metric 3 Flute Standard length

metric 3 Flute Standard length

metric 3 Flute Standard length

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

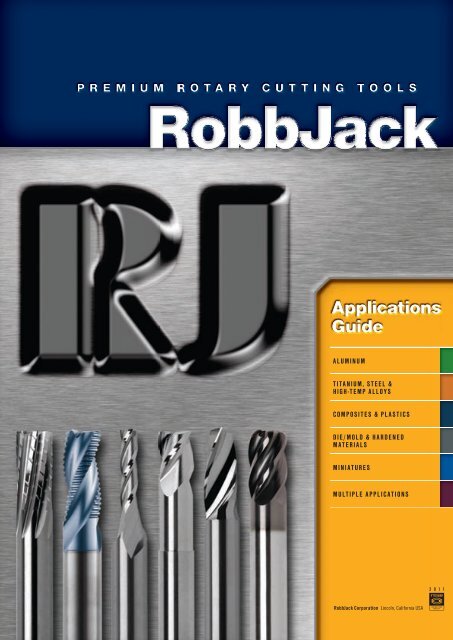

PremiumPremiumPremium r otary Cuttingotary Cuttingotary Cutting t oolsoolsoolsApplicationsApplicationsApplicationsGuideGuideGuideGuideGuideGuideAluminumTiTAnium, ST eel &HigH -Temp AlloySCompoS i T e S & p l ASTi CSDie/m olD & HA r D eneDmATeriA l Sm iniATureSm ulT iple AppliCATionSRobbJack Corporation Lincoln, California USARobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJackRobbJack2 0 1 1

SolutionMaximum RemovalRates in Aluminum?Deep Pockets inAluminum?Machining High-Temperature Alloys?MA1 Series 10MFM Series 12MXG andMXF Series 20RoutingComposites?Drilling Holesin Composites?Cutting HardenedDie Steels?Micro Machining?Tools for OtherApplications?Diamond CoatedInserts?MPCD and MCPCDMCR Compressionand MCE RoutersMPCD DrillsDiamond-CoatedCarbide DrillsRobbJack’sMDM, MTM, andMHM Tool SeriesA CompleteLine of MicroMachining ToolsQuality Tools for EveryImaginable Materialand ApplicationMP830Diamond CoatedInserts32–353438–424549562

Catalog Sectionsat a glanceAluMInuM APPlICATIOnS 9MA1-201 2 <strong>Flute</strong> Stub Length 10MA1-303 3 <strong>Flute</strong> <strong>Standard</strong> Length 11MFM 2 <strong>Flute</strong> (Short to Long Reach) 12MFM 3 <strong>Flute</strong> (Short to Long Reach) 14MS1-201 2 <strong>Flute</strong> C-2 Grade Stub Length 16MC1-201 2 <strong>Flute</strong> C-2 Grade <strong>Standard</strong> Length 17MC1-301 3 <strong>Flute</strong> C-2 Grade <strong>Standard</strong> Length 17TITAnIuM, STeelS & HIgH-TeMP AllOyS 19MXg-402 4 <strong>Flute</strong> <strong>Standard</strong> Length 20MXg-402Bn 4 <strong>Flute</strong> Ball End <strong>Standard</strong> Length 20MXg-502 5 <strong>Flute</strong> <strong>Standard</strong> Length 20MXF-602/802 6/8 <strong>Flute</strong> <strong>Standard</strong> Length 21MST-341 3 <strong>Flute</strong> Super Tuffy Carbide Stub Length 23MSTR-301 3 <strong>Flute</strong> Super Tuffy Carbide Ruffer Stub Length 24MSTR-303 3 <strong>Flute</strong> Super Tuffy Carbide Ruffer <strong>Standard</strong> Length 24MSTR-401 4 <strong>Flute</strong> Super Tuffy Carbide Ruffer Stub Length 25MSTR-404 4 <strong>Flute</strong> Super Tuffy Carbide Ruffer <strong>Standard</strong> Length 25MB-440 4 <strong>Flute</strong> Tuffy Ball End <strong>Standard</strong> Length 40° Helix 26MST-360 3 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> Length 27MST-646 6 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> Length 28MST-430 4 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> Length 29MST-434 4 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> Length 29COMPOSITeS & PlASTICS 31MCPCD-203 Composite 2 <strong>Flute</strong> <strong>Standard</strong> Length 35MPCD-203 2 <strong>Flute</strong> <strong>Standard</strong> Length 35MCR Compression Router – 4/6 <strong>Flute</strong> 32MCe Carbide Composite Router – 6/8 <strong>Flute</strong> 33MP810/MF104 Diamond Coated <strong>Standard</strong> Length Drills 34CSKB/CSKI Countersink Bodies and Diamond Coated Inserts 36DIe/MOlD & HARDeneD MATeRIAlS 37MDM-201 2 <strong>Flute</strong> Tuffy Ball End Extended Length 38MTM-201 2 <strong>Flute</strong> Tuffy Grade Toroid End Mill 40MHM Multi-<strong>Flute</strong> Tuffy Grade 42MP820 2, 4 <strong>Flute</strong> Diamond Coated Mold Maker End Mills 43MP820 2, 4 <strong>Flute</strong> Diamond Coated Big Shank Tools 44MInIATuReS APPlICATIOnS 45MSS-2 2 <strong>Flute</strong> Miniature Stub Length 46MSR-2 2 <strong>Flute</strong> Miniature <strong>Standard</strong> Length 46MSS-2Bn 2 <strong>Flute</strong> Miniature Stub Length Ball End 47MSR-2Bn 2 <strong>Flute</strong> Miniature <strong>Standard</strong> Length Ball End 47MSS-4 4 <strong>Flute</strong> Miniature Stub Length 48MSR-4 4 <strong>Flute</strong> Miniature <strong>Standard</strong> Length 48MAH Accuhold – End Mill Extension Holder 48, 57MulTIPle APPlICATIOnS 49MTl-303 3 <strong>Flute</strong> Tuffy Grade Extra Length 50MC8-201 2 <strong>Flute</strong> C-2 Grade Stub Length 51MC8-203 2 <strong>Flute</strong> C-2 Grade <strong>Standard</strong> Length 51MTS-401 4 <strong>Flute</strong> Tuffy Grade Stub Length 52MSB-201 2 <strong>Flute</strong> Tuffy Ball End Mill Stub 53MB-203 2 <strong>Flute</strong> Tuffy Ball End <strong>Standard</strong> Length 53MSB-301 3 <strong>Flute</strong> Tuffy Ball End Stub Length 54MB-333 3 <strong>Flute</strong> Tuffy Ball End <strong>Standard</strong> Length 54MnR-204 2 <strong>Flute</strong> C-2 Grade <strong>Standard</strong> Length 55MnR-303 3 <strong>Flute</strong> C-2 Grade <strong>Standard</strong> Length 55MP830 Diamond Coated Inserts 56MAH Accuhold – End Mill Extension Holder 48, 57Tool Symbol GuideCharacteristicsSquare End Corner Break Chamfer Corner Radius Toroid Ball End118° 118 / 20° 135 / 20° EllipticalDrill Tip Drill Tip Drill Tip Drill Tip1 <strong>Flute</strong> 2 <strong>Flute</strong> 3 <strong>Flute</strong> 4 <strong>Flute</strong> 5 <strong>Flute</strong> 6 <strong>Flute</strong> 8 <strong>Flute</strong> 10 <strong>Flute</strong>10° Helix 30° Helix 35° Helix 40° Helix 45° Helix 60° Helix Coolant Feather BlendGroovesNecked Mirror Edge T-Process Flats Polished PCD DiamondHoneApplicationsSlotting Side Milling Axial Depth Helical Radial Step Conventional Ramping HighInterpolation OverPerformance3-D High-Speed Roughing Semi- Finishing Dry Wet Cold AirFinishingSpray MistHole DrillingMaterialsAluminum Copper Titanium Magnesium Cast Iron Steel Stainless Steel Super AlloysPlastics Composites 40 HRc 50 HRc 64 HRc BrassHardness Hardness HardnessCoatingsTitanium Titanium Aluminum Diamond Diamond-LikeNitride Carbo-Nitride Titan. Nitride Coated (DCC) Carbon (DLC)3

Speed & Feeds/FormulasMaterialSMMSurface Meters/MinuteAluminum / non-FerrousCLPT FactorFerrous2024 Max RPM ,02566061 (T1–T3) Max RPM ,01286061 (T4–T6) Max RPM ,02567075 Max RPM ,0256Non-FerrousBrass 230 ,0128Copper 190 ,0128Magnesium Max RPM ,0256Titanium, Steel and High-Temp AlloysTitaniumCommercially Pure 100 ,00486AL-4V 55 ,00486AL-6V 35 ,004Steel1018–1020 110 ,00644130 80 ,00324140 70 ,00324340 90 ,0032Tool Steel AnnealedA2 110 ,0032D2 80 ,0032H13 70 ,0032P20 110 ,00496Stainless Steel303 150 ,0048304 70 ,0032316 75 ,003215-5 / 17-4 PH 60 ,0032440C 60 ,0032Inconel625 / 718 30 ,0036Composites & PlasticsG10 Fiberglass / Polyester 300 ,0136Graphite 300 ,0256Graphite Fiber / Epoxy 250 ,008Plastics 400 ,0256Die/MoldSee Die/Mold sectionOther Material ApplicationsCast IronDuctile Iron 110 ,0096Gray Cast Iron 150 ,0128ClPT Factor(Chip Load per Tooth = Tool Diameter × CLPT Factor)METRIC SIzESSurface Meters per Minute = RPM x ,00314 × Tool DiameterRPM =Feedrate (mm/min.) =Surface Meters per Minute x 318,057Tool DiameterRPM × CLPT Factor × Tool Diameter× Number of <strong>Flute</strong>sChip Load per Tooth (CLPT) = CLPT Factor × Tool Diametercm 3 /min =Width (mm) Depth (mm) Feedrate (mm/min)1000Horsepower = 1,341 × kWkW = ,7457 × HorsepowerExamples on how to calculate the Chip Load per Tool (CLPT) from the CLPT FactorMultiply Tool Diameter by CLPT Factor – Use a Minimum Chip Load per Tooth of ,0025 mmExample 1:3 mm diameter tool cutting 6061T6 Aluminum: ,3 mm × ,0256 = ,0768 mm CLPTExample 2:12 mm Diameter tool cutting304 stainless: 12 mm × ,0032 = ,0384 mm CLPTSpeed & Feed Calculations nowOnline at www.robbjack.com!• Quick, Easy Calculations• End Mill Speeds and Feeds• Slitting Saw Speeds and Feeds• Troubleshooting• Printable Results• Simultaneous Tool RecommendationsClick on the red button at www.robbjack.com4

Coolant groovesIssues?end mill modificationsCoolant Grooves allow coolant to flow aroundthe outside of the tool for through-spindlecoolant applications. It is a lower-cost optionto through-the-tool coolant holes.To order a RobbJack tool with a CoolantGrooves, use the existing Part Number, andadd -CG.Example:An MA1-201-12 with coolant grooves is PartNumber:MA1-201-12-CgSee price sheet for pricingChatterProblems?Mirror edge Our edge preparation dampensvibration to help eliminate chatter.Mirror EdgeNon-Mirror EdgeApplications• Deep pocket and thin wall aluminum• Long reaches more than 3:1 <strong>length</strong>to-diameterratio• Plunging corners in titanium, steels,stainless, aluminum, etc.• High end valves used with FeatherBlend and T-ProcessMust Use CoolantChipping?T-ProcessT-Process is a honed edgewe put on an end mill tohelp eliminate chipping.Our patented Mirror Edge geometry helps toeliminate chatter. This geometry can be usedin any application where chatter is a problem,usually for thin walls, valves, deep pockets orwhere the tool sticks out more than 3:1 <strong>length</strong>to diameter ratio.To order RobbJack tools with Mirror Edge, usethe existing Part Number, and add -ME.Example:An MA1-201-12 with Mirror Edge is PartNumber:MA1-201-12-MeSee price sheet for pricingPros: T-Process strengthens the edge, helpseliminate chipping and gives a smooth edge.Cons: T-Process will bring up a burr in certainmaterials, and it is not for materials that likea sharp edge, such as aluminum and plastics.To order a RobbJack tool with a T-Process, usethe existing Part Number, and add -TP.Example:An MXG-402-16 with a T-Process is PartNumber:MXg-402-16-TPSee price sheet for pricing5

end mill modificationsReachReachProblems?Feather Blend A smooth transition from the cuttingdiameter to the neck diameter.Feather Blend<strong>Standard</strong> NeckApplications• Any necked tool• Eliminates swirl lines duringplunging• Eliminates stress risers in partsModify any standard tool with aneck to get the job done quickly.A neck will increase rigidity, reduce tool deflectionand last longer than a long <strong>length</strong> of cut tool.Necking can be added to most standard tools in1–2 days.To order a RobbJack tool with a Reach, use theexisting Part Number, and add -N and the desired<strong>length</strong> from the end of the tool.Example:An MA1-201-12 necked with 1,0mm Reach is PartNumber:MA1-201-12-n 1,0mmSee price sheet for pricingA tool necked with Feather Blend is a reduction inthe tool diameter after the cutting <strong>length</strong> so the toolcan cut deeper than its cutting <strong>length</strong>. It featuresa smooth transition from the cutting diameter tothe neck diameter. Feather Blend reduces staircasemarks and stress risers in parts and helps to maintainthe strongest tool possible.Swirl Marks?Wiper FlatsA Wiper Flat is asmall flat on the endof the tool wherethere is no concavity.It is used to minimizeswirl marks on thefloor of parts.45°Chamfer?Pros: A Wiper Flat gives better floor finishes.Cons: Wiper Flats will increase surface contact,not for use on thin floors.To order a RobbJack tool with a Wiper Flats, usethe existing Part Number, and add -WF.Example:An MA1-201-12 with wiper flats is Part Number:MA1-201-12-WFSee price sheet for pricing45° Chamfer To order a RobbJack tool with a 45° Chamfer,use the existing Part Number, add -CH andamount of Chamfer.Example:MA1-201-12 with a ,040mm 45° chamfer isPart Number:MA1-201-12-CH ,040mmSee price sheet for pricing6

Corner RadiusRadius?end mill modificationsTo order a RobbJack tool with a Corner Radius,use the existing Part Number, add -CR anddesired Radius Size.Example:An MA1-201-12 with a ,005 corner radius isPart Number:MA1-201-12-CR ,005See price sheet for pricingFull RadiusRadius?WeldonFlats?Weldon To order a RobbJack tool with a Full Radius (orBall End), use the existing Part Number, andadd -BN.Example:An MA1-201-12 with a Full Radius (Ball End) isPart Number:MA1-201-12-BnSee price sheet for pricingTo order RobbJack tools with Weldon Flats, usethe existing Part Number, and add -FL.Example:An MA1-201-12 with a Weldon Flat is PartNumber:MA1-201-12-FlNo ChargeRegrinding!Let RobbJack recondition your usedcutting tools and get RobbJack qualitygrinds and specifications on tools withany brand name!Wouldn’t it be nice if resharpened tools performedas well as new? Let us regrind yours theway we do ours and it can happen. We will addour grinds and finishes to any tools, regardlessof manufacturer. Our prices are competitive,our delivery is usually the best in the industry,and we do our own, in-house PVD coatings andre-coatings.gO gReenTry RobbJack’s in-house carbiderecycling program.Many times the tools we receive for regrindingare too badly damaged to justify reconditioning.For all tools that we determine fall into thiscategory, we will either:Return the tools to youmarked “No Work Done”(NWD)OR…Put the tools, as scrap, intoour recycling program andsend you a certificate for a10% discount on your nextregrinding order.We will offer you this choiceevery time we receive toolsthat we determine are NWD. Werecycle scrap tools to carbidere-manufacturers, who crush thetools and use the recycled shardsand powder to make shredders ornon-critical carbide grades.yOuR OWn COATIngGet state-of-the art coatingtechnology without delivery hassles.RobbJack owns and operates their PVD coatingfacility in Lincoln, CA under the tenets ofISO9000 certification. Our factory-trainedtechnicians take the same special care withyour tools as with ours, assuring you of the bestPVD coatings available. We do this as part ofour process, reducing or eliminating delays indelivery.Download our Regrinding OrderForm at www.robbjack.com to getstarted. Email or Call us!RobbJack EuropeRolf SchwarzE-mail: schwarz-rolf@web.deTel: +49 173 681 8478Mailbox/Fax: +49(0)3212-13245997

AluminumTools forAluminumApplications8

Aluminum Applications ToolsAluminumMA1201MA1303MFM201/202/203/204/205MFM301/302/303/304/305MS1201/301/401MC1201/3012 <strong>Flute</strong> 103 <strong>Flute</strong> 112 <strong>Flute</strong>(Short to Long Reach) 123 <strong>Flute</strong>(Short to Long Reach) 142, 3 and 4 <strong>Flute</strong> 162 and 3 <strong>Flute</strong> 17MSB 201MB 203MnR204/3032 <strong>Flute</strong> Ball End(See Multiple Applications) 532 and 3 <strong>Flute</strong>(See Multiple Applications) 55MInIATuReS (See Miniatures Applications) 459

AluminumMA1 2 <strong>Flute</strong> High performance Tools for AluminumCharacteristicsSquare End Corner Break 2 <strong>Flute</strong> 30° HelixApplicationsSlotting Side Milling Helical Ramping High Roughing Semi- Finishing Dry Wet Cold Air Spray MistInterpolationPerformanceFinishingmaterialsCoatingsAluminum Copper Magnesium Plastics BrassDiamond-LikeCarbon (DLC)Available withCoolantGroovesSee Page 5ShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMA1 Series Tolerances:Cutting Dia. = −0,025/−0,038 mmShank Dia. = −0,002/−0,005 mm<strong>Flute</strong> Length (10D) = +1,5/−0,000 mmOAL = +/−1,000 mmAvailable withWiperFlatsSee Page 6MA1-201 <strong>metric</strong> 2 <strong>Flute</strong> Stub <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerChamferOverallLengthTool NumberUncoated3 mm 3 mm 4,5 mm 0,12 mm 38 mm MA1-201-034 mm 4 mm 6 mm 0,12 mm 50 mm MA1-201-045 mm 5 mm 7,5 mm 0,12 mm 50 mm MA1-201-056 mm 6 mm 9 mm 0,12 mm 50 mm MA1-201-068 mm 8 mm 12 mm 0,25 mm 63 mm MA1-201-0810 mm 10 mm 15 mm 0,25 mm 72 mm MA1-201-1012 mm 12 mm 18 mm 0,25 mm 83 mm MA1-201-1216 mm 16 mm 24 mm 0,25 mm 92 mm MA1-201-1620 mm 20 mm 30 mm 0,3 mm 104 mm MA1-201-20Tool NumberDLC CoatedMA1-201-03 DLCMA1-201-04 DLCMA1-201-05 DLCMA1-201-06 DLCMA1-201-08 DLCMA1-201-10 DLCMA1-201-12 DLCMA1-201-16 DLCMA1-201-20 DLCSee RobbJack Videos onwww.youtube.com/user/RobbJackCorpTMMA1-201 SPeeD & FeeDToolDiameterAluminum 6061-T6,7075, 2024Brass Copper Plastic MagnesiumRPM CLPT RPM CLPT RPM CLPT RPM CLPT RPM CLPT3 mm Max 0,077 mm 24300 0,038 mm 19400 0,038 mm 42000 0,077 mm Max 0,077 mm4 mm Max 0,102 mm 18200 0,051 mm 14600 0,051 mm 31500 0,102 mm Max 0,102 mm5 mm Max 0,128 mm 14600 0,064 mm 11600 0,064 mm 25200 0,128 mm Max 0,128 mm6 mm Max 0,154 mm 12100 0,077 mm 9700 0,077 mm 21000 0,154 mm Max 0,154 mm8 mm Max 0,205 mm 9100 0,102 mm 7300 0,102 mm 15800 0,205 mm Max 0,205 mm10 mm Max 0,256 mm 7300 0,128 mm 5800 0,128 mm 12600 0,256 mm Max 0,256 mm12 mm Max 0,307 mm 6100 0,154 mm 4900 0,154 mm 10500 0,307 mm Max 0,307 mm16 mm Max 0,410 mm 4500 0,205 mm 3600 0,205 mm 7900 0,410 mm Max 0,410 mm20 mm Max 0,512 mm 3600 0,256 mm 2900 0,256 mm 6300 0,512 mm Max 0,512 mmAxial depth of cut up to 1 × diameter of the tool10

3 <strong>Flute</strong> High performance Tools for Aluminum MA1AluminumCharacteristicsApplicationsmaterialsSquare End Corner Break 3 <strong>Flute</strong> 35° Helix Mirror Edge PolishedSlotting Side Milling Helical Ramping High Roughing Semi- Finishing WetInterpolationPerformanceFinishingAluminum Copper Magnesium BrassMA1-303 Series:Polished& MirrorEdge!CoatingsDiamond-LikeCarbon (DLC)ShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMA1 Series Tolerances:Cutting Dia. = −0,025/−0,038 mmShank Dia. = −0,002/−0,005 mm<strong>Flute</strong> Length (10D) = +1,500/−0,000 mmOAL = +/−1,000 mmMA1-303 <strong>metric</strong> 3 <strong>Flute</strong> <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerChamferOverallLengthTool NumberUncoated3 mm 3 mm 8 mm 0,1 mm 38 mm MA1-303-034 mm 4 mm 12 mm 0,1 mm 50 mm MA1-303-045 mm 5 mm 14 mm 0,1 mm 50 mm MA1-303-056 mm 6 mm 15 mm 0,1 mm 63 mm MA1-303-068 mm 8 mm 20 mm 0,1 mm 63 mm MA1-303-0810 mm 10 mm 22 mm 0,1 mm 72 mm MA1-303-1012 mm 12 mm 26 mm 0,2 mm 83 mm MA1-303-1216 mm 16 mm 33 mm 0,2 mm 92 mm MA1-303-1620 mm 20 mm 42 mm 0,2 mm 104 mm MA1-303-20Tool NumberDLC CoatedMA1-303-03 DLCMA1-303-04 DLCMA1-303-05 DLCMA1-303-06 DLCMA1-303-08 DLCMA1-303-10 DLCMA1-303-12 DLCMA1-303-16 DLCMA1-303-20 DLCMA1-303 SPeeD & FeeDToolDiameterAluminum6061-T6Aluminum6061-T3Aluminum7075Aluminum2024RPM CLPT RPM CLPT RPM CLPT RPM CLPT3 mm Max 0,048 mm Max 0,042 mm Max 0,048 mm Max 0,048 mm4 mm Max 0,064 mm Max 0,056 mm Max 0,064 mm Max 0,064 mm5 mm Max 0,080 mm Max 0,070 mm Max 0,080 mm Max 0,080 mm6 mm Max 0,096 mm Max 0,084 mm Max 0,096 mm Max 0,096 mm8 mm Max 0,128 mm Max 0,112 mm Max 0,128 mm Max 0,128 mm10 mm Max 0,160 mm Max 0,140 mm Max 0,160 mm Max 0,160 mm12 mm Max 0,192 mm Max 0,168 mm Max 0,192 mm Max 0,192 mm16 mm Max 0,256 mm Max 0,224 mm Max 0,256 mm Max 0,256 mm20 mm Max 0,320 mm Max 0,280 mm Max 0,320 mm Max 0,320 mmAxial depth of cut up to 1.5 × diameter of the tool with 50% radial step over.11

AluminumMFM <strong>metric</strong> 2 <strong>Flute</strong> High performance Tools for AluminumCharacteristicsCorner Radius 2 <strong>Flute</strong> 40° Helix Feather Blend Necked Mirror EdgeApplicationsmaterialsCoatingsSlotting Side Milling Helical Ramping High 3-D Roughing Semi- Finishing WetInterpolationPerformanceFinishingAluminum Copper Magnesium BrassDiamond-LikeCarbon (DLC)MFM Seriescomes withMirrorEdge!for ChatterReductionShankDiameterOverall LengthReach<strong>Flute</strong>LengthRadiusCutterDiameterMFM Series Tolerances:Cutting Dia. = −0,025/−0,038 mmShank Dia. = −0,002/−0,005 mm<strong>Flute</strong> Length (10D) = +1,500/−,000 mmOAL = +/− 1,000 mmsmlxlshortmedlongx longsmlxlMFM 2 <strong>Flute</strong> <strong>metric</strong> (Short to long reach)CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadiusReachLength*OverallLengthTool NumberUncoated6 mm 6 mm 7 mm 0,5 mm 12 mm 75 mm MFM-201-06-0506 mm 6 mm 7 mm 1,0 mm 12 mm 75 mm MFM-201-06-1006 mm 6 mm 7 mm 0,5 mm 18 mm 75 mm MFM-202-06-0506 mm 6 mm 7 mm 1,0 mm 18 mm 75 mm MFM-202-06-1006 mm 6 mm 7 mm 0,5 mm 24 mm 75 mm MFM-203-06-0506 mm 6 mm 7 mm 1,0 mm 24 mm 75 mm MFM-203-06-1006 mm 6 mm 7 mm 0,5 mm 30 mm 75 mm MFM-204-06-0506 mm 6 mm 7 mm 1,0 mm 30 mm 75 mm MFM-204-06-1008 mm 8 mm 9 mm 1,0 mm 16 mm 80 mm MFM-201-08-1008 mm 8 mm 9 mm 2,0 mm 16 mm 80 mm MFM-201-08-2008 mm 8 mm 9 mm 2,5 mm 16 mm 80 mm MFM-201-08-2508 mm 8 mm 9 mm 1,0 mm 24 mm 80 mm MFM-202-08-1008 mm 8 mm 9 mm 2,0 mm 24 mm 80 mm MFM-202-08-2008 mm 8 mm 9 mm 2,5 mm 24 mm 80 mm MFM-202-08-2508 mm 8 mm 9 mm 1,0 mm 32 mm 80 mm MFM-203-08-1008 mm 8 mm 9 mm 2,0 mm 32 mm 80 mm MFM-203-08-2008 mm 8 mm 9 mm 2,5 mm 32 mm 80 mm MFM-203-08-2508 mm 8 mm 9 mm 1,0 mm 40 mm 80 mm MFM-204-08-1008 mm 8 mm 9 mm 2,0 mm 40 mm 80 mm MFM-204-08-2008 mm 8 mm 9 mm 2,5 mm 40 mm 80 mm MFM-204-08-25010 mm 10 mm 11 mm 1,5 mm 20 mm 100 mm MFM-201-10-15010 mm 10 mm 11 mm 2,5 mm 20 mm 100 mm MFM-201-10-25010 mm 10 mm 11 mm 1,5 mm 30 mm 100 mm MFM-202-10-15010 mm 10 mm 11 mm 2,5 mm 30 mm 100 mm MFM-202-10-25010 mm 10 mm 11 mm 1,5 mm 40 mm 100 mm MFM-203-10-15010 mm 10 mm 11 mm 2,5 mm 40 mm 100 mm MFM-203-10-25010 mm 10 mm 11 mm 1,5 mm 50 mm 100 mm MFM-204-10-15010 mm 10 mm 11 mm 2,5 mm 50 mm 100 mm MFM-204-10-250*Other Reach Lengths available upon request.Tool NumberDLC CoatedMFM-201-06-050 DLCMFM-201-06-100 DLCMFM-202-06-050 DLCMFM-202-06-100 DLCMFM-203-06-050 DLCMFM-203-06-100 DLCMFM-204-06-050 DLCMFM-204-06-100 DLCMFM-201-08-100 DLCMFM-201-08-200 DLCMFM-201-08-250 DLCMFM-202-08-100 DLCMFM-202-08-200 DLCMFM-202-08-250 DLCMFM-203-08-100 DLCMFM-203-08-200 DLCMFM-203-08-250 DLCMFM-204-08-100 DLCMFM-204-08-200 DLCMFM-204-08-250 DLCMFM-201-10-150 DLCMFM-201-10-250 DLCMFM-202-10-150 DLCMFM-202-10-250 DLCMFM-203-10-150 DLCMFM-203-10-250 DLCMFM-204-10-150 DLCMFM-204-10-250 DLCConTinueD on nexT Page—6 mmDIAMETER8 mmDIAMETER10 mmDIAMETER12

<strong>metric</strong> 2 <strong>Flute</strong> High performance Tools for Aluminum MFMAluminumsmlxlMFM 2 <strong>Flute</strong> <strong>metric</strong> (Short to long reach)CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadius—ConTinueD fRoM PReviousReachLength*OverallLengthTool NumberUncoated12 mm 12 mm 13 mm 1,5 mm 24 mm 110 mm MFM-201-12-15012 mm 12 mm 13 mm 2,5 mm 24 mm 110 mm MFM-201-12-25012 mm 12 mm 13 mm 4,0 mm 24 mm 110 mm MFM-201-12-40012 mm 12 mm 13 mm 1,5 mm 36 mm 110 mm MFM-202-12-15012 mm 12 mm 13 mm 2,5 mm 36 mm 110 mm MFM-202-12-25012 mm 12 mm 13 mm 4,0 mm 36 mm 110 mm MFM-202-12-40012 mm 12 mm 13 mm 1,5 mm 48 mm 110 mm MFM-203-12-15012 mm 12 mm 13 mm 2,5 mm 48 mm 110 mm MFM-203-12-25012 mm 12 mm 13 mm 4,0 mm 48 mm 110 mm MFM-203-12-40012 mm 12 mm 13 mm 1,5 mm 60 mm 110 mm MFM-204-12-15012 mm 12 mm 13 mm 2,5 mm 60 mm 110 mm MFM-204-12-25012 mm 12 mm 13 mm 4,0 mm 60 mm 110 mm MFM-204-12-400Tool NumberDLC CoatedMFM-201-12-150 DLCMFM-201-12-250 DLCMFM-201-12-400 DLCMFM-202-12-150 DLCMFM-202-12-250 DLCMFM-202-12-400 DLCMFM-203-12-150 DLCMFM-203-12-250 DLCMFM-203-12-400 DLCMFM-204-12-150 DLCMFM-204-12-250 DLCMFM-204-12-400 DLC12 mmDIAMETERx long long medium short16 mm 16 mm 17 mm 2,0 mm 32 mm 130 mm MFM-201-16-20016 mm 16 mm 17 mm 2,5 mm 32 mm 130 mm MFM-201-16-25016 mm 16 mm 17 mm 3,0 mm 32 mm 130 mm MFM-201-16-30016 mm 16 mm 17 mm 4,0 mm 32 mm 130 mm MFM-201-16-40016 mm 16 mm 17 mm 2,0 mm 48 mm 130 mm MFM-202-16-20016 mm 16 mm 17 mm 2,5 mm 48 mm 130 mm MFM-202-16-25016 mm 16 mm 17 mm 3,0 mm 48 mm 130 mm MFM-202-16-30016 mm 16 mm 17 mm 4,0 mm 48 mm 130 mm MFM-202-16-40016 mm 16 mm 17 mm 2,0 mm 64 mm 130 mm MFM-203-16-20016 mm 16 mm 17 mm 2,5 mm 64 mm 130 mm MFM-203-16-25016 mm 16 mm 17 mm 3,0 mm 64 mm 130 mm MFM-203-16-30016 mm 16 mm 17 mm 4,0 mm 64 mm 130 mm MFM-203-16-40016 mm 16 mm 17 mm 2,0 mm 80 mm 130 mm MFM-204-16-20016 mm 16 mm 17 mm 2,5 mm 80 mm 130 mm MFM-204-16-25016 mm 16 mm 17 mm 3,0 mm 80 mm 130 mm MFM-204-16-30016 mm 16 mm 17 mm 4,0 mm 80 mm 130 mm MFM-204-16-400MFM-201-16-200 DLCMFM-201-16-250 DLCMFM-201-16-300 DLCMFM-201-16-400 DLCMFM-202-16-200 DLCMFM-202-16-250 DLCMFM-202-16-300 DLCMFM-202-16-400 DLCMFM-203-16-200 DLCMFM-203-16-250 DLCMFM-203-16-300 DLCMFM-203-16-400 DLCMFM-204-16-200 DLCMFM-204-16-250 DLCMFM-204-16-300 DLCMFM-204-16-400 DLC16 mmDIAMETERx long long medium short20 mm 20 mm 21 mm 2,0 mm 40 mm 150 mm MFM-201-20-20020 mm 20 mm 21 mm 2,5 mm 40 mm 150 mm MFM-201-20-25020 mm 20 mm 21 mm 3,0 mm 40 mm 150 mm MFM-201-20-30020 mm 20 mm 21 mm 4,0 mm 40 mm 150 mm MFM-201-20-40020 mm 20 mm 21 mm 2,0 mm 60 mm 150 mm MFM-202-20-20020 mm 20 mm 21 mm 2,5 mm 60 mm 150 mm MFM-202-20-25020 mm 20 mm 21 mm 3,0 mm 60 mm 150 mm MFM-202-20-30020 mm 20 mm 21 mm 4,0 mm 60 mm 150 mm MFM-202-20-40020 mm 20 mm 21 mm 2,0 mm 80 mm 150 mm MFM-203-20-20020 mm 20 mm 21 mm 2,5 mm 80 mm 150 mm MFM-203-20-25020 mm 20 mm 21 mm 3,0 mm 80 mm 150 mm MFM-203-20-30020 mm 20 mm 21 mm 4,0 mm 80 mm 150 mm MFM-203-20-40020 mm 20 mm 21 mm 2,0 mm 100 mm 150 mm MFM-204-20-20020 mm 20 mm 21 mm 2,5 mm 100 mm 150 mm MFM-204-20-25020 mm 20 mm 21 mm 3,0 mm 100 mm 150 mm MFM-204-20-30020 mm 20 mm 21 mm 4,0 mm 100 mm 150 mm MFM-204-20-400MFM-201-20-200 DLCMFM-201-20-250 DLCMFM-201-20-300 DLCMFM-201-20-400 DLCMFM-202-20-200 DLCMFM-202-20-250 DLCMFM-202-20-300 DLCMFM-202-20-400 DLCMFM-203-20-200 DLCMFM-203-20-250 DLCMFM-203-20-300 DLCMFM-203-20-400 DLCMFM-204-20-200 DLCMFM-204-20-250 DLCMFM-204-20-300 DLCMFM-204-20-400 DLC20 mmDIAMETERsmxl25 mm 25 mm 26 mm 2,5 mm 50 mm 165 mm MFM-201-25-25025 mm 25 mm 26 mm 4,0 mm 50 mm 165 mm MFM-201-25-40025 mm 25 mm 26 mm 2,5 mm 75 mm 165 mm MFM-202-25-25025 mm 25 mm 26 mm 4,0 mm 75 mm 165 mm MFM-202-25-40025 mm 25 mm 26 mm 2,5 mm 100 mm 165 mm MFM-204-25-25025 mm 25 mm 26 mm 4,0 mm 100 mm 165 mm MFM-204-25-400*Other Reach Lengths available upon request.MFM-201-25-250 DLCMFM-201-25-400 DLCMFM-202-25-250 DLCMFM-202-25-400 DLCMFM-204-25-250 DLCMFM-204-25-400 DLC25 mmDIAMETER13

AluminumMFM <strong>metric</strong> 3 <strong>Flute</strong> High performance Tools for AluminumCharacteristicsApplicationsmaterialsCoatingsCorner Radius 3 <strong>Flute</strong> 40° Helix Feather Blend Necked Mirror EdgeSlotting Side Milling Helical Ramping High 3-D Roughing Semi- Finishing WetInterpolationPerformanceFinishingAluminum Copper Magnesium BrassDiamond-LikeCarbon (DLC)MFM Seriescomes withMirrorEdge!for ChatterReductionShankDiameterOverall LengthReach<strong>Flute</strong> LengthRadiusCutterDiameterMFM Series Tolerances:Cutting Dia. = −0,025/−0,038 mmShank Dia. = −0,002/−0,005 mm<strong>Flute</strong> Length (10D) = +1,500/−,000 mmOAL = +/− 1,000 mm14smlxlshortmedlongx longsmlxlsmMFM 3 <strong>Flute</strong> <strong>metric</strong> (Short to long reach)CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadiusReachLength*OverallLengthTool NumberUncoated6 mm 6 mm 7 mm 0,5 mm 12 mm 75 mm MFM-301-06-0506 mm 6 mm 7 mm 1,0 mm 12 mm 75 mm MFM-301-06-1006 mm 6 mm 7 mm 0,5 mm 18 mm 75 mm MFM-302-06-0506 mm 6 mm 7 mm 1,0 mm 18 mm 75 mm MFM-302-06-1006 mm 6 mm 7 mm 0,5 mm 24 mm 75 mm MFM-303-06-0506 mm 6 mm 7 mm 1,0 mm 24 mm 75 mm MFM-303-06-1006 mm 6 mm 7 mm 0,5 mm 30 mm 75 mm MFM-304-06-0506 mm 6 mm 7 mm 1,0 mm 30 mm 75 mm MFM-304-06-1008 mm 8 mm 9 mm 1,0 mm 16 mm 80 mm MFM-301-08-1008 mm 8 mm 9 mm 2,0 mm 16 mm 80 mm MFM-301-08-2008 mm 8 mm 9 mm 2,5 mm 16 mm 80 mm MFM-301-08-2508 mm 8 mm 9 mm 1,0 mm 24 mm 80 mm MFM-302-08-1008 mm 8 mm 9 mm 2,0 mm 24 mm 80 mm MFM-302-08-2008 mm 8 mm 9 mm 2,5 mm 24 mm 80 mm MFM-302-08-2508 mm 8 mm 9 mm 1,0 mm 32 mm 80 mm MFM-303-08-1008 mm 8 mm 9 mm 2,0 mm 32 mm 80 mm MFM-303-08-2008 mm 8 mm 9 mm 2,5 mm 32 mm 80 mm MFM-303-08-2508 mm 8 mm 9 mm 1,0 mm 40 mm 80 mm MFM-304-08-1008 mm 8 mm 9 mm 2,0 mm 40 mm 80 mm MFM-304-08-2008 mm 8 mm 9 mm 2,5 mm 40 mm 80 mm MFM-304-08-25010 mm 10 mm 11 mm 1,5 mm 20 mm 100 mm MFM-301-10-15010 mm 10 mm 11 mm 2,5 mm 20 mm 100 mm MFM-301-10-25010 mm 10 mm 11 mm 1,5 mm 30 mm 100 mm MFM-302-10-15010 mm 10 mm 11 mm 2,5 mm 30 mm 100 mm MFM-302-10-25010 mm 10 mm 11 mm 1,5 mm 40 mm 100 mm MFM-303-10-15010 mm 10 mm 11 mm 2,5 mm 40 mm 100 mm MFM-303-10-25010 mm 10 mm 11 mm 1,5 mm 50 mm 100 mm MFM-304-10-15010 mm 10 mm 11 mm 2,5 mm 50 mm 100 mm MFM-204-10-25012 mm 12 mm 13 mm 1,5 mm 24 mm 110 mm MFM-301-12-15012 mm 12 mm 13 mm 2,5 mm 24 mm 110 mm MFM-301-12-25012 mm 12 mm 13 mm 4,0 mm 24 mm 110 mm MFM-301-12-40012 mm 12 mm 13 mm 1,5 mm 36 mm 110 mm MFM-302-12-15012 mm 12 mm 13 mm 2,5 mm 36 mm 110 mm MFM-302-12-25012 mm 12 mm 13 mm 4,0 mm 36 mm 110 mm MFM-302-12-400*Other Reach Lengths available upon request.Tool NumberDLC CoatedMFM-301-06-050 DLCMFM-301-06-100 DLCMFM-302-06-050 DLCMFM-302-06-100 DLCMFM-303-06-050 DLCMFM-303-06-100 DLCMFM-304-06-050 DLCMFM-304-06-100 DLCMFM-301-08-100 DLCMFM-301-08-200 DLCMFM-301-08-250 DLCMFM-302-08-100 DLCMFM-302-08-200 DLCMFM-302-08-250 DLCMFM-303-08-100 DLCMFM-303-08-200 DLCMFM-303-08-250 DLCMFM-304-08-100 DLCMFM-304-08-200 DLCMFM-304-08-250 DLCMFM-301-10-150 DLCMFM-301-10-250 DLCMFM-302-10-150 DLCMFM-302-10-250 DLCMFM-303-10-150 DLCMFM-303-10-250 DLCMFM-304-10-150 DLCMFM-304-10-250 DLCMFM-301-12-150 DLCMFM-301-12-250 DLCMFM-301-12-400 DLCMFM-302-12-150 DLCMFM-302-12-250 DLCMFM-302-12-400 DLCConTinueD on nexT Page—6 mmDIAMETER8 mmDIAMETER10 mmDIAMETER12 mmDIAMETER

lxlshortmediumlongx longshortmediumlongx longsmxl<strong>metric</strong> 3 <strong>Flute</strong> High performance Tools for Aluminum MFMMFM 3 <strong>Flute</strong> (Short to long reach)CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadius—ConTinueD fRoM PReviousReachLength*OverallLengthTool NumberUncoated12 mm 12 mm 13 mm 1,5 mm 48 mm 110 mm MFM-303-12-15012 mm 12 mm 13 mm 2,5 mm 48 mm 110 mm MFM-303-12-25012 mm 12 mm 13 mm 4,0 mm 48 mm 110 mm MFM-303-12-40012 mm 12 mm 13 mm 1,5 mm 60 mm 110 mm MFM-304-12-15012 mm 12 mm 13 mm 2,5 mm 60 mm 110 mm MFM-304-12-25012 mm 12 mm 13 mm 4,0 mm 60 mm 110 mm MFM-304-12-40016 mm 16 mm 17 mm 2,0 mm 32 mm 130 mm MFM-301-16-20016 mm 16 mm 17 mm 2,5 mm 32 mm 130 mm MFM-301-16-25016 mm 16 mm 17 mm 3,0 mm 32 mm 130 mm MFM-301-16-30016 mm 16 mm 17 mm 4,0 mm 32 mm 130 mm MFM-301-16-40016 mm 16 mm 17 mm 2,0 mm 48 mm 130 mm MFM-302-16-20016 mm 16 mm 17 mm 2,5 mm 48 mm 130 mm MFM-302-16-25016 mm 16 mm 17 mm 3,0 mm 48 mm 130 mm MFM-302-16-30016 mm 16 mm 17 mm 4,0 mm 48 mm 130 mm MFM-302-16-40016 mm 16 mm 17 mm 2,0 mm 64 mm 130 mm MFM-303-16-20016 mm 16 mm 17 mm 2,5 mm 64 mm 130 mm MFM-303-16-25016 mm 16 mm 17 mm 3,0 mm 64 mm 130 mm MFM-303-16-30016 mm 16 mm 17 mm 4,0 mm 64 mm 130 mm MFM-303-16-40016 mm 16 mm 17 mm 2,0 mm 80 mm 130 mm MFM-304-16-20016 mm 16 mm 17 mm 2,5 mm 80 mm 130 mm MFM-304-16-25016 mm 16 mm 17 mm 3,0 mm 80 mm 130 mm MFM-304-16-30016 mm 16 mm 17 mm 4,0 mm 80 mm 130 mm MFM-304-16-40020 mm 20 mm 21 mm 2,0 mm 40 mm 150 mm MFM-301-20-20020 mm 20 mm 21 mm 2,5 mm 40 mm 150 mm MFM-301-20-25020 mm 20 mm 21 mm 3,0 mm 40 mm 150 mm MFM-301-20-30020 mm 20 mm 21 mm 4,0 mm 40 mm 150 mm MFM-301-20-40020 mm 20 mm 21 mm 2,0 mm 60 mm 150 mm MFM-302-20-20020 mm 20 mm 21 mm 2,5 mm 60 mm 150 mm MFM-302-20-250*Other 20 Reach mm Lengths 20 available mm upon 21 request. mm 3,0 mm 60 mm 150 mm MFM-302-20-30020 mm 20 mm 21 mm 4,0 mm 60 mm 150 mm MFM-302-20-40020 mm 20 mm 21 mm 2,0 mm 80 mm 150 mm MFM-303-20-20020 mm 20 mm 21 mm 2,5 mm 80 mm 150 mm MFM-303-20-25020 mm 20 mm 21 mm 3,0 mm 80 mm 150 mm MFM-303-20-30020 mm 20 mm 21 mm 4,0 mm 80 mm 150 mm MFM-303-20-40020 mm 20 mm 21 mm 2,0 mm 100 mm 150 mm MFM-304-20-20020 mm 20 mm 21 mm 2,5 mm 100 mm 150 mm MFM-304-20-25020 mm 20 mm 21 mm 3,0 mm 100 mm 150 mm MFM-304-20-30020 mm 20 mm 21 mm 4,0 mm 100 mm 150 mm MFM-304-20-40025 mm 25 mm 26 mm 2,5 mm 50 mm 165 mm MFM-301-25-25025 mm 25 mm 26 mm 4,0 mm 50 mm 165 mm MFM-301-25-40025 mm 25 mm 26 mm 2,5 mm 75 mm 165 mm MFM-302-25-25025 mm 25 mm 26 mm 4,0 mm 75 mm 165 mm MFM-302-25-40025 mm 25 mm 26 mm 2,5 mm 100 mm 165 mm MFM-304-25-25025 mm 25 mm 26 mm 4,0 mm 100 mm 165 mm MFM-304-25-400*Other Reach Lengths available upon request.Tool NumberDLC CoatedMFM-303-12-150 DLCMFM-303-12-250 DLCMFM-303-12-400 DLCMFM-304-12-150 DLCMFM-304-12-250 DLCMFM-304-12-400 DLCMFM-301-16-200 DLCMFM-301-16-250 DLCMFM-301-16-300 DLCMFM-301-16-400 DLCMFM-302-16-200 DLCMFM-302-16-250 DLCMFM-302-16-300 DLCMFM-302-16-400 DLCMFM-303-16-200 DLCMFM-303-16-250 DLCMFM-303-16-300 DLCMFM-303-16-400 DLCMFM-304-16-200 DLCMFM-304-16-250 DLCMFM-304-16-300 DLCMFM-304-16-400 DLCMFM-301-20-200 DLCMFM-301-20-250 DLCMFM-301-20-300 DLCMFM-301-20-400 DLCMFM-302-20-200 DLCMFM-302-20-250 DLCMFM-302-20-300 DLCConTinueD on nexT Page—MFM-302-20-400 DLCMFM-303-20-200 DLCMFM-303-20-250 DLCMFM-303-20-300 DLCMFM-303-20-400 DLCMFM-304-20-200 DLCMFM-304-20-250 DLCMFM-304-20-300 DLCMFM-304-20-400 DLCMFM-301-25-250 DLCMFM-301-25-400 DLCMFM-302-25-250 DLCMFM-302-25-400 DLCMFM-304-25-250 DLCMFM-304-25-400 DLC12 mmDIAMETER16 mmDIAMETER20 mmDIAMETER25 mmDIAMETERAluminumMFM SeRIeS SPeeD & FeeDToolDiameterTypicalZ-DepthAluminum6061-T6Aluminum6061-T3Aluminum7075Aluminum2024RPM CLPT RPM CLPT RPM CLPT RPM CLPT6 mm 4 mm Max 0,096 mm Max 0,084 mm Max 0,096 mm Max 0,096 mm8 mm 4 mm Max 0,128 mm Max 0,112 mm Max 0,128 mm Max 0,128 mm10 mm 5 mm Max 0,16 mm Max 0,14 mm Max 0,16 mm Max 0,16 mm12 mm 5 mm Max 0,192 mm Max 0,168 mm Max 0,192 mm Max 0,192 mm16 mm 5 mm Max 0,256 mm Max 0,224 mm Max 0,256 mm Max 0,256 mm20 mm 6,5 mm Max 0,32 mm Max 0,28 mm Max 0,32 mm Max 0,32 mm25 mm 6,5 mm Max 0,4 mm Max 0,35 mm Max 0,4 mm Max 0,4 mmZ-Depth of cut per pass should be deeper than the corner radius to help reduce chatter15

AluminumMS1 C-2 grade Carbide end millsCharacteristicsSquare End 2 <strong>Flute</strong> 3 <strong>Flute</strong> 4 <strong>Flute</strong> 30° HelixApplicationsSlotting Side Milling High Roughing Semi- Finishing Dry Wet Cold Air Spray MistPerformanceFinishingmaterialsAluminum Copper Magnesium Plastics Composites BrassCoatingsDiamond-LikeCarbon (DLC)ShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMS1 TolerancesCutting Dia. = +,000/−,075 mmShank Dia. = −,002/−,005 mm<strong>Flute</strong> Length = +0,500/+1,500 mmOAL = ±1,000 mmSlotting Side Milling HelicalInterpolationMS1-201 <strong>metric</strong> 2 <strong>Flute</strong> C-2 grade Stub <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthMS1-201 <strong>metric</strong> 2 <strong>Flute</strong> C-2 grade Stub <strong>length</strong>Tool NumberUncoated2 mm 3 mm 5 mm 38 mm MS1-201-023 mm 3 mm 6 mm 38 mm MS1-201-034 mm 4 mm 8 mm 50 mm MS1-201-045 mm 5 mm 8 mm 50 mm MS1-201-056 mm 6 mm 8 mm 50 mm MS1-201-068 mm 8 mm 12 mm 58 mm MS1-201-0810 mm 10 mm 14 mm 66 mm MS1-201-1012 mm 12 mm 16 mm 73 mm MS1-201-1216 mm 16 mm 20 mm 82 mm MS1-201-1620 mm 20 mm 25 mm 92 mm MS1-201-20CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength2 mm 3 mm 5 mm 38 mm3 mm 3 mm 6 mm 38 mm4 mm 4 mm 8 mm 50 mm5 mm 5 mm 8 mm 50 mm6 mm 6 mm 8 mm 50 mm8 mm 8 mm 12 mm 58 mm10 mm 10 mm 14 mm 66 mm12 mm 12 mm 16 mm 73 mm16 mm 16 mm 20 mm 82 mm20 mm 20 mm 25 mm 92 mmSlotting Side Milling HelicalInterpolationTool NumberDLC CoatedMS1-201-02 DLCMS1-201-03 DLCMS1-201-04 DLCMS1-201-05 DLCMS1-201-06 DLCMS1-201-08 DLCMS1-201-10 DLCMS1-201-12 DLCMS1-201-16 DLCMS1-201-20 DLCAvailable withWiperFlatsSee Page 6Available with45°Available withCoolantGroovesSee Page 5ChamferSee Page 616

C-2 grade Carbide end mills MC1AluminumCharacteristicsSquare End 2 <strong>Flute</strong> 3 <strong>Flute</strong> 30° HelixApplicationsSlotting Side Milling Conventional High Roughing Semi- Finishing Dry Wet Cold Air Spray MistPerformanceFinishingmaterialsAluminum Copper Magnesium Plastics Composites BrassCoatingsDiamond-LikeCarbon (DLC)Overall LengthShankDiameter<strong>Flute</strong> LengthOverall LengthCutterDiameterCutterDiameterMC1 TolerancesCutting Dia. = +,000/−,075mmShank Dia. = −,002/−,005mm<strong>Flute</strong> Length = +0,500/+1,500mmOAL = ±1,000mm<strong>Flute</strong> LengthSlotting Side Milling HelicalInterpolationMC1-201 <strong>metric</strong> 2 <strong>Flute</strong> C-2 grade <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthToolNumber2 mm 3 mm 8 mm 38 mm MC1-201-023 mm 3 mm 12 mm 38 mm MC1-201-034 mm 4 mm 12 mm 50 mm MC1-201-045 mm 5 mm 14 mm 50 mm MC1-201-056 mm 6 mm 14 mm 57 mm MC1-201-068 mm 8 mm 16 mm 63 mm MC1-201-0810 mm 10 mm 20 mm 72 mm MC1-201-1012 mm 12 mm 25 mm 83 mm MC1-201-1216 mm 16 mm 32 mm 92 mm MC1-201-1620 mm 20 mm 38 mm 104 mm MC1-201-2025 mm 25 mm 38 mm 104 mm MC1-201-25Tool NumberDLC CoatedMC1-201-02 DLCMC1-201-03 DLCMC1-201-04 DLCMC1-201-05 DLCMC1-201-06 DLCMC1-201-08 DLCMC1-201-10 DLCMC1-201-12 DLCMC1-201-16 DLCMC1-201-20 DLCMC1-201-25 DLCSide MillingMC1-301 <strong>metric</strong> 3 <strong>Flute</strong> C-2 grade <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthToolNumber2 mm 3 mm 8 mm 38 mm MC1-301-023 mm 3 mm 12 mm 38 mm MC1-301-034 mm 4 mm 12 mm 50 mm MC1-301-045 mm 5 mm 14 mm 50 mm MC1-301-056 mm 6 mm 14 mm 57 mm MC1-301-068 mm 8 mm 16 mm 63 mm MC1-301-0810 mm 10 mm 20 mm 72 mm MC1-301-1012 mm 12 mm 25 mm 83 mm MC1-301-1216 mm 16 mm 32 mm 92 mm MC1-301-1620 mm 20 mm 38 mm 104 mm MC1-301-2025 mm 25 mm 38 mm 104 mm MC1-301-25Tool NumberDLC CoatedMC1-301-02 DLCMC1-301-03 DLCMC1-301-04 DLCMC1-301-05 DLCMC1-301-06 DLCMC1-301-08 DLCMC1-301-10 DLCMC1-301-12 DLCMC1-301-16 DLCMC1-301-20 DLCMC1-301-25 DLC17

Steel & Hi-Temp AlloysTools forTitanium,Steel &High-TempAlloys18

Titanium, Steel & High-Temp Alloys ToolsMXg402MXg5024 <strong>Flute</strong> Tuffy Grade 205 <strong>Flute</strong> Tuffy Grade 20MXg-Bn 4 <strong>Flute</strong> Tuffy Grade, Ball End 20Steel & Hi-Temp AlloysMXF 6 and 8 <strong>Flute</strong> Tuffy Grade 21MST343MSTR301/303MSTR401/404MB440MST360/646MST430/434MTS4013 <strong>Flute</strong> Super Tuffy Grade 233 <strong>Flute</strong> Super Tuffy Grade 244 <strong>Flute</strong> Super Tuffy Grade 254 <strong>Flute</strong> Tuffy Grade Ball End 263 and 6 <strong>Flute</strong> Super Tuffy Grade 274 <strong>Flute</strong> Super Tuffy Grade 294 <strong>Flute</strong>(See Multiple Applications) 52MInIATuReS (See Miniatures Applications) 4519

MXg Tuffy grade Carbide end millsCharacteristicsSquare End Corner Radius Ball End 4 <strong>Flute</strong> 5 <strong>Flute</strong>Steel & Hi-Temp AlloysApplicationsmaterialsCoatingsSlotting Side Milling Helical Ramping High Roughing Semi- Finishing Dry Wet Cold Air Spray MistInterpolationPerformanceFinishingTitanium Cast Iron Steel Stainless Steel Super Alloys 40 HRcHardnessAluminumTitan. NitrideShankDiameterOverall LengthCutterDiameterMXG TolerancesCutting Dia. = −,025/−,050 mmShank Dia. = −,002/−,005 mm<strong>Flute</strong> Length = +0,50/+1,50 mmOAL = +/− 1,00 mmShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameter<strong>Flute</strong> Length4 <strong>Flute</strong>MXg-402 <strong>metric</strong> 4 <strong>Flute</strong> <strong>Standard</strong> <strong>length</strong>CuttingDiameterCornerRadiusShankDiameter<strong>Flute</strong>LengthOverallLength6 mm ,50–,55 mm 6 mm 14 mm 57 mm8 mm ,55–,60 mm 8 mm 16 mm 63 mm10 mm ,60–,65 mm 10 mm 20 mm 72 mm12 mm ,65–,70 mm 12 mm 25 mm 83 mm16 mm ,70–,75 mm 16 mm 32 mm 92 mm20 mm ,90–1,0 mm 20 mm 38 mm 104 mmTool NumberaiTin CoatedMXG-402-06MXG-402-08MXG-402-10MXG-402-12MXG-402-16MXG-402-205 <strong>Flute</strong>MXg-502 <strong>metric</strong> 5 <strong>Flute</strong> <strong>Standard</strong> <strong>length</strong>CuttingDiameterCornerRadiusShankDiameter<strong>Flute</strong>LengthOverallLength6 mm ,50–,55 mm 6 mm 14 mm 57 mm8 mm ,55–,60 mm 8 mm 16 mm 63 mm10 mm ,60–,65 mm 10 mm 20 mm 72 mm12 mm ,65–,70 mm 12 mm 25 mm 83 mm16 mm ,70–,75 mm 16 mm 32 mm 92 mm20 mm ,90–1,0 mm 20 mm 38 mm 104 mmTool NumberaiTin CoatedMXG-502-06MXG-502-08MXG-502-10MXG-502-12MXG-502-16MXG-502-204 <strong>Flute</strong>MXg-402Bn <strong>metric</strong> 4 <strong>Flute</strong> Ball end <strong>Standard</strong> <strong>length</strong>CuttingDiameterCornerRadiusShankDiameter<strong>Flute</strong>LengthOverallLength6 mm – 6 mm 14 mm 57 mm8 mm – 8 mm 16 mm 63 mm10 mm – 10 mm 20 mm 72 mm12 mm – 12 mm 25 mm 83 mm16 mm – 16 mm 32 mm 92 mm20 mm – 20 mm 38 mm 104 mmTool NumberaiTin CoatedMXG-402-06BNMXG-402-08BNMXG-402-10BNMXG-402-12BNMXG-402-16BNMXG-402-20BN20

Tuffy grade Carbide end mills MXFCharacteristicsSquare End Corner Radius 6 <strong>Flute</strong> 8 <strong>Flute</strong> 45° HelixApplicationsmaterialsCoatingsSide Milling High Semi- Finishing Dry Wet Cold Air Spray MistPerformance FinishingTitanium Cast Iron Steel Stainless Steel Super Alloys 40 HRcHardnessAluminumTitan. NitrideSteel & Hi-Temp AlloysShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMXF TolerancesCutting Dia. = -,025/−,050mmShank Dia. = −,002/−,005mm<strong>Flute</strong> Length = +0,500/+1,500mmOAL = ±1,000mmMXF-602/802 6/8 <strong>Flute</strong> <strong>Standard</strong> <strong>length</strong>CuttingDiameterCornerRadiusShankDiameter<strong>Flute</strong>LengthOverallLength10 2,0 10 20 7210 2,5 10 20 7210 3,0 10 20 7212 2,0 12 25 8312 2,5 12 25 8312 3,0 12 25 8316 2,0 16 32 9216 2,5 16 32 9216 3,0 16 32 9220 2,0 20 38 10420 2,5 20 38 10420 3,0 20 38 10425 2,0 25 38 10425 2,5 25 38 10425 3,0 25 38 104Tool NumberaiTin CoatedMXF-602-10-020MXF-602-10-025MXF-602-10-030MXF-602-12-020MXF-602-12-025MXF-602-12-030MXF-602-16-020MXF-602-16-025MXF-602-16-030MXF-602-20-020MXF-602-20-025MXF-802-20-030MXF-802-25-020MXF-802-25-025MXF-802-35-030NeedReach?See End MillModifications (page 6)21

MXg MXF Speed & FeedMXg SeRIeS SPeeD & FeeDSteel & Hi-Temp AlloysMaterialSurface6 mm 8 mm 10 mm 12 mm 16 mm 20 mmMetersRPM mm/min RPM mm/min RPM mm/min RPM mm/min RPM mm/min RPM mm/minCasT iRonDuctile 122 6475 706 4851 869 3881 978 3235 1087 2426 978 1941 869Gray 160 8498 1060 6367 1304 5094 1467 4245 1630 3184 1467 2547 1304inConeL625 / 718 30 1619 108 1213 134 970 150 809 167 606 150 485 134sTeeL1018 / 1020 152 8093 807 6063 994 4851 1118 4043 1242 3032 1118 2426 9944130 122 6475 505 4851 621 3881 699 3235 776 2426 699 1941 6214140 122 6475 505 4851 621 3881 699 3235 776 2426 699 1941 6214340 126 6717 523 5033 644 4027 725 3356 805 2517 725 2013 644sTainLess sTeeL303 168 8903 791 6670 973 5337 1095 4448 1217 3335 1095 2668 973304 122 6475 444 4851 546 3881 615 3235 683 2426 615 1941 546316 122 6475 444 4851 546 3881 615 3235 683 2426 615 1941 54615-5 / 17-4 91 4856 333 3638 410 2911 461 2426 512 1819 461 1455 41013-8 91 4856 333 3638 410 2911 461 2426 512 1819 461 1455 410440C 91 4856 333 3638 410 2911 461 2426 512 1819 461 1455 410TooL sTeeL (anneaLeD)A2 122 6475 444 4851 546 3881 615 3235 683 2426 615 1941 546D2 110 5827 400 4366 492 3493 553 2911 615 2183 553 1747 492H13 122 6475 444 4851 546 3881 615 3235 683 2426 615 1941 546P20 122 6475 575 4851 708 3881 796 3235 885 2426 796 1941 708TiTaniuMCom. pure 91 4856 431 3638 531 2911 597 2426 664 1819 597 1455 5316AL-4V 61 3237 222 2425 273 1941 307 1617 342 1213 307 970 2736AL-6V 53 2833 194 2122 239 1698 269 1415 299 1061 269 8491 × Dia.2391 × Dia..7 × Dia.general guidelines• Speed and feeds are based on applicationswith very rigid machine tools, toolholders,and fixturing. Speeds and feeds will varydramatically depending on the application.Extreme forces can be generated and canMXF SeRIeS SPeeD & FeeDcause damage, if not appropriate for thecutting conditions.• Helical interpolation or ramping should beused to enter pockets.• For the highest material removal rates andlongest tool life profile milling is preferredover slotting (See diagrams at right).• Use shrink fit or equivalent tool holder. Ifnot, use flats to eliminate slippage in thetool holder!• Climb milling is recommended.• For ball end tools reduce feed rate by 10%.MaterialSurface 10mm 12mm 16mm 20mm 25mmMetersRPM mm/min RPM mm/min RPM mm/min RPM mm/min RPM mm/minCasT iRonDuctile 122 3881 734 3235 815 2426 734 1941 869 1554 761Gray 160 5094 1100 4245 1223 3184 1100 2547 1304 2040 1141inConeL625 / 718 46 1455 165 1213 183 910 165 728 196 583 171sTeeL1018 / 1020 152 4851 786 4043 873 3032 786 2426 931 1942 8154130 122 3881 524 3235 582 2426 524 1941 621 1554 5434140 122 3881 524 3235 582 2426 524 1941 621 1554 5434340 126 4027 544 3356 604 2517 544 2013 644 1612 564sTainLess sTeeL303 168 5337 778 4448 865 3335 778 2668 922 2137 807304 122 3881 461 3235 512 2426 461 1941 546 1554 478316 122 3881 461 3235 512 2426 461 1941 546 1554 47815-5 / 17-4 91 2911 346 2426 384 1819 346 1455 410 1165 35913-8 91 2911 346 2426 384 1819 346 1455 410 1165 359440C 91 2911 346 2426 384 1819 346 1455 410 1165 359TooL sTeeL (anneaLeD)A2 122 3881 461 3235 512 2426 461 1941 546 1554 478D2 110 3493 415 2911 461 2183 415 1747 492 1399 430H13 122 3881 461 3235 512 2426 461 1941 546 1554 478P20 122 3881 566 3235 629 2426 566 1941 671 1554 587TiTaniuMCom. pure 91 2911 424 2426 472 1819 424 1455 503 1165 4406AL-4V 116 3687 538 3073 597 2304 538 1844 637 1476 5576AL-6V 53 1698 248 1415 275 1061 248 849 293 680 257Slotting1 × Dia..5 × Dia..7 × Dia.Finish Profiling1.5 × Dia..02 × Dia..02 × Dia..7 Profiling × Dia..5 × Dia.1.5 × Dia..5 × Dia.1.5 × Dia..02 × Dia.22

Super Tuffy grade Carbide end mills MSTCharacteristicsSquare End Corner Radius 3 <strong>Flute</strong> 40° Helix T-ProcessHoneApplicationsmaterialsCoatingsSlotting Side Milling HelicalInterpolationRamping HighPerformanceRoughing Semi-FinishingFinishing Dry Wet Cold Air Spray MistCast Iron Steel Stainless Steel Super AlloysTitanium Titanium AluminumNitride Carbo-Nitride Titan. NitrideSteel & Hi-Temp AlloysShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMST-341 TolerancesCutting Dia. = +,000/−,075 mmShank Dia. = −,002/−,005 mmOAL = ±1,000 mm<strong>Flute</strong> Length = +0,500/+1,500 mmHONEDEDGE!MST-341 <strong>metric</strong> 3 <strong>Flute</strong> Super Tuffy Carbide Stub <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerBreak SizeOverallLengthTool NumberUncoated3 mm 3 mm 6 mm ,075/,125 mm 38 mm MST-341-034 mm 4 mm 8 mm ,075/,125 mm 50 mm MST-341-045 mm 5 mm 8 mm ,075/,125 mm 50 mm MST-341-056 mm 6 mm 8 mm ,075/,125 mm 57 mm MST-341-068 mm 8 mm 12 mm ,100/,150 mm 63 mm MST-341-0810 mm 10 mm 14 mm ,125/,175 mm 72 mm MST-341-1012 mm 12 mm 16 mm ,150/,130 mm 83 mm MST-341-1216 mm 16 mm 20 mm ,230/,280 mm 92 mm MST-341-1620 mm 20 mm 25 mm ,280/,360 mm 104 mm MST-341-20CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerBreak SizeOverallLength3 mm 3 mm 6 mm ,075/,125 mm 38 mm4 mm 4 mm 8 mm ,075/,125 mm 50 mm5 mm 5 mm 8 mm ,075/,125 mm 50 mm6 mm 6 mm 8 mm ,075/,125 mm 57 mm8 mm 8 mm 12 mm ,100/,150 mm 63 mm10 mm 10 mm 14 mm ,125/,175 mm 72 mm12 mm 12 mm 16 mm ,150/,130 mm 83 mm16 mm 16 mm 20 mm ,230/,280 mm 92 mm20 mm 20 mm 25 mm ,280/,360 mm 104 mmTool NumberTin CoatedMST-341-03 TMST-341-04 TMST-341-05 TMST-341-06 TMST-341-08 TMST-341-10 TMST-341-12 TMST-341-16 TMST-341-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerBreak SizeOverallLength3 mm 3 mm 6 mm ,075/,125 mm 38 mm4 mm 4 mm 8 mm ,075/,125 mm 50 mm5 mm 5 mm 8 mm ,075/,125 mm 50 mm6 mm 6 mm 8 mm ,075/,125 mm 57 mm8 mm 8 mm 12 mm ,100/,150 mm 63 mm10 mm 10 mm 14 mm ,125/,175 mm 72 mm12 mm 12 mm 16 mm ,150/,130 mm 83 mm16 mm 16 mm 20 mm ,230/,280 mm 92 mm20 mm 20 mm 25 mm ,280/,360 mm 104 mmTool NumberTiCn CoatedMST-341-03 CMST-341-04 CMST-341-05 CMST-341-06 CMST-341-08 CMST-341-10 CMST-341-12 CMST-341-16 CMST-341-20 CCuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerBreak SizeOverallLength3 mm 3 mm 6 mm ,075/,125 mm 38 mm4 mm 4 mm 8 mm ,075/,125 mm 50 mm5 mm 5 mm 8 mm ,075/,125 mm 50 mm6 mm 6 mm 8 mm ,075/,125 mm 57 mm8 mm 8 mm 12 mm ,100/,150 mm 63 mm10 mm 10 mm 14 mm ,125/,175 mm 72 mm12 mm 12 mm 16 mm ,150/,130 mm 83 mm16 mm 16 mm 20 mm ,230/,280 mm 92 mm20 mm 20 mm 25 mm ,280/,360 mm 104 mmTool NumberaiTin CoatedMST-341-03 AMST-341-04 AMST-341-05 AMST-341-06 AMST-341-08 AMST-341-10 AMST-341-12 AMST-341-16 AMST-341-20 A23

MSTR 3 <strong>Flute</strong> Super Tuffy grade Carbide ruffersSteel & Hi-Temp AlloysCharacteristicsApplicationsmaterialsCoatingsSquare End Corner Break 3 <strong>Flute</strong> 30° Helix T-ProcessHoneSlotting Side Milling Ramping Roughing Dry Wet Cold Air Spray MistCast Iron Steel Stainless SteelTitanium Titanium AluminumNitride Carbo-Nitride Titan. NitrideSTR Seriescomes withT-ProcessHonedEdgesShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMSTR TolerancesCutting Dia. = −,075/−,180 mmShank Dia. = −,002/−,005 mmOAL = ±1,000 mm<strong>Flute</strong> Length = +0,500/+1,500 mmHONEDEDGE!MSTR-301 <strong>metric</strong> 3 <strong>Flute</strong> Super Tuffy Carbide ruffer Stub <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthTool NumberUncoated6 mm 6 mm 8 mm 57 mm MSTR-301-068 mm 8 mm 12 mm 63 mm MSTR-301-0810 mm 10 mm 14 mm 72 mm MSTR-301-1012 mm 12 mm 16 mm 83 mm MSTR-301-1216 mm 16 mm 20 mm 92 mm MSTR-301-1620 mm 20 mm 25 mm 104 mm MSTR-301-20Tool NumberTin CoatedMSTR-301-06 TMSTR-301-08 TMSTR-301-10 TMSTR-301-12 TMSTR-301-16 TMSTR-301-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength6 mm 6 mm 8 mm 57 mm8 mm 8 mm 12 mm 63 mm10 mm 10 mm 14 mm 72 mm12 mm 12 mm 16 mm 83 mm16 mm 16 mm 20 mm 92 mm20 mm 20 mm 25 mm 104 mmTool NumberTiCn CoatedMSTR-301-06 CMSTR-301-08 CMSTR-301-10 CMSTR-301-12 CMSTR-301-16 CMSTR-301-20 CTool NumberaiTin CoatedMSTR-301-06 AMSTR-301-08 AMSTR-301-10 AMSTR-301-12 AMSTR-301-16 AMSTR-301-20 AHONEDEDGE!MSTR-303 <strong>metric</strong> 3 <strong>Flute</strong> Super Tuffy Carbide ruffer <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthTool NumberUncoated6 mm 6 mm 14 mm 57 mm MSTR-303-068 mm 8 mm 16 mm 63 mm MSTR-303-0810 mm 10 mm 20 mm 72 mm MSTR-303-1012 mm 12 mm 25 mm 83 mm MSTR-303-1216 mm 16 mm 32 mm 92 mm MSTR-303-1620 mm 20 mm 38 mm 104 mm MSTR-303-20Tool NumberTin CoatedMSTR-303-06 TMSTR-303-08 TMSTR-303-10 TMSTR-303-12 TMSTR-303-16 TMSTR-303-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberTiCn CoatedMSTR-303-06 CMSTR-303-08 CMSTR-303-10 CMSTR-303-12 CMSTR-303-16 CMSTR-303-20 CTool NumberaiTin CoatedMSTR-303-06 AMSTR-303-08 AMSTR-303-10 AMSTR-303-12 AMSTR-303-16 AMSTR-303-20 A24

4 <strong>Flute</strong> Super Tuffy grade Carbide ruffers MSTRCharacteristicsSquare End Corner Break 4 <strong>Flute</strong> 30° Helix T-ProcessHoneApplicationsmaterialsCoatingsSide Milling Ramping Roughing Dry Wet Cold Air Spray MistCast Iron Steel Stainless SteelTitanium Titanium AluminumNitride Carbo-Nitride Titan. NitrideSteel & Hi-Temp AlloysShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMSTR TolerancesCutting Dia. = −,075/−,180 mmShank Dia. = −,002/−,005 mmOAL = ±1,000 mm<strong>Flute</strong> Length = +0,500/+1,500 mmHONEDEDGE!MSTR-401 <strong>metric</strong> 4 <strong>Flute</strong> Super Tuffy Carbide ruffer Stub <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthTool NumberUncoated6 mm 6 mm 8 mm 57 mm MSTR-401-068 mm 8 mm 12 mm 63 mm MSTR-401-0810 mm 10 mm 14 mm 72 mm MSTR-401-1012 mm 12 mm 16 mm 83 mm MSTR-401-1216 mm 16 mm 20 mm 92 mm MSTR-401-1620 mm 20 mm 25 mm 104 mm MSTR-401-20Tool NumberTin CoatedMSTR-401-06 TMSTR-401-08 TMSTR-401-10 TMSTR-401-12 TMSTR-401-16 TMSTR-401-16 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength6 mm 6 mm 8 mm 57 mm8 mm 8 mm 12 mm 63 mm10 mm 10 mm 14 mm 72 mm12 mm 12 mm 16 mm 83 mm16 mm 16 mm 20 mm 92 mm20 mm 20 mm 25 mm 104 mmTool NumberTiCn CoatedMSTR-401-06 CMSTR-401-08 CMSTR-401-10 CMSTR-401-12 CMSTR-401-16 CMSTR-401-16 CTool NumberaiTin CoatedMSTR-401-06 AMSTR-401-08 AMSTR-401-10 AMSTR-401-12 AMSTR-401-16 AMSTR-401-16 AHONEDEDGE!MSTR-404 <strong>metric</strong> 4 <strong>Flute</strong> Super Tuffy Carbide ruffer <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthTool NumberUncoated6 mm 6 mm 14 mm 57 mm MSTR-404-068 mm 8 mm 16 mm 63 mm MSTR-404-0810 mm 10 mm 20 mm 72 mm MSTR-404-1012 mm 12 mm 25 mm 83 mm MSTR-404-1216 mm 16 mm 32 mm 92 mm MSTR-404-1620 mm 20 mm 38 mm 104 mm MSTR-404-20Tool NumberTin CoatedMSTR-404-06 TMSTR-404-08 TMSTR-404-10 TMSTR-404-12 TMSTR-404-16 TMSTR-404-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberTiCn CoatedMSTR-404-06 CMSTR-404-08 CMSTR-404-10 CMSTR-404-12 CMSTR-404-16 CMSTR-404-20 CTool NumberaiTin CoatedMSTR-404-06 AMSTR-404-08 AMSTR-404-10 AMSTR-404-12 AMSTR-404-16 AMSTR-404-20 A25

MB 4 <strong>Flute</strong> Tuffy grade Carbide Ball end millsCharacteristicsBall End 4 <strong>Flute</strong> 40° Helix T-ProcessHoneSteel & Hi-Temp AlloysApplicationsmaterialsCoatingsSlotting Side Milling HelicalInterpolationConventional Ramping HighPerformance3-D Roughing Semi- FinishingFinishingCast Iron Steel Stainless Steel Super AlloysTitanium Titanium AluminumNitride Carbo-Nitride Titan. NitrideShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMB TolerancesCutting Dia. = +,000/−,075 mmShank Dia. = −,002/−,005 mmOAL = ±1,000 mm<strong>Flute</strong> Length = +0,500/+1,500 mmHONEDEDGE!MB-440 <strong>metric</strong> 4 <strong>Flute</strong> Tuffy Ball end <strong>Standard</strong> <strong>length</strong> 40° HelixCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthTool NumberUncoated3 mm 3 mm 12 mm 38 mm MB-440-034 mm 4 mm 12 mm 50 mm MB-440-045 mm 5 mm 14 mm 50 mm MB-440-056 mm 6 mm 14 mm 57 mm MB-440-068 mm 8 mm 16 mm 63 mm MB-440-0810 mm 10 mm 20 mm 72 mm MB-440-1012 mm 12 mm 25 mm 83 mm MB-440-1216 mm 16 mm 32 mm 92 mm MB-440-1620 mm 20 mm 38 mm 104 mm MB-440-20CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength3 mm 3 mm 12 mm 38 mm4 mm 4 mm 12 mm 50 mm5 mm 5 mm 14 mm 50 mm6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberTin CoatedMB-440-03 TMB-440-04 TMB-440-05 TMB-440-06 TMB-440-08 TMB-440-10 TMB-440-12 TMB-440-16 TMB-440-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength3 mm 3 mm 12 mm 38 mm4 mm 4 mm 12 mm 50 mm5 mm 5 mm 14 mm 50 mm6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberTiCn CoatedMB-440-03 CMB-440-04 CMB-440-05 CMB-440-06 CMB-440-08 CMB-440-10 CMB-440-12 CMB-440-16 CMB-440-20 CCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength3 mm 3 mm 12 mm 38 mm4 mm 4 mm 12 mm 50 mm5 mm 5 mm 14 mm 50 mm6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberaiTin CoatedMB-440-03 AMB-440-04 AMB-440-05 AMB-440-06 AMB-440-08 AMB-440-10 AMB-440-12 AMB-440-16 AMB-440-20 A26

3 <strong>Flute</strong> Super Tuffy grade Carbide end mills MSTCharacteristicsSquare End 3 <strong>Flute</strong> 60° HelixApplicationsmaterialsCoatingsSide Milling Finishing Dry Wet Cold Air Spray MistCast Iron Steel Stainless Steel Super AlloysTitanium Titanium AluminumNitride Carbo-Nitride Titan. NitrideSteel & Hi-Temp AlloysShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMST-360 TolerancesCutting Dia. = +,000/−,075 mmShank Dia. = −,002/−,005 mm<strong>Flute</strong> Length = +0,500/+1,500 mmOAL = ±1,000 mmMST-360 <strong>metric</strong> 3 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthTool NumberUncoated3 mm 3 mm 12 mm 38 mm MST-360-034 mm 4 mm 12 mm 50 mm MST-360-045 mm 5 mm 14 mm 50 mm MST-360-056 mm 6 mm 14 mm 57 mm MST-360-068 mm 8 mm 16 mm 63 mm MST-360-0810 mm 10 mm 20 mm 72 mm MST-360-1012 mm 12 mm 25 mm 83 mm MST-360-1216 mm 16 mm 32 mm 92 mm MST-360-1620 mm 20 mm 38 mm 104 mm MST-360-20CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength3 mm 3 mm 12 mm 38 mm4 mm 4 mm 12 mm 50 mm5 mm 5 mm 14 mm 50 mm6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberTin CoatedMST-360-03 TMST-360-04 TMST-360-05 TMST-360-06 TMST-360-08 TMST-360-10 TMST-360-12 TMST-360-16 TMST-360-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength3 mm 3 mm 12 mm 38 mm4 mm 4 mm 12 mm 50 mm5 mm 5 mm 14 mm 50 mm6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberTiCn CoatedMST-360-03 CMST-360-04 CMST-360-05 CMST-360-06 CMST-360-08 CMST-360-10 CMST-360-12 CMST-360-16 CMST-360-20 CCuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLength3 mm 3 mm 12 mm 38 mm4 mm 4 mm 12 mm 50 mm5 mm 5 mm 14 mm 50 mm6 mm 6 mm 14 mm 57 mm8 mm 8 mm 16 mm 63 mm10 mm 10 mm 20 mm 72 mm12 mm 12 mm 25 mm 83 mm16 mm 16 mm 32 mm 92 mm20 mm 20 mm 38 mm 104 mmTool NumberaiTin CoatedMST-360-03 AMST-360-04 AMST-360-05 AMST-360-06 AMST-360-08 AMST-360-10 AMST-360-12 AMST-360-16 AMST-360-20 A27

MST 6 <strong>Flute</strong> Super Tuffy grade Carbide end millsSteel & Hi-Temp AlloysCharacteristicsApplicationsmaterialsCoatingsSquare End Corner Radius 6 <strong>Flute</strong> 40° HelixSide Milling Semi- Finishing Dry Wet Cold Air Spray MistFinishingCast Iron Steel Stainless Steel Super AlloysTitanium Titanium AluminumNitride Carbo-Nitride Titan. NitrideAvailable withCoolantGroovesSee Page 5ShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMST-646 TolerancesCutting Dia. = +,025/−,000 mmShank Dia. = −,002/−,005 mm<strong>Flute</strong> Length = +0,500/+1,500 mmOAL = ±1,000 mm+TolerancesHonedRadiusMST-646 <strong>metric</strong> 6 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadiusOverallLengthTool NumberUncoated10 mm 10 mm 20 mm ,125/,180 mm 72 mm MST-646-1012 mm 12 mm 25 mm ,150/,230 mm 83 mm MST-646-1216 mm 16 mm 32 mm ,230/,280 mm 92 mm MST-646-1620 mm 20 mm 38 mm ,280/,355 mm 104 mm MST-646-20CuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadiusOverallLength10 mm 10 mm 20 mm ,125/,180 mm 72 mm12 mm 12 mm 25 mm ,150/,230 mm 83 mm16 mm 16 mm 32 mm ,230/,280 mm 92 mm20 mm 20 mm 38 mm ,280/,355 mm 104 mmTool NumberTin CoatedMST-646-10 TMST-646-12 TMST-646-16 TMST-646-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadiusOverallLength10 mm 10 mm 20 mm ,125/,180 mm 72 mm12 mm 12 mm 25 mm ,150/,230 mm 83 mm16 mm 16 mm 32 mm ,230/,280 mm 92 mm20 mm 20 mm 38 mm ,280/,355 mm 104 mmTool NumberTiCn CoatedMST-646-10 CMST-646-12 CMST-646-16 CMST-646-20 CCuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerRadiusOverallLength10 mm 10 mm 20 mm ,125/,180 mm 72 mm12 mm 12 mm 25 mm ,150/,230 mm 83 mm16 mm 16 mm 32 mm ,230/,280 mm 92 mm20 mm 20 mm 38 mm ,280/,355 mm 104 mmTool NumberaiTin CoatedMST-646-10 AMST-646-12 AMST-646-16 AMST-646-20 A28

4 <strong>Flute</strong> Super Tuffy grade Carbide end mills MSTCharacteristicsSquare End 4 <strong>Flute</strong> 30° HelixApplicationsmaterialsCoatingsSide Milling Roughing Semi- Finishing Dry Wet Cold Air Spray MistFinishingCast Iron Steel Stainless Steel Super AlloysTitanium Titanium AluminumNitride Carbo-Nitride Titan. NitrideSteel & Hi-Temp AlloysShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMST-430 and MST-434 TolerancesCutting Dia. = +,025/−,000 mmShank Dia. = −,002/−,005 mm<strong>Flute</strong> Length = +0,500/+1,500 mmOAL = ±1 000 mmSharpEdges+TolerancesMST-430 <strong>metric</strong> 4 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthOverallLengthTool NumberUncoated3 mm 3 mm 12 mm 38 mm MST-430-034 mm 4 mm 12 mm 50 mm MST-430-045 mm 5 mm 14 mm 50 mm MST-430-056 mm 6 mm 14 mm 57 mm MST-430-068mm 8 mm 16 mm 63 mm MST-430-0810 mm 10 mm 20 mm 72 mm MST-430-1012 mm 12 mm 25 mm 83 mm MST-430-1216 mm 16 mm 32 mm 92 mm MST-430-1620 mm 20 mm 38 mm 104 mm MST-430-20Tool NumberTin CoatedMST-430-03 TMST-430-04 TMST-430-05 TMST-430-06 TMST-430-08 TMST-430-10 TMST-430-12 TMST-430-16 TMST-430-20 TTool NumberTiCn CoatedMST-430-03 CMST-430-04 CMST-430-05 CMST-430-06 CMST-430-08 CMST-430-10 CMST-430-12 CMST-430-16 CMST-430-20 CTool NumberaiTin CoatedMST-430-03 AMST-430-04 AMST-430-05 AMST-430-06 AMST-430-08 AMST-430-10 AMST-430-12 AMST-430-16 AMST-430-20 AT-ProcessHoneMST-434 <strong>metric</strong> 4 <strong>Flute</strong> Super Tuffy Carbide <strong>Standard</strong> <strong>length</strong>HONEDEDGE!+TolerancesCuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerBreak SizeOverallLengthTool NumberUncoated3 mm 3 mm 12 mm ,075/,125 mm 38 mm MST-434-034 mm 4 mm 12 mm ,075/,125 mm 50 mm MST-434-045 mm 5 mm 14 mm ,075/,125 mm 50 mm MST-434-056 mm 6 mm 14 mm ,075/,125 mm 57 mm MST-434-068 mm 8 mm 16 mm ,100/,150 mm 63 mm MST-434-0810 mm 10 mm 20 mm ,125/,175 mm 72 mm MST-434-1012 mm 12 mm 25 mm ,150/,130 mm 83 mm MST-434-1216 mm 16 mm 32 mm ,230/,280 mm 92 mm MST-434-1620 mm 20 mm 38 mm ,280/,360 mm 104 mm MST-434-20Tool NumberTin CoatedMST-434-03 TMST-434-04 TMST-434-05 TMST-434-06 TMST-434-08 TMST-434-10 TMST-434-12 TMST-434-16 TMST-434-20 TCuttingDiameterShankDiameter<strong>Flute</strong>LengthCornerBreak SizeOverallLength3 mm 3 mm 12 mm ,075/,125 mm 38 mm4 mm 4 mm 12 mm ,075/,125 mm 50 mm5 mm 5 mm 14 mm ,075/,125 mm 50 mm6 mm 6 mm 14 mm ,075/,125 mm 57 mm8 mm 8 mm 16 mm ,100/,150 mm 63 mm10 mm 10 mm 20 mm ,125/,175 mm 72 mm12 mm 12 mm 25 mm ,150/,130 mm 83 mm16 mm 16 mm 32 mm ,230/,280 mm 92 mm20 mm 20 mm 38 mm ,280/,360 mm 104 mmTool NumberTiCn CoatedMST-434-03 CMST-434-04 CMST-434-05 CMST-434-06 CMST-434-08 CMST-434-10 CMST-434-12 CMST-434-16 CMST-434-20 CTool NumberaiTin CoatedMST-434-03 AMST-434-04 AMST-434-05 AMST-434-06 AMST-434-08 AMST-434-10 AMST-434-12 AMST-434-16 AMST-434-20 A29

Composites & plasticsTools forComposites& Plastics30

Composites & Plastics ToolsMCPCD203 routersMCPCD203 routersMCR402/6022 <strong>Flute</strong> PCD-Tipped Routers118° Point 352 <strong>Flute</strong> PCD-Tipped RoutersSquare End 354 and 6 <strong>Flute</strong> Compression Routers 32MCe602/802MP810/MF104Drills6 and 8 <strong>Flute</strong> Carbide Composite Routers 33Diamond Coated Drills 34Composites & plasticsCSKB/CSKICountersink Bodies andDiamond Coated Inserts 36MInIATuReS (See Miniatures Applications) 45MA1201(See Aluminum Applications) 10Made toOrder<strong>Standard</strong>sAvailable on Request!31

MCR Compression routerCharacteristicsSquare End 4 <strong>Flute</strong> 6 <strong>Flute</strong>ApplicationsSlotting Side Milling Helical Ramping Roughing Semi- Finishing Dry Wet Cold Air Spray MistInterpolationFinishingmaterialsCompositesCoatingsDiamond Diamond-LikeCoated (DCC) Carbon (DLC)Composites & plasticsShankDiameterOverall Length<strong>Flute</strong> LengthCutterDiameterMCR TolerancesCutting Dia. = -,025/−,075mmShank Dia. = −,002/−,005mm<strong>Flute</strong> Length = +0,500/+1,500mmOAL = ±1,000mmMCR Compression router – 4/6 <strong>Flute</strong> uncoatedCuttingDiameterShankDiameterNumberof <strong>Flute</strong>sUpshearLength<strong>Flute</strong>LengthOverallLengthTool NumberUncoated6mm 6mm 4 5mm 20mm 63mm MCR-402-0610mm 10mm 6 6mm 25mm 63mm MCR-602-1012mm 12mm 6 6mm 28mm 76mm MCR-602-12Diamond-LikeCarbon (DLC)MCR Compression router – 4/6 <strong>Flute</strong> Black Widow DlC CoatedCuttingDiameterShankDiameterNumberof <strong>Flute</strong>sUpshearLength<strong>Flute</strong>LengthOverallLength6mm 6mm 4 5mm 20mm 63mm10mm 10mm 6 6mm 25mm 63mm12mm 12mm 6 6mm 28mm 76mmTool NumberDLC CoatedMCR-402-06 DLCMCR-602-10 DLCMCR-602-12 DLCMCR Compression router – 4/6 <strong>Flute</strong> Diamond CoatedCuttingDiameterShankDiameterNumberof <strong>Flute</strong>sUpshearLengthDiamondCoated (DCC)<strong>Flute</strong>Length10-20XTool Life!OverallLength6mm 6mm 4 5mm 20mm 63mm10mm 10mm 6 6mm 25mm 63mm12mm 12mm 6 6mm 28mm 76mmTool NumberDiamond CoatedMCR-402-06 DMCR-602-10 DMCR-602-12 D32

Carbide Composite router MCeCharacteristicsSquare End 6 <strong>Flute</strong> 8 <strong>Flute</strong>ApplicationsSlotting Side Milling Helical Ramping Roughing Semi- Finishing Dry Wet Cold Air Spray MistInterpolationFinishingmaterialsCompositesShankDiameterCoatingsDiamondDiamond-LikeCoated (DCC) Carbon (DLC)Overall Length<strong>Flute</strong> LengthCutterDiameterMCE TolerancesCutting Dia. = -,025/−,075mmShank Dia. = −,002/−,005mm<strong>Flute</strong> Length = +0,500/+1,500mmOAL = ±1,000mmNEW!Composites & plasticsMCe Carbide Composite router – 6/8 <strong>Flute</strong> uncoatedCuttingDiameterShankDiameterNumberof <strong>Flute</strong>s<strong>Flute</strong>LengthOverallLengthTool NumberUncoated6mm 6mm 6 20mm 63mm MCE-602-0610mm 10mm 8 25mm 63mm MCE-802-1012mm 12mm 8 28mm 76mm MCE-802-12Diamond-LikeCarbon (DLC)MCe Carbide Composite router – 6/8 <strong>Flute</strong> Black Widow DlC CoatedCuttingDiameterShankDiameterNumberof <strong>Flute</strong>s<strong>Flute</strong>LengthOverallLength6mm 6mm 6 20mm 63mm10mm 10mm 8 25mm 63mm12mm 12mm 8 28mm 76mmTool NumberDLC CoatedMCE-602-06 DLCMCE-802-10 DLCMCE-802-12 DLCDiamondCoated (DCC)MCe Carbide Composite router – 6/8 <strong>Flute</strong> Diamond CoatedCuttingDiameterShankDiameterNumberof <strong>Flute</strong>s<strong>Flute</strong>LengthOverallLength6mm 6mm 6 20mm 63mm10mm 10mm 8 25mm 63mm12mm 12mm 8 28mm 76mm10-20XTool Life!Tool NumberDiamond CoatedMCE-602-06 DMCE-802-10 DMCE-802-12 D33

MP810/MF104 Diamond Coated Aircraft DrillsCharacteristics2 <strong>Flute</strong> 118° EllipticalDrill Tip Drill TipApplicationsHole Drilling Dry Wet Cold Air Spray MistComposites & plasticsToolDiameterToolDiametermaterialsCoatingsAluminum Copper Magnesium Plastics Composites BrassDiamondCoated (DCC)Overall LengthOverall Length<strong>Flute</strong> Length<strong>Flute</strong> LengthMP810/MF104 Drills TolerancesTool Dia. = +,0000/−,0005"Shank Dia. = −,0001/−,0002"<strong>Flute</strong> Length = +,030"OAL = +,060"10-20XTool LifeOverCarbide!MP810 118° Diamond Coated <strong>Standard</strong> <strong>length</strong> Drills – 4 FacetToolDiameter<strong>Flute</strong>LengthOverallLength0,0980" 1,4" 2,7"0,1285" 1,4" 2,7"0,1421" 1,4" 2,7"0,1560" 1,4" 2,7"0,1655" 1,4" 2,7"0,1734" 1,4" 2,7"0,1900" 1,4" 2,7"0,1915" 1,4" 2,7"0,1990" 1,4" 2,7"0,2055" 1,4" 2,7"0,2210" 1,4" 2,7"0,2515" 1,4" 2,7"0,2590" 1,4" 2,7"0,2710" 1,4" 2,7"0,2770" 1,4" 2,7"0,2800" 1,4" 2,7"0,2812" 1,4" 2,7"0,3135" 1,5" 2,7"0,3765" 1,5" 2,7"Tool NumberDiamond CoatedMP810-100345-1MP810-100344-1MP810-100402-1MP810-100409-1MP810-100335-1MP810-100404-1MP810-100400-1MP810-100336-1MP810-100411-1MP810-100405-1MP810-100346-1MP810-100337-1MP810-100406-1MP810-100407-1MP810-100412-1MP810-100408-1MP810-100410-1MP810-100338-1MP810-100341-1MF104 elliptical Diamond Coated <strong>Standard</strong> <strong>length</strong> DrillsToolDiameter<strong>Flute</strong>LengthOverallLength0,0980" 1,4" 2,7"0,1285" 1,4" 2,7"0,1421" 1,4" 2,7"0,1560" 1,4" 2,7"0,1655" 1,4" 2,7"0,1734" 1,4" 2,7"0,1900" 1,4" 2,7"0,1915" 1,4" 2,7"0,1990" 1,4" 2,7"0,2055" 1,4" 2,7"0,2210" 1,4" 2,7"0,2515" 1,4" 2,7"0,2590" 1,4" 2,7"0,2710" 1,4" 2,7"0,2770" 1,4" 2,7"0,2800" 1,4" 2,7"0,2812" 1,4" 2,7"0,3135" 1,5" 2,7"0,3765" 1,5" 2,7"Tool NumberDiamond CoatedMF104-100001-1MF104-100003-1MF104-100005-1MF104-100006-1MF104-100007-1MF104-100008-1MF104-100009-1MF104-100010-1MF104-100011-1MF104-100012-1MF104-100004-1MF104-100002-1MF104-100013-1MF104-100014-1MF104-100015-1MF104-100016-1MF104-100017-1MF104-100018-1MF104-100019-134

pCD-Tipped router Bits MPCD/MCPCDCharacteristicsSquare End Ball End 2 <strong>Flute</strong> 118° PCD DiamondDrill TipApplicationsSlotting Side Milling Helical Ramping Roughing Semi- Finishing Dry Wet Cold Air Spray MistInterpolationFinishingShankDiameterShankDiametermaterialsAluminum Copper Magnesium Plastics Composites BrassOverall LengthOverall Length<strong>Flute</strong> Length<strong>Flute</strong>LengthCutterDiameterCutterDiameterMPCD TolerancesCutting Dia. = ±0,076mmShank Dia. = −,003/−,005mm<strong>Flute</strong> Length = ±,76mmOAL = ±1,5mm10-20XTool LifeOverCarbide!Composites & plastics118°Drill TipMCPCD-203 Drill point Composite 2 <strong>Flute</strong> <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameterNumberof <strong>Flute</strong>s<strong>Flute</strong>LengthDrillPointOverallLengthToolNumber3mm 3mm 2 8mm 118° 38mm MCPCD-203-03-1186mm 6mm 2 14mm 118° 50mm MCPCD-203-06-11810mm 10mm 2 16mm 118° 63mm MCPCD-203-10-11812mm 12mm 2 22mm 118° 76mm MCPCD-203-12-118MCPCD-203Specifically Designed forCFRPMaterialsSee RobbJack Videos onTMwww.youtube.com/user/RobbJackCorpMCPCD-203 Square end Composite 2 <strong>Flute</strong> <strong>Standard</strong> <strong>length</strong>CuttingDiameterShankDiameterNumberof <strong>Flute</strong>s<strong>Flute</strong>LengthSquare EndEndStyleOverallLengthToolNumber3mm 3mm 2 8mm SE 38mm MCPCD-203-036mm 6mm 2 14mm SE 50mm MCPCD-203-0610mm 10mm 2 16mm SE 63mm MCPCD-203-1012mm 12mm 2 22mm SE 76mm MCPCD-203-12Made toOrder<strong>Standard</strong>sAvailable on Request!35

CSKB/CSKI Countersink Bodies & insertsCharacteristicsApplicationsmaterials1 <strong>Flute</strong>Aluminum Copper Magnesium Plastics Composites Brass10-20XTool LifeOverCarbide!CoatingsDiamondCoated (DCC)Composites & plasticsBodyDiameterThreadedShankIncludeAngleInsert(Sold Separately)PilotDiameter101501 or 101501LCam PinCSKB Countersink BodiesBodyDiameterThreadSizePilotSize RangeAnglePartNumber5/8" 1/4"-28 0,097-0,257 100° CSKB1T-6XXXX1-13/4" 3/8"-24 0,257-0,319 100° CSKB1T-7XXXX1-17/8" 3/8"-24 0,319-0,394 100° CSKB1T-8XXXX1-11" 7/16"-20 0,394-0,559 100° CSKB1T-9XXXX1-1CSKI Countersink insertsBodyDiameterThreadSizeAnglePartNumber5/8" 25° Double-Angle 100° CSKIC-6IC025-13/4",7/8", 1" 25° Double-Angle 100° CSKIC-7IC025-15/8" 0,020" Radius 100° CSKIC-6IR020-13/4",7/8", 1" 0,035" Radius 100° CSKIC-7IR035-2*For the tool holder body specify the pilot diameter XXXX (e.g. 0.2515" is 2515).36

Tools forDie/Mold& HardenedMaterialsDie/moldMDM2 <strong>Flute</strong> Extended LengthBall Nose 38MTM2 <strong>Flute</strong> Extended LengthToroidal Corner Radius 40MHM4, 6, 8 and 10 <strong>Flute</strong>Corner Radius 42MP820 2, 4 <strong>Flute</strong> Diamond Coated 43MP8202, 4 <strong>Flute</strong> Big ShankDiamond Coated 4437

MDM Die/mold end millsCharacteristicsBall End 2 <strong>Flute</strong> 30° HelixNEWSizes NowAvailable!ApplicationsConventional Ramping High 3-D Roughing Semi- Finishing Dry Cold Air Spray MistPerformanceFinishingmaterials40 HRc 50 HRc 64 HRcHardness Hardness HardnessCoatingsAluminumTitan. NitrideShankDiameterStyle AOverall LengthBlend Angle<strong>Flute</strong> LengthCutterDiameterShankDiameterStyle COverall LengthCutterDiameter<strong>Flute</strong> LengthShankDiameterStyle BOverall LengthBlend AngleDraft AngleReach Length<strong>Flute</strong> LengthCutterDiameterMDM TolerancesCutting Dia. (0,5 - 5) = +/- ,008mmCutting Dia. (6 - 12) = - ,018/-,033mmShank Dia. = −,002/−,005mm<strong>Flute</strong> Length = +0,500/+1,500mmOAL = ±1,000mmDie/mold38MDM-201 2 <strong>Flute</strong> Tuffy Ball end extended <strong>length</strong>CuttingDiameterShankDiameter<strong>Flute</strong>LengthReachLengthDraftAngleBlendAngleToolStyleOverallLength0.5 mm 6 mm 0,5 mm – – 8° A 63 mm0.5 mm 6 mm 0,5 mm 1 mm 3° 18° B 63 mm0.5 mm 6 mm 0,5 mm 3 mm 1,5° 16,5° B 63 mm0.5 mm 6 mm 0,5 mm 5 mm 1,5° 16,5° B 63 mm0.5 mm 6 mm 0,5 mm 10 mm 1,5° 16,5° B 63 mm0.8 mm 6 mm 0,8 mm – – 8° A 63 mm0.8 mm 6 mm 0,8 mm 3 mm 3° 18° B 63 mm0.8 mm 6 mm 0,8 mm 5 mm 1,5° 16,5° B 63 mm0.8 mm 6 mm 0,8 mm 10 mm 1,5° 16,5° B 63 mm0.8 mm 6 mm 0,8 mm 15 mm 1,5° 16,5° B 63 mm1 mm 6 mm 1 mm – – 8° A 63 mm1 mm 6 mm 1 mm 3 mm 3° 18° B 63 mm1 mm 6 mm 1 mm 5 mm 1,5° 16,5° B 63 mm1 mm 6 mm 1 mm 10 mm 1,5° 16,5° B 63 mm1 mm 6 mm 1 mm 20 mm 1,5° 16,5° B 63 mm1.5 mm 6 mm 1,5 mm – – 8° A 63 mm1.5 mm 6 mm 1,5 mm 5 mm 3° 18° B 63 mm1.5 mm 6 mm 1,5 mm 10 mm 1,5° 16,5° B 63 mm1.5 mm 6 mm 1,5 mm 20 mm 1,5° 16,5° B 63 mm1.5 mm 6 mm 1,5 mm 30 mm 1,5° 16,5° B 63 mm2 mm 6 mm 2 mm – – 8° A 63 mm2 mm 6 mm 2 mm 5 mm 3° 18° B 63 mm2 mm 6 mm 2 mm 10 mm 1,5° 16,5° B 63 mm2 mm 6 mm 2 mm 20 mm 1,5° 16,5° B 63 mm2 mm 6 mm 2 mm 30 mm 1,5° 16,5° B 63 mm3 mm 6 mm 3 mm – – 8° A 75 mm3 mm 6 mm 3 mm 5 mm 3° 18° B 75 mm3 mm 6 mm 3 mm 15 mm 1,5° 16,5° B 75 mm3 mm 6 mm 3 mm 30 mm 1° 16° B 75 mm3 mm 6 mm 3 mm 45 mm 1° 16° B 75 mmTool NumberaiTin CoatedMDM-201-0.5MDM-203-0.5MDM-204-0.5MDM-205-0.5MDM-206-0.5MDM-201-0.8MDM-203-0.8MDM-204-0.8MDM-205-0.8MDM-206-0.8MDM-201-01MDM-203-01MDM-204-01MDM-205-01MDM-206-01MDM-201-01.5MDM-203-01.5MDM-204-01.5MDM-205-01.5MDM-206-01.5MDM-201-02MDM-203-02MDM-204-02MDM-205-02MDM-206-02MDM-201-03MDM-203-03MDM-204-03MDM-205-03MDM-206-03ConTinueD on nexT Page—