SCOTT AST™ DRYER

SCOTT AST™ DRYER

SCOTT AST™ DRYER

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

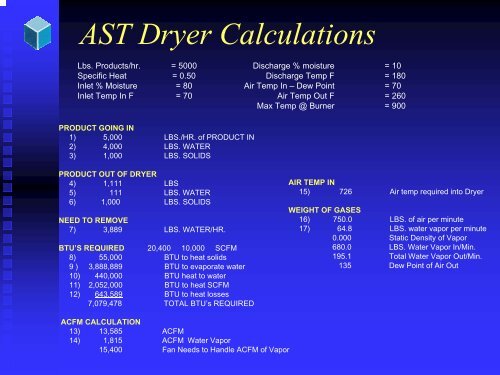

AST Dryer CalculationsLbs. Products/hr. = 5000 Discharge % moisture = 10Specific Heat = 0.50 Discharge Temp F = 180Inlet % Moisture = 80 Air Temp In – Dew Point = 70Inlet Temp In F = 70 Air Temp Out F = 260Max Temp @ Burner = 900PRODUCT GOING IN1) 5,000 LBS./HR. of PRODUCT IN2) 4,000 LBS. WATER3) 1,000 LBS. SOLIDSPRODUCT OUT OF <strong>DRYER</strong>4) 1,111 LBS5) 111 LBS. WATER6) 1,000 LBS. SOLIDSNEED TO REMOVE7) 3,889 LBS. WATER/HR.BTU’S REQUIRED 20,400 10,000 SCFM8) 55,000 BTU to heat solids9 ) 3,888,889 BTU to evaporate water10) 440,000 BTU heat to water11) 2,052,000 BTU to heat SCFM12) 643,589 BTU to heat losses7,079,478 TOTAL BTU’s REQUIREDAIR TEMP IN15) 726 Air temp required into DryerWEIGHT OF GASES16) 750.0 LBS. of air per minute17) 64.8 LBS. water vapor per minute0.000 Static Density of Vapor680.0 LBS. Water Vapor In/Min.195.1 Total Water Vapor Out/Min.135 Dew Point of Air OutACFM CALCULATION13) 13,585 ACFM14) 1,815 ACFM Water Vapor15,400 Fan Needs to Handle ACFM of Vapor