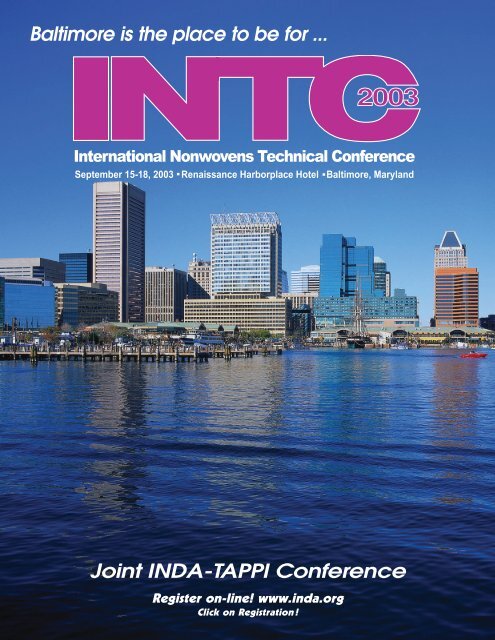

Baltimore is the place to be for - INDA

Baltimore is the place to be for - INDA

Baltimore is the place to be for - INDA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2PROGRAM OVERVIEWSunday, Septem<strong>be</strong>r 14, 2003Reg<strong>is</strong>tration ........................................................ 2:00 p.m. –Monday, Septem<strong>be</strong>r 15, 2003Reg<strong>is</strong>tration .......................................................10:00 a.m. –Conference ....................................................... 1:00 p.m. –Nonwovens Steering Committee Meeting(By invitation only): ......................................... 4:30 p.m. –Tuesday, Septem<strong>be</strong>r 16, 2003TAPPI Committee Meetings:Filtration .......................................................... 7:30 a.m. –Insulation ........................................................ 7:30 a.m. –Binders & Additives ....................................... 7:30 a.m. –Reg<strong>is</strong>tration ........................................................ 8:00 a.m. –Keynote & Award Ceremony ......................... 9:00 a.m. –Conference ....................................................... 2:00 p.m. –New Technologies Showcase ......................... 2:00 p.m. –Table<strong>to</strong>p Event & Reception .......................... 5:30 p.m. –Wednesday, Septem<strong>be</strong>r 17, 2003TAPPI Committee Meetings:Polymers & Fi<strong>be</strong>rs........................................... 7:30 a.m. –Building & Industrial Mat ............................... 7:30 a.m. –Process Technology ...................................... 7:30 a.m. –Properties & Per<strong>for</strong>mance............................ 7:30 a.m. –Reg<strong>is</strong>tration 8:30 a.m.-4:00 p.m.Conference 9:00 a.m.-4:30 p.m.Networking Event:<strong>Baltimore</strong> Orioles v. NY Yankees ................. 5:00 p.m. –(Tickets must <strong>be</strong> pre-purchased.)Thursday, Septem<strong>be</strong>r 18, 2003TAPPI Building & Industrial MatSubcommittee Mtg. ......................................... 7:00 a.m. –Reg<strong>is</strong>tration ........................................................ 8:30 a.m. –Conference ....................................................... 9:00 a.m. –5:00 p.m.5:30 p.m.5:30 p.m.6:00 p.m.8:45 a.m.8:45 a.m.8:45 a.m.7:00 p.m.12:30 p.m.5:30 p.m.5:30 p.m.7:00 p.m.8:45 a.m.8:45 a.m.8:45 a.m.8:45 a.m.game end9:00 a.m.11:30 a.m.12:00 p.m.TAPPI MEETINGAGENDASRena<strong>is</strong>sance Harbor<strong>place</strong> Hotel,<strong>Baltimore</strong>, MDTAPPI meetings are open <strong>to</strong> all INTCattendees regardless of TAPPImem<strong>be</strong>rship. Everyone <strong>is</strong> invited <strong>to</strong>attend and participate. Acontinental breakfast will <strong>be</strong> servedeach morning <strong>for</strong> meetingattendees.Nonwoven Div<strong>is</strong>ion SteeringCommittee4:30 pm, Monday, Septem<strong>be</strong>r 15Committee Leadership; CommitteeReports; 2003 Awards; TechnicalJournal; Joint Filtration Committee-D<strong>is</strong>cussion.TAPPI Filtration Committee7:30 am, Tuesday, Septem<strong>be</strong>r 16Committee Leadership &Mem<strong>be</strong>rship; INTC 2004 SessionDeveloper(s); Filtration Short Courseat INTC 2004-D<strong>is</strong>cussion; JointFiltration Committee-D<strong>is</strong>cussion.TAPPI Insulation Committee7:30 am, Tuesday, Septem<strong>be</strong>r 16Presentation of M<strong>is</strong>sion Statement &Scope; Review of Technical Session;2004 Short Course; Methods’Subcommittee; Insulation Industry;Mem<strong>be</strong>rship; Technical References.TAPPI Binders & AdditivesCommittee7:30 am, Tuesday, Septem<strong>be</strong>r 16Review of Binders & AdditivesSession; INTC 2004.TAPPI Building & IndustrialMaterial Committee7:30 am, Wednesday, Septem<strong>be</strong>r 17Updates on Building Specifications,Test Method Qualification andSpring 2004 meeting.TAPPI Polymers & Fi<strong>be</strong>rsCommittee7:30 am, Wednesday, Septem<strong>be</strong>r 17Featured Speaker: Karl Counts,Herty Foundation.TAPPI Building & IndustrialMaterial Subcommittee7:00 am, Thursday, Septem<strong>be</strong>r 18

GROWING, GROWING, GROWING... BIGGEST EVENT EVERIn <strong>the</strong> past, INTC was a three-day event. Now, it has grown <strong>to</strong> a fourdayevent. Why? The INTC committee d<strong>is</strong>covered so many state-of<strong>the</strong>-artpapers, a four day <strong>for</strong>mat was <strong>the</strong> only solution. And, whatdoes th<strong>is</strong> mean <strong>for</strong> you? You simply get “more bang <strong>for</strong> <strong>the</strong> buck.”Even more reasons <strong>for</strong> you <strong>to</strong> reg<strong>is</strong>ter <strong>for</strong> INTC.CONFERENCE HIGHLIGHTSKEYNOTER: Thomas Kehl, Freuden<strong>be</strong>rgFreuden<strong>be</strong>rg Nonwovens’ Managing Direc<strong>to</strong>r & Speaker of <strong>the</strong>Management Board, Thomas Kehl, will present <strong>the</strong> keynote,“Speeding Up <strong>the</strong> Process from Development <strong>to</strong> Market.”NEW SESSIONS!!INTC 2003 will offer two new sessions as part of <strong>INDA</strong>/TAPPI’scommitment <strong>to</strong> bring <strong>the</strong> nonwovens industry <strong>the</strong> latest in technologicaladvancements:Nanofi<strong>be</strong>rs—those hot little fi<strong>be</strong>rs used in a multitude of end-uses—will <strong>be</strong> <strong>the</strong> focus of a two-part session that you will not want <strong>to</strong> m<strong>is</strong>s!Insulation—<strong>the</strong>rmal and acoustical—will focus on <strong>the</strong> latest developmentsand applications within th<strong>is</strong> industry.LEADING EDGEINFORMATION• Au<strong>to</strong>motive• Barriers• Binders & Additives• Building & Industrial Mat• Filtration• Fin<strong>is</strong>hes & Surfaces• Hydroentangling• Insulation• Modeling• Polymers & Fi<strong>be</strong>rs• Properties & Per<strong>for</strong>mance• Spunbonding/Melt Blowing• Thermal Bonding• WipesSPECIAL FEATURES• Nanofi<strong>be</strong>rs• Binders & Additives Tu<strong>to</strong>rial• Table-<strong>to</strong>p D<strong>is</strong>plays• New Technology ShowcaseINTC…DESIGNED FOR:• Nonwoven Fabric Producers• Converters of NonwovenFabrics• Suppliers <strong>to</strong> Nonwoven FabricProducersFor Managers withResponsibility <strong>for</strong>:• New Product Development• Research & Development• Technical Marketing & Sales• Testing & Quality Control3

CONFERENCEPROGRAMMondaySeptem<strong>be</strong>r 15, 2003MODELINGBINDERS &ADDITIVESTUTORIAL1:00 pm - 4:00 pmModera<strong>to</strong>r: Roy Brough<strong>to</strong>n, Ph.D.,Auburn UniversityChemical BindersMichèle Mlynar, Rohm & HaasCompanyThe tu<strong>to</strong>rial will <strong>be</strong>gin with anintroduction on <strong>the</strong> various types ofbinders and reasons <strong>for</strong> <strong>the</strong>ir use in<strong>the</strong> nonwoven industry.Chemical BindersApplication TechnologiesRon Pangrazi, Air Products PolymersL.P.We will <strong>the</strong>n review <strong>the</strong> majorbinder application methods:saturation, print, spray and foam, aswell as <strong>the</strong> dec<strong>is</strong>ion making process<strong>be</strong>hind <strong>the</strong> use of each of <strong>the</strong>semethods.Processing Aids <strong>for</strong> ResinBonded Nonwoven WebsJacqueline Mulgrew, Rohm & HaasCompanyThe tu<strong>to</strong>rial will continue with areview of processing aids used <strong>to</strong>apply binders <strong>for</strong> trouble-freemanufacturing and conversion or<strong>for</strong> specific end-use <strong>be</strong>nefits.4Thermosetting ResinsPeter D. Wallace, Borden ChemicalWe will <strong>the</strong>n learn about <strong>the</strong>chem<strong>is</strong>try, properties and uses ofurea-<strong>for</strong>maldehyde, phenolic andmelamine resins and how <strong>the</strong>yrelate <strong>to</strong> actual application,s<strong>to</strong>rage and handling situations.Introduction <strong>to</strong> Wetting,Spreading & AdhesionB.S. Gupta, North Carolina StateUniversityThe tu<strong>to</strong>rial will fin<strong>is</strong>h with ad<strong>is</strong>cussion on <strong>the</strong> basics of wetting,spreading and adhesion of bindersand additives along with <strong>the</strong>interrelationships <strong>be</strong>tween liquidsand adhesion.1:00 pm - 4:00 pmModera<strong>to</strong>r: G.P.S. (Paul) Kochar,Ph.D., DuPontUse of a Commercial CFDPackage <strong>to</strong> Improve MeltBlowing Dies-Part IDimitro<strong>is</strong> V. Papavassiliou, Ph.D.,University of OklahomaLearn how computational fluiddynamics (CFD) software can <strong>be</strong>applied <strong>to</strong> improve melt blowingdies.Use of a Commercial CFDPackage <strong>to</strong> Improve MeltBlowing Dies-Part IIRo<strong>be</strong>rt L. Shambaugh, Ph.D.,University of OklahomaHear how you can save money andtime using CFD software <strong>to</strong> predictmelt blowing die <strong>be</strong>havior <strong>for</strong> diedesigns <strong>for</strong> which no experimentalresults ex<strong>is</strong>t.New Developments in <strong>the</strong>Assessment of ProtectiveFabrics UsingComputational ModelsRoger W. Hill, Creare IncorporatedLearn about <strong>the</strong> continuingadvances in CFD <strong>to</strong> predict andanalyze <strong>the</strong> per<strong>for</strong>mance ofprotective fabrics.It’s All About Cost CuttingPrior <strong>to</strong> Metal Cutting in<strong>the</strong> Nonwovens IndustryAnniruda Mukhopadhyay, Ph.D.,Fluent, Inc.Presented will <strong>be</strong> an example ofcost-effective simulations of real lifemanufacturing problems and <strong>the</strong>

end-user’s perspective on <strong>the</strong>investment of CFD modeling vs.plant trials.Application ofElectrowetting <strong>to</strong>D<strong>is</strong>tribution of Fin<strong>is</strong>hes onNonwoven FabricsYash Kamath, TRI Prince<strong>to</strong>nExplored will <strong>be</strong> <strong>the</strong> use of electricfields <strong>to</strong> control <strong>the</strong> d<strong>is</strong>tribution offin<strong>is</strong>hes on nonwoven fabrics.PROPERTIES &PERFORMANCE1:00 pm - 3:00 pmModera<strong>to</strong>r: Yash Kamath, TRI/Prince<strong>to</strong>nFR Cot<strong>to</strong>n Nonwovens asFlame Barrier <strong>for</strong> MattressesD.V. Parikh, Ph.D., Sou<strong>the</strong>rn RegionalResearch Center, USDAFire retardant cot<strong>to</strong>n barriers are aneffective and economical way <strong>to</strong>comply with new fire-res<strong>is</strong>tant<strong>be</strong>dding leg<strong>is</strong>lation going in<strong>to</strong> effectin January 2004. Presented will <strong>be</strong><strong>the</strong> evolution of <strong>the</strong> standard,development of a FR Griege cot<strong>to</strong>nand test results from <strong>the</strong> Cali<strong>for</strong>niaBureau of Home Furn<strong>is</strong>hings andThermal Insulation.Pore Structure ofNonwovens ContainingHydrophobic andHydrophilic ConstituentsAkshaya Jena, Ph.D. and Kr<strong>is</strong>hnaGupta, Ph.D., Porous Materials, Inc.In th<strong>is</strong> investigation severaltechniques have <strong>be</strong>en used <strong>to</strong>characterize <strong>the</strong> complex porestructure of nonwovens containinghydrophobic and hydrophilic pores.Ensemble Diffraction ForOn- and Off-Line Sizing ofNonwoven Fi<strong>be</strong>rsChr<strong>is</strong> Fandrey, Powerscope, Inc.Learn about a new technique thathas <strong>be</strong>en developed <strong>to</strong> accuratelydetermine <strong>the</strong> fi<strong>be</strong>r diameterd<strong>is</strong>tribution <strong>for</strong> both offline websand <strong>the</strong> online production of fi<strong>be</strong>rsFormation & Structure ofNonwoven Spacer FabricsS.J. Russell, Ph.D., University of LeedsThe <strong>for</strong>mation, structure andproperties of current nonwovenspacer fabrics will <strong>be</strong> reviewed and<strong>the</strong>ir technical capabilities andlimitations will <strong>be</strong> considered.HYDROENTANGLING3:00 pm - 5:00 pmModera<strong>to</strong>r: Bob Averell, WellmanFi<strong>be</strong>rsSpunlace News onComposite StructuresAlfred Watzl, Fle<strong>is</strong>sner GmbH & Co.Learn about <strong>the</strong> intensive ef<strong>for</strong>tsthat are underway <strong>to</strong> createmachinery capable of producingcomposite webs that are soft,absor<strong>be</strong>nt and strong.Structure Process PropertyRelationships inHydroentangledNonwovensBehnam Pourdeyhimi, Ph.D., NCRCThe role of hydroentangling energyon entanglement and its influenceon critical mechanical propertieswill <strong>be</strong> d<strong>is</strong>cussed <strong>for</strong> two differentfi<strong>be</strong>r types.A Study on CavitationInside HydroentanglingNozzlesHooman Vahedi Tafreshi, Ph.D.,NCRCD<strong>is</strong>cussed will <strong>be</strong> <strong>the</strong> results of aseries of unsteady state simulationsthat show <strong>the</strong> inception and <strong>the</strong>time-evolution of <strong>the</strong> cavitationcloud inside hydroentanglingnozzles with different inletroundness.The Role of Nozzle Designin Character<strong>is</strong>tics of HydroentanglingWaterjets:Experimental StudyAsli Begenir, Sara LeeThe results of an experimental studycarried out on <strong>the</strong> cone-capillaryconfiguration of waterjets atdifferent pressures will <strong>be</strong> presented.5

THERMALBONDINGSTUDENT PAPERCOMPETITIONNEW TECHNOLOGYSHOWCASE4:00 pm - 5:30 pmModera<strong>to</strong>r: Dave Bucheck, 3MNonwovens Technology CenterBiodegradable/Compostable NonwovensFrom Cot<strong>to</strong>n-BasedCompositionsGajanan Bhat, Ph.D., University ofTennesseeThe production, structure, propertiesand products of cot<strong>to</strong>n-basednonwovens will <strong>be</strong> d<strong>is</strong>cussed.Review of Thermally PointBonded Nonwovens-Materials, Processes &PropertiesStephen Michielsen, Ph.D., GeorgiaInstitute of TechnologyTh<strong>is</strong> paper will review how <strong>the</strong><strong>the</strong>rmal bonding process trans<strong>for</strong>ms<strong>the</strong> material properties of feedfi<strong>be</strong>rs, <strong>the</strong> implications <strong>for</strong> materialselection, new experimental resultsof <strong>the</strong> mechanical properties ofnonwovens, and new <strong>the</strong>oreticalmodels that descri<strong>be</strong> <strong>the</strong>mechanical <strong>be</strong>havior of <strong>the</strong>rmallypoint bonded nonwovens.Numerical Modeling ofThermobondedNonwovensDieter H. Muller, Prof. Dr.-Ing,University of BremenPresented will <strong>be</strong> a numericalmethod <strong>for</strong> <strong>the</strong> prediction ofnonwoven tensile <strong>be</strong>haviordepending on <strong>the</strong> bond pointgeometry and process parameters.4:00 pm - 5:00 pmModera<strong>to</strong>r: Edward Vaughn, Ph.D.,Clemson UniversityUp and coming young professionalswill present papers detailing <strong>the</strong>irnonwovens research. The winner will<strong>be</strong> announced at <strong>the</strong> Tuesdayaward ceremony.TuesdaySeptem<strong>be</strong>r 16, 2003Keynote & AwardCeremony9:00 am - 12:30 pmEmcee: Tom Ryle, Clopay PlasticProductsKeynoteSpeeding Up <strong>the</strong> Processfrom Development<strong>to</strong> MarketThomas Kehl, Freuden<strong>be</strong>rg,Managing Direc<strong>to</strong>r & Speaker of<strong>the</strong> Management Board ofFreuden<strong>be</strong>rg NonwovensNonwoven Forecast Panel:Lee Sullivan, Freuden<strong>be</strong>rgNonwovensTed Wirtz, <strong>INDA</strong>Leo Cancio, Clopay PlasticProductsAwards <strong>for</strong> <strong>the</strong> <strong>be</strong>st INTC 2002papers will <strong>be</strong> presented along with<strong>the</strong> 2003 Best Student Paper award,<strong>INDA</strong>’s Lifetime TechnicalAchievement Award and TAPPI’sawards <strong>for</strong> Technical Achievementand Leadership & Service.2:00 pm - 5:30 pmModera<strong>to</strong>r: Bryan Thomas,Sou<strong>the</strong>ast Nonwovens, Inc.These popular ten-minutepresentations are back <strong>to</strong> provideattendees with in<strong>for</strong>mation aboutnew products, services andtechnologies available <strong>to</strong> <strong>the</strong>m.Don’t m<strong>is</strong>s it!!POLYMERS &FIBERS2:00 pm - 5:00 pmModera<strong>to</strong>r: Greg Ponitz, WG SteveNew Lyocell Fi<strong>be</strong>rs <strong>for</strong>Nonwovens ApplicationsNick Simpson, Tencel Ltd.A review of recent developmentsand use of Lyocell in nonwovenapplications along with a d<strong>is</strong>cussionof <strong>the</strong> methodology, per<strong>for</strong>manceand character<strong>is</strong>tics of <strong>the</strong> fi<strong>be</strong>r.Polyester Fi<strong>be</strong>rs <strong>for</strong>Nonwoven ApplicationsIvo Edward Ruzek, IndustrialConsultingA look at polyester fi<strong>be</strong>rs and <strong>the</strong>advanced technology that hasrequired a closer look at how andwhen <strong>the</strong>se fi<strong>be</strong>rs are used in <strong>the</strong>creation of nonwoven fabrics.Polypropylene HollowFi<strong>be</strong>rs Produced with ShortThreadline SpunbondingRo<strong>be</strong>rt L. Shambaugh, Ph.D.,University of OklahomaPresented will <strong>be</strong> an economicalalternative <strong>to</strong> solid fi<strong>be</strong>rs created ontraditional spinlines.Reg<strong>is</strong>ter on Sunday <strong>to</strong> avoid <strong>the</strong> Monday crowd!6

Preliminary Study on Fi<strong>be</strong>rSplitting of BicomponentMelt Blown Fi<strong>be</strong>rsChr<strong>is</strong>tine (Qin) Sun, Ph.D., Universityof TennesseeThe results of an investigation on <strong>the</strong>splitting <strong>be</strong>havior and resultingproperties of bicomponent meltblown fi<strong>be</strong>rs after hydroentangmen<strong>to</strong>r chemical treatment will <strong>be</strong>presented.Fea<strong>the</strong>r Fi<strong>be</strong>r/CelluloseFi<strong>be</strong>r/PolypropyleneComposites Manufacturedvia <strong>the</strong> WetlayPapermaking ProcessTodd Aaron Bullions, Ph.D., VirginiaPolytechnic Institute and StateUniversityD<strong>is</strong>cussed will <strong>be</strong> <strong>the</strong> creation of afea<strong>the</strong>r, cellulose andpolypropylene prepreg, its uses as amoldable composite and itsmechanical properties.SPUNBOND/MELTBLOWN2:00 pm - 5:00 pmModera<strong>to</strong>r: Bill Haile, EastmanChemical CompanyNew SpunbondTechnologyJoachim Brenk, Ph.D., NeumagA presentation detailing <strong>the</strong>technology <strong>be</strong>hind a new highspeedprocess <strong>to</strong> create very finebicomponent filaments will <strong>be</strong>offered.Improvements in SpunbondFormation throughPre and Post SpinningApparatus DesignEd McNally, Nordson CorporationScientific data regarding <strong>the</strong>improvement of spunbond laydownthrough proper apparatus designwill <strong>be</strong> presented.Effects of ExtrusionCoating Parameters on<strong>the</strong> Physical Propertiesand Aes<strong>the</strong>tics of aCoated PolypropyleneSpunbond NonwovenMatt Weir, Milliken Coated ProductsIn th<strong>is</strong> paper <strong>the</strong> relationships<strong>be</strong>tween extrusion coating processparameters and <strong>the</strong> mechanicaland aes<strong>the</strong>tic properties of coatedspunbond nonwovens areinvestigated. Th<strong>is</strong> paper descri<strong>be</strong>s<strong>the</strong> extrusion coating process, <strong>the</strong>nonwoven substrates and polymersinvestigated, and d<strong>is</strong>cusses <strong>the</strong>results of stat<strong>is</strong>tically designedexperiments on <strong>the</strong>se systems.Web Structure Formationin Melt Blowing-Probabil<strong>is</strong>tic ModelingApproachRajeev Chhabra, Ph.D., Procter &Gamble and Ro<strong>be</strong>rt L. Shambaugh,Ph.D., University of OklahomaA modeling approach <strong>to</strong> controlprocess and material variablesaffecting <strong>for</strong>mation quality of a meltblown web will <strong>be</strong> d<strong>is</strong>cussed.An Investigation of Fi<strong>be</strong>rSplitting of BicomponentMelt Blown Microfi<strong>be</strong>rNonwovens by WaterTreatmentDong Zhang, Ph.D., TANDEC,University of TennesseeThe results of a process-structurepropertystudy on <strong>the</strong> effects of apost-water treatment <strong>for</strong>bicomponent melt blown web will<strong>be</strong> presented.TABLETOP EVENT& RECEPTION5:30 pm - 7:00 pmChat with your colleagues at th<strong>is</strong>networking event immediatelyfollowing <strong>the</strong> New TechnologyShowcase.7

WednesdaySeptem<strong>be</strong>r 17, 2003INSULATION9:00 am - 12:30 pmModera<strong>to</strong>r: Rick Bruyea, DyneaCorporationA H<strong>is</strong><strong>to</strong>rical Perspectiveon <strong>the</strong> Use of CellulosicMaterials <strong>for</strong> ThermalInsulation and <strong>the</strong> CurrentState of <strong>the</strong> ArtIvan T. Smith, U.S. GreenFi<strong>be</strong>r LLCA review of <strong>the</strong> h<strong>is</strong><strong>to</strong>rical uses ofcellulosic insulation materials andnew ASTM standards that haveopened up new applications <strong>for</strong> itsuse.Born In Fire-Benefits ofSlag/Rock Wool InsulationJames C. Shriver, Thermafi<strong>be</strong>rAn overview of slag/rock woolinsulation products and <strong>the</strong>ir<strong>be</strong>nefits <strong>to</strong> society will <strong>be</strong> presentedalong with an introduction <strong>to</strong> <strong>the</strong>manufacturing and typical end-usesof th<strong>is</strong> material.Formaldehyde Em<strong>is</strong>sionsfrom Thermal InsulationProductsC.W. Axten, Health R<strong>is</strong>k Solutions,LLCThe results of a study testing <strong>the</strong> offgassing of <strong>the</strong>rmal insulationproducts <strong>for</strong> <strong>for</strong>maldehydeconcentration in indoor air will <strong>be</strong>presented.Acoustical InsulationStanley D. Gatland II, CertainTeedCorporationTh<strong>is</strong> paper will identify <strong>the</strong> <strong>be</strong>nefitsof sound control and descri<strong>be</strong> <strong>the</strong>physics <strong>be</strong>hind different types ofsound control techniques, designsand products.The Thermal Analys<strong>is</strong> ofInsulationDavid J. McCaa, Ph.D., CertainTeedCorporationLearn how <strong>the</strong> <strong>the</strong>rmal properties ofinsulation are determined andwhich are important in any givenapplication.All Cellulosic CompositeNonwoven MaterialsIoan I. Negulescu, Ph.D., Lou<strong>is</strong>ianaState UniversityD<strong>is</strong>cussed will <strong>be</strong> both <strong>the</strong>preparation and <strong>the</strong>characterization of bio-based allcellulosic composite nonwovenmaterials used as <strong>the</strong>rmal and/orsound insulation.World’s LargestTechnical ConferenceNANOFIBERS I9:00 am - 12:30 pmModera<strong>to</strong>r: Larry Wadsworth, Ph.D.,University of TennesseeElectrospinning ofNanofi<strong>be</strong>rs FromBiodegradable PolymersG<strong>is</strong>ela Buschle-Diller, Ph.D., AuburnUniversityPresented will <strong>be</strong> <strong>the</strong> results ofresearch comparing fine-diameterbiopolymers and traditionalpolymers used in medical andindustrial applications. Fi<strong>be</strong>rmorphologies and mechanicalproperties will <strong>be</strong> d<strong>is</strong>cussed.Fi<strong>be</strong>r Charging Effects onTarget Coverage inElectrospinningPeter D. Tsai, Ph.D., University ofTennesseeThe results of a study examining <strong>the</strong>spinning conditions necessary <strong>to</strong>combine streams of two separatepolymers in<strong>to</strong> one nonwoven mat ofelectrospun fi<strong>be</strong>rs will <strong>be</strong> presented.Patterned ElectrostaticFi<strong>be</strong>r Spray Deposition:Particle Interactions & AirFlowPhil Gibson, Ph.D., U.S. Army NatickSoldier CenterD<strong>is</strong>cussed will <strong>be</strong> techniques used <strong>to</strong>control nanofi<strong>be</strong>rs spray depositionby varying <strong>the</strong> conductivity of <strong>the</strong>target substrate.Incorporation ofElectrospun Nanofi<strong>be</strong>rsin<strong>to</strong> Functional StructuresKr<strong>is</strong>tine M. Graham, DonaldsonCompany, Inc.Th<strong>is</strong> paper will d<strong>is</strong>cuss <strong>the</strong>incorporation of electrospunnanofi<strong>be</strong>rs in<strong>to</strong> functional structuresand will address application-basedper<strong>for</strong>mance attributes.8

Multicomponent Fi<strong>be</strong>rTechnology <strong>for</strong> Filtrationand O<strong>the</strong>r ApplicationsJohn Hagewood, Ph.D., Hills Inc.Offered will <strong>be</strong> <strong>the</strong> technology<strong>be</strong>hind producing micro- and nanosizedfi<strong>be</strong>rs with <strong>be</strong>tter cons<strong>is</strong>tencyusing traditional melt spinningtechnology ra<strong>the</strong>r than fi<strong>be</strong>rscreated with melt blown orelectrospinning technology.Properties of OrientedElectrospun Nylon 6,6Nanofi<strong>be</strong>rsKevin M. Kit, Ph.D., University ofTennesseeTh<strong>is</strong> paper descri<strong>be</strong>s <strong>the</strong> effect ofhigh speed winding on electrospunnylon 6,6. Significant fi<strong>be</strong>r andmolecular alignment was observedonly at higher speeds.BINDERS &ADDITIVES9:00 am - 11:30 amModera<strong>to</strong>r: Chr<strong>is</strong><strong>to</strong>pher Barcomb,National StarchParticle Containment &Immobilization in RollGood MaterialsSamuel C. Baer, Ph.D., BBANonwovensTh<strong>is</strong> paper examines and compares<strong>the</strong> efficiency of various powdercontainment methods and <strong>the</strong>ireffect on properties such asabsor<strong>be</strong>nt capacity and fluidpermeability.The Future of NonylphenolEthoxylates in NonwovensBarbara Losey, Alkylphenols &Ethoxylates Research CouncilTh<strong>is</strong> paper will d<strong>is</strong>cuss currentregula<strong>to</strong>ry activities and <strong>the</strong>irimplications <strong>for</strong> <strong>the</strong> use of NPES innonwoven applications.Hitting <strong>the</strong> Target:Accurate AdhesiveApplication at IncreasingLine SpeedsLarry Saidman, Nordson CorporationD<strong>is</strong>cussed will <strong>be</strong> <strong>the</strong> improvingapplication technologies enabling<strong>be</strong>tter adhesive pattern accuracyand improved product features atreduced costs.Acrylic ThermosetsBarry Weinstein, Rohm & HaasCompanyLearn about <strong>the</strong> properties, use andadvantages of environmentallyfriendly acrylic <strong>the</strong>rmoset resinsBUILDING &INDUSTRIAL MAT2:30 pm - 4:30 pmModera<strong>to</strong>r: Kent Brown, BordenChemicalA Case Study ofNonwovens ProductDevelopment in <strong>the</strong>Roofing MembraneMarketMichael P. Bouchette, M&DAssociatesA study of a small company’sstrategic dec<strong>is</strong>ion <strong>to</strong> compete in <strong>the</strong>roofing membrane market will <strong>be</strong>examined.New Wide-Width HighSpeed Glass MatLen Negvesky, Fi<strong>be</strong>rteq, LLCShared will <strong>be</strong> a look inside a stateof-<strong>the</strong>-artfacility producing widewidthglass mat and several keymiles<strong>to</strong>nes achieved during <strong>the</strong>facility’s creation.Using Dynamic FluidSurface Tension <strong>to</strong>Fingerprint Glass Fi<strong>be</strong>rD<strong>is</strong>persion in <strong>the</strong>Production of Wet-LaidFi<strong>be</strong>rglass MatVic<strong>to</strong>r P. Janule, SensaDyneLearn how surface tension can <strong>be</strong>used <strong>to</strong> characterize and verify <strong>the</strong>manufacture of a <strong>for</strong>mulation <strong>for</strong>glass mat production.9

NANOFIBERS II2:30 pm - 4:30 pmModera<strong>to</strong>r: T.M. Singh, Ph.D., TMConsultingQuality Control inManufacturing ofElectrospun Nanofi<strong>be</strong>rCompositesDmitry M. Luzhansky, DonaldsonCompany, Inc.Quality control methods in largescaleproduction of nanofi<strong>be</strong>rcomposites will <strong>be</strong> d<strong>is</strong>cussed alongwith four evaluation <strong>to</strong>olsdeveloped <strong>for</strong> commerciallyprocessing nanofi<strong>be</strong>rs.Control of Deposition &Orientation of ElectrospunNanofi<strong>be</strong>rsNavin Bunyan, University ofMassachusetts-LowellThe objective of th<strong>is</strong> research <strong>is</strong> <strong>to</strong>redesign <strong>the</strong> ex<strong>is</strong>ting electrospinningprocess <strong>to</strong> improve <strong>the</strong> control over<strong>the</strong> orientation of <strong>the</strong> deposited dryfi<strong>be</strong>r on a grounded target; acompar<strong>is</strong>on <strong>be</strong>tween experimentaland <strong>the</strong>oretical results <strong>for</strong> <strong>the</strong>process will <strong>be</strong> presented.Rip-S<strong>to</strong>p Rein<strong>for</strong>cement ofUltra-Thin MembranesWith ElectrospunNonwoven MaterialsKevin C. White, Ph.D., PhysicalSciences Inc.A presentation on <strong>the</strong> applicationof directed electrospinning <strong>to</strong>rein<strong>for</strong>ce membranes and filmsresulting in increased tear strengthwith negligible increases in mass will<strong>be</strong> offered.Increase of Strength &Surface Energy byExposing <strong>the</strong> ElectrospunNanofi<strong>be</strong>r Fabrics <strong>to</strong> <strong>the</strong>One Atmosphere Uni<strong>for</strong>mGlow D<strong>is</strong>charge PlasmaPeter P. Tsai, Ph.D., University ofTennesseeTh<strong>is</strong> paper will present <strong>the</strong> results ofa study <strong>to</strong> increase <strong>the</strong> strength ofelectrospun nanofi<strong>be</strong>rs fabrics byexposing <strong>the</strong>m <strong>to</strong> One AtmosphereUni<strong>for</strong>m Glow D<strong>is</strong>charge Plasma.Also d<strong>is</strong>cussed will <strong>be</strong> <strong>the</strong> effect of<strong>the</strong> plasma conditions, including <strong>the</strong>electrical parameters and workinggases on <strong>the</strong> increase of <strong>the</strong> fabricstrength.BARRIERS2:30 pm - 4:30 pmModera<strong>to</strong>r: Joe Palomo,CardinalHealthIs It Not Time <strong>to</strong> UpdateAATCC 42 Test Method &Make It Relevant <strong>to</strong> OurPresent Testing Needs?Carl Palenske, Palenske Consulting Inc.Th<strong>is</strong> paper will cover four studiesdesigned <strong>to</strong> <strong>is</strong>olate and evaluate<strong>the</strong> variables associated withAATCC 42 test method <strong>to</strong> producea more useful test method using <strong>the</strong>same testing principles but withtighter parameters giving moremeaningful results.Protective BreathableMembranes: NewProtective Needs HaveDemanded and YieldedDevelopments BeyondSimple Microporous andMonolithic FilmsJoel Martz, Techguard Systems LLCLearn how recent global eventshave resulted in <strong>the</strong> developmen<strong>to</strong>f membranes with new protectiveabilities that are cost-effective andmore com<strong>for</strong>table than currentlyused barriers.Plasma Treatment:Hydrophobic &Antimicrobial Properties<strong>for</strong> Nonwoven TextilesGita Ramasawmy, Ph.D., KansasState UniversityThe objective of th<strong>is</strong> presentation <strong>is</strong><strong>to</strong> evaluate <strong>the</strong> efficiency ofplasma treatment in providing abarrier against blood and micro<strong>be</strong>sover conventional fin<strong>is</strong>hes.10

Cellulose BasedNonwovens: The Key <strong>to</strong>Combining Barrier &Thermal Protection inApparel ApplicationsCharlie Ro<strong>be</strong>rson, Prec<strong>is</strong>ion FabricsGroup, Inc.Th<strong>is</strong> paper will d<strong>is</strong>cuss <strong>the</strong> hazards ofwearing non-flame retardant barriergarments over <strong>the</strong>rmally protectivegarments and how <strong>the</strong> use ofcomparable flame retardantgarments yields unexpected<strong>be</strong>nefits in terms of <strong>the</strong>rmalprotection.ThursdaySeptem<strong>be</strong>r 18, 2003AUTOMOTIVE9:00 am - 10:30 amModera<strong>to</strong>r: D.V. Parikh, Ph.D., USDAImproving <strong>the</strong> ImpactStrength of Natural Fi<strong>be</strong>rRein<strong>for</strong>ced Composites BySpecifically DesignedMaterial and ProcessingParametersDieter H. Mueller, Ph.D., University ofBremenTh<strong>is</strong> paper descri<strong>be</strong>s <strong>the</strong> effect ofseveral material parameters such asfi<strong>be</strong>r fineness or fleece compositionas well as <strong>the</strong> impact of <strong>the</strong> processconditions on compositecharacter<strong>is</strong>tics.Compar<strong>is</strong>on of Kenaf,Bagasse, and RamieAu<strong>to</strong>motive Nonwovens:Uni<strong>for</strong>m Structure vs.Sandwich StructureYan Chen, Ph.D., Lou<strong>is</strong>iana StateUniversityPresented will <strong>be</strong> <strong>the</strong> results of astudy comparing mono-content/single-layer and multi-content/multilayeredcomposites structures interms of mechanical properties,<strong>the</strong>rmal properties and acousticalproperties.Increasing Technical Usesof Nonwovens inAu<strong>to</strong>motivesBill Smith, Industrial Textile AssociatesD<strong>is</strong>cussed will <strong>be</strong> <strong>the</strong> adoption ofnonwovens in au<strong>to</strong>motiveapplications as well as <strong>the</strong>ir currentand future uses in au<strong>to</strong>mobiles.FILTRATION9:00 am - 12:00 pmModera<strong>to</strong>r: Chr<strong>is</strong> Shields, LydallFiltration & SeparationDiesel Fuel & LubricantFiltration RequirementsGary Bessee, Southwest ResearchInstituteD<strong>is</strong>cussed will <strong>be</strong> some of <strong>the</strong> olderfuel and lubricant test methods, <strong>the</strong>new and future test methods, andhow some of <strong>the</strong> media and filtercompanies are attempting <strong>to</strong> solve<strong>the</strong> engine filtration problems.Continued Evolution ofPolyester Spunbond in <strong>the</strong>Filtration MarketMitch McCreary, BBA FiltrationSpunbonded products withimproved uni<strong>for</strong>mity <strong>for</strong> diagnosticmedical products will <strong>be</strong> presented.11

Electret Media <strong>for</strong> HVACFiltration ApplicationsDavid L. Myers, Kim<strong>be</strong>rly-ClarkCorporationTh<strong>is</strong> paper provides an overview ofcurrent electret media typesdetailing media structure andcharging techniques. Fundamentalimpact of environmental fac<strong>to</strong>rs onfiltration per<strong>for</strong>mance <strong>is</strong> presentedalong with field studies detailing inuseper<strong>for</strong>mance of filtersmanufactured with charged media.Characterizing Melt BlownMedia Per<strong>for</strong>mance inLiquid Filtration ApplicationsChr<strong>is</strong><strong>to</strong>pher Shields, Lydall Filtration& SeparationTh<strong>is</strong> paper evaluates melt blownmedia at several different weightsand micron ratings and compares<strong>the</strong>ir per<strong>for</strong>mance <strong>for</strong> particleremoval, dirt holding capacity andfilter life.High TemperatureCeramic Fi<strong>be</strong>r NonwovenFilter Media Applied inSelf-Cleaning Filter SystemsRichard D. Nixdorf, IndustrialCeramic Solutions, LLCLearn about <strong>the</strong> nonwoven processthat has <strong>be</strong>en developed <strong>for</strong>converting silicon carbide ceramicfi<strong>be</strong>rs <strong>to</strong> a durable filter mediacapable of withstanding <strong>the</strong>pressure of high velocity gas andliquid streams.Properties of Glass Fi<strong>be</strong>r<strong>for</strong> Filtration: Influence ofForming ProcessJon F. Bauer, Johns ManvilleTechnical CenterD<strong>is</strong>cover how new characterization<strong>to</strong>ols and methods have enhanced<strong>the</strong> understanding of glass fi<strong>be</strong>rsurface properties and how <strong>the</strong>seproperties can <strong>be</strong> controlled <strong>to</strong>offer unique solutions <strong>to</strong> currentfiltration demands.FINISHES &SURFACES9:00 am - 10:00 amModera<strong>to</strong>r: Greg Jones, Ph.D.,Clopay Plastic ProductsNewer Flame-RetardantTechnology UsingNanoparticlesGita Ramaswamy, Ph.D., KansasState UniversityThe study results of <strong>the</strong> use of nanosizedantimony pen<strong>to</strong>xide overconventional antimony trioxide assynerg<strong>is</strong>t in flame-retardant fin<strong>is</strong>hingof 100% cot<strong>to</strong>n fabrics using DBDOwill <strong>be</strong> presented.Atmospheric Plasma-Enhanced ChemicalVapor Deposition—TheNew Functional Process<strong>for</strong> Delivering HighPer<strong>for</strong>mance CoatingsRory A. Wolf, Enercon IndustriesCorporationD<strong>is</strong>cussed will <strong>be</strong> <strong>the</strong> recentadvancements in <strong>the</strong> delivery ofatmospheric plasma depositions ofpolymer coatings <strong>to</strong> enhance <strong>the</strong>surface functionalization ofnonwovens.WIPES10:00 am - 11:30 amModera<strong>to</strong>r: James MarshallOathout, E.I. Dupont de Nemoursand Co., Inc.Dynamic Wiping Efficiency<strong>for</strong> Removal of Liquid &Particles From SurfacesJames Marshall Oathout, E.I. Dupontde Nemours and Co., Inc.New procedures are descri<strong>be</strong>d <strong>for</strong>investigating <strong>the</strong> three fac<strong>to</strong>rsespecially important in <strong>the</strong> removalof liquid and particles from a criticalsurface using a wiper.Marring of Au<strong>to</strong>motiveClearcoats Caused ByNonwoven WipesBehnam Pourdeyhimi, Ph.D., NCRCReported will <strong>be</strong> <strong>the</strong> use of threecommon wipes within <strong>the</strong>au<strong>to</strong>motive industry and <strong>the</strong> varioustechniques developed <strong>to</strong>accurately measure <strong>the</strong> scratchand mar damage caused byinappropriate use of wipe material.The Dynamics of Three-Dimensional WiperSystemsLeonard B. Torobin, Ph.D., TheNanofi<strong>be</strong>r GroupTh<strong>is</strong> paper will demonstrate <strong>the</strong>cleansing ability of a threedimensionalwiper system whencompared <strong>to</strong> a conventional sheetwiper.Program subject <strong>to</strong> last minute changes andcancellations. The opinions are those of <strong>the</strong>speakers and not necessarily those of <strong>INDA</strong>, TAPPIor <strong>the</strong>ir Boards of Direc<strong>to</strong>rs12

INTC 2003 CommitteeMem<strong>be</strong>rsConference ChairTom Ryle, Clopay Plastic ProductsTechnical Program Co-ChairsMichèle Mlynar, Rohm & Haas CompanyBill Haile, Eastman Chemical CompanyBob Averell, Wellman, Inc.Chr<strong>is</strong><strong>to</strong>her Barcomb, National Starch & ChemicalCompanySubhash Batra, Ph.D., NCRCGajanan Bhat, Ph.D., University of TennesseeRoy Brough<strong>to</strong>n, Ph.D., Auburn UniversityKent Brown, Borden Chemical, Inc.Rick Bruyea, Dynea CorporationBhuvenesh Goswami, Ph.D., Clemson UniversityNatalie Grooms, Borden Chemical, Inc.Kr<strong>is</strong>hna Gupta, Ph.D., Porous Materials Inc.Rudy Jan<strong>is</strong>, DuPont NonwovensGreg Jones, Clopay Plastic ProductsYashavanth Kamath, Ph.D., TRI/Prince<strong>to</strong>nG.P.S. (Paul) Kochar, Ph.D., DuPontDaniel LaVietes, Ph.D., Elk CorporationSteve Michielsen, Ph.D., Georgia Tech UniversityAniruddha Mukhopadhyay, Fluent Inc.J. Marshall Oathout, DuPont SontaraTechnologiesJoe Palomo, Cardinal HealthDV Parikh, Ph.D., USDAGreg Ponitz, W.G. Steve Company, Inc.Behnam Pourdeyhimi, Ph.D., NCRCKelly Rennels, Ahlstrom Technical SpecialtiesChr<strong>is</strong> Shields, Lydall Filtration & SeparationTM Singh, Ph.D., TM ConsultingAllan Stahl, TANDECBryan Thomas, Sou<strong>the</strong>ast Nonwovens, Inc.Edward Vaughn, Clemson UniversityLarry Wadsworth, Ph.D., University of TennesseePeter Wallace, Borden Chemical, Inc.Hotel In<strong>for</strong>mationRena<strong>is</strong>sance Harbor<strong>place</strong> Hotel202 East Pratt Street<strong>Baltimore</strong>, Maryland 21202Reservations: 1-800-468-3571Rate: $170.00 Single/DoubleGroup rate will <strong>be</strong> extended three (3) daysprior and three (3) days post based uponavailability.Cut-Off Date: August 15, 2003Identify yourself with <strong>INDA</strong>/TAPPI INTC 2003conference.13

Network withThese Companies3M Corp.A. Celli International Inc.AAF InternationalABB Industrial Drying Asea BrownBoveriAbsor<strong>be</strong>nt Technologies Inc.AceAcord<strong>is</strong> CellulosicsAction Industries Inc.Adhesives Research, Inc.Advance Glass Fi<strong>be</strong>r YarnsAeg<strong>is</strong> EnvironmentsAET Specialty Nets & NonwovensDiv<strong>is</strong>ion Of Applied ExtrusionTechnologies, Inc.AhlstromAir Products Polymers, L.P.Airaid Filter Co.Albany InternationalAlkylphenols & Ethoxylates ResearchCouncilAllasso Industries, Inc.Allegiance HealthcareAl-Othman Plastic IndustriesAmerican Institute Management StudyAmerican Kuhne Corp.American Nonwovens Corp.American Roller Co.American Sahm Co.American Truetzschler, Inc.AmerichemAmerico Manufacturing Co., Inc.Ameripol Synpol Corp.Amer-sil S.AArco Polypropylene LLCARJO Wiggins Center Of ResearchArmstrong World IndustriesAshland Specialty Chemical Co.Ason Neumag Corp., A Div<strong>is</strong>ion OfNeumag/SaurergroupAstenJohnson Specialty FabricsATEXAtlanta N<strong>is</strong>seki Claf, Inc.Atlantic Mills Inc.A<strong>to</strong> Fina PetrochemicalsA<strong>to</strong>finaAuburn UniversityAvecia Inc.Avgol America Inc.B.F. PerkinsBasell North America Inc.BASFBayer Corp.BBA Industrial Nonwovens GmbHBE & K Engineering Co.Belchem Fi<strong>be</strong>r Materials GmbHBem<strong>is</strong> Associates Inc.Bem<strong>is</strong> Cus<strong>to</strong>m ProductsBercen, Inc.BF PerkinsBiax-Fi<strong>be</strong>rfilm Corp.Bidim Ind. E Com LTDA - BBANonwovensBIK, University Of BremenBinder Microplast LPBirla Management Corp. LtdBlocksom & Co.Bohlander AssociatesBonlam S.A. De C.V. PGI Nonwovens -A Mem<strong>be</strong>r Of The InterTech GroupBorden ChemicalBoyd Converting Co., Inc.14BP Fabrics And Fi<strong>be</strong>rs Co.BP PolypropyleneBreitenbach, Inc.Buckeye TechnologiesButterworth ConsultingCamfil FarrCanadian Forest Products Ltd., Panel& Fibre Div<strong>is</strong>ionCan<strong>for</strong> USACarbon Fi<strong>be</strong>rsCardinalHealthCargill, Inc./DurafibreCellu T<strong>is</strong>sue HoldingsCEREX Advanced Fabrics, L.P.Certainteed Corp.Chembond Corp.Chemical Market Resources, Inc.Chevron PhillipsCibaClaremont Flock Corp.Clark-Schwe<strong>be</strong>l Tech-Fab Co.Cleaver Associates, Inc.Clopay Plastic Products Co.CNS, Inc.Coatema Coating Machinery GmbHCognex Corp., Surface InspectionSystems Div<strong>is</strong>ionColbond NonwovensCollano AdhesivesComcraftComerio Ercole SpAConcept IndustriesConglas/UPFConwed PlasticsCorium InternationalCot<strong>to</strong>n Inc.Crafts TechnologyCrane & Co. Inc.Creare Inc.CTA AcousticCTT Group - Centre For TextileTechnologiesCuno, Inc.DAK AmericasDawson Textile MachineryDegussa-Goldschmidt Chemical Corp.DelStar Technologies, Inc.Dexter Corp.Dilo Inc.DIMON InternationalDonaldson Co. Inc. CorporateTechnologyDonghua UniversityDow Chemical Co.DuPont Chemical Solutions Enterpr<strong>is</strong>eEastman Chemical Co.Ecole Des Mines De NantesEdward C. Homonoff & AssociatesElectrolock, Inc.Elk Corp.Empire State Paper Research InstituteEnercon Industries Corp.Engineered Fi<strong>be</strong>rs Technology, LLCEqu<strong>is</strong>tar Chemicals LPES Fi<strong>be</strong>rV<strong>is</strong>ionsESpin TechnologiesEthicon ProductsEuro<strong>the</strong>rm Gauging SystemsExxonMobil Chemical Co.Familia Del Pacifico Ltda.FibairFi<strong>be</strong>r Bond Corp.Fi<strong>be</strong>r Innovation TechnologyFi<strong>be</strong>rMark, Inc.Fi<strong>be</strong>rV<strong>is</strong>ions Inc.Fieldcrest Canno Inc.Filter Materials, A Div<strong>is</strong>ion Of GusmerEnterpr<strong>is</strong>es Inc.Filtration AdsorptionFiltrona Richmond Inc.First Quality NonwovensF<strong>is</strong>hburne Corp.Fi-Tech Inc.Fle<strong>is</strong>sner GmbH & Co.Fle<strong>is</strong>sner Inc.Fluent Inc.Formosa Plastics Corp, USAFoss Manufacturing Co. Inc.Franklin InternationalFreuden<strong>be</strong>rg Nonwovens NorthAmericaGAF Materials Corp.Gage Products Co.Gas<strong>to</strong>n Systems, Inc.Gates Rub<strong>be</strong>r Co.Gelok International Corp.General Econopak Inc.General Electric SiliconesGeorgia Institute Of TechnologyGeorgia Pacific Resins Inc.Georgia State UniversityGeorgia-Pacific Corp. - Fluff Pulp &Specialty Fi<strong>be</strong>rsGeorgia-Pacific Nonwovens GroupGKD-USA, Inc.Glens Falls Interweb, Inc.Glo<strong>be</strong> IndustriesGlo-Tex International, Inc.Gouls<strong>to</strong>n Technologies, Inc.Graham Medical Products Div. of LittleRapids Corp.Green Bay NonwovensGreene Natural Fi<strong>be</strong>rsGroz-Beckert USA Inc.H.B. Fuller & Co.Henkel AdhesivesHercules Pulp And Paper Div<strong>is</strong>ionHerty FoundationHickory Springs/Inno-Therm Products,LLCHills Inc.Hobbs Industries Inc.Hollinee, LLCHollingsworth & Vose Co.HoneywellHoyle AssociatesHydac Technology Corp.ICBT Inc.IMERYS Pigments & AdditivesIntercontinental Polymers, Inc.International Nonwovens JournalITW DynatecJ&J EthiconJanesville ProductsJohann Borgers GmbH & Co. KGJohns Manville Corp.Johnson & Johnson Personal ProductsWorldwideJournal Of Industrial TextilesKAO Chemicals Americas Corp.Kelmar IndustriesKelmar Industries, A Div<strong>is</strong>ion Of WackerSiliconesKendall - ConfabKim<strong>be</strong>rly-Clark Corp.Kinetik Enterpr<strong>is</strong>esKline & Co.Knauf Fi<strong>be</strong>r Glass GmBhKT GroupKufferathLan<strong>to</strong>r, Inc.Lapoint IndustriesLasor/Systronics Inc.Lauscha Fi<strong>be</strong>r InternationalLeggett & Platt, Inc.Leigh Fi<strong>be</strong>rs Inc.Lenzing Fi<strong>be</strong>rs Corp.Loughborough UniversityLou<strong>is</strong> P. Batson Co.Lou<strong>is</strong>iana State University, School OfHuman EcologyLydall Industrial Thermal SolutionsLysac Technologies, Inc.M/K SystemsMahlo-America Inc. Mahlo-GermanyMaier America, LLC., A Div<strong>is</strong>ion OfChr<strong>is</strong>tian Maier GmbH & Co,Mallard Creek Polymers, Inc.Martin Au<strong>to</strong>matic Inc.Martin Color-Fi Inc.McCooe & AssociatesMCW TechnologiesMead Specialty PaperMegtec SystemsMetso Paper USA, Inc.Mid America Fi<strong>be</strong>r Co.Milliken & Co. Monarch PlantMOCONMolnlycke Health Care ABMonadnock Non-Wovens, LLCNordsonOwens CorningPaper Converting Machine Co.Paragon Trade Brands, Inc.Parker Hannifin Racor Div<strong>is</strong>ionParkinson TechnologiesPegas, A.S.Perry Equipment Corp.PGI NonwovensPJ AssociatesPliant Corp.Polyvel, Inc.Porex TechnologiesPrec<strong>is</strong>ion Cus<strong>to</strong>m Coatings Inc.Prec<strong>is</strong>ion Fabrics Group Inc.Procter & GambleQuin-T Corp.-NHRayonierRayTech Composites, Inc.Reckitt Benck<strong>is</strong>er, Inc.Reichhold, Inc.Reifenhauser GmbH & Co.RF TechnologiesRohm & Haas CompanySmith, Johnson & AssociatesTamko Roofing Products Inc.The Clorox Services Co.The Dow Chemical Co.The Hoover Co.TiconaTNS Advanced TechnologiesTontine FibresTredegar Film ProductsTriosyn Corp.Tyco - Kendall Healthcare ProductsU.S. Pacific Procurement Co. Ltd.UMISTUnifrax Corp.UniLever HPC NAVinamul PolymersVita NonwovensVoith FabricsVoith Sulzer Paper TechnologyVyTech Industries Inc.W.L. Gore & AssociatesWebtech L.L.CWolfson School Of Mechanical &Manufacturing Engineering

Joint <strong>INDA</strong>-TAPPI ConferenceREGISTRATION: To reg<strong>is</strong>ter <strong>for</strong> INTC 2003, peel and stick mailingla<strong>be</strong>l here. Use a separate <strong>for</strong>m <strong>for</strong> each individual (copy th<strong>is</strong> <strong>for</strong>m <strong>for</strong> additionalreg<strong>is</strong>trations). By reg<strong>is</strong>tering early, you qualify <strong>for</strong> significant savings from<strong>the</strong> regular reg<strong>is</strong>tration fee.Name ___________________________________________________(last name/surname)(first name)Title ________________________________________Organization ___________________________________________ e-mail: _________________________________________Address __________________________________________________________________________________________________City _____________________________________ State ________________ Zip ________________ Country __________Telephone ____________________________________________ Fax ___________________________________________❑ Yes, I’m interested in d<strong>is</strong>playing at <strong>the</strong> table-<strong>to</strong>p event.Please send in<strong>for</strong>mation.You must check ONE answer in each section in order <strong>for</strong> us<strong>to</strong> process your reg<strong>is</strong>tration.Your organization’s Primary Affiliation with Nonwovens Industry (check only one):50 ❑ Roll Goods Producer/Supplier51 ❑ Converters52 ❑ End User of Nonwovens (check end-uses that apply)❑ Agricultural/landscaping❑ Apparel❑ Au<strong>to</strong>motive❑ Construction❑ Diapers❑ Filtration❑ Geotextiles❑ Healthcare❑ Home Furn<strong>is</strong>hings❑ Packaging❑ Personal Care❑ Protective Apparel❑ Sor<strong>be</strong>nts❑ WipesBe recognized at INTC 2003. Special sponsorship opportunities.❑ Yes, I’m interested in sponsoring: ❑ Coffee Break $500;❑ Attendee Cloth Bags $1500 (limited <strong>to</strong> 9 companies);❑ Reception $2500. ❑ CD Jewel Case $5000.Payment <strong>is</strong> <strong>to</strong> <strong>be</strong> included with reg<strong>is</strong>tration.53 ❑ Machinery/Equipment Manufacturer54 ❑ Supplier of Binders, Chemicals, Adhesives, etc.55 ❑ Supplier of Fi<strong>be</strong>rs, Pulps, etc.56 ❑ Supplier of Films, Tapes, etc.57 ❑ Comm<strong>is</strong>sion Services (i.e. dyeing, fin<strong>is</strong>hing,printing, sewing, slitting, etc.)58 ❑ Research/Consulting59 ❑ Paper/Packaging60 ❑ Health Services61 ❑ Transportation62 ❑ Wholesale/Retail D<strong>is</strong>tribution94 ❑ Association96 ❑ Academic Institution97 ❑ Government98 ❑ Press/Publ<strong>is</strong>hing99 ❑ O<strong>the</strong>r (please specify) _______________________Primary Title or Job Function (check only one):01 ❑ Owner/Principal02 ❑ Chief Executive Officer03 ❑ Corporate/Div<strong>is</strong>ion Management04 ❑ Plant/Production Management05 ❑ Quality Control/Engineering06 ❑ Research and Development07 ❑ Purchasing08 ❑ Sales09 ❑ Consultant11 ❑ Marketing45 ❑ Press-Edi<strong>to</strong>rial46 ❑ Press-O<strong>the</strong>r Than Edi<strong>to</strong>rial47 ❑ Government Employee48 ❑ Academic - Faculty49 ❑ Academic - Student10 ❑ O<strong>the</strong>r (please specify) ______________REGISTRATION FEES: Be<strong>for</strong>e August 7, 2003 After August 7, 2003<strong>INDA</strong>/TAPPI*<strong>INDA</strong>/TAPPI*(Please check boxes and circle fees) Mem<strong>be</strong>r Non-Mem<strong>be</strong>r Mem<strong>be</strong>r Non-Mem<strong>be</strong>r❑ Full Reg<strong>is</strong>tration $950 $1330 $1140 $1595❑ Gov’t/Academic/Faculty $250 $ 250 $ 300 $ 300❑ Fulltime Student (W/ID) $ 60 $ 60 $ 60 $ 60❑ Reception (Reception <strong>is</strong> included in Full Reg<strong>is</strong>tration) $ 45 $ 45 $ 45 $ 45❑ I w<strong>is</strong>h <strong>to</strong> receive <strong>the</strong> 2003 proceedings in book <strong>for</strong>m $ 50 $ 75 $ 50 $ 75(A CD of <strong>the</strong> proceedings will <strong>be</strong> provided as part of <strong>the</strong> reg<strong>is</strong>tration fee.)❑ Please check here if you have a d<strong>is</strong>ability that requires special ass<strong>is</strong>tance or accommodation <strong>to</strong> fully participate.Attach a written description of needs.<strong>INDA</strong> must receive all special ass<strong>is</strong>tance requests by August 7, 2003 in order <strong>to</strong> accommodate.* ❑ TAPPI Mem<strong>be</strong>r #______________________________PAYMENT:FULL PAYMENT MUST ACCOMPANY THIS REGISTRATION. You may also charge reg<strong>is</strong>tration <strong>to</strong> your MasterCard, VISA or AmericanExpress Card. International Reg<strong>is</strong>trations: MasterCard, VISA, American Express, Check/Money Order (must <strong>be</strong> in U.S. funds drawn on aU.S. bank, and made payable <strong>to</strong> <strong>INDA</strong>), or wire transferred <strong>to</strong> Bank of America (<strong>for</strong>merly NationsBank), ABA#053000196, <strong>for</strong> final credit <strong>to</strong><strong>INDA</strong>, A/C#0041250069, reference INTC 2003.To pre-reg<strong>is</strong>ter, mail th<strong>is</strong> <strong>for</strong>m and payment or credit card in<strong>for</strong>mation <strong>be</strong><strong>for</strong>eMETHOD OF PAYMENT:August 7, 2003. Cancellations must <strong>be</strong> in writing and received by <strong>INDA</strong> <strong>be</strong><strong>for</strong>eAugust 7, 2003. No refunds <strong>for</strong> cancellations received after <strong>the</strong>se dates.Return <strong>to</strong>:INTC 2003<strong>INDA</strong>/TAPPIP.O. Box 1288, Cary, NC 27512-1288Telephone or Fax reg<strong>is</strong>trations (by credit card only) by August 7, 2003Tel. (919) 233-1210 (ext. 126), Fax (919) 233-1282❑ Check (made payable <strong>to</strong> <strong>INDA</strong>) ❑ MasterCard❑ Money Order (made payable <strong>to</strong> <strong>INDA</strong>) ❑ VISA❑ Wire Transfer (attach confirmation) ❑ AMEXTotal Enclosed $ ___________Card Num<strong>be</strong>r ____________________________Card Expires Month _______ Year ______Signature _______________________________Rec’d. Amount Ck. # CCC I R15