Tahiti CondensingMod. KR 55 - Portsdean Technical

Tahiti CondensingMod. KR 55 - Portsdean Technical

Tahiti CondensingMod. KR 55 - Portsdean Technical

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

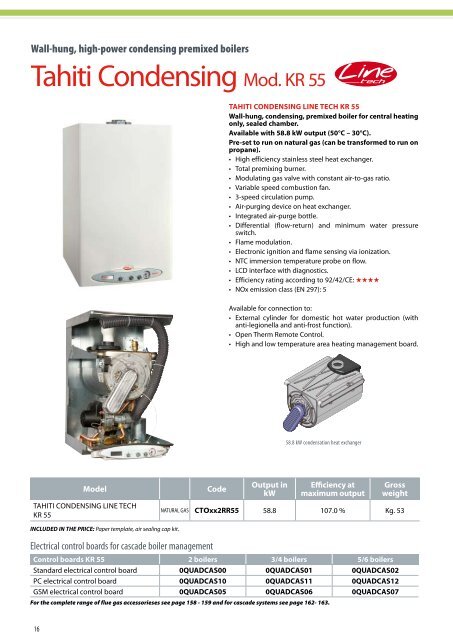

Wall-hung, high-power condensing premixed boilers<strong>Tahiti</strong> Condensing Mod. <strong>KR</strong> <strong>55</strong><strong>Tahiti</strong> CONDENSING LINE TECH <strong>KR</strong> <strong>55</strong>Wall-hung, condensing, premixed boiler for central heatingonly, sealed chamber.Available with 58.8 kW output (50°C – 30°C).Pre-set to run on natural gas (can be transformed to run onpropane).• High efficiency stainless steel heat exchanger.• Total premixing burner.• Modulating gas valve with constant air-to-gas ratio.• Variable speed combustion fan.• 3-speed circulation pump.• Air-purging device on heat exchanger.• Integrated air-purge bottle.• Differential (flow-return) and minimum water pressureswitch.• Flame modulation.• Electronic ignition and flame sensing via ionization.• NTC immersion temperature probe on flow.• LCD interface with diagnostics.• Efficiency rating according to 92/42/CE: ★★★★• NOx emission class (EN 297): 5Available for connection to:• External cylinder for domestic hot water production (withanti-legionella and anti-frost function).• Open Therm Remote Control.• High and low temperature area heating management board.58.8 kW condensation heat exchangerModelTAHITI CONDENSING LINE TECH<strong>KR</strong> <strong>55</strong>CodeOutput inkWEfficiency atmaximum outputGrossweightNatural gas CTOxx2RR<strong>55</strong> 58.8 107.0 % Kg. 53INCLUDED IN THE PRICE: Paper template, air sealing cap kit.Electrical control boards for cascade boiler managementControl boards <strong>KR</strong> <strong>55</strong> 2 boilers 3/4 boilers 5/6 boilersStandard electrical control board 0QUADCAS00 0QUADCAS01 0QUADCAS02PC electrical control board 0QUADCAS10 0QUADCAS11 0QUADCAS12GSM electrical control board 0QUADCAS05 0QUADCAS06 0QUADCAS07For the complete range of flue gas accessorieses see page 158 - 159 and for cascade systems see page 162- 163.16

<strong>Tahiti</strong> Condensing Line Tech Mod. <strong>KR</strong> <strong>55</strong> Hydraulic layout987654321011121314151617181 Condensate drain siphon2 Modulating gas valve3 Safety thermostat4 Modulating fan5 Condensing primary heat exchanger6 Ignition electrode7 Air-purging device8 Combustion air intake system9 Flue gas discharge system10 Flue gas analysis point11 Flue gas thermostat12 Central heating temperature probe13 Detection electrode14 Fan control sensor15 Air-purging device16 Circulation pump17 Minimum/differential pressure switch18 Unloading tap19 Loading tapSGMFRCondensate drainGas inletCH system flowCold water inletCH system return191S G MF RHead available for boiler (by-pass closed)800Mod. <strong>KR</strong> <strong>55</strong>700600500mbar40030020010000 500 1000 1500 2000 2500l/hV3V2V118

TECHNICAL SPECIFICATIONS <strong>KR</strong> <strong>55</strong>Gas categoryII2H3PNominal heat input kW <strong>55</strong>.0Nominal heat output (80-60°C) kW 53.5Nominal heat output (50-30°C) kW 58.8Minimum heat output (80-60°C) kW 14.1Minimum heat output (50-30°C) kW 15.7Useful efficiency at nominal heat input (80-60°C) % 97.3Useful efficiency at nominal heat input (80-60°C) % 97.0Useful efficiency at nominal heat input (50-30°C) % 107.0Useful efficiency at minimum heat input (50-30°C) % 108.1Useful efficiency at 30% % 108.9Casing heat loss with burner on at nominal heat input % 0.46Casing heat loss with burner on at minimum heat input % 0.83Casing heat losses with burner off % 0.36Chimney heat loss with burner on at nominal heat input % 2.04Chimney heat loss with burner on at minimum heat input % 1.89Energy efficiency mark (92/42 EEC)★ ★ ★ ★NOx class (EN 297/EN 483) 5Maximum working pressure bar 4Maximum working temperature °C 83Temperature adjustment °C 20 - 78Central heating consumption at nominal heat output (80-60°C) Natural gas m 3 /h 5.82Central heating consumption at minimum heat output (80-60°C) Natural gas m 3 /h 1.534Central heating consumption at nominal heat output (80-60°C) Propane kg/h 4.26Central heating consumption at minimum heat output (80-60°C) Propane kg/h 1.124ΔT flue gas/air at nominal heat input °C 44∆T flue gas/air at minimum heat input °C 39Flue gas flow rate at nominal heat input g/s 25.1Flue gas flow rate at minimum heat input g/s 6.6CO 2 at nominal heat input Natural gas % 9.0CO 2 at nominal heat input Propane % 10.0Residual available head at nominal heat input Pa 290Residual available head at minimum heat input Pa 23Supply pressure Natural gas mbar 20Supply pressure Propane mbar 37Diaphragm diameter Natural gas mm 8.2Diaphragm diameter Propane mm 5.9Power supply voltage/frequency V/Hz 230/50Fuse on the power supply A 2Absorbed electric power W 245Electric protection ratingIPX4DGas fitting G3/4Central heating fittings G 1L x H x D mm 450x750x534Gross weight kg 53Net weight kg 51.419

Wall-hung, high-power condensing premixed boilers<strong>Tahiti</strong> Condensing Mod. <strong>KR</strong> 85<strong>Tahiti</strong> CONDENSING LINE TECH <strong>KR</strong> 85Wall-hung, condensing, premixed boiler for central heatingonly, sealed chamber.Available with 90.4 kW output (50°C – 30°C).Pre-set to run on natural gas (can be transformed to run onpropane).• High efficiency stainless steel heat exchanger.• Total premixing burner.• Modulating gas valve with constant air-to-gas ratio.• Variable speed combustion fan.• 3-speed circulation pump.• Air-purging device on heat exchanger.• Integrated air-purge bottle.• Differential water pressure switch (flow-return) and minimum.• Flame modulation.• Electronic ignition and flame sensing via ionization.• NTC immersion temperature probe on flow.• LCD interface with diagnostics.• Efficiency rating according to 92/42/CE: ★★★★• NOx emission class (EN 297): 5Available for connection to:• External cylinder for domestic hot water production (withanti-legionella and anti-frost function).• Open Therm Remote Control.• High and low temperature area heating management board.Accessorieses supplied with theboiler included in the price:Tronchettoaspirazione ariaØ 80 mm.ModelTAHITI CONDENSING LINE TECH<strong>KR</strong> 85CodeOutput inkWEfficiency atmaximum outputGrossweightNatural gas CTOxx2RR85 90.4 106.4 % Kg. 77INCLUDED IN THE PRICE: Paper template, kit tronchetto aspirazione aria Ø 80 мм. con tappo di chiusura.Electrical control boards for cascade boiler managementControl boards <strong>KR</strong> 85 2 boilers 3/4 boilers 5/6 boilersStandard electrical control board 0QUADCAS00 0QUADCAS01 0QUADCAS02PC electrical control board 0QUADCAS10 0QUADCAS11 0QUADCAS12GSM electrical control board 0QUADCAS05 0QUADCAS06 0QUADCAS07For the complete range of flue gas Accessorieses see page 160 - 161 and for cascade systems see page 162- 163.20

Dimensions and coupling centre distances<strong>Tahiti</strong> Condensing Mod. <strong>KR</strong>89 135 148 7850 75042127MØ100 mm flue gasdischargetop view62Ø80 mmair intakeFRATTENZIONE:Questa caldaia utiliz zascarichi sdoppiati conaspirazione aria Ø 80 мм.e scarico fumi Ø 100 мм.oppure la fumisteria pergli impianti a cascatadisponibile a pag. 162 - 163.450534GSIS220. 5RCAccessorieses43 56 173 98 80bottom viewG Gas inlet (3/4”)M CH system flow (1”)F Domestic cold water inlet (1/2”)R CH system return (1”)S Condensate drainItem Description CodeRemote control0CREMOTO05External probe0SONDAES01Electric kit for zone management complete with external probe0KITZONE00Temperature probe for cylinder0KITSOND00Paper fixing template0DIMACAR12Boiler cover0COPERIG01For the complete range of flue gas Accessorieses see page 160 - 161 and for cascade systems see page 162- 163.21

<strong>Tahiti</strong> Condensing Line Tech Mod. <strong>KR</strong> 85 Hydraulic layout87654321910111213141516171 Condensate drain siphon2 Modulating gas valve3 Modulating fan4 Safety thermostat5 Condensing primary heat exchanger6 Ignition electrode7 Central heating temperature probe8 Flue gas discharge system9 Air-purging device10 Flue gas thermal fuse11 Detection electrode12 Air-purging device13 Fan control sensor14 Circulation pump15 Unloading tap16 Minimum/differential pressure switch17 Loading tapSGMFRCondensate drainGas inletCH system flowCold water inletCH system returnS G MF RHead available for boiler (by-pass closed)900Mod. <strong>KR</strong> 85800700600mbar50040030020010000 500 1000 1500 2000 2500 2500 3000 3500 4000 4500l/hV3V2V122