SWARNA AGARWAL (BANSAL) - INDA

SWARNA AGARWAL (BANSAL) - INDA

SWARNA AGARWAL (BANSAL) - INDA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

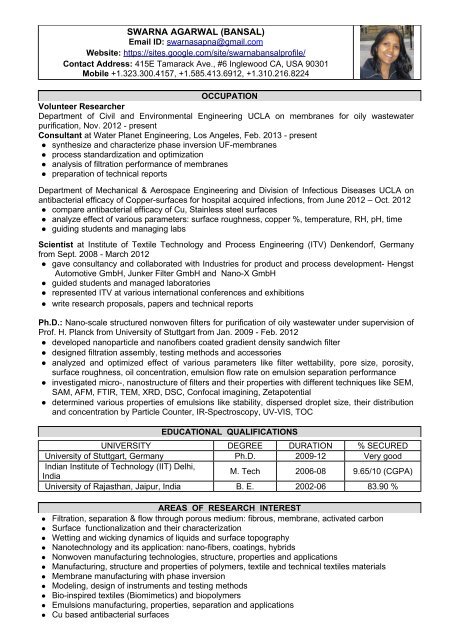

<strong>SWARNA</strong> <strong>AGARWAL</strong> (<strong>BANSAL</strong>)Email ID: swarnasapna@gmail.comWebsite: https://sites.google.com/site/swarnabansalprofile/Contact Address: 415E Tamarack Ave., #6 Inglewood CA, USA 90301Mobile +1.323.300.4157, +1.585.413.6912, +1.310.216.8224OCCUPATIONVolunteer ResearcherDepartment of Civil and Environmental Engineering UCLA on membranes for oily wastewaterpurification, Nov. 2012 - presentConsultant at Water Planet Engineering, Los Angeles, Feb. 2013 - present● synthesize and characterize phase inversion UF-membranes● process standardization and optimization● analysis of filtration performance of membranes● preparation of technical reportsDepartment of Mechanical & Aerospace Engineering and Division of Infectious Diseases UCLA onantibacterial efficacy of Copper-surfaces for hospital acquired infections, from June 2012 – Oct. 2012● compare antibacterial efficacy of Cu, Stainless steel surfaces● analyze effect of various parameters: surface roughness, copper %, temperature, RH, pH, time● guiding students and managing labsScientist at Institute of Textile Technology and Process Engineering (ITV) Denkendorf, Germanyfrom Sept. 2008 - March 2012● gave consultancy and collaborated with Industries for product and process development- HengstAutomotive GmbH, Junker Filter GmbH and Nano-X GmbH● guided students and managed laboratories● represented ITV at various international conferences and exhibitions● write research proposals, papers and technical reportsPh.D.: Nano-scale structured nonwoven filters for purification of oily wastewater under supervision ofProf. H. Planck from University of Stuttgart from Jan. 2009 - Feb. 2012● developed nanoparticle and nanofibers coated gradient density sandwich filter● designed filtration assembly, testing methods and accessories● analyzed and optimized effect of various parameters like filter wettability, pore size, porosity,surface roughness, oil concentration, emulsion flow rate on emulsion separation performance● investigated micro-, nanostructure of filters and their properties with different techniques like SEM,SAM, AFM, FTIR, TEM, XRD, DSC, Confocal imagining, Zetapotential● determined various properties of emulsions like stability, dispersed droplet size, their distributionand concentration by Particle Counter, IR-Spectroscopy, UV-VIS, TOCEDUCATIONAL QUALIFICATIONSUNIVERSITY DEGREE DURATION % SECUREDUniversity of Stuttgart, Germany Ph.D. 2009-12 Very goodIndian Institute of Technology (IIT) Delhi,IndiaM. Tech 2006-08 9.65/10 (CGPA)University of Rajasthan, Jaipur, India B. E. 2002-06 83.90 %●●●●●●●●●●●AREAS OF RESEARCH INTERESTFiltration, separation & flow through porous medium: fibrous, membrane, activated carbonSurface functionalization and their characterizationWetting and wicking dynamics of liquids and surface topographyNanotechnology and its application: nano-fibers, coatings, hybridsNonwoven manufacturing technologies, structure, properties and applicationsManufacturing, structure and properties of polymers, textile and technical textiles materialsMembrane manufacturing with phase inversionModeling, design of instruments and testing methodsBio-inspired textiles (Biomimetics) and biopolymersEmulsions manufacturing, properties, separation and applicationsCu based antibacterial surfaces

SKILL SETS● Computer skills: Windows, Linux, MS office, MS visio, photoshop, internet savvy● Technical skills: Statistics, quality control, technical consultancy, MATLAB, AUTOCAD, Minitab● Teaching skills: Supervision, presentation, counselor● Soft skills: Project management, planning, co-ordination and implementation● Language skills: English, German, Hindi, Sanskrit● Art skills: Poetry, sketching, computer graphics, designing, photography and cookingPUBLICATIONS AND CONFERENCE PROCEEDINGS1. S. Bansal, Structure and Properties of Bulky Wavemaker Nonwovens for Automotives: Effect ofvarious process parameters and fiber properties, ISBN 978-3-8383-7983-82. S. Bansal, Voluminous Wavemaker nonwovens for automotive, Managing Innovations in Textile2010, Manchester, UK3. S. Bansal, Voluminous Wavemaker nonwovens for mobiltech, TexSci-2010, TU Liberec, CzechRepublic4. S. Bansal, 3D innovative Wavemaker nonwovens for mobiltech, ICTN-2010, IIT Delhi, India5. S. Bansal, Innovative aspects of emulsion breakdown by nanocoated fibrous media, 39 th TextileResearch Symposium 2010, IIT Delhi, India6. S. Bansal, Wetting dynamics of isooctane droplet on nanocoated textile surfaces in water, 39 thTextile Research Symposium 2010, IIT Delhi, India7. S. Bansal, V. von Arnim, H. Planck, Effect of fibrous filter properties on the oil-in-water-emulsionseparation and filtration performance, Journal of Hazardious Materials, 190, 2011, 45-508. S. Bansal, Novel aspects of liquid-liquid separation by nanocoated filter, Jahrestreffen desFlüssigkeits-abtrennung DECHEMA-2011, Frankfurt, Germany9. S. Bansal, Nano-coated nonwoven filter media for oil-in-water emulsion separation, Filtech-2011Wiesbaden, Germany10.S. Bansal, Nanoparticles coated filter media for effective separation of secondary emulsions,Techtextil-2011, Frankfurt Germany11.S. Bansal, Nano-Modified Sandwich Filter for Breakdown of Secondary Oil-in-Water Emulsion,Filtrex-2011, EDANA, India12.S. Agarwal, V. von Arnim, T. Stegmaier, H. Planck, A. Agarwal, Role of surface wettability androughness in emulsion separation, Separation and Purification Technology, 107, 2013, 19–25ACADEMIC PROJECTS AND INDUSTRIAL TRAININGSMajor M.Tech. Project: Effect of process parameters and fiber properties on Wavemakernonwovens for mobiltech: Replacement of PU foam with PET made 3D voluminous nonwovens● prepared fiber blends, cross lapped, needle punch and wavemaker nonwovens● operated fiber opener-blender, carding, cross-lapper, needle punching, wavemaker, thermalbonding machines● analyzed effect of various parameters on wavemaker nonwovens properties and cushioningperformance: bonding fiber percentage, various wavemaker machine settings, feed web GSMThis project was rated as an excellent work at IIT Delhi and ITV Denkendorf, Germany.Minor Projects:● Effect of fabric construction parameters and moisture regain on thermal transmission behavior ofplain cotton woven fabrics, Prof. V. K. Kothari.● Vertical wicking behavior of cotton yarns and plain woven fabrics, Prof. R. S. Rengasamy.● Comparison of ring and rotor yarn count and pick density on transmission properties of plainwoven cotton fabrics, Prof. R. S. Rengasamy and Prof. Apurba Das.● Effect different silicon coating treatments on properties of plain woven nylon fabric for automotiveAirbag, Prof. V.P. Singh, MLVTEC Bhilwara, India.Indrustrial Trainings● Sangam Suitings, Bhilwara, India● Rajasthan Spinning and Weaving Mills Ltd. Banswara and Bhilwara, IndiaACHIEVEMENTS● Outstanding Technical Paper Award, Filtrex-2011 EDANA● Outstanding student award Dr. Amrik Singh Gold Medal and Prize at IIT Delhi, India 2008● DAAD-2007 fellowship to undertake master project in Germany, 2007-2008● 2 nd All India Rank in Graduate Aptitude Test for Engineers (GATE) 2006● Sport Secretary at MLVTEC Bhilwara for the session 2005-06