the largest selection of low profile pancake head ... - Triangle Fastener

the largest selection of low profile pancake head ... - Triangle Fastener

the largest selection of low profile pancake head ... - Triangle Fastener

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

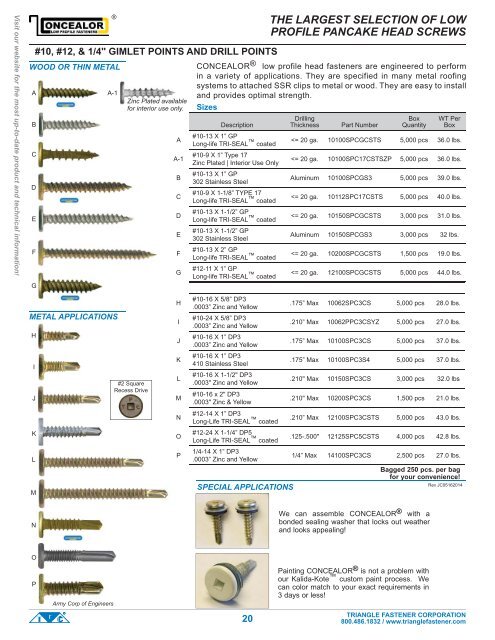

®CONCEALORULTRA LOW PROFILE FASTENERNeed it Ultra Low?50% thinner than a standard<strong>pancake</strong> <strong>head</strong>.No more dimpling <strong>of</strong> <strong>the</strong> panel.Special taperIncrease <strong>head</strong> strength andcountersinks into <strong>the</strong> wood.Coarse threadPulls fastener tight into <strong>the</strong>wood without stripping andincreases pullout.Minimum 1" thread lengthProvides full thread engagementfor increased pullout!Sharp gimlet pointFast penetration into steelclips up to 24 gauge thick!ULTRA LOW PROFILEFASTENERSUse <strong>the</strong> original ultra <strong>low</strong> pr<strong>of</strong>ile fastener...CONCEALOR ® ULPThe CONCEALOR ® ULP is an ultra <strong>low</strong> pr<strong>of</strong>ile screwengineered to attach standing seam ro<strong>of</strong> clips to wood.They are <strong>the</strong> preferred screw for attaching clip-lessmetal ro<strong>of</strong> panels, and are easy to install providingoptimal strength. ULP's are supplied with TRI-SEAL1,000-hours salt spray coating which can be used in ACQand fire treated lumber.Visit our website for <strong>the</strong> most up-to-date product and technical information!ABCDNow available in lengthsup to 2-1/8"!Zinc Plated availablefor interior use only.#2 SquareRecess DriveAA-1BCDSizesDescription#10-9 X 1-1/8” ULP (CS)Long-life TRI-SEAL coated#10-9 X 1-1/8” ULP (CS)Zinc Plated Interior Use Only#10-9 X 1-1/8” ULP (410 SS)Passivated#10-9 X 1-5/8” ULP (CS)Long-life TRI-SEAL coated#10-9 X 2-1/8” ULP(CS)Long-life TRI-SEAL coatedDrillingThickness24ga maximumBagged 250 pcs. per bagfor your convenience!Part NumberBoxQuantityWT PerBox

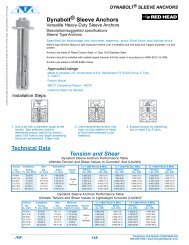

Visit our website for <strong>the</strong> most up-to-date product and technical information!CLIP DETAILS1-7/8”2-1/4”®STANDING SEAM ROOF CLIPAND SCREWS - LOAD TESTEDAre you tired <strong>of</strong> having to calculate <strong>the</strong> uplift loads<strong>of</strong> SSR clips used in your metal ro<strong>of</strong> assembly?We have a solution...<strong>the</strong> SSR CLIP KIT!We provide a 1-7/8" tall fixed clip that is UL classified and hasbeen independently tested to certify its ultimate uplift loadcapacity.Clips are supplied with approved fasteners that meet yourspecific application requirement.Our SSR fixed clips are engineered to high standards. They areproduced to tight tolerances so <strong>the</strong>y install easily and perform withmany different panel brands. Specifically designed for a Snap-Lockstyle SSR panel.• Clip is high strength 18ga. galvanized steel for superior performance.• 1-7/8" tall providing additional clearance between <strong>the</strong> panel and <strong>the</strong>decking for better air f<strong>low</strong> and energy efficiency.• UL classified.• Compatible for PAK-CLAD, Snap-Clad,and Fabral thin seam panels.FASTENER DETAILSOur CONCEALOR® <strong>low</strong> pr<strong>of</strong>ile <strong>head</strong> screws are engineered toperform in a variety <strong>of</strong> applications. They are easy to install andprovide exceptional pullout.• High performance CONCEALOR® Low Pr<strong>of</strong>ile ClipScrews for a variety <strong>of</strong> substrates.• Carbon steel with TRI-SEAL long-life coating orstainless steel.• Square recess drive for optimal installation stability.• #10, #12, #14 diameters in lengths up to 9" long!• MIAMI-DADE approved!TECHNICAL DATAThese loads are from tests conductedat an independent laboratory. They arevalues for <strong>the</strong> clip assembly; where <strong>the</strong>clip is attached to <strong>the</strong> substrate usingtwo (2) screws.A load was applied to <strong>the</strong> vertical leg<strong>of</strong> <strong>the</strong> clip until failure LOADoccurred.Loads are ultimate foreach clip and screwassembly.Report #JS031711Concealor is a registered trademark <strong>of</strong><strong>Triangle</strong> <strong>Fastener</strong> Corporation. Copyright 2011RUpload Test Results - Clip and Screw Assembly - Average UltimatePLYWOOD OSB 2X PINE METAL (50KSI minimum)ScrewType 1/2” 5/8” 3/4” 7/16” 19/32” 23/32” 1” EMBD 1 22 ga 1 20 ga 18 ga 16 ga 14 ga#10-9 GP 486 598 834 217 491 538 978#12-14 GP 436 665 786 182 491 678 800#10 DP3 661 *1194 *1334#12 DP3 706 *1088 *1296#14-13 DP1 520 725 *1173 234 552 611 *1175 736 8391/4 DP3 683 *1047 *1325* Denotes clip failure | Tore ClipClip dimensions: 1-1/8" x 3 1/2" x 1 7/8" | 18 ga. Galvanized Steel | 1/2" Screw Offset1. Denotes test set-up using two inches <strong>of</strong> foam insulation on top <strong>of</strong> deck. A 16 ga. burying platewas between <strong>the</strong> clip and <strong>the</strong> insulation.NOTE: To produce values listed in this chart, clip must be installed using CONCEALOR® <strong>pancake</strong><strong>head</strong> screws only.Load values are a result <strong>of</strong> tests conducted at Farabaugh Engineering Services, McKeesport PA.Report # XXXXX. Certified test report available.CONTACT TFC FOR SPECIFIC LENGTHDISCLAIMER: ALL DATA AND SPECIFICATIONS ARE BASED ON LABORATORY TESTS. APPROPRIATE SAFETY FACTORS SHOULDBE USED BY THE USER OR SPECIFIER. DETERMINING THE PROPER FASTENER IS THE RESPONSIBILITY OF THE USER ORSPECIFIER. BECAUSE APPLICATION CONDITIONS VARY, WE ASSUME NO LIABILITY FOR THE USE OF THIS INFORMATION.TRIANGLE FASTENER CORPORATION800.486.1832 / www.trianglefastener.com20-B

#12-24 DP4 - THICK METAL®#12 DP4 CONCEALOR® Heavy Dutyfasteners can drill and tap up to 1/4"steel! Great for heavy gauge applicationsrequiring a <strong>low</strong> pr<strong>of</strong>ile <strong>head</strong>. Coatedwith an epoxy finish that exceedsFM4470 specification assuring long-lifecorrosion resistance.#3 SquareRecess DriveVariety <strong>of</strong> LengthsATHE LARGEST SELECTION OF LOWPROFILE PANCAKE HEAD SCREWSFasten into metal from 14 gauge up to 1/4"(For optimal strength, consider using our 1/4-14 DP3 listed on page 22.)ABCDEFDescriptionAttachmentThicknessPart NumberCartonQuantityWt PerM Pcs#12-24 x 1-3/8” DP4

Visit our website for <strong>the</strong> most up-to-date product and technical information!#14 DP1 CONCEALOR ® withTRI-SEAL coating provides<strong>the</strong> best corrosion protection in<strong>the</strong> industry! Salt spray testsconfirm that TRI-SEALcoating provides over 10 timesmore resistance to red rust thanblack epoxy coated screws. It isengineered to perform in avariety <strong>of</strong> applications.FM approved for preliminaryattachment <strong>of</strong> nail baseinsulation without <strong>the</strong> use <strong>of</strong>stress plates.Here is why we use a special thread...We use a buttress thread form that providesexceptional clamping loads. It is specified inmany metal ro<strong>of</strong>ing systems to attached SSRclips over rigid insulation into metal deck.CONCEALOR® withButtress Thread®#14-13 DP1 with TRI-SEAL 1,000 hour salt spray coatingOrdinary ThreadFormLonger 4-1/4" thread on 5", 6", 7", 8", 9" lengths.#2 SquareRecess Drive“Flat" thread keeps<strong>the</strong> joint tight“Tapered" threadtends to cause <strong>the</strong>joint to loosenSizesDescriptionAttachmentThicknessPart NumberCartonQuantityWt PerCarton#14-13 x 1-1/2” DP1

Visit our website for <strong>the</strong> most up-to-date product and technical information!A®THE LARGEST SELECTION OF LOWPROFILE PANCAKE HEAD SCREWS1/4-14 DP3 - DRILL AND TAP UP TO 1/4" THICK STEELFasten into metal from 20 gauge up to 1/4"#14 DP3 CONCEALOR ® <strong>pancake</strong> <strong>head</strong> screws are designed for heavy gauge applications and can drilland tap up to 1/4” steel. The 1/4-14 thread produces greater strength and resists bending compared tosmaller diameter screws.These screws are coated with TRI-SEAL long-life coating that exceeds FM4470 specification and provide1,000-hours salt spray performance.SPECIAL HEAD DESIGN• 5/8” diameter <strong>head</strong> increasespullover strength andminimizes dimpling.• #3 square recess drive providesstability during installation.Choose from a variety <strong>of</strong> lengths!DescriptionAttachmentThicknessPart NumberCartonQuantityWt PerM PcsA 1/4-14 x 2” DP3 1.000” Max 14200SPC3CSTS 1,000 pcs 19#B 1/4-14 x 3” DP3 1.375” to 2.125” 14300SPC3CSTS 1,000 pcs 27#C 1/4-14 x 4” DP3 1.625” to 3.125” 14400SPC3CSTS 500 pcs 34#D 1/4-14 x 5” DP3 2.750” to 4.125” 14500SPC3CSTS 500 pcs 42#E 1/4-14 x 6” DP3 3.750” to 5.125” 14600SPC3CSTS 500 pcs 50#F 1/4-14 x 7" DP3 4.750" to 5.125" 14700SPC3CSTS 500 pcs 50#G 1/4-14 x 8" DP3 5.750" to 7.125" 14800SPC3CSTS 250 pcs 34#PERFORMANCE SPECIFICATIONSPullout Strength (Ultimate Average in Pounds)Gauge16ga(.060”)14ga(.075”)12ga(.105”)1/8”(.125”)3/16”(.188”)1/4”(.250”)BCDESpecial “un-threaded” section is engineered to eliminate“jacking” when installing insulated panels!Pullout 579 736 1232 2011 3291 *4,0601 Test at Farabaugh Engineering | Report # T196-14Contact TFC for tensile strength <strong>of</strong> test material* Exceeds tensile strengthRev JC060614Mechanical andPhysical PropertiesThread Diameter: 1/4” (.250” nominal)Thread Pitch: 14Head Diameter: .625"Head Thickness: .100"Material: C-1022Case Hardened per SAE J-78Tensile Strength: 3,850 lbs.Torsional Strength: 150 lbs.-in.Shear Strength: 2,600 lbs.REV.JES082712FGSPECIAL APPLICATIONSUse to attach a variety <strong>of</strong> material to steel up to 1/4” thick!ARCHITECTURALINSULATED PANELSSTRUCTURALINSULATED PANELSNAILBASEMETAL ROOFCLIPSTRIANGLE FASTENERCORPORATIONR22TRIANGLE FASTENER CORPORATION800.486.1832 / www.trianglefastener.com

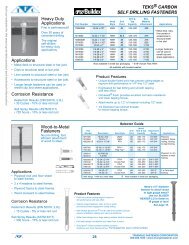

PULLOUT LOADSPullout In Steel - Average Ultimate in PoundsFF<strong>Fastener</strong>Diameter& Point24 ga(.024”)Pullout In Wood - Average Ultimate in PoundsZinc PlatedSteelScrews 222 ga(.021”)20 ga(.030”)OrganicCoated SteelScrews 218 ga(.048”)Hot-DipGalvanizedSteel Nails 3and ScrewsMaterial Thickness16 ga 14 ga(.060”) (.075”)Zinc-AlloyHead SteelScrews12 ga(.105”)<strong>Fastener</strong> MaterialStainlessCapped HeadSteel Screws1/8”(.125”)3/16”(.188”)1/4”(.250”)1/2”(.500”)#10-16 DP3 208 267 295 503 710 968#12-14 DP3 215 292 343 555 752 1,066#12-24 DP5 687 986 1,850 1,670 2,673 *3,844#12-24 DP4 375 500 978 1,200 2,000 *3,844 *3,844#14-13 DP1 338 574 720 961 1,000 1,3501/4-14 DP3 (1) 579 736 1232 2011 3291 *4,0601 Test at Farabaugh Engineering | Report # T196-14Rev JC060614 * Exceeds tensile strengthContact TFC for tensile strength <strong>of</strong> test materialWood Type<strong>Fastener</strong>Dia. & Point1/2”Ply5/8”Ply3/4”Ply7/16”OSB19/32”OSB23/32”OSB2 x 4SYP#10-13 GP 375 505 654 166 357 442 737#10-9 GP 383 395 574 136 256 514 813#12-14 DP1/Lap 376 415 598 251 351 378 550#12-11 GP 418 455 624 146 379 573 918#14-13 DP1 434 475 626 153 327 457 991Farabaugh Engineering Test: Project No. T279-10Rev 042811Decking fasteners tested with full thread embedment.2 x 4 SYP with 1” embedmentFASTENER PROPERTIESThread Typeand PointThreadMajor Dia. MaterialHeadDia.HeadThickness DriveREV JC070312Finish#10-16 DP2 .180” C1022 .435” .080” #2 Sq .0003” Zinc & Yel<strong>low</strong>#10-24 DP3 .185” C1022 .435” .080” #2 Sq .0003” Zinc & Yel<strong>low</strong>#10-13 GP .190”#10-16 DP3 .180”#10-9 GP (ULP) .200”#12-11 GP .220”C1022302 SSC1022410 SSC1022410 SSC1022302 SS.450” .080” #2 Sq.450” .080” #2 Sq.435” .040” #2 Sq.450” .080” #2 SqTRI-SEAL CoatedPassivated.0003” Zinc & Yel<strong>low</strong>.0002" Zinc & ClearTRI-SEAL CoatedPassivatedTRI-SEAL CoatedPassivated#12-14 DP1 .210” C1022 .450” .080” #2 Sq .0003” Zinc & Yel<strong>low</strong>#12-14 DP3(SD300).210”C1022304 SS.450”.500”.080”.090”#2 SqT-30 Torx#12-24 DP5 .210” C1022 .425” .110” #3 Sq#14-13 DP1 .238” C1022 .500” .090” #2 Sq1/4-14 DP3 (1")(2", 3", 4", 5", 6")TOOLING®.245” C1022.500”.625".080”.100"#2 Sq#3 SqScrew-gun RPMCarbon Steel & 410SS Screws: 2,500 RPM maximum302 & 304 Stainless Steel Screws: 1,000 RPMmaximumFor optimal performance, use screw-guns with torquecontrol feature.DO NOT OVER-TORQUE FASTENERS..0003” Zinc & Yel<strong>low</strong>.0003” Zinc & Yel<strong>low</strong>TRI-SEAL Coated.0003” Zinc & Yel<strong>low</strong>TRI-SEAL Coated.0003” Zinc & Yel<strong>low</strong>TRI-SEAL CoatedFASTENER COMPATIBILITY FOR METAL ROOFING AND WALL CLADDINGTable developed by <strong>the</strong> Metal Construction Association Members (Rev. by MCA 09.27.10)300SeriesStainlessSteel400SeriesStainlessSteelMetal Ro<strong>of</strong> orWall Cladding MaterialAluminumCopper andCopper AlloysUnpainted Galvanized Steel Yes 4 Yes Yes Yes Yes Yes No Yes YesPainted Galvanized Steel Yes 4 Yes Yes Yes Yes Yes No Yes YesUnpainted Galvalume Steel No Yes Yes Yes Yes Yes No Yes YesPainted Galvalume Steel Yes 4 Yes Yes Yes Yes Yes No Yes 4 Yes 4Aluminum No Yes No No No Yes No Yes NoCopper & Copper Alloys No No No No No No No Yes Yes 4Stainless Steel No No No Yes Yes Yes Yes Yes YesZinc alloy No No No No No Yes No Yes YesTECHNICAL DATAPULLOVERScrewTee Clip 24 ga.(Ave. Ultimate)Zee Clip 24 ga.(Ave. Ultimate)#10 DP3 415 lbs. 510 lbs.#12 GP 430 lbs. 692 lbs.#14 DP1 407 lbs. 677 lbs.* Berridge ClipsPERFORMANCE SPECIFICATIONSREV.JES082712Minimum Ultimate<strong>Fastener</strong> Diameter& MaterialThreadDiameterTensile(lbs.)Shear(lbs.)Torsional(lbs-in)#10-9 / Carbon 0.200” 1,520 1,150 60#10-9 / 410SS 0.200” 2,500 1,625 85#10-13 / Carbon 0.195” 1,725 1,125 60#10-13 / 302SS 0.195” 1,040 701 45#10-16 / Carbon 0.186” 2,100 1,400 61#10-16 / 410SS 0.186” 3,200 2,130 92#12-11 / Carbon 0.220" 2,500 2,000 95#12-14 / Carbon 0.212” 2,778 2,000 100#12-14 / 302SS 0.212” 2,630 1,978 85#12-24 / Carbon 0.213” 3,450 2,420 1101/4-14 / Carbon 0.243” 3,850 2,600 150#14-13 / Carbon 0.235” 3,620 2,500 115SALT SPRAYThe chart be<strong>low</strong> provides general information with regard to corrosionresistance <strong>of</strong> various plating and coatings. Contact TFC for detailedinformation.SALT SPRAY Per ASTM F1941 & B117 (0% red rust) Rev. 120313Carbon steel and 410 stainless steel materialsCoatingSalt Spray.00015” min. (3 um) zinc plating with clear chromate 15hrs.0002” min. (6um) zinc plating with clear chromate 24hrsPassivated 410 Stainless Steel48hrs.0003” min. (8 um) zinc plating with clear chromate 48hrs.0003” min. (8 um) zinc plating with yel<strong>low</strong> di-chromate 120hrs.0005” min. (12 um) zinc plating with clear chromate 72hrs.0007” min. (14 um) mechanical zinc with clear chromate 72hrsEpoxy (E-Coat) (ACQ Compatible)100hrsTRI-SEAL Long-life coating1,000hrsPassivated 302 & 304 SS1,000hrsFastening Tips• A minimum <strong>of</strong> three (3) factors <strong>of</strong> safety should be used for most self-drilling or self-tappingfasteners. Consult a design pr<strong>of</strong>essional for appropriate values.• Install fastener perpendicular to <strong>the</strong> work surface and tighten to no more thanapproximately 70% <strong>of</strong> <strong>the</strong> torsional strength.• Al<strong>low</strong> at least three full threads to extend beyond <strong>the</strong> material. For wood applications,al<strong>low</strong> 1” minimum embedment or full thread embedment in plywood and OSB for optimalpullout resistance.Refer to page 16 for detailedinformation about this chart.DISCLAIMER: ALL DATAAND SPECIFICATIONSARE BASED ONLABORATORY TESTS.APPROPRIATE SAFETYFACTORS SHOULDBE USED BY THEUSER OR SPECIFIER.DETERMINING THEPROPER FASTENER ISTHE RESPONSIBILITYOF THE USER ORSPECIFIER. BECAUSEA P P L I C A T I O NCONDITIONS VARY, WEASSUME NO LIABILITYFOR THE USE OF THISINFORMATION.Visit our website for <strong>the</strong> most up-to-date product and technical information!TRIANGLE FASTENERCORPORATIONR23TRIANGLE FASTENER CORPORATION800.486.1832 / www.trianglefastener.com