FreshMix⢠Water Storage Mixing System - CB&I

FreshMix⢠Water Storage Mixing System - CB&I

FreshMix⢠Water Storage Mixing System - CB&I

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

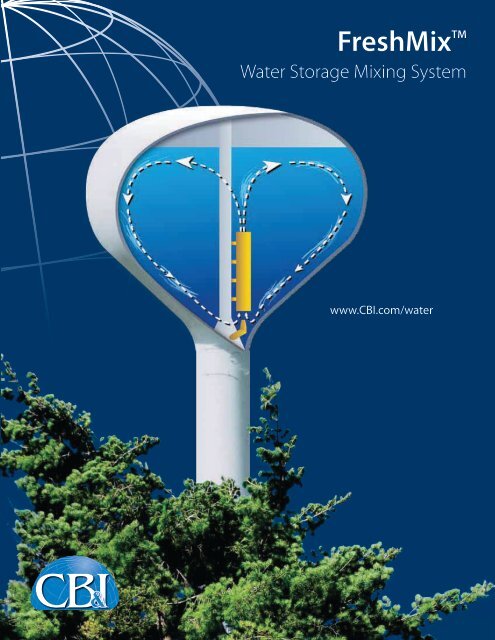

FreshMix TM<strong>Water</strong> <strong>Storage</strong> <strong>Mixing</strong> <strong>System</strong>www.CBI.com/waterEngineering Solutions . . . Delivering Results

FreshMix TM <strong>Water</strong> <strong>Storage</strong> <strong>Mixing</strong> <strong>System</strong>Proven DesignCB&I has completed more than 100 FreshMixinstallations since the patented eductor mixingsystem was developed during an extensive pilotand full-scale test program. The results from thistesting allowed CB&I engineers to develop amathematical model to accurately determine theeductor mixing flow rate.CB&I engineers also developed a computationalfluid dynamic (CFD) model to illustrate themixing effectiveness of a FreshMix system in awater storage tank. The CFD results show mixingflow patterns, velocities, and the degree towhich a chemical, such as chlorine, is distributedthroughout the tank volume.The FreshMix <strong>System</strong> Solution• Reduces taste and odor problems• Uses the motive force of the enteringwater to mix the contents in a tank• Is a simple and efficient mixing—system composedof only the eductor nozzle and a draft tube• Has no moving parts• Requires minimal hydraulic head to operate,reducing energy costs compared with othermixing systems• Uses no baffles or valves• Has no submerged electrical motors• Can be installed in new and existing tanksSpecificationsFor your next project, CB&I will gladly provide a sample specification, detail drawings, and a design datasheet foryour use. To ensure you receive a mixing system that meets your needs, CB&I recommends that you provide thedesign conditions and mixing requirements. Contact our regional sales offices to receive guidance on specifying aFreshMix system for your project.

FreshMix <strong>System</strong> AdvantagesStandpipeSReSeRvoiRSelevated WateRStoRage tankSReduces Undesired Tastes and OdorsThe FreshMix system eliminatesstagnant areas and creates a moreuniform residual chlorine concentrationthroughout the tank to prevent thegeneration of tastes and odors.Designed To Meet SpecificOperating conditionsInstead of just adding valves to helpcirculate the water, CB&I will designthe FreshMix system to maximize themixing rate, depending on how thetank is operated.Higher <strong>Mixing</strong> RateThe FreshMix system is normallydesigned to produce a flow multiplierof up to 3:1, but can be designeddepending on how the tank will beoperated.Quicker TurnoverDue to their high mixing rates, FreshMixsystems will turn over the tank contentsin a short time. This is especiallyimportant in tanks that are not filledfrequently.complete <strong>Mixing</strong>Unlike many other systems that provideonly local mixing, FreshMix systems blendthe entire contents of a tank.Eliminates Dual Risers andinlet PipingThe FreshMix system eliminates theneed, initial cost, and maintenance ofdual risers and inlet piping, as well astheir associated insulation, valve vault,valving and instrumentation.introduces No contaminantsNo oils, greases, exhaust fumes, orairborne contaminants are introducedinto the water since the FreshMix systemuses no centrifugal pumps, blowers, orother mechanical equipment.Minimizes Operating andMaintenance costsThe FreshMix system has no movingparts and is powered solely by theenergy of the incoming water. Thereare no valves requiring periodic, andexpensive, replacement or mechanicalequipment to operate and maintain.Minimizes capital costsThe FreshMix system consists of paintedcarbon steel components that are easilyand economically integrated with thetank, which also makes it NSF compliant.Simple DesignNo baffles, valves, or replacement partsare required, unlike other mixing systemdesigns. There are also no moving partsor electrical motors (submerged orotherwise).cb&i’s patentedFreshMix mixing systemis an economicalmethod to reduce tasteand odor formation innew or existing potablewater storage tanks.

Engineering Solutions…Delivering ResultsCB&I has provided superior value and reliability to the water storage industry formore than a century. We built our first standpipe in 1893 and our first elevated waterstorage tank in 1894, pioneered the transition to welded steel tanks in the 1930s, andinvented the original <strong>Water</strong>sphere®, <strong>Water</strong>spheroid® and Hydropillar® storage tanks.We have built more than 25,000 water storage tanks around the world and inventedthe FreshMix mixing system to ensure adequate disinfection in storage tanks.CB&I is one of the few companies with the capability to self-perform all facetsof a water storage project, from conception to completion. We can handle theengineering, foundation construction, fabrication, tank construction and painting.This comprehensive approach helps our customers achieve the most cost-effectiveand functional solutions. With our in-house personnel, we also provide completedesign-build services to guide all aspects of a project, from preliminary planning topost-construction services.At CB&I, we focus on providing water storage solutions safely, to the highestquality standards, on time, and at a competitive price. We are ready with skilled andexperienced people to deliver your next FreshMix system project. Contact one of ourregional sales offices or visit our website at www.cbi.com/water.Corporate Office:The Hague, NetherlandsWorldwide Administrative Office:The Woodlands, Texas USAOnly employees, agents, or representatives authorized under and pursuant to writtenagreement with CB&I are authorized to distribute this brochure to an actual orpotential client of CB&I. ©Copyright 2012 by Chicago Bridge & Iron Company.All rights reserved. Printed in USA. B9335-1 Rev1