metric 3 Flute Standard length

metric 3 Flute Standard length

metric 3 Flute Standard length

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

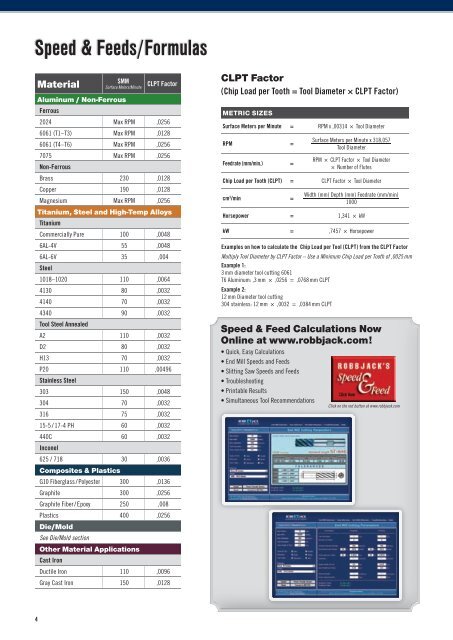

Speed & Feeds/FormulasMaterialSMMSurface Meters/MinuteAluminum / non-FerrousCLPT FactorFerrous2024 Max RPM ,02566061 (T1–T3) Max RPM ,01286061 (T4–T6) Max RPM ,02567075 Max RPM ,0256Non-FerrousBrass 230 ,0128Copper 190 ,0128Magnesium Max RPM ,0256Titanium, Steel and High-Temp AlloysTitaniumCommercially Pure 100 ,00486AL-4V 55 ,00486AL-6V 35 ,004Steel1018–1020 110 ,00644130 80 ,00324140 70 ,00324340 90 ,0032Tool Steel AnnealedA2 110 ,0032D2 80 ,0032H13 70 ,0032P20 110 ,00496Stainless Steel303 150 ,0048304 70 ,0032316 75 ,003215-5 / 17-4 PH 60 ,0032440C 60 ,0032Inconel625 / 718 30 ,0036Composites & PlasticsG10 Fiberglass / Polyester 300 ,0136Graphite 300 ,0256Graphite Fiber / Epoxy 250 ,008Plastics 400 ,0256Die/MoldSee Die/Mold sectionOther Material ApplicationsCast IronDuctile Iron 110 ,0096Gray Cast Iron 150 ,0128ClPT Factor(Chip Load per Tooth = Tool Diameter × CLPT Factor)METRIC SIzESSurface Meters per Minute = RPM x ,00314 × Tool DiameterRPM =Feedrate (mm/min.) =Surface Meters per Minute x 318,057Tool DiameterRPM × CLPT Factor × Tool Diameter× Number of <strong>Flute</strong>sChip Load per Tooth (CLPT) = CLPT Factor × Tool Diametercm 3 /min =Width (mm) Depth (mm) Feedrate (mm/min)1000Horsepower = 1,341 × kWkW = ,7457 × HorsepowerExamples on how to calculate the Chip Load per Tool (CLPT) from the CLPT FactorMultiply Tool Diameter by CLPT Factor – Use a Minimum Chip Load per Tooth of ,0025 mmExample 1:3 mm diameter tool cutting 6061T6 Aluminum: ,3 mm × ,0256 = ,0768 mm CLPTExample 2:12 mm Diameter tool cutting304 stainless: 12 mm × ,0032 = ,0384 mm CLPTSpeed & Feed Calculations nowOnline at www.robbjack.com!• Quick, Easy Calculations• End Mill Speeds and Feeds• Slitting Saw Speeds and Feeds• Troubleshooting• Printable Results• Simultaneous Tool RecommendationsClick on the red button at www.robbjack.com4