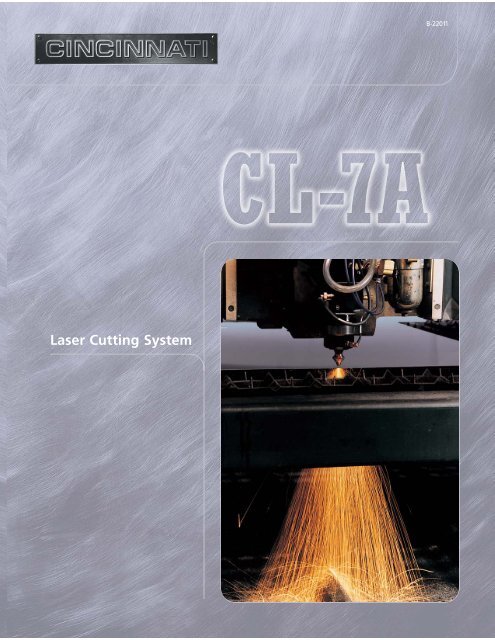

<strong>Laser</strong> <strong>Cutting</strong> <strong>System</strong><br />

B-22011

The CL-7A laser provides enhanced<br />

productivity, performance, accuracy and reliability.<br />

The CINCINNATI CL-7A <strong>Laser</strong> <strong>Cutting</strong> <strong>System</strong><br />

incorporates the latest in resonator technology, motion<br />

control systems, electronics, beam delivery, fiber<br />

optics communications and software technology to<br />

greatly enhance machine productivity, performance<br />

and accuracy. This machine outperforms punch presses<br />

and conventional lasers when cutting a wide range of<br />

materials and thicknesses.<br />

Customers who own a CL-7A <strong>Laser</strong> <strong>Cutting</strong><br />

<strong>System</strong> experience the following tangible benefits:<br />

• Enhanced Productivity<br />

• Accuracy and Part Quality<br />

• Machine Durability and Reliability<br />

• Unmatched Support Services<br />

3

4<br />

Enhanced productivity.<br />

Powerful, Simple, Accurate Controls<br />

The conveniently located, industrial PC with 15” color touchscreen<br />

display, Windows 2000 ® , full-sized keyboard and custom control<br />

panel provides the operator with a user-friendly Human Machine<br />

Interface (HMI). Complete part programs are quickly processed<br />

and optimized with cutting parameters from the PC. High-speed<br />

DSP motion controllers communicate with encoders and servo<br />

amplifiers through a high-speed fiber optic bus for noise-free data<br />

transfer. The unique combination of proven technologies increases<br />

processing speeds to improve productivity.<br />

Fast Setup<br />

The CL-7A is an ideal job shop laser, because it can productively<br />

cut a wide variety of materials, including: Mild Steel, Stainless<br />

Steel, Aluminum, Bronze, Wood, Acrylic, Rubber, Titanium and<br />

Galvanized. Most setups take only a few seconds. Easy access<br />

lens drawers and self-centering nozzle tips reduce the time<br />

required for the most complicated setups to only seconds.

The CL-7A is a robust machine, engineered for a demanding operating environment where productivity is paramount.<br />

A choice of resonators maximizes cutting performance for the application so accurate parts are processed quickly.<br />

The CL-7A’s exceptional stiffness, fabricated gantry and motion control system are designed for optimum productivity.<br />

Innovative, high-quality features abound in the CL-7A. The Windows 2000 operating system, Digital Signal Processor (DSP)<br />

motion controller, fiber optic bus, parameter library and dual pallet design are uniquely integrated for optimum part processing.<br />

All of these innovations, and more, combine to provide you with more parts per hour, every single day.<br />

CINCINNATI Programming and<br />

Nesting Software<br />

This Computer Aided Manufacturing (CAM) software takes 2D<br />

Computer Aided Design (CAD) files in DXF or IGES format and<br />

converts them into the machine code necessary to run the<br />

CINCINNATI laser. The software runs in a Windows ® environment<br />

offline and on the machine. The active nesting capabilities can<br />

improve material utilization by 30% over grid nesting.<br />

The nesting program optimizes the tool path utilizing the<br />

exclusive CINCINNATI Feature Avoidance Software allowing for<br />

head down operation. By keeping the laser head in the down<br />

position when moving from feature to feature, part and nest cut<br />

times will be significantly reduced.<br />

Periodic software upgrades ensure that the latest cutting<br />

techniques are available to increase part quality and productivity.<br />

Productive Dual Pallets<br />

Dual pallet cutting tables ensure greater productivity by<br />

permitting continuous laser processing. Machine run time can<br />

be optimized when part unloading and raw material loading<br />

are performed simultaneously with cutting. This feature provides<br />

more parts per hour, every single day of operation.<br />

The straight forward rail guided pallet system eliminates the<br />

potential of downtime common on more complicated designs.<br />

The CL-7A is manufactured in a number of table sizes to<br />

be highly productive in a wide variety of applications.<br />

5

6<br />

Accuracy and part quality.<br />

Power<br />

(Watts)<br />

DPC Relationship<br />

Feedrate (IPM)<br />

Dynamic Power Control (DPC )<br />

To ensure consistent kerf width and edge condition, the<br />

CL-7A employs a unique feature, Dynamic Power Control<br />

(DPC). DPC automatically and continuously adjusts laser<br />

power to the machine's feed rate which is critical in<br />

maintaining a consistent cutting process. DPC eliminates<br />

the need for conventional power control, which typically<br />

requires involved CNC programming techniques. Instead,<br />

cutting parameters stored in the control's material library<br />

are used by the DPC to maintain the power/feed rate<br />

relationship suitable for the particular material being cut.

The CL-7A sets a new standard for positioning accuracy and beam quality. An advanced motion<br />

control system, and DSP technology all combine to ensure accurate cutting head positioning.<br />

In addition to position accuracy, the CL-7A has Dynamic Power Control (DPC) which controls kerf<br />

width so that the parts are highly accurate.<br />

Low beam divergence and Dynamic Power Control enable an extremely consistent cutting process across an<br />

entire sheet of material. Every part cut on a CL-7A has a high quality edge with minimal heat affected zone.<br />

Advanced Resonator Technology<br />

The unique Diffusion Cooled Resonator design produces<br />

a laser beam with unequaled mode quality, beam stability<br />

and a full angle divergence of less than one milliradian.<br />

Exceptional mode quality and small divergence combine<br />

to create a beam that can be focused to a smaller, hotter<br />

spot than conventional resonators. This concentrated<br />

energy results in a cut with superior edge condition and<br />

a smaller heat affected zone.<br />

With the Diffusion Cooled Resonator, many materials including<br />

stainless steel, can be cut with lower nitrogen assist gas<br />

pressure. Lower assist gas pressure also allows plastic coated<br />

material to be cut more efficiently with less effect on the<br />

material coating.<br />

Preloaded Ball Screws and Linear Bearings<br />

Preloaded ball screws and linear bearings accurately drive<br />

the gantry and cutting head. The ball screws and linear bearings<br />

are located above the cutting area, and they are further<br />

protected from contaminates with bellows and covers.<br />

Digital Drive <strong>System</strong><br />

The positioning accuracy of the CL-7A is ±.001" over the<br />

entire cutting area. The fiber-optically linked brushless AC<br />

servomotors precisely drive the CL-7A laser head. Preloaded<br />

ball screws and guide bearings combined with a rigid<br />

aluminum gantry assure accurate positioning.<br />

7

8<br />

Machine durability and reliability.<br />

Beam Delivery <strong>System</strong><br />

The beam delivery system is enclosed in a constant volume,<br />

balanced chamber with two bellows each for X and Y<br />

motion. One bellows contracts while the other expands<br />

during cutting head travel to maintain a constant internal<br />

volume. The beam delivery system bellows is purged with<br />

dry, filtered, compressed air. This positive pressure beam<br />

purge assures a dry, clean environment for beam delivery,<br />

which prolongs mirror life in the demanding environment<br />

of many fabricating shops, and ensures stable power at the<br />

workpiece. The resonator and beam delivery systems are<br />

mounted on the main frame, providing beam delivery stability,<br />

compactness of design and no special foundation requirements.

The solid heavy-duty construction of the CL-7A <strong>Laser</strong> <strong>Cutting</strong> <strong>System</strong> provides an excellent machine foundation for the resonator,<br />

beam delivery system, machine drive and motion controls. The frame is fabricated from thick steel plate with exceptional torsional<br />

stiffness to provide many years of consistent, accurate production.<br />

The CL-7A advanced design incorporates far fewer parts in the resonator, drive and control systems. Simplification of the power supply<br />

improves resonator reliability and maintainability. Fewer optics in the resonator and beam delivery system results in high reliability and<br />

lower maintenance. A reliable fiber optic bus replaces multiple wiring harnesses thus reducing susceptibility to electrical noise and<br />

improving reliability.<br />

Diffusion Cooled Resonator<br />

This patented resonator design consisting of front and<br />

rear metal mirrors and two parallel RF electrodes,<br />

generates the beam in an extremely tight vacuum chamber.<br />

Excitation of the laser gas takes place in the gap<br />

between these electrodes, which are water cooled to<br />

dissipate the heat generated in the discharge. The<br />

electrodes and resonator optics are mounted at 45˚ to<br />

the horizontal to produce a linearly polarized beam,<br />

minimizing additional optics. The RF generator is directly<br />

coupled to the electrodes, thereby achieving delivery of<br />

the high energy without using any cables. The simplicity<br />

and elegance of this design yield high reliability.<br />

Rugged, Rigid Frame For<br />

Precision Machinery<br />

<strong>Cincinnati</strong> <strong>Incorporated</strong> pioneered all steel plate construction<br />

for precision machinery over 75 years ago. The frame is<br />

fabricated from 3 /4" to 1 1 /2" steel plate. It is stress-relieved<br />

before machining to ensure that critical dimensions remain<br />

stable. The mass of the frame effectively dampens vibrations<br />

from other equipment, a requirement for optical stability. The<br />

load frame is a separate component which allows material<br />

handling to occur without affecting the cutting process.<br />

9

10<br />

Motion <strong>System</strong><br />

Accuracy (over entire cutting area)<br />

Absolute positioning per axis: ................±0.001" (±0.025mm)<br />

Repeatability per axis: ..............................0.001" (0.025mm)<br />

<strong>Laser</strong> Type<br />

Diffusion cooled C0 2 resonator or fast axial flow (Class IV laser product)<br />

CNC Control<br />

Pentium ® -based PC; Windows 2000 ® operating system; network interface, digital signal processor motion controller.<br />

Machine Dimensions<br />

A<br />

Difussion<br />

Cooled<br />

A<br />

Fast Axial<br />

Flow<br />

B<br />

C<br />

D<br />

Weight<br />

48" X 96"<br />

(1,219 X 2,438mm)<br />

89"<br />

(2,259mm)<br />

101"<br />

(2,565mm)<br />

34.5"<br />

(876mm)<br />

335”<br />

(8,509mm)<br />

163"<br />

(4,140mm)<br />

26,300 lbs.<br />

Table Size<br />

60" x 120"<br />

(1,524 x 3,048mm)<br />

89"<br />

(2,259mm)<br />

101"<br />

(2,565mm)<br />

34.5"<br />

(876mm)<br />

381”<br />

(9,677mm)<br />

175"<br />

(4,445mm)<br />

31,300 lbs.<br />

Windows ® and Windows 2000 ® are registered trademarks of the Microsoft Corporation.<br />

Pentium ® is a registered trademark of Intel Corporation.<br />

Specifications<br />

72" x 144"<br />

(1,829 x 3,658mm)<br />

89"<br />

(2,259mm)<br />

101"<br />

(2,565mm)<br />

34.5"<br />

(876mm)<br />

472”<br />

(11,989mm)<br />

187"<br />

(4,750mm)<br />

35,800 lbs.

A<br />

D<br />

Standard Features<br />

• Breakaway Non-contact Head<br />

with Magnetic Coupling<br />

• Touchscreen PC Control<br />

• Compressed Air/Dryer Filter<br />

• Custom Macros<br />

• Fast Axial Flow or<br />

Diffusion Cooled Resonator<br />

• Dynamic Power Control (DPC )<br />

• Inch/Metric Programming<br />

• Ethernet Network Card<br />

Due to a continuing product development program, engineering data and dimensions are subject to change without notice.<br />

Certified foundation plans will be furnished for each installation.<br />

C<br />

B<br />

• Precision Ball Screw Drive <strong>System</strong><br />

• Programmable High Pressure Assist<br />

Gas (400 PSI Maximum)<br />

• Quick-Adjust Material Clamps<br />

• Remote Operator Station<br />

• Replaceable Material Support Grids<br />

• Safety Lights<br />

• Safety Mats<br />

• Scrap Removal <strong>System</strong><br />

• Fume Collection Plenum<br />

11

12<br />

Opposite Hand Configuration<br />

Lower Pallet Special Function (LPSF)<br />

Options<br />

Selecting a “mirror image” configuration enables one operator to control two machines<br />

from a single location. This increases productivity. In other cases, the opposite hand layout<br />

allows the laser to be placed in an area that would be unsuitable for the standard machine.<br />

Commonly called “bar cutting” or “square tube cutting,” this<br />

allows the cutting of parts on the lower pallet. These parts can be<br />

up to 7" (178mm) high and 24" (610mm) wide. LPSF includes special<br />

operating software and a Plexiglas reflection shield for the<br />

gantry. LPSF inhibits motion of the pallets, since large boxes would<br />

interfere with pallet motion.<br />

Fume Blower<br />

A high-volume blower with self-contained motor<br />

drive efficiently exhausts fumes from the entire<br />

cutting area of the laser.

Rapid Pierce<br />

Rapid pierce significantly reduces the amount of time it takes to<br />

pierce through 3 ⁄16" (4.8mm) or thicker materials. For parts or nests<br />

that require numerous pieces, the overall processing time is greatly<br />

reduced. An automatic oil mist and air blow-off are included.<br />

Tactile Foot<br />

The tactile foot holds the material<br />

flat on the cutting table. It is<br />

especially useful when processing<br />

very thin materials. Nonmetallic<br />

materials such as wood,<br />

plastic and acrylic can also be<br />

processed with this head.<br />

Optical Probe<br />

This locates sheets on the<br />

cutting pallet, and can be used<br />

to locate edges or to identify sheet<br />

position from two pre-punched<br />

holes. Once the optical probe<br />

locates these holes, it changes the<br />

orientation of the laser coordinate<br />

system to within ±0.005" to<br />

accurately cut the programmed<br />

parts out of the sheet.<br />

Auto-Focus Head<br />

The auto-focus head with one<br />

5” and 7.5” lens and drawer,<br />

reduces set-up time by controlling<br />

the focus adjustment. The<br />

focus is automated to change<br />

focus based on material<br />

requirements in the paremeter<br />

libriary. In additon, the focus<br />

can be progammed to compensate<br />

for beam length changes.<br />

Diode<br />

Alignment <strong>Laser</strong><br />

Assists in positioning<br />

the cutting beam in the<br />

proper starting location.<br />

This option also provides confirmation<br />

of shutter closure.<br />

Automatic<br />

Lubrication <strong>System</strong><br />

Grease is automatically pumped to the ball screws and<br />

linear bearings, reducing maintenance time and assuring<br />

the proper lubrication of critical components.<br />

13

14<br />

Ball Transfer Load Station<br />

Sheet or plate can be easily rolled on or off the pallet grid with<br />

ball transfers to speed material handling in the load/unload area.<br />

Pneumatically operated ball transfers are mounted on pipe stands,<br />

allowing them to pass through the pallet grid. They are electrically<br />

interlocked to prevent improper or unsafe motion.<br />

Modular Material Handling <strong>System</strong><br />

The Modular Material Handling <strong>System</strong> (MMHS) reduces<br />

labor and increases productivity by automatically loading<br />

and unloading the CL-7A. The basic functions of transporting,<br />

separating, and storing both raw materials and cut<br />

parts are performed by the MMHS. Unattended operation<br />

can be achieved using a variety of layouts. There are four<br />

(4) standard systems and limited custom layouts available<br />

to meet your specific<br />

needs. Due to<br />

its modularity,<br />

additional components<br />

and lasers<br />

can be added to<br />

the system. The<br />

MMHS is able to<br />

grow with your<br />

business.<br />

Fast-Axial Flow Resonator<br />

This resonator with higher power cuts thicker materials for<br />

improved versatility. The proven fast-axial flow resonator uses<br />

advanced turbine blower technology for reliability and low laser<br />

gas consumption.<br />

The RF power supply is compact and dependable, especially when<br />

compared to vacuum tube designs.<br />

Helical RF antennae excite the laser gas effectively; therefore, the<br />

resonator can produce more power with fewer internal optics.<br />

Fewer internal optics means lower operating and maintenance<br />

costs as well as higher reliability.<br />

The fast-axial flow features electronic shutter with trigger-discharge<br />

electrodes. This improves the pulsing characteristics of the<br />

RF resonator. The sharper pulses produce smoother cut edges and<br />

reduce the heat-affected zone bordering the cut. Fine cutting<br />

technology using enhanced pulsing allow intricate features to be<br />

accurately cut.

Operator Training<br />

CINCINNATI laser Operator Training Program at our facility helps<br />

ensure each customer achieves maximum productivity from<br />

their investment.<br />

Training programs are five days long. They include classroom and<br />

hands-on instruction for the proper and safe operation of a<br />

CINCINNATI laser. Instruction includes:<br />

• Introduction to the CINCINNATI laser system<br />

• Fundamentals of <strong>Laser</strong> Operation<br />

• Start-Up and Shutdown Procedures<br />

• Operation of Machine Controls<br />

• Programming and Machine Operation<br />

• Hands-On Operation<br />

• Maintenance<br />

• Safety<br />

Advanced Application Training<br />

CINCINNATI provides on-site advanced application training after<br />

installation of the laser. Customers understand even<br />

better the capabilities of the CL-7A, its ease of programming<br />

and its operating features. Other training is available, including<br />

ongoing applications assistance and software classes.<br />

Support Services<br />

Comprehensive Service<br />

CINCINNATI provides single-source responsibility for<br />

installation, service and parts, to ensure optimum performance and<br />

trouble-free operation. An extensive network of factory-service representatives<br />

are located throughout North America. A service technician<br />

is provided to perform the first planned maintenance.<br />

CL-7A Maintenance Training<br />

CINCINNATI offers maintenance training using classroom instruction<br />

and hands-on instruction. The Resonator Maintenance training covers<br />

planned maintenance. The Frame Maintenance topics include<br />

computer interfacing, software updating and reloading, component<br />

function and touble shooting.<br />

Fast Replacement Parts<br />

An extensive inventory of replacement parts is stocked, ensuring<br />

fast response. In-stock replacement parts are shipped within hours<br />

of your call, reducing downtime.<br />

The Parts Department is available weekdays from 8:00 A.M. until<br />

8:00 P.M. Eastern Time. Our rapid-response program enables customers<br />

to contact CINCINNATI after hours and on weekends for placing<br />

emergency orders or for obtaining technical or service assistance.<br />

Safety<br />

Every laser designed by CINCINNATI meets all applicable requirements<br />

of Federal Regulation 21CFR, Subpart J, as a Class IV laser product, at the<br />

date of manufacture, and applicable sections of American National<br />

Standards Institute Z136.1 for the safe use of lasers.<br />

Hazards inside the laser enclosure are guarded against unauthorized<br />

access. Clearly visible laser signs and symbols warn personnel in the<br />

area that a laser beam may exist within protected enclosures.<br />

Interlocks, safety mats and redundant deactivation systems guard<br />

against accidental access to the beam. An<br />

optional high-volume blower provides fume<br />

removal over the entire cutting area.<br />

A comprehensive operator’s manual<br />

provides instructions for safe operation.<br />

15

<strong>Cincinnati</strong> <strong>Incorporated</strong> headquarters includes manufacturing facilities, offices and a Technical Center.<br />

A technologically advanced manufacturer of<br />

metalworking machinery, <strong>Cincinnati</strong> <strong>Incorporated</strong><br />

places its reputation for quality and productivity<br />

behind every product.<br />

<strong>Cincinnati</strong> <strong>Incorporated</strong> maintains a modern<br />

industrial facility where product development,<br />

manufacturing, sales and support functions combine<br />

to assure complete customer service and<br />

satisfaction.<br />

An experienced, competent staff of engineers<br />

conducts research and development in new areas<br />

of metalworking technology, as well as ongoing<br />

improvement programs for current products.<br />

CAD/CAM machine design contributes to low-cost<br />

customization and shorter deliveries.<br />

Customers may visit the Customer Productivity<br />

Center to watch parts being cut and discuss<br />

unique applications with Product Specialists to<br />

verify production efficiency and savings.<br />

©2005 CINCINNATI INCORPORATED<br />

Like all CINCINNATI products, the CL-7A<br />

<strong>Laser</strong> <strong>Cutting</strong> <strong>System</strong> offers exceptional value.<br />

To learn more, call your CINCINNATI representative<br />

or phone us direct.<br />

The Customer Productivity Center demonstrates<br />

today’s latest shearing, forming, stamping<br />

and laser cutting technologies.<br />

Box 11111, <strong>Cincinnati</strong>, Ohio 45211<br />

Phone: (513) 367-7100<br />

FAX: (513) 367-7552<br />

E-Mail info@e-ci.com<br />

Web Site: www.e-ci.com<br />

Printed in U.S.A. 3M 1/05 API