You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

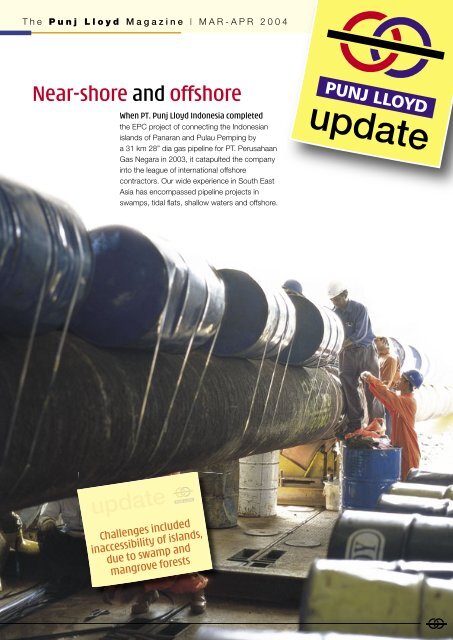

<strong>update</strong>punj lloyd’s indonesianperspectiveIndonesia over a decade<strong>Punj</strong> <strong>Lloyd</strong> Limitedstarted its operations inIndonesia in 1993 witha contract to lay the 16”dia 210 km multi productBalongan Jakarta pipeline.At the time <strong>Punj</strong> <strong>Lloyd</strong> wasthe only Indian companyin the hydrocarbonsector in Indonesia. Workcommenced in April 1993and we completed thepipeline in 12 months,against a completionschedule of 16 months.Pertamina, the stateownedoil and gascompany of Indonesia,commended <strong>Punj</strong> <strong>Lloyd</strong>for its early projectcompletion.Some of the challengesfaced in the executionof the project were thelanguage barrier andcultural differences, whichwe overcame by hiringand training local staff atthe offi ce and site levels.Interacting and workingwith the locals also gaveus a valuable insight intothe Indonesian workculture. We created apermanent bank of trainedlocal personnel whocontinue to work on allour subsequent projectsin Indonesia. The pipelineroute passed through theisland of Java which hasthe highest density ofpopulation in the world.Working through thepopulated villages andtowns was a logisticalchallenge, both for ourmen and machines. Wecontributed towardscommunity developmentby helping the locals builda mosque and a school ina densely populated areaalong the pipeline route.Indonesia being a tropicalcountry, is traversedby several rivers acrosswhich the pipeline passed.These we crossed byopen cut method, augurboring and by horizontaldirectional drilling,a technology which wasrarely used those days.HDD as it is commonlyknown, is an environmentprotective technology,favoured universally.<strong>Punj</strong> <strong>Lloyd</strong> has itsown rig and has asubsidiary company,PLN Construction Pvt Ltd,which undertakesHDD work.

In 1996 <strong>Punj</strong> <strong>Lloyd</strong> wasawarded two prestigiousEPC projects, theKertapati Jambi pipelineand Satellite ‘A’ TegalGede-Tangerang pipelineby Pertamina. However,the economic crisis struckthe country and all stateowned projects weresuspended. At a timewhen many internationalcompanies relocatedthemselves, <strong>Punj</strong> <strong>Lloyd</strong><strong>update</strong>presence in the regionhas resulted incontinued investmentin construction andamphibian equipment

was committed tocontinue its operationsin Indonesia. The yearsduring the crisis were noteasy ones, however, wepride ourselves in meetingchallenges head-on.In 1997 PT. <strong>Punj</strong><strong>Lloyd</strong> Indonesia wasincorporated to establisha regional presence inSouth East Asia.We soon bagged aswamp and near shorepipeline project from Pt.Bouygues Offshore (nowknown as Saipem) forthe owner, TOTAL E&PIndonesie. Our work forthis project has resultedin our continued presencein Kalimantan, withTOTAL E&P Indonesieas our client.Our commitment toestablish a presence inthe region has resultedin continued investmentin construction andamphibian equipment.Our equipment yardincludes a jetty for smallships and barges.<strong>update</strong>TOTAL awardedan EPC swampand shallow waterpipeline project

over a decade

<strong>update</strong>Safe Manhours in Indonesia1.89 million Panaran Pemping1.32 million Tunu 91.31 million Tunu 71.25 million Caltex1.12 million Tunu 80.85 million Tunu 4&5

We also undertook field development work in Duri Sumatra for PT. Caltex.In 2002 <strong>Punj</strong> <strong>Lloyd</strong> was awarded an EPC onshore, swamp and shallow water pipeline project by PerusahaanGas Negara. Perusahaan Gas Negara owns most of the gas pipelines in Indonesia. The pipeline was part of theSumatra Singapore pipeline and our section included hopping islands of Panaran and Pemping. This project trulylaunched our offshore division, as until then we were acknowledged leaders in swamp, tidal flats and near shorepipeline laying.Also in 2002, Total awarded us an EPC pipeline project, that of Tunu Field Development Phase 9. And asa confirmation of their continued confidence in our project management capabilities, Total awarded us, oncompetitive basis, an EPC project- Peciko gas processing facilities at Senipah.<strong>Punj</strong> <strong>Lloyd</strong> Limited and Pt. <strong>Punj</strong> <strong>Lloyd</strong> Indonesia over the last decade have built on its reputation to provideinternational standards of quality construction and HSE practices, completing projects on time for oil and gasmajors of the hydrocarbon and infrastructure sectors in the Far East. P K Gupta

The Peciko EPC Project takes offThe PECIKO Phase IVproject in Senipah, EastKalimantan, Indonesia willsoon be completed byPT. <strong>Punj</strong> <strong>Lloyd</strong> Indonesiafor TOTAL E&P Indonesie.The project comprises twotrains of 550 MMSCFDmedium pressure gascompression facility. Workscope includes detailedengineering, procurementand supply, construction,pre-commissioningand assistance forcommissioning.PECIKO is a gas andcondensate fi eld locatedoffshore East Kalimantan,south of Mahakam riverdelta, 25 km fromTOTAL E&P Indonesie’sSenipah terminal. Thework is a part of theoverall developmentprogramme of TOTAL inthis gas fi eld region.The onshore facilities willreceive, treat, compressand export the mediumpressure production fl owsfrom PECIKO Phase IVoffshore fi elds.To overcome lowpressure of 30 barg. at theoffshore fi elds, the newfacilities will compressthe inlet gas to 40 barg.medium pressure forsupply to the export gaspipeline, terminating atBontang LNG plant.The award of theproject by TOTAL E&PIndonesie was againstinternational competitivebidding. The teamincludes Indian engineersand Indonesiansupervisors and workmen.While sourcing of materialwas carried outworldwide, maximumlocal resources wereutilised. Challengesincluded developmentof site and housingfacilities amid densetropical forest, settingup an effectivecommunication systemand an elaborateamphibian transportsystem to overcomeinaccessibility of the site.The achievement oftransporting and installingtwo turbo compressors,each weighing 300 MTwith dimensions of 27 Mlength, 15.50 M heightand 7.15 M width,was due to meticulousplanning and stringentsafety precautions andprocedures.The compressors wereunloaded at the Senipahjetty and were erected at adistance of 1.5 km on theirrespective foundations.Inland transportationwas by means of a selfpropelled modular trailerwith 118 axle lines and<strong>update</strong>maximumlocal resourceswere utilised216 tyres. The entireerection was carried outwithout the use of anycrane. Four hydraulicjacks of 150 MT capacitywere used.This feat wasaccomplished inspiteof heavy rains and wasexecuted in 11 days. A K Gupta

<strong>update</strong>tunu field developmentproject phase 9/epsc 2New Horizons, New Aspirations…TUNU, a gas andcondensate fi eld locatedEast of Kalimantan(Indonesia) on the outer<strong>mar</strong>gin of the Mahakamdelta, is partially onshorein swamp areas andpartially offshore inshallow waters.Tunu Phase 9development allowsTOTAL to meet itsproduction requirementsby constructing trunklinesto connect new GatheringTesting Satellite Stationsto the existing pipelinenetwork. <strong>Punj</strong> <strong>Lloyd</strong>was awarded the EPCcontract for Tunu FieldDevelopment Project– Phase 9 /EPSC 2.The offshore pipelayingoperation had to contendwith currents exceeding8.5 knots. The 20” diapipeline had to be laidfrom the shoreline (KP2100) to the offshoreplatform, GatheringTesting Satellite Stationat KP0. The pipestringwas fabricated in twosections of 1300 m and900 m. Lateral guidepiles were driven in tworows, 3 m apart alongthe entire length, to arrestthe lateral movement ofthe pipestring at hightide. Custom built polybuoys were attached tothe pipestring during thepulling operation.A cutter suction dredgerwas deployed for pretrenchingdue to thepresence of clustersof sand dunes in theoffshore sea.A work barge with afour point mooring systemwas positioned to pullthe string. The barge wasequipped with a 75 Tcrane, a dual RTK GPSpositioning system anda 7 T winch with 22 mmwire rope.The wire rope was laidby a push boat betweenthe two lateral guideScope of WorkEngineering and procurement of all material• 20” dia 19.05 mm CC API 5L Grade X 65 15.7 km• 8” dia 18.6 mm API 5L Grade X 65 with a 2” dia piggy back line 1.7 kmPipeline construction• Offshore by conventional method 3.2 km in shallow water• Offshore by Push Pull method 2.3 km• Swamp Push Pull 5.8 km• HDD in swamp with Rig mounted on Barge 4.1 km• Bottom Pull Shore Approach 2 kmpiles. The fi rst string of with design calculations,900 m was successfully sketches, assessment,pulled offshore. The tieinof the two strings was using underwater divers’constant monitoring,completed in a swamp expertise.trench, using four fl exiyokebarges with two dogleg at fi ve platformsInstallation of risers andswamp excavators. As of 8” with 2” piggy backtie-ins, radiography and line and 20” dia wasfi eld joint coating on successfully completed.fl exi-yoke barges are high This was the fi rst time thattide dependent, timing is the installation of risersvery critical.and dogleg assemblyPulling operations was handled by us. Piperesumed at the Gathering laying on an existingTesting Satellite platform pipe rack is a very critical(KP0) in spite of currents activity as it is parallel to aof 3 knots and the pipeline live pipeline within a verywas successfully pulled congested area.

<strong>update</strong>laying of the longestpipeline lengthof 2000 m by HorizontalDirectional DrillingThe offshore pipelinesare laid with accuracyof ±5 m while theplatform position is fi xed.A comprehensive metrologyis performed by diversto fi nalize the length ofthe dogleg based on theactual position of the laidpipeline. The dogleg spoolis fabricated on the bargeitself. The fi nal tie-in isdone in 2G position atthe location above theriser clamp.PT. <strong>Punj</strong> <strong>Lloyd</strong> Indonesiaacquired a 230 ft bargewith a deck loadingcapacity of 10 T/m 2 . Thebarge is fi tted with fourdavits each for SWL (asafe working load) of35 T and is supportedon four point mooringsystem. The mooringwinches have a capacityof 35 T with a drumcapacity of 900 mtr.Two cranes of 150 Tand 50 T are mountedon this barge in order tocarry out the installationof riser and doglegassemblies. The barge isfi tted with dual RTK GPSPositioning System. Priorto mobilisation at site thepositioning systems arecalibrated for accuracy.Another milestonesuccessfully met wasthe laying of the longestlength of 2000 m pipelineby Horizontal DirectionalDrilling. The pipestringhad to be prepared andwet stored in the opensea, with currents ofthree knots. This wasthe longest HDD lengthundertaken by <strong>Punj</strong> <strong>Lloyd</strong>.<strong>update</strong> A Rajendrapulled with designcalculations, sketches,assessment, constantmonitoring, usingunderwater divers’expertise

It is an example ofmeticulous planning,to give a spurt to newbusiness lines, as also tomeet the needs of existingprojects - Tunu Phase 9and Peciko.The Sungaipuranbase camp of PT. <strong>Punj</strong><strong>Lloyd</strong> Indonesiaexemplifi es all this andmore. Sprawling over anarea of 45,000 m 2 , it islocated by the Mahakamriver in East Kalimantan.Built in a record tenmonths, the base campis accessible by both riverand road, the nearestairport being Balikpapan,140 km away and thenearest city, Sa<strong>mar</strong>inda,about 20 km away.The camp housesthe PT. <strong>Punj</strong> <strong>Lloyd</strong>Indonesia offi ce, residentialaccommodation, messingand recreational facilitiesof <strong>Punj</strong> <strong>Lloyd</strong> andTOTAL E&P Indonesiepersonnel, covering anarea of 8,000 m 2 .The recently builtfabrication shop isspread over 1,200 m 2with a 10 T monorailgantry certifi ed by Migas.Pre-fabricated pipingamounting to 48,000 inchdia for the Peciko projectis being fabricated atthe shop.The storage area forstacking pipes andfi ttings for pre-fabricationis 4,500 m 2 . Aftercompletion of radiography,pipe spools are stacked inan area of 5,000 m 2 nearthe sandblasting yard.The yard has twosandblasting sheds withtwo working nozzles.Post sand blasting andSungaipuranBase Campcatalysingnew business

<strong>update</strong>Sprawling overan area of 45,000 m 2located by the Mahakamriver in East Kalimantanpainting, the pipe spoolsare stacked in an areaclose to the loadingjetty, ready for seatransportation tothe project site.The workshop,extending over 3,000 m 2is capable of undertakingmaintenance of heavyswamp equipmentlike <strong>mar</strong>sh buggies,swamp cranes, swampexcavators, pontoons andconstruction equipmentlike crawler cranes,welding machines,power generators andcompressors.An area of 6,500 m 2has been ear<strong>mar</strong>kedfor storage of line pipesrequired in pipelineprojects. This is built overwell-compacted groundaccessible by crane onboth sides. This storagearea caters to the needof Tunu Phase 9 project,with 2,000 pipes rangingfrom 8” to 20” dia.The warehouse includesa covered area of 640 m 2in addition to the openstorage area. Inventory ismaintained and <strong>update</strong>don an ORACLE basedERP system.Future plans includeconstruction of a skidway with a capacity of1,000 T for fabricationand launch of offshoreplatforms and expansionof the area by 6,000 m 2 .The construction of theskid way is expected tocommence soon.PT. <strong>Punj</strong> <strong>Lloyd</strong> Indonesia,with an excellent logisticsbase in East Kalimantan,is poised for executionof any project in SouthEast Asia. S Vyas

PT <strong>Punj</strong> <strong>Lloyd</strong>IndonesiaHSE rating86%AuditTOTAL E&P Indonesie conducts an HSE audit annuallyon all its contractors, based on their area of operations.PT. <strong>Punj</strong> <strong>Lloyd</strong> Indonesia was audited under the VeryHigh Risk category for the Tunu Phase 9 project.A high level audit team led by Mr John Martin ofDevelopmentDepartment:Methods &15 criteria of HSE auditProcedures TOTAL Policy Statementconducted theEmergency Response Procedureaudit based onSafety Rules – Safety Manual15 criteria.New Employee Orientation ProgramIt was a proudHSE Meeting Programmoment forHSE Training ProgramPT. <strong>Punj</strong> <strong>Lloyd</strong>Equipment and Materials ManagementPersonal Protective EquipmentIndonesia at TunuHSE Inspection ProgramPhase 9 whenAccident Reporting Procedurethe rating of 86%Professional HSE Supportwas awarded.Industrial HygieneEnvironmentStatistical Injury & Illness DataIncident InvestigationSafety first,Safety alwaysAt all the sites of PT. <strong>Punj</strong> <strong>Lloyd</strong> Indonesia,safety induction, environment training and fi rst aidprogrammes are conducted for all employees,from site management to subcontractors’personnel. On completion of the programme anundertaking is taken from the work crew to abideby the HSE rules in the course of construction.Safety and fi rst aid programmes are regularlyrepeated as an ongoing exercise.Daily toolbox talks are held prior to constructionactivity. The toolbox talk topic is preparedby the HSE department and conducted bythe supervisor. Contents include day to dayproblems faced and hazards at site. ProjectSafety Committee meetings are held weekly withcontractors and subcontractors. Inspections andaudits are constantly carried out. Managementwalks are conducted and hazard observationreports are inculcated at all levels.The HSE objectives achieved in 2003encompass major explosion, fatality and losttime incident, fi re incident, accident frequency,accident severity, near miss ratio, environmentalincidents, vehicle incidents and hazardobservation, with most equalling zero.As part of emergency preparedness, thereis always a medical professional on site. TheRumah Sakit Umum hospital is contractedto attend to major injury cases. In addition,emergency evacuation drill is conductedregularly to create awareness among the crewabout emergency systems and action to betaken by them. P KolwalkarCorporate Office <strong>Punj</strong> <strong>Lloyd</strong> Ltd. <strong>Punj</strong> <strong>Lloyd</strong> House, 17-18 Nehru Place, New Delhi 110019 India Tel +91 11 26200123 Fax +91 11 26200111 Email info@punjlloyd.comOther Offices <strong>Punj</strong> <strong>Lloyd</strong> Ltd. PO Box 28907, 202 Al Otaiba Building Khalifa Street Abu Dhabi UAE Tel +971 2 6261604 Fax +971 2 6267789 Email pllad@emirates.net.ae<strong>Punj</strong> <strong>Lloyd</strong> Ltd. PO Box 704, Postal Code 133, Al Khuwair, Sultanate of Oman Tel +968 597728 Fax +968 597493 | <strong>Punj</strong> <strong>Lloyd</strong> Kazakhstan LLP Astana International Hote l,113 Baitursynov Str. 480072 Almaty, Republic of Kazakhstan Tel +7 3272 501233, 507258 Fax +7 3272 501223 Email punjlloyd@nursat.kz <strong>Punj</strong> <strong>Lloyd</strong> - LIMAK JV 74 MahatmaGandhi Road, GOP 06700 Ankara, Turkey Tel +90 312 4466364, 4469714 Fax +90 312 4466794 Email plljv@plljv.com <strong>Punj</strong> <strong>Lloyd</strong> Ltd. Banmore Industrial Area, Banmore, DistrictMorena 476444 Madhya Pradesh, India Tel +91 7532 243644, 243534 Fax +91 7532 243297 | <strong>Punj</strong> <strong>Lloyd</strong> (Malaysia) Sdn. Bhd. Cosmos Centre, 69/1 New Circular Road Dhaka1217, Bangladesh Tel +880 2 9330859, 8312024 Fax +880 2 8314602 | <strong>Punj</strong> <strong>Lloyd</strong> Ltd. Bin Yousef Group Companies WLL, 9th Floor, Almana Tower, Old Airport Road, PO Box3264 Doha, Qatar Tel +974 4622127, 4626172 Fax +974 4626180 Email pbali@punjlloyd.com | Pt. <strong>Punj</strong> <strong>Lloyd</strong> Indonesia Ventura Building, 4th Floor, Suite 401B Jl. R A Kartini26, Jakarta 12430 Indonesia Tel +6221 7591 4766, 7591 4762 Fax +6221 7591 4241 Email svyas@ptpli.com | Mr. Erich Niedermeyr Area Manager Kutterlingerweg 383059Kolbermoor, Germany Tel +49 8061 5616 Fax +49 8061 370450 Email e.niecons@t-online.de <strong>Punj</strong> <strong>Lloyd</strong> Ltd. 32 Harley House Marylebone Road, London NW1 5HF UKTel +44 20 7486 6009 Fax +44 20 7935 5086 Email info@punjlloyd.com | <strong>Punj</strong> <strong>Lloyd</strong> Ltd. 1 TV Industrial Estate, SK Ahire Marg, Worli, Mumbai 400025 Tel +91 22 24924421,56602835 Fax +91 22 24936861 Email dmankame@punjlloyd.comwww.punjlloyd.comProject ExportsPromotion CouncilStrategic Business UnitsCivil Construction | Pipelines | Tankage & Terminals | Telecom | Turnkey & Composite ConstructionPlant and Facility Management | Power Plants | High Value Engineering