Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

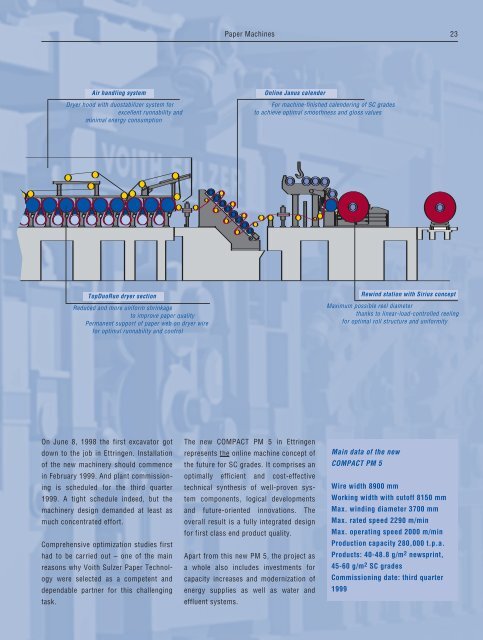

Air handling system<br />

Dryer hood with duostabilizer system for<br />

excellent runnability and<br />

minimal energy consumption<br />

TopDuoRun dryer section<br />

Reduced and more uniform shrinkage<br />

to improve paper quality<br />

Permanent support of paper web on dryer wire<br />

for optimal runnability and control<br />

On June 8, 1998 the first excavator got<br />

down to the job in Ettringen. Installation<br />

of the new machinery should commence<br />

in February 1999. And plant commissioning<br />

is scheduled for the third quarter<br />

1999. A tight schedule indeed, but the<br />

machinery design demanded at least as<br />

much concentrated effort.<br />

Comprehensive optimization studies first<br />

had to be carried out – one of the main<br />

reasons why <strong>Voith</strong> Sulzer <strong>Paper</strong> Technology<br />

were selected as a competent and<br />

dependable partner for this challenging<br />

task.<br />

<strong>Paper</strong> Machines<br />

The new COMPACT PM 5 in Ettringen<br />

represents the online machine concept of<br />

the future for SC grades. It comprises an<br />

optimally efficient and cost-effective<br />

technical synthesis of well-proven system<br />

components, logical developments<br />

and future-oriented innovations. The<br />

overall result is a fully integrated design<br />

for first class end product quality.<br />

Apart from this new PM 5, the project as<br />

a whole also includes investments for<br />

capacity increases and modernization of<br />

energy supplies as well as water and<br />

effluent systems.<br />

Online Janus calender<br />

For machine-finished calendering of SC grades<br />

to achieve optimal smoothness and gloss values<br />

Main data of the new<br />

COMPACT PM 5<br />

Wire width 8900 mm<br />

Working width with cutoff 8150 mm<br />

Max. winding diameter 3700 mm<br />

Max. rated speed 2290 m/min<br />

Max. operating speed 2000 m/min<br />

Production capacity 280,000 t.p.a.<br />

Products: 40-48.8 g/m2 newsprint,<br />

45-60 g/m2 SC grades<br />

Commissioning date: third quarter<br />

1999<br />

23<br />

Rewind station with Sirius concept<br />

Maximum possible reel diameter<br />

thanks to linear-load-controlled reeling<br />

for optimal roll structure and uniformity