Author: Professor, Dr. Dietrich Stein - TrenchlessOnline

Author: Professor, Dr. Dietrich Stein - TrenchlessOnline

Author: Professor, Dr. Dietrich Stein - TrenchlessOnline

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• The most essential information on microtunneling<br />

85 figures and pictures, plus 26 charts with unique, color graphics<br />

Presents main lines and laterals<br />

Covers pilot tube and conventional microtunneling<br />

<strong>Author</strong>: <strong>Professor</strong>, <strong>Dr</strong>. <strong>Dietrich</strong> <strong>Stein</strong>; <strong>Stein</strong> and Partner GmbH Price: $50*<br />

Free Shipping for NASTT Members!<br />

*Shipping & handling not included<br />

S h i p p i n g I n f o r m a t i o n<br />

Name ________________________________________________________________________________Company_________________________________________________<br />

Address ___________________________________________________________________________________________________________________________________________<br />

City ____________________________________State _______________Zip/Postal Code ____________________________Country___________________________________<br />

Phone Number _____________________________________________Fax_________________________________________E-mail____________________________________<br />

W h a t i s y o u r C o m p a n y ' s P r i m a r y I n d u s t r y [check one]<br />

❒ Government ❒ Contractor ❒ Engineering Firm ❒ Utility Company ❒ Mfg/Supplier<br />

W h a t i s y o u r J o b T i t l e [check one]<br />

❒ Owner/Partner, Pres, VP, CEO/COO/CFO/Treasurer<br />

❒ Director, Commissioner, Supt/Supv, Foreman, Engineer, Administrator, Manager<br />

❒ Operator, Field Personnel, Technician, Other<br />

P a y m e n t I n f o r m a t i o n<br />

Reviewed by Prof. Ray Sterling, Director of the<br />

Trenchless Technology Center at Louisiana Tech University<br />

“A rare jewel!” According to German Prof. <strong>Dr</strong>. J. Wagner<br />

Totally new calculation approach for jacking pipe<br />

Extensive discussion of geotechnical considerations<br />

Comprehensive review of pipe materials<br />

Fantastic guide for the design of trenchless technology installations<br />

<strong>Author</strong>: <strong>Professor</strong>, <strong>Dr</strong>. <strong>Dietrich</strong> <strong>Stein</strong>; <strong>Stein</strong> and Partner GmbH Price: $160*<br />

❒ I a m a M e m b e r o f N A S T T<br />

Member ID ________________________<br />

Please Select Your Book ❒ TT Installation $160 ❒ Microtunneling Methods $50<br />

❒ Check Enclosed [make payable to Benjamin Media Inc. in US funds only] ❒ Visa ❒ MasterCard<br />

Name on Credit Card ______________________________________________________________________________________________________________________________<br />

Credit Card Billing Address [if different from above] ________________________________________________________________________________________________<br />

City ____________________________________State________________________<br />

Ordering Information<br />

Zip/Postal Code ________________________Country _____________________<br />

•Fax completed form to: 330.657.2855<br />

Credit Card # __________________________Exp. ________________________<br />

Mail completed form to: Benjamin Media Inc.<br />

Security Code [3-digit number from back of card]___________________<br />

PO Box 190, Peninsula, OH 44264<br />

Signature ______________________________Date ________________________<br />

Online: www.trenchlessonline.com/bookstore.htm<br />

Circle 53 on reader service card.

Circle 1 on reader service card.

CONTENTS<br />

VOLUME 16 • NUMBER 9 SEPTEMBER 2007 WWW.TRENCHLESSONLINE.COM<br />

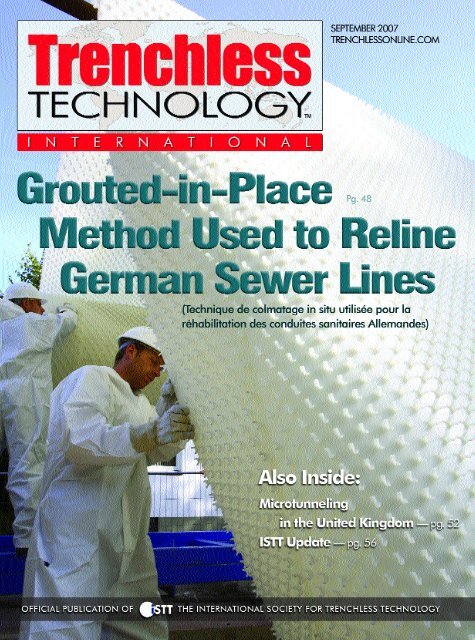

ON THE COVER<br />

CIPP work has become a staple of the Miami-Dade Water and Sewer<br />

Department. Photo by Sid Hoeltzell, Miami.<br />

COVER STORY<br />

20 Trenchless Thrives in Miami-Dade, Fla.<br />

In the early 1990s, the Miami-Dade County Water and Sewer Department<br />

(MDWSD) had in all likelihood the largest chemical grouting program for<br />

its sewer collection system in the United States. Fast-forward to 2007<br />

and MDWSD is still on the cutting edge of cities involved in rehabilitating<br />

their infrastructure. By Sharon M.Bueno<br />

FEATURES<br />

26 A Tale of Two Manholes<br />

For two experienced municipal contractors, one in the cold northern<br />

Great Lakes region, the other in the tropical coast of Florida, adding the<br />

complication of extreme weather conditions to already challenging projects<br />

required all of their creative thinking and job planning skills.<br />

By Suzan Marie Chin<br />

34 Perspective on Pipe Bursting<br />

America’s cities are facing a problem that collectively involves millions of<br />

miles of pipe and easily tops the trillion-dollar mark. There might be<br />

cause for despair if the only way to replace water, gas and sewer pipe<br />

was the time-consuming process of ripping up roads and yards by<br />

open-cut excavation. Thank goodness it’s not. By Kevin Smith<br />

28 WEFTEC 2007 Meets in San Diego<br />

Water and wastewater professionals from around the world can quench<br />

their thirst for knowledge and new technologies by attending WEFTEC<br />

2007, the largest annual water quality conference and exhibition in North<br />

America. By Pam Stask<br />

INTERNATIONAL SECTION:<br />

48 Grouted-in-Place Pipe Method<br />

Used to Reline German Sewer Lines<br />

52 Motorized Small Boring Units<br />

Power Through Rock on U.K. Pipeline<br />

56 ISTT Newsletter<br />

TRENCHLESS TECHNOLOGY (ISSN 1064-4156) is published monthly, with a Directory in May. Copyright 2007, Benjamin Media, Inc., P.O. Box 190, Peninsula, OH<br />

44264.All rights reserved. No part of this publication may be reproduced or transmitted by any means without written permission from the publisher. One-year<br />

subscription rates: complimentary in the United States and Canada, and $99.00 in other foreign countries. Single copy rate: $10.00. Subscriptions and classified<br />

advertising should be addressed to the Peninsula office. Periodical Postage Paid at Peninsula, Ohio and at additional mailing offices. POSTMASTER: send address<br />

changes to TRENCHLESS TECHNOLOGY, P.O. Box 190, Peninsula, OH 44264 USA.<br />

Canadian Subscriptions: Canada Post Agreement Number 40040393. Send change of address information and blocks of undeliverable copies to P.O. Box 1051,<br />

Fort Erie, ON L2A 6C7.<br />

www.trenchlessonline.com<br />

DEPARTMENTS<br />

6 News<br />

15 People<br />

16 TTC Newsletter<br />

59 Calender<br />

65 E-Biz<br />

COLUMNS<br />

4 Publisher’s Message<br />

18 Industry Watch<br />

59 Technical Forum<br />

66 Point of View<br />

MARKETPLACE<br />

60 Business Cards<br />

64 Index of Advertisers<br />

Promoting Technology in the Utility<br />

Construction Industry<br />

Coming in October...<br />

Announcement of the 2007<br />

Trenchless Technology Projects<br />

of the Year<br />

September 2007 TRENCHLESS TECHNOLOGY 3

PUBLISHER’S MESSAGE<br />

Contaminated Water <strong>Dr</strong>aws<br />

$4 Billion in Claims<br />

A recent Congressional hearing that has probed drinking water<br />

problems at Camp Lejeune, N.C., has brought dramatic attention to<br />

our drinking water infrastructure.As many as 1 million people were<br />

exposed to contaminated water dating back to the 1970s at Camp<br />

Lejeune, according to a document from a federal<br />

health agency.<br />

The problem resulted from the chemicals<br />

TCE (a degreasing solvent) and PCE (a dry-cleaning agent).The government<br />

describes them as probable carcinogens and believes that<br />

the water was contaminated by a dry cleaner adjacent to Camp<br />

Lejeune and by industrial activities on the base.As reported Aug. 15<br />

by ABC News,“At least 850 former residents of the base have filed<br />

administrative claims, seeking nearly $4 billion, for exposure to the<br />

industrial solvents.”The issue is whether exposure to the solvents possibly<br />

caused birth defects and leukemia in babies.<br />

With our litigious society in the United States, it is hard to imagine<br />

that the claims from this will stop at $4 billon.The magnitude<br />

of this problem, and particularly how far back in time this is being<br />

investigated, should be an eye-opener for our local officials in<br />

addressing their water and wastewater infrastructure problems.<br />

Pipeline Inspection Supplement<br />

We are pleased to include in this issue of Trenchless Technology a special pipe inspection<br />

supplement.Technological improvements have advanced the means by which local<br />

officials can get a much more accurate evaluation of their underground pipelines. CCTV<br />

has a proven track record and now you are finding advanced camera systems, sonar and<br />

other remarkable innovations, as well as sophisticated data management systems. Our<br />

managing editor Sharon Bueno and assistant editor Katherine Fulton have done an<br />

excellent job of pulling all this information together for your review.<br />

Miami-Dade, Fla.<br />

Miami-Dade has been at the forefront in the use of trenchless technology going back<br />

to the late 1980s. Soil conditions are especially favorable for the use of grouting annular<br />

space in pipeline rehabilitation, as well as pipe relining. Leading much of this effort has<br />

been Luis Aguiar,chief of water transmission and distribution with Miami-Dade Water and<br />

Sewer Department (MDWSD) and Rod Lovett, chief of the MDWSD sewage collection<br />

division.As Miami-Dade moves into its next phase of underground infrastructure work, it<br />

is now embraces such trenchless methods as cured-in-place pipe (CIPP) and lateral<br />

inspection and lining. Be sure to read this comprehensive report on Miami-Dade in this<br />

issue.<br />

Trenchless Technology International<br />

You will note in this issue an international section.Bi-monthly,we<br />

do a special front cover (on top of our regular cover) for our 3,500<br />

international readers.These readers are principally ISTT members<br />

outside of North America.<br />

We do this because Trenchless Technology International is the<br />

“Official Publication of ISTT.” So whether you are in the United<br />

States, Canada, Europe or China, we provide you with the latest<br />

information about the trenchless industry — indeed we are the No.<br />

1 source of trenchless information in the world!<br />

Regards,<br />

Bernard P. Krzys<br />

President & Publisher<br />

Publisher<br />

Bernard P. Krzys<br />

Associate Publisher<br />

Robert D. Krzys<br />

Editor<br />

James W. Rush<br />

Managing Editor<br />

Sharon M. Bueno<br />

Assistant Editors<br />

Katherine Fulton<br />

Bradley Kramer<br />

Contributing Staff Editors<br />

Keith Gribbins<br />

Jason Morgan<br />

Nick Zubko<br />

Creative Director<br />

W. M. Conley<br />

Senior Graphic Designer<br />

Edward A. Haney<br />

Graphic Designers<br />

Sarah Hayes<br />

Chris Slogar<br />

Elizabeth C. Stull<br />

Marketing Manager<br />

Kelly Dadich<br />

Sales Representatives<br />

Dan Sisko<br />

Greg Thompson<br />

Circulation Manager<br />

Alexis R.Tarbet<br />

Web & Interactive Manager<br />

Mark Gorman<br />

Editorial Advisory Board<br />

Chairman<br />

<strong>Dr</strong>.Tom Iseley, P.E.<br />

Sekisui SPR Americas, LLC.<br />

Greer, South Carolina<br />

Alex Buehler<br />

Insituform Technologies Inc.<br />

Chesterfield, Missouri<br />

<strong>Dr</strong>. Samuel Ariaratnam<br />

Arizona State University<br />

Tempe,Arizona<br />

David Bennett, P.E.<br />

Bennett/Staheli Engineers<br />

Sacramento, California<br />

Steven R. Kramer, P.E.<br />

Jacobs Civil Inc.<br />

Arlington,Virginia<br />

Joseph Loiacono, ing.<br />

Sanexen<br />

Montreal, Quebec<br />

Ronald T.Thompson, P.E.<br />

Malcolm Pirnie Inc.<br />

Jackson, Mississippi<br />

Irene McSweeney Woodfall, P.E.<br />

Boston Water and Sewer Commission<br />

Boston, Massachusetts<br />

Editorial & Advertising Offices<br />

1770 Main St., P.O. Box 190<br />

Peninsula, OH 44264 USA<br />

(330) 467-7588 Fax: (330) 468-2289<br />

www.trenchlessonline.com<br />

e-mail: info@benjaminmedia.com<br />

4 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com

Circle 2 on reader service card.

NEWS<br />

Letters to the Editor<br />

I just received my July issue and wanted to say CONGRATULA-<br />

TIONS on 15 years as the publisher of the leading publication in<br />

the trenchless industry. It seems like only yesterday we first talked<br />

about this infant industry and would it survive. Now you tell me it’s<br />

been 15 years. My God how time flies when you are just “kids.”<br />

You deserve a lot of thank yous from this industry. I know of no<br />

other individuals who have done more for the industry or worked<br />

harder for it than you and your great staff.<br />

Here’s looking at another 15.<br />

Doc Bennett, International Vice President, CUES Inc.<br />

Congratulations to you for your 15-year successful run publishing<br />

Trenchless Technology. It has been rewarding and fun for me to<br />

be associated with Trenchless Technology for these past 11 years.<br />

My association with members of your staff, past and present, has<br />

been most enjoyable. Over the years, I’ve learned a lot about the<br />

business and have met many individuals in the trenchless field. I<br />

have respect and high regard for the men and women in the<br />

trenchless world. I’ve been able to follow the evolution of no-dig<br />

and am amazed at the changes and the rapidity of such.<br />

Chester Rufh, Retired <strong>Professor</strong> at Youngstown State University, Youngstown, Ohio<br />

(Editor’s Note: Chester is Bernie Krzys’ first cousin and has been a frequent<br />

support staff member at numerous Trenchless Road Shows and conferences<br />

conducted by Trenchless Technology.)<br />

Insituform<br />

Technologies’<br />

Rooney Resigns<br />

The board of directors of Insituform Technologies<br />

Inc. accepted the resignation of president and CEO<br />

Thomas S.Rooney Jr.,effective immediately,according<br />

to a press release dated Aug. 14. Rooney had served<br />

those positions for four years.<br />

The board has begun a search for Rooney’s successor,<br />

considering both internal and external candidates.<br />

While the search is conducted,Alfred J.Woods, a board<br />

director since 1997 and non-executive chairman of the<br />

board since 2003, will serve as interim CEO.<br />

“Our board appreciates Tom Rooney’s contributions<br />

to the company during his four years as president<br />

and CEO. [His] charge was to pursue a threepronged<br />

strategy of growth, technological innovation<br />

and operational excellence. In the latter two areas,<br />

technological innovation and operation excellence,<br />

Insituform has made tremendous strides under Mr.<br />

Rooney’s leadership,”Woods said.<br />

“Unfortunately,since 2005 our growth has stalled as<br />

overall sewer rehab spending in the domestic market<br />

has stagnated. Our board and CEO disagreed on a<br />

Circle 3 on reader service card.<br />

6 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com

number of stylistic and strategic issues<br />

regarding the company’s growth objectives<br />

and the board therefore accepted<br />

Mr. Rooney’s resignation,”Woods said.<br />

Wood emphasized that the board continues<br />

to believe in the three-pronged<br />

strategy.<br />

“Recent market conditions have been<br />

challenging to Insituform. These events<br />

have led the board of directors to believe<br />

their different direction would need different<br />

leadership. Where the company<br />

chooses to go from here is unknown to<br />

me,” Rooney said in a media statement.<br />

“But of this I have no doubt: If we had<br />

not made so many significant improvements,these<br />

new and unforeseen market<br />

conditions would have been even more<br />

threatening.In point of fact,the company<br />

has a very bright future and is in strong,<br />

capable hands… .”<br />

In other Insituform news, David A.<br />

Martin, company vice president and controller,<br />

has been promoted to vice president<br />

and CFO,a post that had been vacant<br />

for 19 months. Martin, who joined<br />

Insituform in 1993, has served as the<br />

company’s principal financial and<br />

accounting officer since January 2006.<br />

Ohio HDD Association<br />

Conducts Seminar<br />

The Ohio HDD Association’s seminar attracted member<br />

contractors, manufacturers, as well as representatives<br />

of Local 18 Operating Engineers.<br />

The Ohio HDD Association hosted a<br />

directional drilling seminar July 11 at<br />

the Precision Directional Boring facility<br />

in Valley City, Ohio.<br />

The all-day session was held at its<br />

training classroom at the facility.<br />

www.trenchlessonline.com<br />

Attendees included manufacturer<br />

representatives and Ohio HDD<br />

Association contractor members, as<br />

well as representatives from Local<br />

18 Operating Engineers.<br />

Ohio HDD president Valerie Rogers<br />

served as moderator for the event.<br />

Presentations were given by John<br />

Christ and Bo Yordy, Baroid Industrial<br />

<strong>Dr</strong>illing Products, on the mechanics<br />

of using drilling fluids and by Terry<br />

Crosier, Digital Control Inc., on locating<br />

and tracking systems.There were<br />

also demonstrations and a questionand-answer<br />

session.<br />

Baroid sponsored breakfast and<br />

lunch was provided by Precision<br />

Directional Boring.<br />

The Ohio HDD Association is looking<br />

forward to presenting more seminars<br />

around the state of Ohio. Look<br />

for announcements concerning the<br />

topics and contact the Ohio HDD<br />

Association if you have anything in<br />

particular you think would be of interest/help<br />

to you as a driller. For more<br />

information about the Ohio HDD<br />

Association, visit www.ohiohdd.com.<br />

Circle 4 on reader service card.<br />

Mears Group Dedicates<br />

Training & Test Facility<br />

Mears Group Inc. dedicated its<br />

new training and testing facility to<br />

its founder, Herb Fluharty, during<br />

open house festivities on July 11-12<br />

at the corporate headquarters in<br />

Rosebush, Mich.<br />

With more than 50 clients, regulators<br />

and 100 Mears employees present,<br />

the company introduced this<br />

new state-of-the-art test site, which<br />

serves as both a training ground for<br />

employees, as well as an industry<br />

research facility for testing the capabilities<br />

of cathodic protection testing<br />

technology.<br />

Hands-on demonstrations were<br />

observed and performed by the<br />

guests who attended the open house<br />

including close interval surveys,<br />

pipeline excavating, direct current<br />

voltage gradient surveys, BRS automated<br />

sandblasting, current attenuation<br />

surveys, pipe direct examination,<br />

ACVG surveys, NDT, casing<br />

ECDA, pipeline recoating and hori-<br />

September 2007 TRENCHLESS TECHNOLOGY 7

NEWS<br />

Mears Group Inc. founder Herb Fluharty cuts the ribbon at the company’s new training and testing facility.<br />

zontal directional drilling.<br />

This new facility, which covers 2.75<br />

acres, serves as the cornerstone for the<br />

training and operator qualification<br />

(OQ) programs for Mears employees.<br />

The site offers field training capabilities<br />

for activities including pipe excavation,<br />

pipe coating removal, surface preparation,<br />

coating application, evaluating<br />

casing isolation, External Corrosion<br />

Direct Assessment (ECDA) indirect<br />

inspection surveys and pipe direct<br />

examinations.<br />

As part of their training, employees<br />

will have an opportunity to hone their<br />

survey skills on the test site, which is<br />

comprised of more than 1,000 ft of<br />

pipe, including 10-, 12-, 20-, 24- and 30in.<br />

diameters.The primary loop of pipe<br />

includes more than 50 coating flaws<br />

that were intentionally created ranging<br />

in size, shape and pipe orientation.<br />

Keeping safety at the core of Mears<br />

training, the company’s current vision<br />

for this facility will be to maximize<br />

training opportunities for new and<br />

existing employees.“We are convinced<br />

that a highly trained work force is a<br />

safer work force.And, it is our commitment<br />

to cultivate a culture with a focus<br />

on safety and quality,” said Mark<br />

Gluskin, senior vice president of<br />

pipeline integrity services for Mears.“In<br />

the end, we will have a better trained<br />

work force with a higher skill level.”<br />

Mears president Scot Fluharty said,<br />

“Safety has always been a big priority<br />

at Mears, but as we analyzed our<br />

records, we found that 90 percent of<br />

our safety issues were related to<br />

employees who worked for us one<br />

year or less.”<br />

8 TRENCHLESS TECHNOLOGY September 2007<br />

Circle 5 on reader service card.<br />

www.trenchlessonline.com

Circle 6 on reader service card.

NEWS<br />

The test facility includes a 100-ft<br />

casing along the 10-in. carrier pipe<br />

for testing electrical isolation and the<br />

effects of electrolyte within the<br />

annular space. Test wires and reference<br />

electrode access holes for<br />

inserting the electrode into the annular<br />

space exist every 10 ft along the<br />

casing. The annular space can be<br />

flooded with varying amounts of<br />

water and variable resistors every 10<br />

ft can be used to change the location<br />

of contacts including simulating<br />

“high resistance” contacts.The carrier<br />

pipe contains prefabricated coating<br />

and metal loss anomalies of<br />

known sizes and locations, research<br />

and development training facility.<br />

Envirosight<br />

Training Facility Opens<br />

Near Pittsburgh<br />

Envirosight officials recently cut the<br />

ribbon on a new 1,500-sq ft annex to<br />

the company’s Delmont, Pa., inspection<br />

vehicle assembly and service center.<br />

The annex extends both the<br />

square footage and the capabilities of<br />

the Delmont facility, allowing the<br />

company to offer enhanced service to<br />

customers throughout the region.<br />

The annex consists of a training<br />

center, where customers can get<br />

hands-on training that covers the latest<br />

inspection technologies, software<br />

and techniques, as well as earn NASS-<br />

CO PACP certification. It also houses<br />

administrative offices, where<br />

Envirosight personnel involved in<br />

vehicle sales and production can<br />

communicate with customers and<br />

apprise them of their order status.<br />

Finally, visitors to the annex can<br />

enjoy a comfortable hospitality<br />

lounge, whether they’re waiting for<br />

training to begin,or onsite to pick up<br />

a new inspection vehicle.<br />

“Our Delmont facility is crucial to<br />

everyday operations, but today is the<br />

first day it gets a public face,” said<br />

Envirosight president Richard<br />

Lindner. “We’re thrilled to welcome<br />

customers for training, factory tours,<br />

and order delivery. Moreover, we’re<br />

excited to bring needed services<br />

closer to a larger portion of our customer<br />

base.”<br />

Envirosight, LLC provides video<br />

pipeline inspection solutions to municipalities,contractors,departments<br />

of transportation<br />

and civil/environmental engineers.<br />

Envirosight is committed to ongoing<br />

innovation, delivering products that<br />

enhance user productivity and inspection<br />

detail. Envirosight serves customers<br />

through a trained network of regional<br />

sales partners who deliver localized support<br />

and expertise with rapid turnaround.All<br />

Envirosight technical employees<br />

hold NASSCO PACP certification.<br />

RapidView IBAK<br />

USA to Hold Open House<br />

RapidView IBAK USA’s second annual<br />

Septemberfest in the Heartland will take<br />

place at its headquarters in Rochester,<br />

Ind., on Sept. 20-21.<br />

If you have any interest in pipeline<br />

inspection techniques or equipment,<br />

please plan on attending one of the many<br />

product operation and maintenance seminars,<br />

PACP and software training, or new<br />

product presentations.Visit with experts<br />

in emergent technologies like laser profiling,<br />

sonar profiling and 360-degree optical<br />

scanning cameras.<br />

And in the evenings you can enjoy<br />

live entertainment and drinks with<br />

other operators, owners, dealers and<br />

engineers in our industry. This year’s<br />

headliner is the Grammy Award winner<br />

The Kentucky Headhunters.<br />

If you are interested in attending<br />

please call (800) 656-4225 or visit<br />

RapidView’s Web site at www.rapidview.com<br />

for reservations and information.<br />

This event is completely free.<br />

Reduced PACP training fees will apply.<br />

ISCO Announces Opening of<br />

Ohio Facility<br />

ISCO Industries, one of the nation’s<br />

largest distributors and manufacturers<br />

of polyethylene (HDPE) piping products,recently<br />

announced the opening of<br />

a sales office and distribution facility in<br />

Zanesville, Ohio.<br />

The facility consists of offices, pipe,<br />

fittings and fusion equipment storage.<br />

This new facility is full service, offering<br />

pipe, fittings and accessories ranging<br />

from 2- to 18-in., a full line of McElroy<br />

fusion equipment for sale and rent and<br />

onsite field service technicians.<br />

With this addition ISCO Industries<br />

continues to take an impressive expan-<br />

Circle 7 on reader service card.<br />

10 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com

Circle 8 on reader service card.

NEWS INTERNATIONAL NEWS<br />

sion track having added facilities in<br />

Stockton, Calif., Dallas, Emporia, Va.,<br />

Mableton, Ga., Johannesburg, Mich.,<br />

and International locations in<br />

Crossfield, Canada and Australia within<br />

the past year.<br />

“The Zanesville facility allows us to<br />

further increase the service to our<br />

customers in eastern Ohio, West<br />

Virginia and Pennsylvania,” said Mark<br />

Kirchdorfer, vice president of ISCO<br />

Industries.“This move is a direct result<br />

of the rapidly growing use of HDPE<br />

across many applications in that part<br />

of the country,” he said.<br />

ISCO sales and technical representatives<br />

will be servicing the new facility,<br />

including Steve Bredemeier, regional<br />

sales manager.<br />

ISCO Industries, headquartered in<br />

Louisville, Ky., stocks and sells HDPE<br />

pipe, fittings and fabrications for various<br />

industrial, municipal, environmental,<br />

golf and landfill applications<br />

throughout the United States and<br />

Canada.The company also rents, services<br />

and sells fusion equipment.<br />

CUIRE Receives Grant to<br />

Conduct a U.S.-China<br />

Workshop on Trenchless<br />

The Center for Underground<br />

Infrastructure Research and Education<br />

(CUIRE) at the University of Texas at<br />

Arlington, received a grant from the<br />

National Science Foundation to conduct<br />

a workshop on Trenchless<br />

Technologies and Critical Underground<br />

Infrastructure Issues, in Wuhan, China,<br />

Oct. 8-14.<br />

Additional funding for this workshop<br />

is obtained from College of<br />

Engineering and Department of Civil<br />

Engineering at the University of Texas<br />

at Arlington and the China University<br />

of Geosciences, the host university.<br />

The U.S. team includes well known<br />

researchers from major universities<br />

and research centers. This award will<br />

provide travel support for U.S. participation<br />

in the workshop, where<br />

researchers from both countries will<br />

review the state-of-the-art of critical<br />

underground techniques, the experiences<br />

in China to-date and exchange<br />

ideas on development of research<br />

strategies.<br />

CUIRE director <strong>Dr</strong>. Mohammad<br />

Najafi will be the principal investigator<br />

(PI) on this project,assisted by several<br />

Co-PIs.The Chinese collaborators<br />

include: <strong>Dr</strong>. Baosong Ma, professor of<br />

civil engineering, the foreign organizer<br />

of this unique workshop; <strong>Dr</strong>.<br />

Huiming Tang, dean of College of<br />

Engineering; and <strong>Dr</strong>. Xiaoming Wu,<br />

professor of civil engineering.<br />

The workshop organizers would<br />

like to include several representatives<br />

from U.S. organizations and industries<br />

to participate in this workshop. The<br />

hotel costs for these participants will<br />

be provided through workshop funds.<br />

For more information, contact <strong>Dr</strong><br />

Najafi at e-mail: najafi@uta.edu or ph:<br />

(817) 272-0507.<br />

Generation Change<br />

at Franz Janssen GmbH<br />

Founder and president Franz<br />

Janssen turned over the operation of<br />

Umwelttechnik Franz Janssen GmbH<br />

Circle 15 on reader service card. Circle 16 on reader service card.<br />

12 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com

The Janssen family: Franz, Anja and Niklas.<br />

to daughter Anja and son Niklas on<br />

May 14, ending an era of almost 40<br />

years of trenchless rehabilitation technology<br />

leadership. Coincidentally, the<br />

date also marks his 65th birthday.<br />

In 1969, Franz Janssen, a mechanic<br />

for agricultural machinery by education<br />

and trade, founded his company<br />

in Kalkar on the Lower Rhine.He started<br />

his business in sewer cleaning and<br />

rehabilitation with his first flushing<br />

car. At a time when many sewers had<br />

to be painstakingly cleaned with<br />

Circle 10 on reader service card.<br />

www.trenchlessonline.com<br />

brushes, Franz Janssen was one of the<br />

first to inspect sewers with modern<br />

TV technology. In the early 1980s, the<br />

entrepreneur turned to the issue of<br />

how sewers could be rehabilitated<br />

applying trenchless technologies, at<br />

that time a pioneering idea.<br />

For the next 20 years, his ideas were<br />

put into action.Janssen developed and<br />

patented novel processes and technologies<br />

for renovating aging sewer<br />

piping infrastructure.<br />

Throughout Europe, the Janssen<br />

Process became the standard for the<br />

rehabilitation of cracks or complex<br />

damages in sewer pipes. Franz’s<br />

method for applying durable PU or<br />

Silica resins from the inside to the outside<br />

of pipe through cracks and openings<br />

was a breakthrough technology<br />

because his technologies offer agency<br />

managers a permanent repair solution<br />

while reducing the cost compared to<br />

conventional dig and replace<br />

approaches<br />

His zeal for inventing and applying<br />

new technologies to customer problems<br />

fueled company growth.From the<br />

single flushing truck back in 1969,<br />

Janssen GmbH has outgrown two previous<br />

company locations and now<br />

counts more than 20 truck systems<br />

operating in Germany and Europe.So it<br />

comes as no surprise that the company<br />

founded by Franz Janssen is seen to this<br />

day as one of the technologically most<br />

advanced and most economical service<br />

companies for sewer cleaning and<br />

rehabilitation.Even with the senior as a<br />

pioneer of trenchless rehabilitation<br />

going from board, the next generation<br />

finds excellent circumstances to take<br />

over and continue the family business.<br />

With his company now firmly<br />

entrenched as one of Europe’s leading<br />

trenchless rehabilitation companies<br />

and a modern, new facility in Goch,<br />

Janssen leaves his legacy to Anja and<br />

Niklas. “I’m proud of what they have<br />

already accomplished,” said Janssen,<br />

referring to his daughter and son,<br />

“Their direction in expanding our<br />

technology and methods to the United<br />

States is working well,” he added.<br />

In September 2006, Janssen GmbH<br />

established a U.S. partner,The Janssen<br />

September 2007 TRENCHLESS TECHNOLOGY 13

INTERNATIONAL NEWS<br />

Process LLC, which is aggressively<br />

marketing the Janssen Lateral<br />

Renovation System to the U.S. municipal<br />

sewer agencies.“This is an exciting<br />

time for Anja and Niklas,” continued<br />

Janssen. “In June, we are sending our<br />

lateral system to America to demonstrate<br />

its capabilities to nine cities.”<br />

Subsite Distributor<br />

in Poland Named<br />

The Charles Machine Works Inc.<br />

recently announced the addition of<br />

Poland’s P.U.H. Poltrade as an official<br />

dealer of Subsite electronic locating<br />

equipment, which is used to locate<br />

and identify underground utilities at<br />

construction jobsites.<br />

P.U.H. Poltrade provides well-proven,<br />

competitive and reliable measurement<br />

and automation solutions for the power<br />

sector, utility, and other industries in<br />

Poland. For more information about<br />

Subsite equipment, call (800) 654-6481<br />

or visit www.subsite.com.<br />

TRENCHLESS ASIA 2008<br />

Set for April in China<br />

TRENCHLESS ASIA is clearly established<br />

as the region’s largest and most<br />

important meeting for trenchless technology<br />

professionals and the third international<br />

event to be held in Shanghai,<br />

April 16-18,2008,is expected to surpass<br />

the two previous successful shows held<br />

in 2004 and 2006.<br />

As little as 10 years ago, conventional<br />

open-cut methods were widely used for<br />

the underground utility installation and<br />

refurbishment in mainland China. The<br />

rapid growth in population, coupled<br />

with the aging underground utility services,inspired<br />

engineers to study the benefits<br />

of trenchless technology. Today,<br />

China is the fastest growing worldwide<br />

market,with huge potential for overseas<br />

exporters.<br />

Trenchless technology is known to be<br />

used in more than 100 cities in China,<br />

with particular emphasis in Shanghai,<br />

Beijing and Guangzhou. The country’s<br />

achievements are competing at world<br />

levels, undertaking some of the most<br />

ambitious projects in terms of complexity,<br />

diameter and distance. The biggest<br />

HDD in the world is also now in China.<br />

As Beijing is set for the 2008 Summer<br />

Olympic Games, Shanghai prepares for<br />

the World Expo in 2010 and<br />

Guangzhou for the Asian Games in the<br />

same year, these major international<br />

events along with many other major<br />

projects provide evidence that the<br />

construction boom will continue for<br />

the foreseeable future. 2010 is also<br />

China’s target to realise the first stage<br />

of the modernisation process to meet<br />

the exploding urban population.<br />

TRENCHLESS ASIA 2008 provides a<br />

timely focus for the industry to display<br />

the world’s finest range of equipment<br />

and services used in the installation,<br />

repair and refurbishment of urban utility<br />

pipelines.<br />

For more information on exhibiting at<br />

TRENCHLESS ASIA 2008. Contact<br />

Caroline Prescot at Westrade Group Ltd.,<br />

at ph:+44 020 8876 1881,e-mail:trenchless@westrade.co.uk<br />

or visit the Web<br />

site: www.westrade.co.uk.<br />

14 TRENCHLESS TECHNOLOGY September 2007<br />

Circle 11 on reader service card.<br />

www.trenchlessonline.com

PEOPLE<br />

Interplastic Names CFO<br />

Interplastic Corp. CEO Jim Wallenfelsz recently announced<br />

that Steven Dittel has been appointed chief financial officer.Dittel<br />

will be responsible for overseeing the management<br />

of the financial and information technology departments.<br />

Dittel brings more than 20 years of financial experience<br />

having served as chief financial officer/director of operations<br />

for Circle C Foods, vice president of finance/director<br />

of operations for Stafford Blaine Designs and vice president<br />

of finance/human resources/information systems for<br />

Addco Inc.<br />

Dittel, a certified public accountant, earned a bachelor’s<br />

of science degree in business from the University of<br />

Minnesota and a master’s degree in management and public<br />

administration from Hamline University.<br />

Barsoom Joins PB<br />

Joseph Barsoom has been named senior principal<br />

engineer in the Denver office of PB, a global infrastructure<br />

consulting, engineering and construction management<br />

organization.<br />

Barsoom has more than 43 years of experience in civil<br />

engineering, and planning, design and construction management<br />

of public works projects. Prior to joining PB, he<br />

served as director of engineering for the wastewater management<br />

division of the City and County of Denver. He<br />

supervised planning, design and construction of flood control,<br />

sanitary and storm sewer systems.<br />

Circle 12 on reader service card.<br />

www.trenchlessonline.com<br />

He earned a master of science degree in civil engineering<br />

from the University of Colorado and a bachelor of science<br />

degree in mining engineering from Assuit<br />

University in Egypt. He is a member of the<br />

American Society of Civil Engineers, the<br />

American Public Works Association and ASTM<br />

International.<br />

Founded in 1885, PB provides strategic<br />

consulting, program management, planning,<br />

engineering and construction management<br />

Barsoom<br />

services for transporation, power, building<br />

and environmental projects.<br />

Herrenknecht AG Appoints N.A. Sales Mgr.<br />

Herrenknecht AG,a global manufacturer of TBM,shield and<br />

mixshield tunneling machines, microtunneling<br />

systems,shaft dinking machines and horizontal<br />

directional drilling rigs recently announcement<br />

the appointment of Julian O’Connell<br />

as its new North American sales manager,<br />

For the past four and half years O’Connell<br />

has worked with the James Fowler Co. of<br />

O’Connell<br />

Dallas and Oregon, in the capacity of tunneling<br />

manager. In his new role with<br />

Herrenknecht, O’Connell’s responsibilities will cover the<br />

whole of North America, including the United States,<br />

Canada and the Caribbean,for the range of equipment with<br />

the company’s Business Unit Utility Tunneling (BU-UT).<br />

September 2007 TRENCHLESS TECHNOLOGY 15

Trenchless Technology<br />

Center Newsletter<br />

National Trenchless Research<br />

Building Completed in June<br />

Work on the research building itself was completed in<br />

June but as soon as the building contractor moved out,<br />

work began on the large soil structure interaction facility<br />

to be built within the high bay research space in the building.<br />

The soil box design was expanded prior to construction<br />

so that it will be a total of 11 ft high and 20 ft x 20 ft<br />

in plan dimensions; 3 ft of the total depth will be below<br />

floor elevation and a 3-ft thick strong floor construction<br />

will both surround and underlay the soil box providing a<br />

tremendous flexibility in terms of applying loading horizontally<br />

and vertically to the soil and structures within it.<br />

Trenchless installation and replacement techniques will be<br />

simulated by a 550,000-lb servo-controlled actuator with a<br />

5-ft stroke that will be mounted horizontally adjacent to<br />

the soil box.A future newsletter will provide a more complete<br />

description of the new facility.<br />

Since the building dedication is planned for early<br />

November, work on the soil box and strong floor is proceeding<br />

at a rapid pace. TTC faculty member <strong>Dr</strong>. Mike<br />

Baumert, assisted by <strong>Dr</strong>. Luke Lee, has taken the major<br />

Trenchless Technology Center Newsletter<br />

S e p t e m b e r 2 0 0 7<br />

TTC Welcomes Irene McSweeny Woodfall to the Industry Advisory Board<br />

The TTC is very pleased to welcome<br />

Irene McSweeney Woodfall<br />

as a public works member of the<br />

TTC Industry Advisory Board.<br />

Irene is the director of construction<br />

of the Boston Water and Sewer<br />

Commission and has a longstanding<br />

involvement in trenchless technology<br />

applications within the<br />

water and sewer sectors. She has<br />

Pouring the 3-ft thick strong floor beneath the soil box.<br />

served on the Board of the North<br />

American Society for Trenchless<br />

Technology and this summer was<br />

on the organizing committee for<br />

the American Society of Civil<br />

Engineers Pipeline Division conference<br />

held in Boston. Irene joins<br />

10 other public works members<br />

from across the country (see sidebar<br />

for details) that provide guid-<br />

The National Trenchless Technology Research Facility.<br />

responsibility for the detailed soil box and strong floor<br />

design and construction. Because of the special issues surrounding<br />

the 320,000-lb anchor points that are distributed<br />

on a 2- to 3-ft spacing across the floor, much of the preparation<br />

work has been carried out by a team of TTC students<br />

supervised by Baumert. It is planned to use the soil testing<br />

facility for controlled<br />

studies of full scale soilstructure<br />

interaction for<br />

pipes up to several feet<br />

in diameter, studies of<br />

forces and ground movement<br />

during pipe bursting<br />

and pipe jacking,<br />

studies of HDD borehole<br />

stability and installation<br />

parameters, as well as<br />

utility locating and pipe<br />

characterization technologies.The<br />

distributed<br />

anchor points beneath<br />

ance to the TTC as to the user<br />

needs for technology development<br />

and problem issues that need<br />

attention. The public works members<br />

provide an excellent balance<br />

to the board, which also currently<br />

includes nine industry members,<br />

eight consultant members, five<br />

association members and two<br />

media members.<br />

Overall layout of the soil structure interaction<br />

the soil box will allow a total vertical load of up to 2.5 million<br />

lbs to be applied to the soil allowing the simulation of<br />

high force biaxial loading conditions.

“Listening” Sessions on Asset Management<br />

The Buried Asset Management Institute (BAMI) has undertaken a project for<br />

the U.S. Environmental Protection Agency (EPA) on the management of buried<br />

utility assets.One aspect of this project involves gathering feedback from municipalities<br />

on issues relating to the implementation of buried asset management<br />

(listening sessions). Because the TTC arranges municipal forum programs across<br />

the United States, the TTC was asked to use its municipal forum program to collect<br />

data for the BAMI project.Eight of the municipal forums held in the first half<br />

of 2007 were used to collect the data on asset management practices and needs.<br />

Discussion sessions and/or questionnaires were distributed at the forums<br />

between February and June 2007 (see municipal forum description for locations<br />

of spring forums).A total of 156 responses to the questionnaire were received.<br />

The questionnaire responses and discussion sessions indicated that there is general<br />

acceptance of the benefits of asset management at the engineering and operations<br />

level in municipalities.There was more skepticism about the level of understanding<br />

of this topic and the willingness of upper management and city councils/mayors<br />

to properly fund and implement such approaches. Guidance was also<br />

received regarding the creation of a national Center of Excellence for Asset<br />

Management. Full information concerning the results of the study will be included<br />

in the BAMI report to the EPA,which is planned to be completed later this year.<br />

2007 Spring Municipal Forum Season Summary<br />

The TTC Municipal Trenchless Technology Users Forum continues to expand<br />

its reach. Two new forum locations were added this spring in Boston and in<br />

Miami. Each forum is hosted by a local municipality or agency and is attended<br />

by municipal participants from surrounding communities. The morning sessions<br />

involve a variety of industry presentations and the afternoon closed sessions<br />

allow peer-to-peer exchange of experiences and expertise among the<br />

municipal participants.The accompanying table provides the summary of the<br />

spring forum programs.<br />

FORUM: LOCATION: DATE: HOST: TOTAL PRESENTATIONS<br />

ATTENDED: GIVEN:<br />

NORTHWEST Olympia,<br />

Wash.<br />

02/28/07 Zheng Lu 43 4<br />

COLORADO Littleton, Colo. 03/01/07 James<br />

Redmond<br />

51 6<br />

BOSTON Boston 03/14/07 Irene<br />

Woodfall<br />

48 5<br />

MINNESOTA Minneapolis 04/12/07 Richard<br />

Profaizer<br />

3 15<br />

NEW YORK Hoboken, N.J. 05/15/07 Fred Pocci 62 5<br />

OHIO Columbus,<br />

Ohio<br />

05/17/07 James Gross 37 5<br />

CALIFORNIA Los Angeles 06/05/07 Keith Hanks 41 5<br />

TEXAS Dallas 06/11/07 Cesar Baptista 47 5<br />

FLORIDA Miami 06/14/07 Victor Cuervo 48 5<br />

TOTALS 408 45<br />

2007 Fall Municipal Forum Season<br />

Fewer forums than normal are planned for the fall 2007 because of the special<br />

preparations being made for the dedication of the National Trenchless<br />

Technology Research Facility in November. All the forums currently being<br />

planned are scheduled for October. So far, the following four forums have been<br />

confirmed:<br />

If you would like further information<br />

FORUM: LOCATION: DATE:<br />

about the forum program either as a pre-<br />

COLORADO Aurora, Colo., 10/01/07<br />

senter, municipal attendee or prospective<br />

NORTHWEST Longview, Wash. 10/04/07 municipal host, please contact the TTC.<br />

LOUISIANA Alexandria, La. 10/24/07<br />

TEXAS Houston 10/25/07<br />

Trenchless Technology Center Newsletter<br />

Industry Advisory Board (AIB)<br />

Gerhard Lang<br />

Amitech USA, LLC<br />

Bernie Krzys<br />

Benjamin Media<br />

Irene McSweeney<br />

Woodfall<br />

Boston Water & Sewer<br />

Commission<br />

Richard Nelson<br />

CH2M HILL<br />

Wayne Querry<br />

City and County of Denver<br />

Troy Norris<br />

City of Atlanta<br />

Bob Johnson<br />

City of Dallas<br />

Joe L. Smith<br />

City of Houston<br />

John Morgan<br />

City of Indianapolis<br />

Keith Hanks<br />

City of Los Angeles<br />

Richard Aillet<br />

City of Ruston<br />

Ali Mustapha<br />

City of Shreveport<br />

Robert Cannon<br />

Composites One<br />

Glyn Hazelden<br />

Gas Technology Institute<br />

(GTI)<br />

Terry Anderson<br />

GCTA<br />

Brian C. Dorwart<br />

Haley & Aldrich, Inc.<br />

Anthony Almeida<br />

Halff Associates, Inc<br />

Rick Turkopp<br />

Hobas Pipe USA, Inc.<br />

Lynn Osborn<br />

Insituform Technologies,<br />

Inc.<br />

Richard St. Aubin<br />

IPEX Inc.<br />

Robert Morrison<br />

Jason Consultants<br />

Lucia Lee<br />

KBR - Kellogg Brown &<br />

Root, Inc<br />

Gunars Sreibers<br />

King County<br />

Vic Weston<br />

LA Contractors’ Educ.<br />

Trust Fund<br />

Cliff Tubbs<br />

Laughlin Thyssen, Inc.<br />

Larry Kiest, Jr<br />

LMK Enterprises, Inc.<br />

Irvin Gemora<br />

NASSCO<br />

George Cowan<br />

New York City - DDC<br />

Robert McKim<br />

Parsons Brinckerhoff<br />

Norman E. Kampbell<br />

Rehabilitation Resource<br />

Solutions, LLC<br />

Michael Burkhard<br />

Reline America, Inc<br />

Denise McClanahan<br />

Reynolds Inliner, LLC<br />

John J. Struzziery<br />

S E A Consultants Inc.<br />

Joseph W. Barsoom<br />

TTC Municipal Users<br />

Program<br />

L. Grant Whittle<br />

Ultraliner, Inc<br />

Robert Carpenter.<br />

Underground Construction<br />

Steve Cooper<br />

Uni-Bell PVC Pipe Assoc.<br />

Trenchless Technology<br />

Center Newsletter<br />

September 2007<br />

Trenchless Technology Center<br />

Louisiana Tech University<br />

Director: <strong>Dr</strong>. Ray Sterling<br />

Associate Director:<br />

<strong>Dr</strong>. Erez Allouche<br />

Director of Municipal Forum Program:<br />

Joe Barsoom<br />

Research Engineer:<br />

Jadranka Simicevic<br />

Secretarial Staff:<br />

Sandi Perry (administrative secretary)<br />

Mailing address:<br />

P.O. Box 10348<br />

Ruston, LA 71272-0046 USA<br />

Phone: (318) 257-4072<br />

Toll Free: (800) 626-8659<br />

Fax: (318) 257-2777<br />

E-mail: ttc@Latech.edu<br />

Web site for TTC:<br />

http://www.ttc.latech.edu<br />

The TTC Newsletter is published<br />

as a department within Trenchless Technology.<br />

All newsletter materials are prepared by TTC.<br />

Communications should be directed to the center.

INDUSTRY WATCH<br />

Aging Infrastructure Must Be Fixed Sooner, Not Later<br />

By Katherine Fulton<br />

“In the past 50 years or so, engineering has made great<br />

advances,” says Bill Marcuson, president of the American<br />

Society of Civil Engineers (ASCE).“Unfortunately, we often<br />

gain knowledge from our mistakes.”<br />

Sadly, these mistakes can sometimes take the form of fatal<br />

catastrophes. While some of these disasters occur despite<br />

vigilance and the best of intentions, many others are the<br />

result of poor maintenance or other preventable measures.<br />

Recently, two American cities had to contend with infrastructure<br />

failures that resulted not only in major damage to<br />

urban areas, but also to tragic losses of life. A steam pipe<br />

explosion in New York City on July 18, injured 45 and indirectly<br />

killed one (the victim suffered a heart attack while<br />

fleeing the scene). Less than a month later, the collapse of<br />

the I-35W Mississippi River bridge in Minneapolis, killed 13<br />

people when it plunged into the river.As crews pick up the<br />

pieces and investigators look into the causes of both accidents,<br />

many are wondering about the state of infrastructure<br />

in their area — and if leaders and decision-makers at all levels<br />

of government will do what it takes to prevent accidents<br />

like this from happening again.<br />

Though investigations into both the New York City and<br />

Minneapolis incidents are not yet conclusive, many agree that<br />

there could be several contributing factors that led to a “perfect<br />

storm” of sorts, resulting in the failure of these systems.<br />

Fabian Hadipriono Tan, a civil engineering professor at The<br />

Ohio State University,states that systemic failures are the result<br />

of either external causes,such as environmental stresses,pressure/wear<br />

on a structure,and so on,or internal causes,such as<br />

design, construction, material or maintenance errors.<br />

“External events are generally expected by us,” says Tan.<br />

“[In the case of the New York City steam pipe,] we normally<br />

have mechanisms like steam traps to relieve water pressure,<br />

to drain water that could create catastrophic events<br />

and so forth.We would also expect that regular and proper<br />

inspection and maintenance procedures be implemented<br />

on this type of infrastructure. External events are expected.<br />

“However, what we normally do not expect to happen<br />

here is what we call internal flaws, such as design errors,<br />

construction problems,material problems and maintenance<br />

of the pipes.We engineers design it and we assume that it is<br />

properly designed, so if there is an error, we don’t expect<br />

that error to happen. Otherwise, it’s not going to be<br />

installed in the first place.”<br />

While a combination of both external and internal causes<br />

could have easily sped the deterioration of these systems,<br />

the final piece of the puzzle could be issues with infrequent<br />

or improper maintenance at a time when funding for public<br />

systems continues to decrease.While no one will be able<br />

to pinpoint a definitive cause until after the investigations<br />

18 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com

into the incidents are complete, Eben Wyman, vice president<br />

of government relations at the National Utility<br />

Contractors Association (NUCA), says that needs continue<br />

to grow even as federal funding shrinks.<br />

“It’s a sad story.Take water and wastewater systems — the<br />

EPA estimates that America’s wastewater infrastructure<br />

faces close to $200 billion in existing, documented needs,”<br />

says Wyman.“To make matters worse, we’ll need $534 billion<br />

for water and sewer systems by 2019 if we don’t up the<br />

ante in terms of investing in our underground, environmental<br />

infrastructure. When you take a broader look at our<br />

roads, bridges, highways, waterways, dams and schools, the<br />

situation doesn’t get any better.”<br />

In addition, various regions of the United States have special<br />

infrastructure needs due to population or environmental<br />

factors, says Marcuson. In some areas, population growth<br />

outpaces infrastructure growth, while areas like the West<br />

Coast and Gulf Coast must contend with the possibilities of<br />

natural disasters such as earthquakes and hurricanes. But<br />

regardless of location, he says that the effect of collapsing<br />

infrastructure is far reaching.<br />

“Crumbling infrastructure impacts the physical health of<br />

our nation’s citizens and the economic health of our country,”<br />

Marcuson says.“These recent failures have gotten the<br />

nation’s attention. Fixing these problems will take real leadership,<br />

but I don’t see anyone addressing the issues surrounding<br />

our infrastructure.This must change.”<br />

But the tide may be turning. According to Wyman, the<br />

Circle 13 on reader service card.<br />

www.trenchlessonline.com<br />

recent disasters have spurred discussion on the state of<br />

America’s infrastructure in Congress. This, combined with<br />

NUCA and the Clean Water Council’s work to increase federal<br />

funding for water and wastewater infrastructure, may<br />

help get federal leaders to give serious consideration to the<br />

needs of infrastructure of all types.Some are already leading<br />

the way.<br />

“Longtime infrastructure champions like Rep. Jim<br />

Oberstar [D-Minn.] are responding accordingly and dragging<br />

others off the sidelines in the process,”says Wyman.“And he’s<br />

not alone — there are lawmakers who consider infrastructure<br />

a high priority, although many continue to need a lot of<br />

educating to realize how important these lifelines are to the<br />

nation.It’s our job to make sure that America’s infrastructure<br />

is a lasting priority and not the flavor of the week, because<br />

there is an overwhelming amount of work to be done.”<br />

Hopefully, the efforts of activists, involved members of<br />

Congress,civil engineers and infrastructure efforts will help<br />

turn the tide against an aging system that is struggling<br />

against time, wear and neglect. It is an effort that must not<br />

be abandoned, according to Marcuson.<br />

“We have underinvested in our infrastructure for decades,<br />

and sadly, we’ve learned that ignoring a problem doesn’t<br />

make it go away,” Marcuson says.“We must invest now or<br />

pay more later.”<br />

Katherine Fulton is an assistant editor of Trenchless<br />

Technology.<br />

September 2007 TRENCHLESS TECHNOLOGY 19

COVER STORY<br />

Trenchless Thrives<br />

In the early 1990s, the Miami-Dade<br />

Water and Sewer Department<br />

(MDWSD) had in all likelihood the<br />

largest chemical grouting program<br />

for its sewer collection system<br />

in the United States. With its fleet of<br />

16 television and grouting systems<br />

and trained crews, Miami-Dade was at<br />

the forefront of addressing its infiltration-and-inflow<br />

(I/I) problems with<br />

the latest technology.<br />

Fast-forward to 2007 and MDWSD<br />

is still on the cutting edge of departments<br />

involved in rehabilitating their<br />

infrastructure.Today, the use of curedin-place<br />

pipe (CIPP) and lateral<br />

inspection and relining replace chem-<br />

ical grouting at the top of the agenda<br />

of work being done in the county.<br />

“The collection system is in better<br />

shape today than it has been in 10 to<br />

15 years,”says Rod Lovett, chief of the<br />

MDWSD sewage collection division.<br />

“We started with a consent agreement<br />

[with U.S. EPA] in 1992 and<br />

we’ve done in total since then about<br />

$400 million to $500 million worth of<br />

work on the system. We analyze the<br />

repair method that is the least expensive<br />

way to make the repair and a<br />

good portion of that has been<br />

through trenchless technologies.”<br />

MDWSD’s budget for trenchless has<br />

grown over the years as opportunities<br />

Trenchless Methods<br />

Remain Key to<br />

the County’s Water<br />

and Sewer Rehab<br />

Success<br />

By Sharon M. Bueno<br />

for use has expanded; approximately<br />

40 percent of its rehab budget is<br />

spent on trenchless projects.<br />

Through the use of fold-and-form<br />

(early on), CIPP, sliplining, pipe bursting,<br />

horizontal directional drilling,TV<br />

inspection, sectional and point<br />

repairs and chemical grouting of<br />

joints, the water and sewer divisions<br />

in Miami-Dade continue to invest<br />

wisely in its infrastructure — something<br />

all utilities need to be doing<br />

these days, Lovett says.<br />

“The state of the infrastructure in<br />

Miami-Dade is the same as the rest of<br />

the country — it is in desperate need<br />

of replacement,”says Luis Aguiar,chief<br />

20 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com

in Miami-Dade, Fla.<br />

of the water transmission and distribution<br />

division.“We need to continue<br />

to invest money to replace the infrastructure<br />

because it is getting to be 50<br />

to 60 years old or older. We have<br />

water mains [in Miami-Dade] that<br />

have been in service since the early<br />

1930s. It is a challenge being faced by<br />

not only Miami-Dade but every<br />

utility across the United States<br />

where the infrastructure is getting<br />

to the point that unless we start<br />

investing money in it, it’s going to<br />

become catastrophic in the<br />

future. And it’s not just the water<br />

and sewer systems. Look at the<br />

steam pipe that blew in New York<br />

City and the bridge that collapsed<br />

in Minnesota [this summer].”<br />

Miami-Dade County is home to<br />

the fifth largest utility in United<br />

States, in terms of miles of service<br />

and customers. MDWSD, with 440<br />

sq miles of service area, maintains<br />

7,100 miles of water lines and<br />

3,600 miles of sewer lines, which<br />

serve approximately 2.4 million<br />

customers and includes 11 wholesale<br />

municipalities.<br />

The average age of the sewer<br />

and water lines are 40 and 60-plus<br />

years old, respectively, with some<br />

sewer lines dating back as far as<br />

1919.A majority of the sewer lines<br />

are made of clay with new pipes<br />

being fusible PVC; the forcemains<br />

are made of ductile iron and prestressed<br />

concrete. MDWSD operates<br />

three water and wastewater<br />

treatment plants each, along with 14<br />

pump stations for water service and<br />

954 pump stations for wastewater.<br />

Trenchless Baptism<br />

Trenchless methods made their first<br />

appearance in the county in the early<br />

1990s when fold-and-form (F/F) was<br />

used to rehab aging sewer lines, as it<br />

was considered more cost-effective at<br />

the time than CIPP, says Lovett and<br />

Aguiar.<br />

“We did some successful fold-andform<br />

programs,” Lovett says.“But now<br />

we are pretty much exclusive to CIPP.<br />

www.trenchlessonline.com<br />

As we progressed, the patents on the<br />

CIPP process wore off and as competition<br />

came in, the price went down.<br />

We have a contract now that we pay<br />

$21.50 per foot for 8-in.CIPP,which is<br />

actually less money than what we<br />

were paying for fold-and-form.”<br />

So far this year, Miami-Dade has<br />

The Miami-Dade Water and Sewer Department completed more<br />

than 40,000 ft of CIPP work so far in 2007.<br />

done 40,600 ft of CIPP work.“That’s<br />

probably down from previous years,”<br />

Lovett notes. “We are going back<br />

through the system [with inspection]<br />

a second time; therefore we are not<br />

finding as much of a problem as we<br />

did the first time.”<br />

Back in the early days when everything<br />

trenchless was new, people<br />

were coming out of the proverbial<br />

woodwork, offering Miami-Dade<br />

can’t-miss solutions and products to<br />

its infrastructure problems. “About<br />

that time, everyone was coming<br />

down here with a magic wand, saying<br />

‘I got the process that’s going to solve<br />

all your problems,’” remembers<br />

Aguiar, who at the time was working<br />

on the sewer side. “It was then we<br />

decided to hire a consultant and form<br />

a committee so we could evaluate the<br />

different processes and materials that<br />

[were being pitched] to us… That is<br />

how we started to expand our<br />

trenchless program.”<br />

The district’s trenchless program<br />

has included over the years<br />

a variety of methods and trenchless<br />

companies, including some<br />

large diameter and interceptor sliplining<br />

work in the mid-1980s<br />

using HOBAS pipe, a program that<br />

lasted until the late 1990s. Pipe<br />

bursting has been used on the<br />

sewer side involving TT<br />

Technologies but is being utilized<br />

to a far larger extent on the water<br />

side today.Televising and grouting<br />

the sewer lines, once the main<br />

cog in its trenchless arsenal, used<br />

such companies as CUES. Regrouting<br />

annular space for liners<br />

added Logiball to the mix.<br />

Today, CIPP continues to be the<br />

most used trenchless method,<br />

contracting the work out to such<br />

companies as Insituform<br />

Technologies. Laterals are taking<br />

center stage these days with companies<br />

such as LMK and Perma-<br />

Liner among others getting the<br />

call.<br />

“Miami-Dade County Water and<br />

Sewer has always been very conservative,”Aguiar<br />

says.“It took a lot of<br />

effort to accept technologies that<br />

were really new to the U.S. market. So<br />

we had to take certain chances.”<br />

The televising and grouting program<br />

was one such chance, using<br />

technology that wasn’t largely accepted<br />

by many utilities at the time.<br />

Through the program, high levels of<br />

I/I were vastly reduced over a fiveyear<br />

period between 1993-98. The<br />

program proved invaluable to<br />

MDWSD and not just in terms of the<br />

I/I results but in the knowledge<br />

gained by its staff. “We had to learn<br />

September 2007 TRENCHLESS TECHNOLOGY 21

COVER STORY<br />

how to do things,” Lovett<br />

says, noting that Larry<br />

Decker, MDSWD assistant<br />

superintendent for the<br />

sewage collection division,<br />

even created a software<br />

program at the time<br />

to record the readings<br />

from the flow monitors;<br />

based on this data, the<br />

county was able to determine<br />

where the heaviest<br />

I/I was concentrated.<br />

Miami-Dade also did its<br />

own television work, having<br />

in excess of 16 trucks<br />

in operation, and crews<br />

working in two shifts.<br />

“Right now we have 17<br />

truck shifts operating and<br />

eight crews that are running<br />

every day,” Lovett says. “We’ve<br />

cut back a bit because we finished<br />

the five-year cycle [of inspection] and<br />

are now on a 10-year cycle. Those<br />

trucks not only do SSES but they also<br />

Longevity of the MDWSD 2,700-member workforce has bred experience<br />

and invaluable trenchless knowledge.<br />

do the grouting.”<br />

The success of that initial TV and<br />

grout program allowed MDWSD to<br />

evolve into inspecting every foot of<br />

mainline in the system, as well as the<br />

laterals. “I haven’t heard of anyone<br />

else in the country that<br />

has done this,” Lovett<br />

explains. “As we go<br />

through the mainline,<br />

we stop at each lateral<br />

connection. We pan-andtilt<br />

[the camera] into<br />

each lateral to see if<br />

there are any leaks. If<br />

there is water running<br />

down in the lateral while<br />

we’re there, we’ll wait<br />

five minutes to see if the<br />

water stops.If it does,we<br />

move on.If it doesn’t,we<br />

identify that particular<br />

lateral as a suspect lateral<br />

and a lateral inspection<br />

team will go out at a<br />

later date and check it.”<br />

Laterals, Laterals, Laterals<br />

One area that MDWSD has aggressively<br />

and proactively addressed in<br />

recent years has been the condition<br />

of the laterals throughout the county.<br />

22 TRENCHLESS TECHNOLOGY September 2007<br />

Circle 14 on reader service card.<br />

www.trenchlessonline.com

Through two pilot programs, more than<br />

1,600 laterals have been inspected and<br />

subsequently 1,000 rehabbed to this<br />

point. The county used a sanitary sewer<br />

evaluation survey (SSES) to assess the<br />

pipes’ condition. SSES uses various equipment<br />

and techniques to detect sewer<br />

pipe defects, blockages and capacity<br />

problems. These techniques include<br />

smoke tests, dye tests, closed-circuit TV<br />

(CCTV), flow monitoring, rain monitoring,<br />

building service connection location/inspection<br />

and flow isolation.<br />

“We did the pilot programs to try to<br />

identify the source of rain-induced I/I that<br />

comes into the system during and after<br />

heavy rains,” says Lovett.“We are looking<br />

closely now at extending the program.”<br />

The project is designed to evaluate a<br />

variety of lining systems, including CIPP<br />

and inner seals. In addition to testing<br />

these products, Miami-Dade is fine-tuning<br />

its flow monitoring techniques to ensure<br />

accurate measurements of the reduction<br />

of infiltration.<br />

The first and smaller pilot program<br />

goes back five years and involved three<br />

www.trenchlessonline.com<br />

basins and 99 laterals. The second<br />

and larger program recently<br />

wrapped up and involved 52 basins<br />

and 1,600 laterals.Estimated cost for<br />

the larger program is $16.5 million,<br />

with actual costs being about $14<br />

million. “The only thing we don’t<br />

have on the second program is the<br />

rainfall data on some of the basins<br />

yet because we haven’t had enough<br />

Circle 9 on reader service card.<br />

rainfall to compare the results,”<br />

Lovett says, explaining that a “qualified<br />

rain event” is one in which at<br />

least 4 ½ in. of rain falls in a 24-hour<br />

period. “We typically get several of<br />

those during our rainy season but it<br />

hasn’t occurred across the county as<br />

a whole;it’s been spotty in the county.<br />

We have been able to qualify<br />

some basins, not all.<br />

September 2007 TRENCHLESS TECHNOLOGY 23

COVER STORY<br />

“The program is dependent on<br />

showing the results of what we’ve<br />

done,” he adds.“There are a lot of<br />

lateral programs across the country<br />

in which all they do is go out<br />

and replace laterals but they don’t<br />

really know what they’ve done.<br />

They have no way of measuring<br />

their success.We wanted to figure<br />

out a way to do that.”<br />

Experience<br />

Breeds Success<br />

Aguiar and Lovett have been<br />

integral parts of the Miami-Dade<br />

infrastructure turnaround over the<br />

years. Aguiar just recently marked<br />

his 30th year with MDWSD and<br />

Lovett has 19 years on the job.<br />

Longevity is the norm among the<br />

2,700 workers at MDWSD, bringing<br />

expertise to the processes<br />

being utilized. Lovett says many<br />

things have changed over the<br />

years and appreciates the expertise<br />

that his staff brings to the job.<br />

CIPP may be the most used trenchless method in MDWSD<br />

but other methods include pipe bursting, HDD, sliplining and<br />

chemical grouting, to name a few.<br />

“I don’t know if we are old pros<br />

but we do know our system very<br />

well. I’ve never felt that what<br />

[Miami-Dade does] is what everyone<br />

should do because everyone<br />

has different circumstances. We<br />

do have a better handle on things,<br />

but most of that is because of the<br />

technology.<br />

“When I first went to work, the<br />

way we responded to sewer problems<br />

was strictly on a reactive<br />

basis,” he says. “If something was<br />

broke, we fixed it. Today, we’re<br />

probably doing 80 percent of our<br />

work on a proactive basis. That’s<br />

what’s changed and it was a long<br />

time in coming. And it was the<br />

right thing to do.”<br />

Sharon M. Bueno is managing editor<br />

of Trenchless Technology.<br />

Circle 17 on reader service card. Circle 18 on reader service card.<br />

24 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com

Circle 19 on reader service card.

MANHOLE FOCUS<br />

A Tale of Two Manholes<br />

No matter how extreme the weather or<br />

terrain, two seasoned contractors prove<br />

successful manhole rehabilitation can be<br />