Earn - TrenchlessOnline

Earn - TrenchlessOnline

Earn - TrenchlessOnline

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ment: “We tend to use Christmas tree heads for softer materials,<br />

but in hard rock, they wear very hard on the ABM, particularly<br />

on the gear box and transmission. Roller cone heads cut<br />

rock a little better, but there is still the problem with maintaining<br />

the ABM. With the Robbins Motorized SBU in particular, all<br />

of the rock cutting is done at the front — the ABM is simply<br />

pushing the casing and turning a small invert auger.”<br />

Raising the Stakes in Kentucky<br />

In 2010, Capitol completed a record-setting bore at the<br />

Ripple Creek Sanitary Sewer in Cold Springs. The 440-ft<br />

long crossing was excavated in just 24 days using a 24-in.<br />

diameter SBU-A with 4-in. hex auger and a 48-in. ABM with<br />

60,000 lbs of thrust.<br />

The crew ran into some difficulty when excavating in<br />

unpredictably mixed layers of shale and limestone. Mud<br />

seams ran throughout the rock and at one point the SBU-A<br />

was excavating in a full face of dirt. “We fought the head drifting<br />

for most of the bore because of the layers in the rock. We<br />

made adjustments to the steering fins to help control this<br />

and on several occasions we had to pull the casing back and<br />

forth, reaming the hole out to allow the casing and cutters to<br />

clear the spoils from the bottom and left hand side to avoid<br />

further drifting,” said Kyle Lucas. The crew continued to pull<br />

the auger string and check the grade throughout the bore.<br />

The machine broke through on Nov. 24, 2010, 8 in. off<br />

line and exactly on grade. “I believe we could have pushed<br />

another 100 ft or so in this material. The jacking pressures<br />

were lower than expected, and our rotational pressure was<br />

For more information visit www.trenchlessonline.com/info<br />

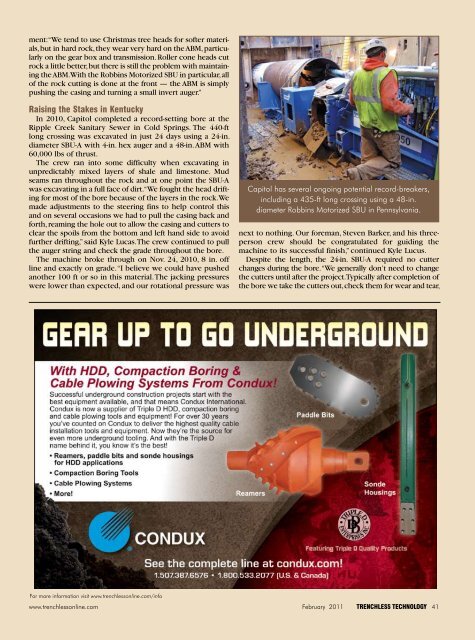

Capitol has several ongoing potential record-breakers,<br />

including a 435-ft long crossing using a 48-in.<br />

diameter Robbins Motorized SBU in Pennsylvania.<br />

next to nothing. Our foreman, Steven Barker, and his threeperson<br />

crew should be congratulated for guiding the<br />

machine to its successful finish,” continued Kyle Lucus.<br />

Despite the length, the 24-in. SBU-A required no cutter<br />

changes during the bore. “We generally don’t need to change<br />

the cutters until after the project. Typically after completion of<br />

the bore we take the cutters out, check them for wear and tear,<br />

www.trenchlessonline.com February 2011 TRENCHLESS TECHNOLOGY 41