You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

46<br />

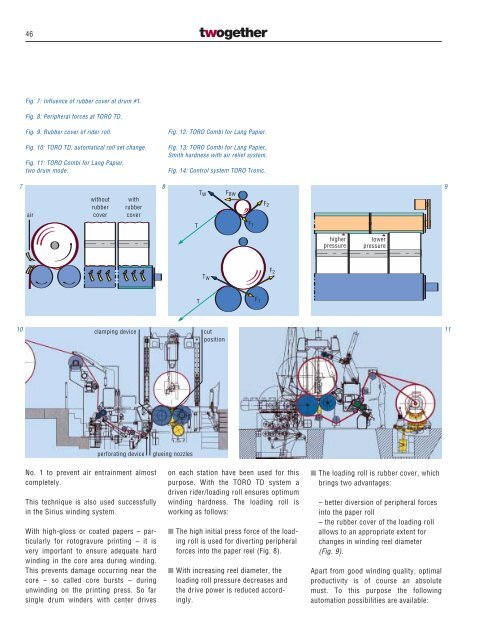

Fig. 7: Influence of rubber cover at drum #1.<br />

Fig. 8: Peripheral forces at TORO TD.<br />

Fig. 9: Rubber cover of rider roll.<br />

Fig. 10: TORO TD, automatical roll set change.<br />

Fig. 11: TORO Combi for Lang Papier,<br />

two drum mode.<br />

7 8 9<br />

TW FBW 10<br />

air<br />

without<br />

rubber<br />

cover<br />

with<br />

rubber<br />

cover<br />

No. 1 to prevent air entrainment almost<br />

completely.<br />

This technique is also used successfully<br />

in the Sirius winding system.<br />

With high-gloss or coated papers – particularly<br />

for rotogravure printing – it is<br />

very important to ensure adequate hard<br />

winding in the core area during winding.<br />

This prevents damage occurring near the<br />

core – so called core bursts – during<br />

unwinding on the printing press. So far<br />

single drum winders with center drives<br />

Fig. 12: TORO Combi for Lang Papier.<br />

Fig. 13: TORO Combi for Lang Papier,<br />

Smith hardness with air relief system.<br />

Fig. 14: Control system TORO Tronic.<br />

T<br />

T<br />

T W<br />

clamping device cut<br />

position<br />

perforating device glueing nozzles<br />

on each station have been used for this<br />

purpose. With the TORO TD system a<br />

driven rider/loading roll ensures optimum<br />

winding hardness. The loading roll is<br />

working as follows:<br />

■ The high initial press force of the loading<br />

roll is used for diverting peripheral<br />

forces into the paper reel (Fig. 8).<br />

■ With increasing reel diameter, the<br />

loading roll pressure decreases and<br />

the drive power is reduced accordingly.<br />

F1<br />

F 1<br />

F 2<br />

F 2<br />

higher<br />

pressure<br />

lower<br />

pressure<br />

■ The loading roll is rubber cover, which<br />

brings two advantages:<br />

– better diversion of peripheral forces<br />

into the paper roll<br />

– the rubber cover of the loading roll<br />

allows to an appropriate extent for<br />

changes in winding reel diameter<br />

(Fig. 9).<br />

Apart from good winding quality, optimal<br />

productivity is of course an absolute<br />

must. To this purpose the following<br />

automation possibilities are available:<br />

11