Visualiner 3D¹ - Snap-on Equipment

Visualiner 3D¹ - Snap-on Equipment

Visualiner 3D¹ - Snap-on Equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

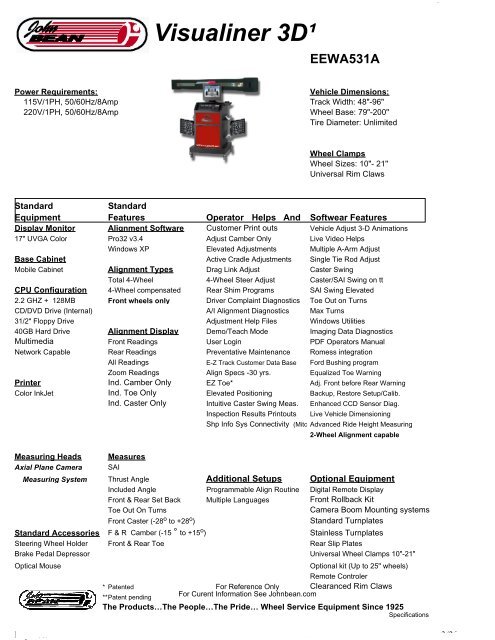

https://www.johnbean.com/securejb/AAJBCINTERNET/PRODUCTSPECIFICATIONS/Aligners/V3d1....3/30/2004<str<strong>on</strong>g>Visualiner</str<strong>on</strong>g> 3D¹EEWA531APage 1 of 2Power Requirements:Vehicle Dimensi<strong>on</strong>s:115V/1PH, 50/60Hz/8Amp Track Width: 48"-96"220V/1PH, 50/60Hz/8Amp Wheel Base: 79"-200"Tire Diameter: UnlimitedWheel ClampsWheel Sizes: 10"- 21"Universal Rim ClawsStandardStandard<strong>Equipment</strong> Features Operator Helps And Softwear FeaturesDisplay M<strong>on</strong>itor Alignment Software Customer Print outs Vehicle Adjust 3-D Animati<strong>on</strong>s17" UVGA Color Pro32 v3.4 Adjust Camber Only Live Video HelpsWindows XP Elevated Adjustments Multiple A-Arm AdjustBase Cabinet Active Cradle Adjustments Single Tie Rod AdjustMobile Cabinet Alignment Types Drag Link Adjust Caster SwingTotal 4-Wheel 4-Wheel Steer Adjust Caster/SAI Swing <strong>on</strong> ttCPU C<strong>on</strong>figurati<strong>on</strong> 4-Wheel compensated Rear Shim Programs SAI Swing Elevated2.2 GHZ + 128MB Fr<strong>on</strong>t wheels <strong>on</strong>ly Driver Complaint Diagnostics Toe Out <strong>on</strong> TurnsCD/DVD Drive (Internal) A/I Alignment Diagnostics Max Turns31/2" Floppy Drive Adjustment Help Files Windows Utilities40GB Hard Drive Alignment Display Demo/Teach Mode Imaging Data DiagnosticsMultimedia Fr<strong>on</strong>t Readings User Login PDF Operators ManualNetwork Capable Rear Readings Preventative Maintenance Romess integrati<strong>on</strong>All Readings E-Z Track Customer Data Base Ford Bushing programZoom Readings Align Specs -30 yrs. Equalized Toe WarningPrinter Ind. Camber Only EZ Toe* Adj. Fr<strong>on</strong>t before Rear WarningColor InkJet Ind. Toe Only Elevated Positi<strong>on</strong>ing Backup, Restore Setup/Calib.Ind. Caster Only Intuitive Caster Swing Meas. Enhanced CCD Sensor Diag.Inspecti<strong>on</strong> Results Printouts Live Vehicle Dimensi<strong>on</strong>ingShp Info Sys C<strong>on</strong>nectivity (Mitc Advanced Ride Height Measuring2-Wheel Alignment capableMeasuring Heads MeasuresAxial Plane Camera SAIMeasuring System Thrust Angle Additi<strong>on</strong>al Setups Opti<strong>on</strong>al <strong>Equipment</strong>Included Angle Programmable Align Routine Digital Remote DisplayFr<strong>on</strong>t & Rear Set Back Multiple Languages Fr<strong>on</strong>t Rollback KitToe Out On TurnsCamera Boom Mounting systemsFr<strong>on</strong>t Caster (-28 o to +28 o )Standard TurnplatesStandard Accessories F & R Camber (-15 ° to +15 o ) Stainless TurnplatesSteering Wheel Holder Fr<strong>on</strong>t & Rear Toe Rear Slip PlatesBrake Pedal Depressor Universal Wheel Clamps 10"-21"Optical MouseOpti<strong>on</strong>al kit (Up to 25" wheels)Remote C<strong>on</strong>troler* Patented For Reference Only Clearanced Rim Claws**Patent pendingFor Curent Informati<strong>on</strong> See Johnbean.comThe Products…The People…The Pride… Wheel Service <strong>Equipment</strong> Since 1925Specificati<strong>on</strong>s

IMAGING TECHNOLOGY V3D 1For Reference OnlyFor Current Informati<strong>on</strong> See Johnbean.comTM

V3D IMAGING TECHNOLOGY3-DIMENSIONAL MODELINGPlanesof theWheelPlane ofthe VehicleAxleSpindleUsing high resoluti<strong>on</strong> digital cameras and patentedthree dimensi<strong>on</strong>al modeling technology, the verticalplanes of each of the vehicle’s wheels as well as theplane of the vehicle itself are modeled. The vehicle’splane is modeled from the center points of each spindleaxis where the wheels attach to the vehicle.The geometric relati<strong>on</strong>ships of each individual wheelplane to each other and to the comm<strong>on</strong> vehicle planedetermine the various measurements which form thebasis for the vehicle’s wheel alignment in threedimensi<strong>on</strong>s. The computer then compares thesemeasurements to the car manufacturers’ specificati<strong>on</strong>sand tells the operator which angles need to be adjustedand by how much. This is d<strong>on</strong>e with live computerizedmodeling rather than gravity based measuring devices.The V3D imaging technology offers easier, faster,and more accurate alignments under a much widerrange of working c<strong>on</strong>diti<strong>on</strong>s.INTUITIVE PROGRAMMINGAfter beginning the alignment, the software is programmed to know what the operator is doing. It anticipates each step and prompts the operator tothe next step without having to key in the specific next step that he would like the machine to do. This makes the alignment easier and faster.If the operator stops turning the wheel after the basiccaster swing, the machine c<strong>on</strong>cludes that this is all theoperator wants to do and proceeds <strong>on</strong> to themeasurement screenIf the operator c<strong>on</strong>tinues turning the wheel bey<strong>on</strong>d thispoint, the machine knows that a toe-out-<strong>on</strong> turnsmeasurement is desired and c<strong>on</strong>tinues accordingly.If operator still c<strong>on</strong>tinues to turn the wheel, the machineknows that a full turn measurement (lock to lock) iswanted and c<strong>on</strong>tinues <strong>on</strong> accordingly.INITIALCUSTOMER PRINT OUTSFINALOPTIONAL EQUIPMENTRoll AroundAdjustment ChairStainless Steel Turntable& V3D Roll Back KitThe “Graphic Printout” shows your customers exactly what needs to be d<strong>on</strong>e tobring their vehicle into proper alignment.GREAT SELLING TOOL!The “Final” print out c<strong>on</strong>firms that a quality alignment has been performed therebyincreasing customer c<strong>on</strong>fidence.Remote Readout With30' CableUniversal Tire ClampFor Reference OnlyFor Current Informati<strong>on</strong> See Johnbean.com

FASTER • MORE ACCURATE • MORE PROFITABLESet-Up ToReadingsIn Under3 Minutes■ Do more alignmentsin less time■ So easy and fun touse that technicianswill actually sellmore alignments■ N<strong>on</strong>-electr<strong>on</strong>ic wheelsensor targets eliminatecalibrati<strong>on</strong>s, wheelsensor maintenance andcut cables■ No comebacks due tocalibrati<strong>on</strong> problemsMount wheel targetsFull, live alignmentreadings in under3 minutesWHAT V3D CUSTOMERS ARE SAYING*Roll vehicle back andforth 8"… the V3D aligner has saved 10-15 minutesper alignment.The 3-D has increased not <strong>on</strong>ly our profit andthe volume of our shop, but also the customersatisfacti<strong>on</strong> … able to almost double the amountof alignments we do.… the number of comebacks has been zero sincewe switched over.Our alignments have increased 3 fold sinceinstalling the V3D aligner-mostly because thetechs like to use the V3D aligner.We tripled our normal fr<strong>on</strong>t end business that week.Alignments are d<strong>on</strong>e in less time, better accuracy.Can take in more alignments. Alignments d<strong>on</strong>ein about half the time.With the new V3D aligner, alignment time forsetup is cut in half.The ease and speed of the V3D make it a surem<strong>on</strong>ey maker.This is <strong>on</strong>e time where I can state that the resultsfar surpassed the claims of your salesman.This allows me to cut down my cost foralignments as compared to other shops in the area.… have increased our alignment sales by 40%.Productivity increases were outstanding. Potentialto increase jobs is 50 to 65%. … My cost peralignment has decreased.We can do more alignments simply because wed<strong>on</strong>'t have comebacks.Productivity increased by over 50%. … Insteadof 1 alignment per hour, we are doing 1 in 30minutes – correctly!… a much faster turn around time for doing wheelalignments.*CALL 1-800-362-4618 FOR A COMPLETE PRINTOUT OF V3D CUSTOMER EXPERIENCES.For Reference OnlyFor Current Informati<strong>on</strong> See Johnbean.com

IMAGING TECHNOLOGYV3D 1FEATURESTotal 4-Wheel Alignment• Fr<strong>on</strong>t caster• Fr<strong>on</strong>t and rear camber• Fr<strong>on</strong>t and rear toe• Thrust included angles• SAI• Fr<strong>on</strong>t and rear set back• Vehicle dimensi<strong>on</strong>sMeter And All Reading Screens• With reading/specificati<strong>on</strong>s and cross values• Meter screensMultiple System C<strong>on</strong>trols• C<strong>on</strong>sole keyboard• Wheel sensor ley pad c<strong>on</strong>trolsSPECIFICATIONSComputer Systems• 17" color display m<strong>on</strong>itor• Mobile cabinet• State-of-the-art CPU Ramand HD memory• Internal CD drive / 3.5 floppy• High capacity hard drive• Deluxe color printer• Druable optical targets• AGP video• Multimedia*See product bid spec sheetOther Software FeaturesAlignment Assistance• Pro32 AI wizard• Multiple A-arm adjust• Elevated adjustments• Active cradle adjustments• Rear shim programs• Align specificati<strong>on</strong>s – 30 years• Vehicle line drawings• Customer data entry• Drag link adjust• EZ toe• Suspensi<strong>on</strong> plus• One key help system• 3-D animati<strong>on</strong> helpsStandard Accessories• Steering wheel holder• Brake pedal depressor• Computer mouse• Wheel clampsOpti<strong>on</strong>al <strong>Equipment</strong>• Remote c<strong>on</strong>troller• Digital remote display• Universal tire clamps• Stainless steel turntables• Standard turntables• Live video adjustments• Driver complaint diagnosis• Floppy disk spec updatesAdditi<strong>on</strong>al Setups• Programmable alignment routines• Set-back in align path• Thrust align <strong>on</strong>ly• Selected cross values• Multiple languagesAvailable Mounting Systems• Multi-level center mount• Fixed level tall center mount• Fixed level short center mount• Fixed level dual tall side mount• Fixed level dual short side mount• Drive-through multi-level mount• Opti<strong>on</strong>al On-Line specificati<strong>on</strong>subscripti<strong>on</strong> services withfloppy disk downloads<strong>Equipment</strong> Specificati<strong>on</strong>s• Wheel size: 10" - 20"• Wheel base: 48" - 200"• Tread width: 48" - 96"Power Requirements• 115V / 1Ph, 50/60 Hz / 8 amp• 230V / 1Ph, 50/60 Hz / 8 amp309 Exchange Avenue • C<strong>on</strong>way, Arkansas 72032 U.S.A. • Fax: 501-450-15851-800-362-4618www.johnbean.comJOHN BEAN ® CANADA • 1-800-362-4608CONTACT OUR INTERNATIONAL DEPARTMENT AT 501-450-1568, 501-450-1526 OR 501-505-2631© 2002 <str<strong>on</strong>g>Snap</str<strong>on</strong>g>-On Technologies, Inc.John Bean ® is a trademark of <str<strong>on</strong>g>Snap</str<strong>on</strong>g>-On Technologies, Inc.All Rights Reserved 6/2002 Form #5832-1For Reference OnlyFor Current Informati<strong>on</strong> See Johnbean.comTM