Hydraulic cylinders type CC • round heads

Hydraulic cylinders type CC • round heads

Hydraulic cylinders type CC • round heads

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

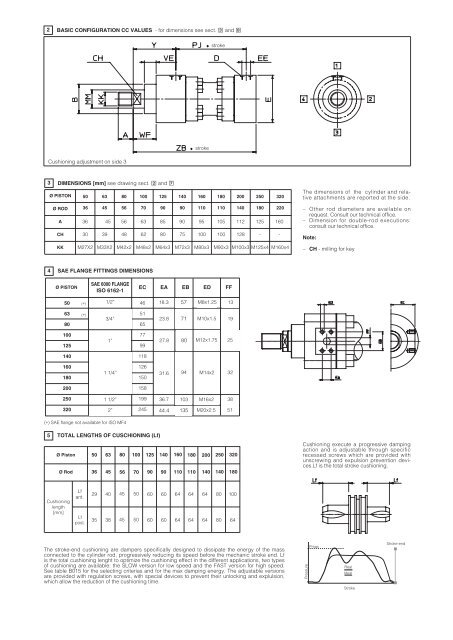

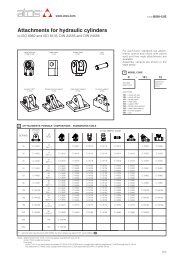

2 BASIC CONFIGURATION <strong>CC</strong> VALUES - for dimensions see sect. � and �<br />

Cushioning adjustment on side 3<br />

3 DIMENSIONS [mm] see drawing sect. � and �<br />

Ø PISTON 50<br />

Ø ROD<br />

A<br />

CH<br />

KK<br />

Ø Piston<br />

Ø Rod<br />

Cushioning<br />

length<br />

[mm]<br />

36<br />

36<br />

30<br />

M27X2<br />

Lf<br />

ant.<br />

Lf<br />

post.<br />

63<br />

45<br />

39<br />

80<br />

56<br />

100<br />

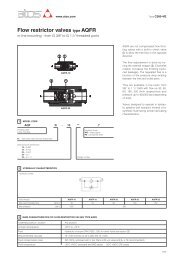

5 TOTAL LENGTHS OF CUSCHIONING (Lf)<br />

45<br />

M33X2<br />

56<br />

48<br />

M42x2<br />

70<br />

63<br />

62<br />

M48x2<br />

4 SAE FLANGE FITTINGS DIMENSIONS<br />

Ø PISTON<br />

50<br />

63<br />

80<br />

100<br />

125<br />

140<br />

160<br />

180<br />

200<br />

250<br />

320<br />

(∗)<br />

(∗)<br />

SAE 6000 FLANGE<br />

ISO 6162-1<br />

1/2”<br />

3/4”<br />

1”<br />

46<br />

51<br />

65<br />

77<br />

99<br />

118<br />

125<br />

90<br />

85<br />

80<br />

M64x3<br />

1 1/4”<br />

126<br />

150<br />

31.6<br />

1 1/2”<br />

2”<br />

(∗) SAE flange not available for ISO MF4<br />

158<br />

199<br />

245<br />

140<br />

29 40 45 50 60 60 64 64 64 80 100<br />

90<br />

stroke<br />

160<br />

110<br />

stroke<br />

180<br />

110<br />

50 63 80 100 125 140 160 180 200 250 320<br />

36 45 56 70 90 90 110 110 140 140 180<br />

35 38 45 50 60 60 64 64 64 80 64<br />

The stroke-end cushioning are dampers specifically designed to dissipate the energy of the mass<br />

connected to the cylinder rod, progressively reducing its speed before the mechanic stroke end. Lf<br />

is the total cushioning lenght to optimize the cushioning effect in the different applications, two <strong>type</strong>s<br />

of cushioning are available: the SLOW version for low speed and the FAST version for high speed.<br />

See table B015 for the selecting criterias and for the max damping energy. The adjustable versions<br />

are provided with regulation screws, with special devices to prevent their unlocking and explulsion,<br />

which allow the reduction of the cushioning time.<br />

90<br />

75<br />

M72x3<br />

95<br />

100<br />

M80x3<br />

105<br />

100<br />

EC EA EB ED FF<br />

18.3<br />

23.8<br />

27.8<br />

36.7<br />

44.4<br />

57<br />

71<br />

80<br />

94<br />

103<br />

135<br />

M8x1.25<br />

M10x1.5<br />

M12x1.75<br />

M14x2<br />

M16x2<br />

M20x2.5<br />

200<br />

140<br />

112<br />

128<br />

250<br />

180<br />

125<br />

320<br />

220<br />

M90x3 M100x3 M125x4 M160x4<br />

13<br />

19<br />

25<br />

32<br />

38<br />

51<br />

-<br />

160<br />

-<br />

The dimensions of the cylinder and relative<br />

attachments are reported at the side.<br />

– Other rod diameters are available on<br />

request. Consult our technical office.<br />

– Dimension for double-rod executions:<br />

consult our technical office.<br />

Note:<br />

– CH - milling for key<br />

Cushioning execute a progressive damping<br />

action and is adjustable through specific<br />

recessed screws which are provided with<br />

unscrewing and expulsion prevention devices.Lf<br />

is the total stroke cushioning.<br />

Pressure<br />

Pmax<br />

Real<br />

Ideal<br />

Stroke<br />

Stroke-end