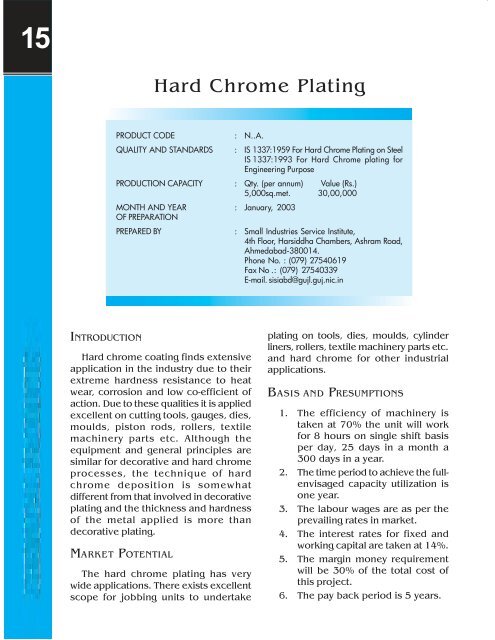

Hard Chrome Plating - Dc Msme

Hard Chrome Plating - Dc Msme

Hard Chrome Plating - Dc Msme

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

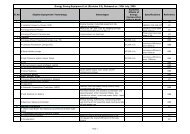

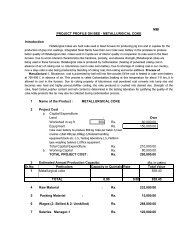

HARD CHROME PLATING83Repair and Maintenance 1,500Transportation charges 1,500Advertisement publicity 1,000Insurance 1,000Miscellaneous Expenses 1,000Total 10,000(v) Total Recurring Expenditure(per month)(Rs.)(i+ii+iii+iv)= Rs. 24,000+1,10,000+20,000+10,000= Rs. 1,64,000(vi) Total Working Capital (on 3 months basis)Rs. 4,92,000C. Total Capital Investmenti) Fixed Capital Rs. 7,47,900ii) Working capital Rs. 4,92,000Total Rs. 12,39,000Machinery UtilizationSince the unit totally depends on thejob work, the work should be assuredbefore starting the unit. The suggestedplant and machinery are sufficient toachieve the target.FINANCIAL ANALYSIS(1) Cost of Production (per year) (Rs.)(i) Total recurring cost 19,68,000(ii) Depreciation on building @ 5% 7,500(iii) Depreciation on machinery 47,7,95and equipment @ 10%(iv) Depreciation on office equipment @ 20% 10,000(v) Interest on total capital 1,73,586investment @14%Total 22,06,881Or say 22,07,000(2) Turnover (per year)Item Qty Rate Value(Sq.mtrs.) (Rs.) (Rs.)<strong>Hard</strong> chrome plating 15000 200 30,00,000(3) Net Profit (per year)= Turnover – Cost of productionRs. 30,00000 – 22,07,000= Rs. 7,93,000(4) Net Profit Ratio= Net Profit per annum × 100Turnover per annual= 7,93,000 × 10030,00000= 26.4%(5) Rate of Return= Net profit per annum × 100Total investment= 7,93,000 × 10012,39,900= 63.9%(6) Break-even Point(i) Fixed Cost(Rs.)a) Depreciation on Building @ 5% 7,500b) Depreciation on Machinery 47,795and Equipment 10%c) Depreciation on office 10,000Equipment @ 20%d) Insurance 12,000e) Interest on total investment 1,73,586e) 40% of salary and wages 1,15,200f) 40% of other contingent expenses 43,200Total 4,09,281Or say 4,09,000(ii) Net Profit (per year) Rs. 7,93,000B.E.P. = FC × 100FC + Profit per year= 4,09,000 × 1004,09,000 + 7,93,000= 34%Addresses of Machineryand Equipment Suppliers1. M/s. Jindal Electricals390-A Industrial Area “A”,Ludhiana-140003.

84HARD CHROME PLATING2. M/s. Usha Rectifier Corporation(India) Ltd.12, Mathura Road,Faridabad.3. M/s. Hind Rectifier Pvt. Ltd.Kamani Chambers,Nicol Road,Ballard Estate,Mumbai.4. M/s. Bright Metal IndustriesArakashan Road,Paharganj,New Delhi-110055.Addresses of Raw Material Suppliers1. M/s. Delta Chemicals Pvt. Ltd.J-1, Cama Industrial Zone,Goregaon (E),Mumbai-400063.2. M/s. Platewal processes andChemicalsPandra Road,Atlandra,Vadodra-390012.3. M/s. Grawer and Weil (India)Ltd.Sukh Sagar,6th Floor,N.S Patkar Marg, Chowpatty,Mumbai-400077.