metric 3 Flute Standard length

metric 3 Flute Standard length

metric 3 Flute Standard length

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

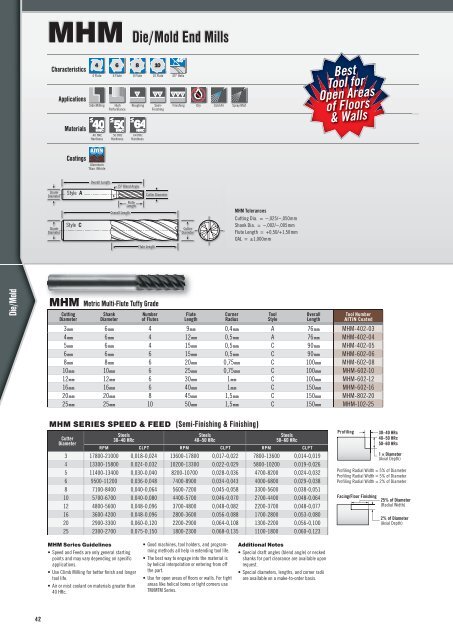

MHM Die/mold end millsCharacteristicsApplicationsmaterials4 <strong>Flute</strong> 6 <strong>Flute</strong> 8 <strong>Flute</strong> 10 <strong>Flute</strong> 45° HelixSide Milling High Roughing Semi- Finishing Dry Cold Air Spray MistPerformanceFinishing40 HRc 50 HRc 64 HRcHardness Hardness HardnessBestTool forOpen Areasof Floors& WallsCoatingsAluminumTitan. NitrideShankDiameterShankDiameterStyle AStyle COverall Length15° Blend Angle<strong>Flute</strong>LengthOverall LengthCutter DiameterCutterDiameterMHM TolerancesCutting Dia. = −,025/−,050 mmShank Dia. = −,002/−,005 mm<strong>Flute</strong> Length = +0,50/+1,50 mmOAL = ±1,000 mm<strong>Flute</strong> LengthDie/moldMHM <strong>metric</strong> multi-<strong>Flute</strong> Tuffy gradeCuttingDiameterShankDiameterNumberof <strong>Flute</strong>s<strong>Flute</strong>LengthCornerRadiusToolStyleOverallLength3 mm 6 mm 4 9 mm 0,4 mm A 76 mm4 mm 6 mm 4 12 mm 0,5 mm A 76 mm5 mm 6 mm 4 15 mm 0,5 mm C 90 mm6 mm 6 mm 6 15 mm 0,5 mm C 90 mm8 mm 8 mm 6 20 mm 0,75 mm C 100 mm10 mm 10 mm 6 25 mm 0,75 mm C 100 mm12 mm 12 mm 6 30 mm 1 mm C 100 mm16 mm 16 mm 6 40 mm 1 mm C 150 mm20 mm 20 mm 8 45 mm 1,5 mm C 150 mm25 mm 25 mm 10 50 mm 1,5 mm C 150 mmMHM SeRIeS SPeeD & FeeD (Semi-Finishing & Finishing)Radial Step OverRoughing orSemi-Finishing25%– 40% ofProfilingSteelsSteelsSteelsCutter30–40 HRc40–50 Radial HRc Step Overtool diameter50–60 HRcAxial DepthDiameterRPM CLPT RPM CLPT Roughing or RPM Radial Step Over CLPT for finishingSemi-Finishing depends on finish requirements.3 17800-21000 0,018-0,024 13600-17800 0,017-0,022 25%– 7800-13600 40% of0,014-0,0194 13300-15800 0,024-0,032 10200-13300 0,022-0,029 tool diameter 5800-10200 0,019-0,0265 11400-13400 0,030-0,040 8200-10700 0,028-0,036Profiling4700-8200 0,024-0,0326 9500-11200 0,036-0,048 7400-8900 0,034-0,043 4000-6800 0,029-0,0388 7100-8400 0,040-0,064 5600-7200 0,045-0,058 3300-5600 0,038-0,051 1 × Diameter10 5700-6700 0,040-0,080 4400-5700Profiling0,046-0,07030–40 HRc2700-4400 Profiling Radial Width 0,048-0,064= 5% of Diameter (Axial Depth)40–50 Profiling Radial Width = 5% of Diameter12 4800-5600 0,048-0,096 3700-4800 0,048-0,08250–60 HRc2200-3700 Profiling Radial Width 0,048-0,077= 2% of Diameter16 3600-4200 0,048-0,096 2800-3600 0,056-0,088 1700-2800 0,053-0,0801 × Diameter20 2900-3300 0,060-0,120 2200-2900 0,064-0,108(Axial Depth) 1300-2200 0,056-0,10025 2300-2700 0,075-0,150 1800-2300 0,068-0,135 1100-1800 0,060-0,123Tool NumberaiTin CoatedMHM-402-03MHM-402-04MHM-402-05MHM-602-06MHM-602-08MHM-602-10MHM-602-12MHM-602-16MHM-802-20MHM-102-25Radial Step OverRadial Step Over for finishingdepends on finish requirements.30–40 HRc Profiling Radial Width = 5% of Diameter40–50 HRc Profiling Radial Width = 5% of Diameter50–60 HRc Profiling Radial Width = 2% of DiameterFacing/Floor FinishingRoughing orSemi-Finishing25%– 40% oftool diameterAxial Depth30–40 HRc Profiling Radial Width = 5% of40–50 HRc Profiling Radial Width = 5% of50–60 HRc 30–40 Profiling HRc Axial Radial depth Width = 10% = 2% of to of40–50 HRc Axial depth = 5% of too1 × Diameter(Axial Depth)50–60 HRc Axial depth = 4% of too25% of Diameter(Radial Width)2% of Diameter(Axial Depth)Radial Step Over for findepends on finish requFacing/Floor FinishingMHM Series guidelines• Speed and Feeds are only general startingpoints and may vary depending on specificapplications.• Use Climb Milling for better finish and longertool life.• Air or mist coolant on materials greater than40 HRc.• Good machines, tool holders, and programmingmethods all help in extending tool life.• The best way to engage into the material isby helical interpolation or entering from offthe part.• Use for open areas of floors or walls. For tightareas like helical bores or tight corners useTM/MTM Series.Additional notes• Special draft angles (blend angle) or neckedshanks for part clearance are available uponrequest.• Special diameters, <strong>length</strong>s, and corner radiiare available on a make-to-order basis.42