Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

22<br />

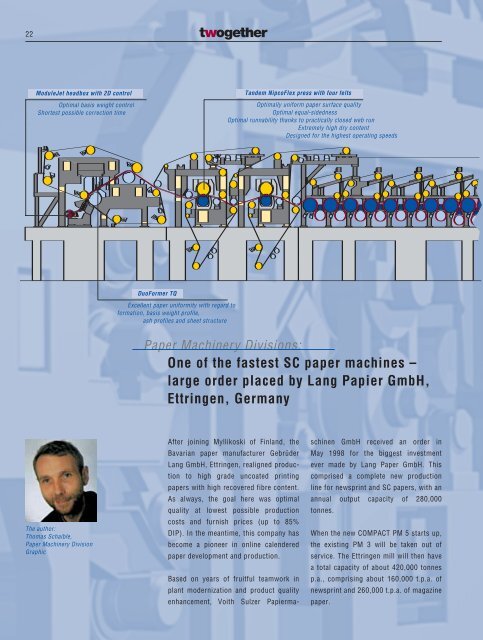

ModuleJet headbox with 2D control<br />

Optimal basis weight control<br />

Shortest possible correction time<br />

The author:<br />

Thomas Schaible,<br />

<strong>Paper</strong> <strong>Machinery</strong> Division<br />

Graphic<br />

DuoFormer TQ<br />

Excellent paper uniformity with regard to<br />

formation, basis weight profile,<br />

ash profiles and sheet structure<br />

Tandem NipcoFlex press with four felts<br />

Optimally uniform paper surface quality<br />

Optimal equal-sidedness<br />

Optimal runnability thanks to practically closed web run<br />

Extremely high dry content<br />

Designed for the highest operating speeds<br />

<strong>Paper</strong> <strong>Machinery</strong> <strong>Divisions</strong>:<br />

One of the fastest SC paper machines –<br />

large order placed by Lang Papier GmbH,<br />

Ettringen, Germany<br />

After joining Myllikoski of Finland, the<br />

Bavarian paper manufacturer Gebrüder<br />

Lang GmbH, Ettringen, realigned production<br />

to high grade uncoated printing<br />

papers with high recovered fibre content.<br />

As always, the goal here was optimal<br />

quality at lowest possible production<br />

costs and furnish prices (up to 85%<br />

DIP). In the meantime, this company has<br />

become a pioneer in online calendered<br />

paper development and production.<br />

Based on years of fruitful teamwork in<br />

plant modernization and product quality<br />

enhancement, <strong>Voith</strong> Sulzer Papierma-<br />

schinen GmbH received an order in<br />

May 1998 for the biggest investment<br />

ever made by Lang <strong>Paper</strong> GmbH. This<br />

comprised a complete new production<br />

line for newsprint and SC papers, with an<br />

annual output capacity of 280,000<br />

tonnes.<br />

When the new COMPACT PM 5 starts up,<br />

the existing PM 3 will be taken out of<br />

service. The Ettringen mill will then have<br />

a total capacity of about 420,000 tonnes<br />

p.a., comprising about 160,000 t.p.a. of<br />

newsprint and 260,000 t.p.a. of magazine<br />

paper.