Earn - TrenchlessOnline

Earn - TrenchlessOnline

Earn - TrenchlessOnline

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Columbus Tunneling Contractor<br />

Takes on the Tough Projects<br />

By Desiree Willis<br />

Ohio contractor Capitol Tunneling Inc. has been in<br />

business for 50 years and is now setting new standards<br />

for hard rock disc cutting heads. The company<br />

has no less than three record-breaking projects, including a<br />

recently completed 440-ft long sanitary sewer line in Cold<br />

Springs, Ky. — a record for a Small Boring Unit (SBU-A) in<br />

the 24-in. diameter range.<br />

The third generation family-owned business began in<br />

1960 and now employs about 50 people in nine crews<br />

working in states east of the Mississippi. Capitol Tunneling’s<br />

use of Robbins SBUs dates back to 1997, when the company<br />

used one of the first models for a 345-ft long water line<br />

extension under a freeway in Louisville. “We wanted to<br />

compare disc cutter performance with standard roller cone<br />

rock cutting,” said Capitol Tunneling president and CEO<br />

Kyle Lucus, of his initial decision to try Robbins SBUs. “The<br />

technology has since proven itself on over 50 successful<br />

projects for the contractor in the last decade.”<br />

Within the last year, Capitol Tunneling has completed<br />

2,766 ft of bores using SBUs ranging in diameter from 24 to<br />

72 in., including two landmark distances. Capitol is now<br />

setting its sights on more records, including two ongoing<br />

bores in Pennsylvania and Virginia. “These machines are an<br />

advantage for us, because they are a dry process, not requiring<br />

additives or slurry like other methods such as roller<br />

cone heads and microtunneling. Because of this we don’t<br />

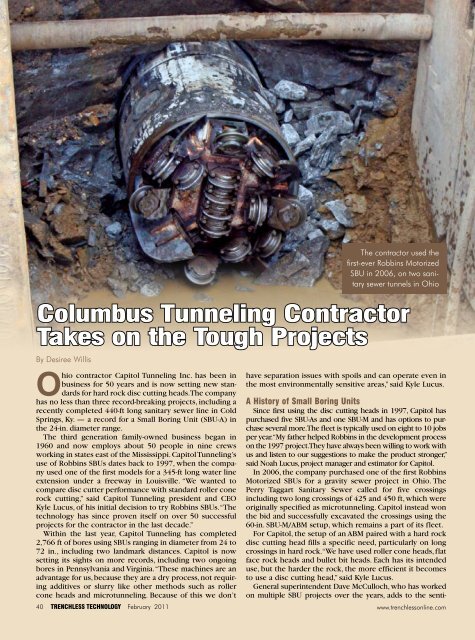

The contractor used the<br />

first-ever Robbins Motorized<br />

SBU in 2006, on two sanitary<br />

sewer tunnels in Ohio<br />

have separation issues with spoils and can operate even in<br />

the most environmentally sensitive areas,” said Kyle Lucus.<br />

A History of Small Boring Units<br />

Since first using the disc cutting heads in 1997, Capitol has<br />

purchased five SBU-As and one SBU-M and has options to purchase<br />

several more. The fleet is typically used on eight to 10 jobs<br />

per year. “My father helped Robbins in the development process<br />

on the 1997 project. They have always been willing to work with<br />

us and listen to our suggestions to make the product stronger,”<br />

said Noah Lucus, project manager and estimator for Capitol.<br />

In 2006, the company purchased one of the first Robbins<br />

Motorized SBUs for a gravity sewer project in Ohio. The<br />

Perry Taggart Sanitary Sewer called for five crossings<br />

including two long crossings of 425 and 450 ft, which were<br />

originally specified as microtunneling. Capitol instead won<br />

the bid and successfully excavated the crossings using the<br />

60-in. SBU-M/ABM setup, which remains a part of its fleet.<br />

For Capitol, the setup of an ABM paired with a hard rock<br />

disc cutting head fills a specific need, particularly on long<br />

crossings in hard rock. “We have used roller cone heads, flat<br />

face rock heads and bullet bit heads. Each has its intended<br />

use, but the harder the rock, the more efficient it becomes<br />

to use a disc cutting head,” said Kyle Lucus.<br />

General superintendent Dave McCulloch, who has worked<br />

on multiple SBU projects over the years, adds to the senti-<br />

40 TRENCHLESS TECHNOLOGY February 2011 www.trenchlessonline.com