POTATO CHIPS MAKING INTRODUCTION: India is one of ... - smallB

POTATO CHIPS MAKING INTRODUCTION: India is one of ... - smallB

POTATO CHIPS MAKING INTRODUCTION: India is one of ... - smallB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

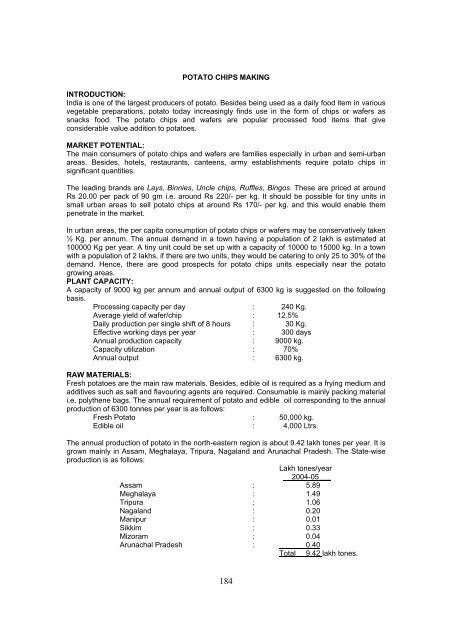

<strong>POTATO</strong> <strong>CHIPS</strong> <strong>MAKING</strong><strong>INTRODUCTION</strong>:<strong>India</strong> <strong>is</strong> <strong>one</strong> <strong>of</strong> the largest producers <strong>of</strong> potato. Besides being used as a daily food item in variousvegetable preparations, potato today increasingly finds use in the form <strong>of</strong> chips or wafers assnacks food. The potato chips and wafers are popular processed food items that giveconsiderable value addition to potatoes.MARKET POTENTIAL:The main consumers <strong>of</strong> potato chips and wafers are families especially in urban and semi-urbanareas. Besides, hotels, restaurants, canteens, army establ<strong>is</strong>hments require potato chips insignificant quantities.The leading brands are Lays, Binnies, Uncle chips, Ruffles, Bingos. These are priced at aroundRs 20.00 per pack <strong>of</strong> 90 gm i.e. around Rs 220/- per kg. It should be possible for tiny units insmall urban areas to sell potato chips at around Rs 170/- per kg. and th<strong>is</strong> would enable thempenetrate in the market.In urban areas, the per capita consumption <strong>of</strong> potato chips or wafers may be conservatively taken½ Kg. per annum. The annual demand in a town having a population <strong>of</strong> 2 lakh <strong>is</strong> estimated at100000 Kg per year. A tiny unit could be set up with a capacity <strong>of</strong> 10000 to 15000 kg. In a townwith a population <strong>of</strong> 2 lakhs, if there are two units, they would be catering to only 25 to 30% <strong>of</strong> thedemand. Hence, there are good prospects for potato chips units especially near the potatogrowing areas.PLANT CAPACITY:A capacity <strong>of</strong> 9000 kg per annum and annual output <strong>of</strong> 6300 kg <strong>is</strong> suggested on the followingbas<strong>is</strong>.Processing capacity per day : 240 Kg.Average yield <strong>of</strong> wafer/chip : 12.5%Daily production per single shift <strong>of</strong> 8 hours : 30 Kg.Effective working days per year : 300 daysAnnual production capacity : 9000 kg.Capacity utilization : 70%Annual output : 6300 kg.RAW MATERIALS:Fresh potatoes are the main raw materials. Besides, edible oil <strong>is</strong> required as a frying medium andadditives such as salt and flavouring agents are required. Consumable <strong>is</strong> mainly packing materiali.e. polythene bags. The annual requirement <strong>of</strong> potato and edible oil corresponding to the annualproduction <strong>of</strong> 6300 tonnes per year <strong>is</strong> as follows:Fresh Potato : 50,000 kg.Edible oil : 4,000 Ltrs.The annual production <strong>of</strong> potato in the north-eastern region <strong>is</strong> about 9.42 lakh t<strong>one</strong>s per year. It <strong>is</strong>grown mainly in Assam, Meghalaya, Tripura, Nagaland and Arunachal Pradesh. The State-w<strong>is</strong>eproduction <strong>is</strong> as follows:Lakh t<strong>one</strong>s/year2004-05___Assam : 5.89Meghalaya : 1.49Tripura : 1.06Nagaland : 0.20Manipur : 0.01Sikkim : 0.33Mizoram : 0.04Arunachal Pradesh : 0.40Total 9.42 lakh t<strong>one</strong>s.184

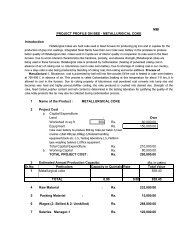

PROCESS :The main process steps in the production <strong>of</strong> potato chips are –(A. V<strong>is</strong>ual inspection and sorting <strong>of</strong> potatoes;(B. Washing;(C. Peeling and trimming;(D. Slicing and cutting;(E. Washing, sorting and dewatering;(F. Frying;(G. Cooling, salting and packing.MACHINERY:The main equipment required are –(A. Potato peeling machine cap. 40/50 kg per hour with 0.5 HP motor.(B. Slicing machine with arrangement to adjust thickness <strong>of</strong> slice complete withmotor etc.(C. Blancher(D. Spin dryer to extract excess mo<strong>is</strong>ture cap.4kg/charge taking 3 to 4 minutescomplete with motor.(E. Deep fat fryer(F. Electric polythene bag sealing machine upto 30cm wide.(G. Weighing machine.INFRASTRUCTURE:The main infrastructure requirements are –Shed : 1000 sq.ft.Power : 2.5 KWWater : 1600 ltrs/day.LOCATION:Keeping in view the availability <strong>of</strong> potatoes, the following locations are suggested.Assam : Barpeta, Mankachar, Tezpur, LakhimpurDibrugarh, Jorhat, Nagaon, Silchar.Meghalaya : Shillong, Tura, Williamnagar, Nongstoin,Jowai.Tripura : AgartalaArunachal Pradesh : TawangNagaland : Kohima, Mokokchung.Sikkim : Rumitek, Dentam, Brang, SomgochooTOTAL CAPITAL REQUIREMENT:The total capital requirement including fixed capital and working capital <strong>is</strong> estimated at Rs 4.29lakh as follows. Of th<strong>is</strong>, the project cost compr<strong>is</strong>ing fixed capital and margin m<strong>one</strong>y on workingcapital <strong>is</strong> Rs 3.59 lakh.(Rs. lakhs)(A. Fixed Capital:Land and BuildingPlant & Machinery 2.25M<strong>is</strong>c. Fixed Assets 0.50Preliminary & Pre-operative expenses 0.45Total (A) 3.20B. Working Capital:Raw materials 7 days 0.12Packing material 2 months 0.08Stock <strong>of</strong> fin<strong>is</strong>hed goods 7 days 0.19Working expenses 1 month 0.16Receivables 15 month 0.54185On rentTotal (B) 1.09Grand Total (A+B) 4.29 lakh

Note: Working capital may be financed as –Bank Finance: 0.70 lakhMargin M<strong>one</strong>y: 0.39 lakhMEANS OF FINANCE:Promoter’s contribution and equity ass<strong>is</strong>tance (35%)Term Loan (65%)TotalRs 1.26 lakhRs 2.33 lakhRs 3.59 lakhOPERATING EXPENSESThe annual operating expenses are estimated at Rs 9.25 lakh as given below:Raw materials and consumables –(Rs. lakh)Potato 50,000 kg. 2.34[ (a) 33000 kg @ Rs 4/kg.for 8 months and(b) 17000 kg @Rs 6/kg.for 4 months]Edible oil 4000 Ltrs@ Rs 55/Ltr. 2.20Additives, flavours, chemicals 0.40Packing materials –Polythene bags, tin containers 0.50Utilities 0.40Wages & salaries 1.50Rent 0.36Other overheads 0.40Selling expenses @ 5% on sales 0.53Interest on term loan @12% 0.28Interest on bank finance @15% 0.11for working capitalDepreciation 0.23Total 9.25SALES REALIZATION:Sales realization <strong>of</strong> 6300 kg <strong>of</strong> Potato chips @ Rs 170/- per kg would be Rs 10.71 lakh.PROFITABILITY:Based on the sales realization and the operating expenses, the pr<strong>of</strong>it (pre-tax) at rated capacitywould be Rs 1.46 lakh per year. Th<strong>is</strong> works out to a return on investment <strong>of</strong> 34%. The plant wouldbreak even at about 46% <strong>of</strong> the rated capacity.HIGHLIGHTS:The major highlights <strong>of</strong> the projects are as follows:Total Capital requirement : Rs 4.29 lakhPromoter’s contribution : Rs 1.26 lakhAnnual Sales realization : Rs 10.71 lakhAnnual operating expenses : Rs 9.25 lakhAnnual Pr<strong>of</strong>it (Pre-tax) : Rs 1.46 lakhPre-tax return on sales : 14%Break-Even Point : 46%Number <strong>of</strong> persons employed : 4 Nos.186

MACHINARY SUPPLIER:1. M/s Gardener’s Corporation, 2. M/s Hindustan Engineering Co.,6, Doctor’s Lane, 25/31, Ropewalk Street,(Near gole Market)Rampart Row.Post Box No. 299,Fort,New Delhi – 110 001. Mumbai – 400 0233. M/s Raylons Metal Works, 4. M/s Prakash Machine Tools,J.B. Nagar,5, Khetra Das Lane,Kondivitta Lane,(Besides Broadway Hotel),Andheri, Kolkata – 700 012Mumbai – 400 0595. M/s B. Sen Barry & Co.65/11, Rohtak Road,Karol Bagh,New Delhi – 110 005.187