WORLD'S FINEST SAWMILLS and Wood Processing ... - Wood-Mizer

WORLD'S FINEST SAWMILLS and Wood Processing ... - Wood-Mizer

WORLD'S FINEST SAWMILLS and Wood Processing ... - Wood-Mizer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

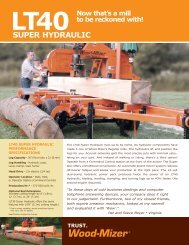

GreenTheinWe know the businesToday, we hear a lot about being “green” <strong>and</strong> makingbetter choices for our world. <strong>Wood</strong>-<strong>Mizer</strong> has alwaysemphasized being good stewards of the environment.In fact, that is exactly what our founders set out to dowith our thin-kerf, portable sawmills. Consequently,a number of tangible <strong>and</strong> measurable environmentalbenefits are realized by utilizing thin-kerf sawmills.Carbon FootprintNo doubt there is some controversy regardinggreenhouse emissions <strong>and</strong> global warming. However,most agree that where greenhouse gases can bereduced with little difficulty or expense, they ought to be.Portable sawmills play an important role in some of thecarbon mitigation strategies many believe to be criticalin reducing atmospheric carbon. For example, portablesawmills often utilize raw materials that otherwise wouldbe left to rot, burn or, at best, processed into chips;all of which eventually release significant amountsof carbon into the atmosphere. By converting thesematerials into lumber, the durable wood productssequester the carbon <strong>and</strong> thereby minimize contributionsto atmospheric greenhouse gasses.Additionally, the lumber recovered from this type ofmaterial reduces the need for additional harvest fromst<strong>and</strong>ing forests.The forests allowed to remain st<strong>and</strong>ing continueto “scrub” carbon from the air <strong>and</strong> release oxygenfurther contributing to atmospheric health, not tomention the reduction in emissions associated withharvesting <strong>and</strong> processing the trees.Increased YieldThe utilization of thin kerf technology also increases theamount of lumber produced from a given volume of logs.Thin kerf sawmill operators often report yields above scaleranging between 30 <strong>and</strong> 200 percent depending on thelength <strong>and</strong> quality of logs being processed. By producingmore lumber <strong>and</strong> less sawdust from a log even more carbonis sequestered. This technology not only allows woodl<strong>and</strong>owners an option for a more profitable business but alsoenhances the environment. L<strong>and</strong> best used for growing treesis optimized by managing not only for greatest incomebut to enhance wildlife habitat, provide watersheds forimproving water quality <strong>and</strong> contribute to atmospheric health.This information is taken from a published article writtenby Jack Petree who is a freelance writer that focuses onenvironmental issues.„We don’t underst<strong>and</strong> at all that there is a crisis now.We advertised just twice in May 2009 <strong>and</strong> the sawingorder book has been full since”Rainer <strong>and</strong> Natali, Saaremaa Isl<strong>and</strong>, EstoniaIn the normal run of things, Finnish Lapl<strong>and</strong>er Samuli Luksua useshis LT40 to process pine logs into material for cabins. But forFinl<strong>and</strong>’s Snow Show near the Arctic circle he switched rawmaterials to one without knots or grain – ice! He cut 500 tonnesof it in 14 days. Most was used to create dramatic sculpturesincluding Penal Colony 2004 designed by Arat Izozaki <strong>and</strong>Yoko Ono. It’s not what the <strong>Wood</strong>-<strong>Mizer</strong> b<strong>and</strong> sawmill is designedfor but it demonstrates its ruggendness <strong>and</strong> versatility.Samuli Luksua, Finl<strong>and</strong>4

s of sawmilling, not just the production of sawmills.Adding Value / Building BusinessesUntil recently the facility had only2 <strong>Wood</strong>-<strong>Mizer</strong> sawmills, <strong>and</strong> productionwas a bottleneck with productionlimited to about 12 000 m 2 of flooringa month. In January 2004 Mr Vladimirbought one more <strong>Wood</strong>-<strong>Mizer</strong> LT40<strong>and</strong> production has increasedto 18 000 m 3 – a 50% increase.Vladimir Becar, Slovakia„The new LT15 b<strong>and</strong> sawmill has in effect enhancedthe quality of the wooden components in our boats,cut costs a bit <strong>and</strong> definitely extended the educationalprogramme. We like to buy timber 'in the round'because it stays greener longer, it's easy to sawboards from it at short notice, it costs less <strong>and</strong> importantly,students witness the entire conversion process,except felling.”Nat Wilson, director, International BoatbuildingTraining College, Oulton Broad, Suffolk, UK„We continually have people visit ourbuilding site <strong>and</strong> they cannot believehow tight the logs fit <strong>and</strong> the qualityof the dimension lumber we havecut with our <strong>Wood</strong>-<strong>Mizer</strong>.The <strong>Wood</strong>-<strong>Mizer</strong> is the bestinvestment I have made ina long time.”Phil Hamilton, Colorado„The b<strong>and</strong> sawmill has becomea good partner <strong>and</strong> the pivotof our small timber processingoperation, which thankfullyhas enabled us to beatthe trend in Swedish woodoperations lately.”Bo Werkströms, Sweden„Kinshasa is an unlikely location for a parquetproducer but Simba Parquet certainly flourishessince a <strong>Wood</strong>-<strong>Mizer</strong> LT70 appeared here <strong>and</strong> ourproduction process become fully controlled 'from logto final form' ”Simba Parquet, Kinshasa, Kongo5

A Growing ConcernAs our name „<strong>Wood</strong>-<strong>Mizer</strong>” would suggest, we are aware that it is ourresponsibility to utilize our forestry resources wisely. We cannot eliminatethe world’s growing need for lumber in the foreseeable future, so we mustget the most from every tree that’s harvested. <strong>Wood</strong>-<strong>Mizer</strong>’s thin kerf makesit the best method available today to efficiently harvest timber – especiallyover the 6mm-9mm kerf of circular mills. Our larger production mills, such asthe LT40 Series, can produce as much lumber per person per day as manyof the largest production mills around – <strong>and</strong> use a third fewer logsin the process.More Quality Lumber per LogIt’s easy to see the difference in output of a <strong>Wood</strong>-<strong>Mizer</strong> over a circular mill.We’re in the business to give you true, accurate lumber – not sawdust.You make more boards out of each log <strong>and</strong> use less horespower, less fuel,less effort, <strong>and</strong> fewer logs to produce the same amount of lumber.Turning Logs into Lumber is SimpleThe first cuts are made across the topof the log. The first cut produces a slabpiece <strong>and</strong> additional cuts produce„flitches” or boards with bark on bothsides.In this illustration, the log has beenrotated 180° to sit on the first flat thatwas made. There are now two parallelflats. Some people stop with this cutto make logs for a home.By rotating the log <strong>and</strong> clamping oneof the flats against the adjustableperpendicular side supports, a third flatcan then be cut. Once the bark isremoved, each cut will producea finished, edged board.If you flip the log over, a final flat canbe cut to square the log into a cant.From here there are several optionsas to how the cant is cut into lumber.<strong>Wood</strong>-<strong>Mizer</strong> Yield(0.68 m 3 )*Circular Mill Yield(0.43 m 3 )** 61 cm x 3 m log sizeEven compared to wide b<strong>and</strong>saw mills the <strong>Wood</strong>-<strong>Mizer</strong> narrow b<strong>and</strong>technology gives a higher yield of sawn timber per cubic meter of log.„Cutting for grade” is a term usedfor sawing hardwood logs to producethe maximum amount of high-gradelumber. This involves rotating the cantto make your cuts on the clearest <strong>and</strong>widest face.Nothing cuts like aEdging lumber is an easy task on the<strong>Wood</strong>-<strong>Mizer</strong>. By st<strong>and</strong>ing any numberof boards on edge, cuts can be madeto any desired width.6

10 Things to ConsiderBefore Buying a Sawmill12345678910See it in action. You wouldn’t buya car without a test drive. The sameprinciple applies to sawmills.Get a reference. Talk to someonewho owns the mill you’re interested in.Ask about the quality of the mill<strong>and</strong> about the company’s customerservice <strong>and</strong> support after the sale.Ask about expertise. Find out howmany b<strong>and</strong> sawmills the company hasmade. There’s no substitute for experiencein designing a quality sawmill.Ask about manufacturing. A lot ofpeople can throw some steel together,stick a blade in there somewhere <strong>and</strong>call it a mill (<strong>and</strong> many do).There are some companies that don’teven manufacture the mills they sell.Compare resale values. The day maycome when you’ll want to sell your mill(possibly because you want to upgradeyour operation). Ensure that you buya sawmill that holds its value well.Compare warranties. You’re buyingmachinery. Parts will wear out over time.Make sure you’re covered well.Compare models <strong>and</strong> engines.Don’t get stuck with the wrong mill.Make sure you have plenty of optionsso you can get the machine that willdo what you need done.A mill for all Seasons. Is the millcapable of operating effectively inall conditions <strong>and</strong> timber types.Safety. Has the mill been designedwith safety of the operator <strong>and</strong> offbearersin mind? Does the blade come to a haltbetween cuts – minimising the risk ofaccident to people <strong>and</strong> equipment?Service <strong>and</strong> Support. Any machineis only as good as the after sales support<strong>and</strong> expertise st<strong>and</strong>ing behind it. Ensurethat you have the best.decisions, decisions7

Segmented Bed SawmillsPerformance SpecificationsLT10LT15LT20BMax. Log Capacity70 cm dia.70 cm dia.80 cm dia.Throat Capacityup to 64 cm wideup to 64 cm wideup to 65 cm wideLength of bed5.4 m (3 bed st<strong>and</strong>ard)5.2 m (2 segments 2.7 m each)5.4 m (3 segments 1.95 m each)7.9 m (3 segments 2.7 m each)LT20B2: 4.8 mLT20B3: 6.8 mLT20B4: 8.8 mLog H<strong>and</strong>lingManualManualManualHead DriveManual CrankPower Up/DownOptional Power FeedPower Up/DownPower FeedPower Options5.5 kW Electric10 HP Diesel15 HP Gas7.5 kW Electric22 HP Diesel25 HP Gas11 kW ElectricSt<strong>and</strong>ard Features• Manual Blade Guide Arm• Manual Blade Guide Arm• Electric Blade Guide Arm• Roller Blade Guides• SW SetworksTypical Options• Loading Ramps• Log Wedge• Bed Section: 1.95 m• SW Setworks• Debarker – AC models only• Loading Ramps• Log Wedge• Trailer Package• Bed Section: 1.95 m or 2.7 m• Debarker• Loading Ramps• Remote Operator Station• Wireless Remote• Bed Section: 2.00 m8

Segmented bed sawmills

LT10<strong>SAWMILLS</strong>Water Lube SystemKeeps the bladein optimum cuttingcondition.Four Side SupportsAdjustable <strong>and</strong> removableto ensure accuracy <strong>and</strong> allowcuts within 2.5 cmof the bed rails.Blade TensioningEasy to operatetensioning system ensurescorrect blade tensionat all times.Four Rail Cleaner<strong>and</strong> Roller WipesHelps to keep bedrails clean <strong>and</strong> freeof debris.Log Clamping SystemAllows you to cut within2.5 cm of the bed.105.5 kW Electric enginePlenty of power froma name you can trust.SafetySafety switch ensures thatthe blade only turns whenthe h<strong>and</strong>le is pushed down.Accurate <strong>and</strong> QuickHead AdjustmentEasily adjust for thicknessof cut <strong>and</strong> simply locksin place to ensureaccurate cuts.Blade Guide ArmEasily adjusts blade guideroller to be close to thematerial to be cut– ensuring accurate cutsevery time.

LT10 Ultra Compact Sawmill for the Needs of Hobby SawyersA complete package ready to saw.The LT10 is a compact hobbyist mill operated with an easy h<strong>and</strong>push feed system. It features a 5.5 kW electric engine witha gravity lube system. The base mill has the capacity to h<strong>and</strong>le70 cm diameter logs by 5.4 m long as st<strong>and</strong>ard.A space saving feature of the LT10 is that it can bedis-assembled <strong>and</strong> stored in your garage or outbuilding.The <strong>Wood</strong>-<strong>Mizer</strong> LT10 is designed as an entry level mill for theweekend sawyers who love the idea of cutting their own lumberbut want to minimize their investment.As with all our mills, the LT10 is backed with the samelegendary service, quality <strong>and</strong> safety features shared bythe rest of the family of <strong>Wood</strong>-<strong>Mizer</strong> mills.LT10 with electric engine<strong>and</strong> segmented bedLog WedgeThe log wedge allows you tolevel tapered logs to ensuremaximum recovery.2 Optional Loading Ramps11

LT15<strong>SAWMILLS</strong>DebarkerEvery LT15 comes prewired<strong>and</strong> ready to fit the optionaldebarker, which extendsblade life by pre-cleaningthe log (AC models only).LT15 sawmillwith diesel engine<strong>and</strong> trailer package12Head OperationBoth the DC <strong>and</strong> the AC millsfeature power up/down <strong>and</strong>a simple h<strong>and</strong> crank systemfor the feed.Optional Power FeedElectrical forward <strong>and</strong> backmovement of the head.Better efficiency productionthroughput.

Compact <strong>and</strong> Versatile – LT15„Keep it simple” said our President, <strong>and</strong> that’s exactly what ourengineers did. They took proven <strong>Wood</strong>-<strong>Mizer</strong> technology (usedin over 35,000 sawmills worldwide!) <strong>and</strong> put it in the mostaffordable package yet.The LT15 offers genuine <strong>Wood</strong>-<strong>Mizer</strong> performance atan unbelievable price. Using the same blades <strong>and</strong> bladeguide systems as our more productive models, this compactpowerhouse can cut logs up to 70 cm in diameter <strong>and</strong> 5.4 mlong in its st<strong>and</strong>ard form. Extra bed sections are availablewhich allow virtually unlimited log length.Whether you want high-quality hardwood lumber for your ownfine cabinets <strong>and</strong> furniture or just plan to harvest a few treesaround the farm for buildings <strong>and</strong> fencing materials; there’sNO better saw for the money than the LT15.The LT15 is often used by farmers <strong>and</strong> Estate Owners to convertsmall volumes of their own timber for local use. Increasingly,due to its enhanced features it is also used in multiple shiftproduction environments.• Up/DownAll LT15's now come equippedwith power up/down as st<strong>and</strong>ard.• Large throat capacity allowscuts up to 64 cm wide.• The LT15 blade guides are the sameas those used on all <strong>Wood</strong>-<strong>Mizer</strong> mills.• The LT15 clamping system enablesyou to cut within 2.5 cm of the bed.• The manual blade guide arm givesmaximum blade stability in anysituations. It is easily adjustable fromthe operator's position.• Semi-cantilever head lowers bothcost <strong>and</strong> weight.• Quick-detach Head/mast to reducelifting weight.• Twin-rails that rest on the ground, withintegral levelling system.• Loading ramps <strong>and</strong> cant hookcome as optional accessories.LT15 with electric engine<strong>and</strong> segmented bedSW SetworksOptional SW setworks increasesproductivity <strong>and</strong> accuracy using ruggedelectronics to quicklyposition the head for the next cut.Log ClampThe adjustable clamp holdsthe log or cant securely<strong>and</strong> allows you to cut towithin 25 mm of the bed.Adjustable Side SupportsThe adjustable sidesupports secure the logor cant during cutting <strong>and</strong>ensure accurate dimensions.Log WedgeThe log wedge allows youto level tapered logs to ensuremaximum recovery.13

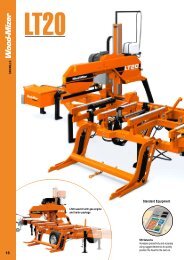

LT20BCantilevered headAssures fast setup, easylevelling, <strong>and</strong> accurate cuts.<strong>SAWMILLS</strong>Electric Blade Guide ArmEasily operated fromthe main control panel.DebarkerThe LT20 sawmill comesprewired <strong>and</strong> ready to fitthe optional debarker,which extends blade lifeby pre-cleaning the log.Loading Ramps(optional equipment)LT20B sawmillwith gas engine1411 kW Electric enginePlenty of power froma name you can trust.SW SetworksIncreases productivity<strong>and</strong> accuracy using ruggedelectronics to quickly positionthe head for the next cut.

The LT20B – the LT20 head with the new "B" bed version.The new “B” bed has been specially designed, followingfeedback from our customers, to allow for simplicity ofinstallation, operation <strong>and</strong> modularity of length of cut.By simply adding or removing bed modules you can quickly<strong>and</strong> easily extend or shorten the cutting length to suit yourorder requirements.We have modified our LT20 head to be used with the “B” bed– thus creating the LT20B. There are no compromises – all ofthe st<strong>and</strong>ard <strong>and</strong> optional features of the LT20 head are stillavailable.The LT20B combines a well proven cutting head with allof the features needed for accurate, efficient <strong>and</strong> productivework, with the rugged simplicity of the B bed.A further advantage of the B bed is to more easily <strong>and</strong> costeffectively practice a method of sawing that is already commonlyused by many of our st<strong>and</strong>ard bed owners. By adding enoughadditional sections to be able to load two logs onto the bedend-to-end, you can have one sawyer cutting each log inrotation. The operator doesn’t stop after the first log is sawnbut continues with the second as the assistant removes boardsfrom the first <strong>and</strong> prepares it for the second stage. This cyclicalprocess is continued thus maximising the time that the headis actually cutting wood, <strong>and</strong> maximising the utilisationof the assistants.LT20B with electric engine<strong>and</strong> segmented bedSide SupportsManually adjusted side supportshelp to secure the log during cutting.Manual Log ClampThe adjustable clamp holdsthe log or cant securely<strong>and</strong> allows you to cut towithin 25 mm of the bed.Manual ToeboardsMounted on the sawmillbed's front <strong>and</strong> rear crossmembers, the toeboardsenable you to lift eitherend of a tapered logby h<strong>and</strong> crank.LT20B REMOTE – with optionalRemote Operator Station15

Classic bed sawMILLSmillsPerformance SpecificationsLT20LT40LT70Max. Log Capacity80 cm dia.90 cm dia.95 cm dia.Throat capacityup to 65 cm wideup to 72 cm wideup to 73 cm wideLength of bedS bed: 4.8 mM bed: 6.8 mL bed: 8.8 mS bed: 5 mM bed: 6.3 mL bed: 8.6 mS bed: 4.8 mM bed: 6.1 mL bed: 8.4 mLog H<strong>and</strong>lingManualHydraulicSuper Hydraulic (M bed) ACManualHydraulicSuper Hydraulic (M bed)ManualHydraulicSuper Hydraulic (M bed)Head DrivePower Feed & Up/DownPower Feed & Up/DownPower Feed & Up/DownPower Options22 HP Diesel25 HP Gas11 kW Electric42 HP Turbo-Diesel33 HP Diesel28 HP Gas18.5 kW Electric15 kW Electric11 kW Electric42 HP Turbo-Diesel18.5 kW Electric15 kW Electric11 kW ElectricSt<strong>and</strong>ard Features• Electric Blade Guide Arm• Roller Blade Guides• SW Setworks• Electric Blade Guide Arm• Roller, Single BlockBlade Guides• SW Setworks• Electric Blade Guide Arm• Roller, Double BlockBlade Guides• PLC Setworks or Accuset• Auto Clutch (DC only)• Lube<strong>Mizer</strong>Typical Options• Debarker• Wireless Remote• Trailer Package• Bed Extension:1.8 m or 3.6 m or 7.2 m• Super HydraulicPackage for M beds(42 HP <strong>and</strong> AC models only)• Debarker• Auto Clutch (DC only)• Lube<strong>Mizer</strong>• Wireless Remote• Hold Down Clamps• Trailer Package• Bed Extension:1.8 m or 3.6 m or 7.2 m• Super HydraulicPackage for M beds(42 HP <strong>and</strong> AC models only)• Debarker• Wireless Remote• Hold Down Clamps• Trailer Package• Bed Extension:1.8 m or 3.6 m or 7.2 m16

Classic bed sawmills

LT20<strong>SAWMILLS</strong>St<strong>and</strong>ard EquipmentLT20 sawmill with gas engine<strong>and</strong> trailer package18SW SetworksIncreases productivity <strong>and</strong> accuracyusing rugged electronics to quicklyposition the head for the next cut.

Simple <strong>and</strong> AffordableIf you want more flexibility to tackle the more dem<strong>and</strong>ing job,the LT20 has the features that you need.The LT20 (<strong>and</strong> LT20B) is the first of our range of mills to featurethe cantilevered head design which allows fast accurate set-upsin any conditions.St<strong>and</strong>ard power up/down <strong>and</strong> power feed on the head furtherincreases productivity <strong>and</strong> control of the cutting process.The bed is our well proven single rail design providing rigidity<strong>and</strong> strength <strong>and</strong> easy access to the log for h<strong>and</strong>ling.Optional Manual hydraulic log loading makes loading eventhe largest logs safe <strong>and</strong> easy, <strong>and</strong> the addition of the optionalwinch operated log turner facilitates the h<strong>and</strong>ling of large logs.From small individual projects to a small business operationthe LT20 provides the tool that you need for success.The LT20 is ideal for start-up businesses <strong>and</strong> smallworkshops who want the higher level of productivity that theLT20 can provide, but don’t need the productivity ofthe LT40 <strong>and</strong> LT70.LT20 stationary sawmill with electric engine<strong>and</strong> hydraulic log h<strong>and</strong>ling• Cantilevered head:Assures fast setup, easylevelling, <strong>and</strong> accurate cuts.• Main bed torque tube:The same frame usedon all <strong>Wood</strong>-<strong>Mizer</strong>professional sawmills.• Four main bed supports:Adjustable to assureaccuracy.• Electric Blade Guide Arm:Easily operated fromthe main control panel.• Heavy-duty adjustableboard supports:Supports swing out fromthe main bed rail to help holdlong cants, beams, or boardson a flat plane while cutting.• Main rails:Induction-hardened,precision steel rods weldedto the top <strong>and</strong> bottom of the10 cm x 20 cm torque tubeof the main frame.• Stainless steel bed sleeves:Protects the saw bed fromwear <strong>and</strong> also preventsstaining of hardwoods.• Water lube system:Keeps the blade inoptimum cutting condition.• Side support:Manually adjusted sidesupports help to securethe log during cutting.• Trailer package:Includes adjustableoutriggers as st<strong>and</strong>ardwith fully complient trailerspecifications.19

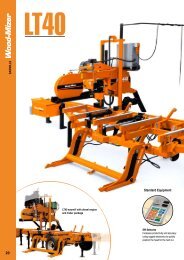

LT40<strong>SAWMILLS</strong>St<strong>and</strong>ard EquipmentLT40 sawmill with diesel engine<strong>and</strong> trailer packageSW SetworksIncreases productivity <strong>and</strong> accuracyusing rugged electronics to quicklyposition the head for the next cut.20

The Mill that Started it AllThe LT40, with many thous<strong>and</strong>s out in the field, is the realworkhorse of our range of sawmills particularly forthe mobile operator who concentrates on custom cuttingfor his income. The LT40, as with all our mills, canbe used in stationary applications <strong>and</strong> many of our ownersthroughout Europe use these mills in multiple shift operationsclocking up tens of thous<strong>and</strong>s of hours.With a wide range of engine, log h<strong>and</strong>ling <strong>and</strong> control optionswe can tailor-make a mill to your exact requirements.The LT40 mills are primarily owned by individualentrepreneurs <strong>and</strong> privately owned businesses whose sourceof income is derived from their sawing operation.LT40 stationary sawmill with electric engine<strong>and</strong> hydraulic log h<strong>and</strong>ling• Hydraulic pump, reservoir,<strong>and</strong> control box: Mountedon the front of the mill.All hoses are mounted insidethe main bed tube.(No second engine required)• Centralized cuttingcontrols: Located on centralconsole. Includes headmovement <strong>and</strong> blade guidearm in-out. Optional:AutoClutch, Lube<strong>Mizer</strong>,debarker, <strong>and</strong> LaserSight.• Log side supports:Raised <strong>and</strong> lowered remotelythrough the control box.• Cantilevered head:Assures fast setup, easyleveling, <strong>and</strong> accurate cuts.• Adjustable Outriggers:Fine adjustable outriggersfitted as st<strong>and</strong>ard on mobilemills – allowing fast <strong>and</strong>precise set-up which ensuresaccurate cutting.• Removable gas tank <strong>and</strong>blade water bottle:Can be lowered for easyaccess to mill.• Trailer package:Includes adjustableoutriggers as st<strong>and</strong>ardwith fully complient trailerspecifications.• Stainless steel bed sleeves:Protect the saw bed fromwear <strong>and</strong> also preventstaining of hardwoods.• Roller/block blade guides:Ensure accuracy, bladestability <strong>and</strong> increasedblade sharp life.21

LT70<strong>SAWMILLS</strong>St<strong>and</strong>ard EquipmentLT70 sawmill with diesel engine<strong>and</strong> trailer packagePLC Setworks(for more details,please see page 42)22

High Capacity SawmillingThe LT70 has been designed to meet the dem<strong>and</strong>sof the modern log processing plant. The head is constructedto be exceptionally durable <strong>and</strong> dependable <strong>and</strong> features600 mm pulley wheels <strong>and</strong> roller double block guides.Mill alignment <strong>and</strong> maintenance requirements have beenreduced to a minimum.Accuset or PLC Setworks, Auto Clutch <strong>and</strong> Lube<strong>Mizer</strong> arest<strong>and</strong>ard on the LT70.The addition of our material h<strong>and</strong>ling options can significantlyincrease productivity, while still keeping all the advantagesof our narrow-b<strong>and</strong> technology.The LT70 is often bought by existing <strong>Wood</strong>-<strong>Mizer</strong> ownerswho now need higher production levels, <strong>and</strong> also by existingentrepreneurs in the timber industry who realise the valueof the increased productivity, yield <strong>and</strong> returns generatedby the LT70 technology.LT70 stationary sawmill with electric engine<strong>and</strong> hydraulic log h<strong>and</strong>ling package• Roller double block bladeguides: Accurate cutting withincreased blade stability.• Hinged blade wheel covers:Facilitate quick bladechanges <strong>and</strong> are easy toclose <strong>and</strong> fasten.• Idler pulley clutch system:Easy access to drive belt forroutine maintenance.• Air bag blade tensioning:Improved blade tensionconsistency in all cuttingconditions.• Accuset: <strong>Wood</strong>-<strong>Mizer</strong>’spowerful setworks comesst<strong>and</strong>ard on the LT70.• Large throat capacity:Allows for cuts up to73 cm wide.• Auto Clutch:Is controlled from the operatorpanel. Comes st<strong>and</strong>ard withthe LT70.• Large cam followerbearings:7.5 cm diameter bearingsused on the topside. Dualsaddle bearing arrangementon the operator side yieldsincreased bearing life.• Trailer package:Includes adjustableoutriggers as st<strong>and</strong>ardwith fully compliant trailerspecifications.• Lube<strong>Mizer</strong>:Pressure pulse system keepsthe blade clean <strong>and</strong> lubricated,increasing overall bladeperformance. Comesst<strong>and</strong>ard with the LT70.23

Log H<strong>and</strong>lingAdd the advantages of hydraulics to the quality <strong>and</strong> durability of the sawmill, <strong>and</strong> much of the physical labor associatedwith sawing is eliminated. Hydraulic levers located at the front of the mill, control the functions of loading, leveling, clamping,<strong>and</strong> turning of the log. Once the log is ready, the operator simply sets the board thickness <strong>and</strong> feed rate from the centralizedcutting controls <strong>and</strong> walks along with each cut.Manual Log H<strong>and</strong>ling<strong>Wood</strong>-<strong>Mizer</strong> sawmillwith manual log h<strong>and</strong>lingToeboardsMounted on the sawmillbed’s front <strong>and</strong> rearbedrails. The toeboardsenable you to lift eitherend of a tapered log byh<strong>and</strong> crank.Log TurnerThis simple accessory,when used in conjunctionwith the manual winch,enables a single operatorto rotate larger diameterlogs.<strong>Wood</strong>-<strong>Mizer</strong> sawmillwith hydraulic log h<strong>and</strong>lingHydraulic PumpThe manual hydraulicpump allows a singleoperator to loadlogs onto the bed.Loading Arms<strong>Wood</strong>-<strong>Mizer</strong> sawmillwith super hydraulic log h<strong>and</strong>ling24

Hydraulic Log H<strong>and</strong>lingCentral Log ClampSpecial two-planeclamping systemsimplifies sawingof stressed logs. Cuts asclose as 2.5 cm fromthe bed are possible.Log TurnerTurning a log or cantfor the next cut is easy.Just move a lever onthe control box.Super Hydraulic Log H<strong>and</strong>lingThe Super Hydraulic Log H<strong>and</strong>lingis available for the LT40 <strong>and</strong> LT70 „M” bed.All features from the Hydraulic Log H<strong>and</strong>lingPLUS:Chain TurnerTurns logs quickly<strong>and</strong> effortlessly ineither direction.Roller ToeboardsExtra-wide rollertoeboardscompensate forlog taper <strong>and</strong> alloweasy log positioning.Power RollerEasily enables youto position the log onthe bedrails.Also can assistin removing sawn cants.Hold Down ClampsInvaluable when cuttinglogs which havecompression ortension wood.Vertical Side SupportsPerfect referencepoints for accurate,square cuts.Loading ArmsLogs can be loadedin seconds with thethrow of a lever. Eacharm features a self-leveling,heavy-duty cylinder.25

REMOTE <strong>SAWMILLS</strong>Performance SpecificationsLT40 RemoteLT70 RemoteMax. Log Capacity90 cm dia.95 cm dia.Throat capacityup to 72 cm wideup to 73 cm wideLength of bedS bed: 5 mM bed: 6.3 mS bed: 4.8 mM bed: 6.1 mLog H<strong>and</strong>lingHydraulicSuper Hydraaulic (M bed only)HydraulicSuper Hydraulic (M bed only)Head DrivePower Feed & Up/DownPower Feed & Up/DownPower Options18.5 kW Electric18.5 kW ElectricSt<strong>and</strong>ard Features• Electric Blade Guide Arm• Roller, Single Block Blade Guides• SW Setworks• Remote Operator Station• Electric Blade Guide Arm• Roller, Double Block Blade Guides• PLC Setworks or Accuset• Remote Operator Station• Lube<strong>Mizer</strong>Typical Options• Super Hydraulic Package for M beds• Debarker• PLC Setworks• Accuset• Hold Down Clamps• Lube<strong>Mizer</strong>• Material H<strong>and</strong>ling• Super Hydraulic Package for M beds• Debarker• Hold Down Clamps• Material H<strong>and</strong>ling26

Remote sawmills

LT40/70 RemoteStationary sawmilling for the professional user<strong>SAWMILLS</strong>The LT40/LT70 Remote combines the proven productioncapabilities of the popular <strong>and</strong> successful LT40/LT70 witha remote control operator st<strong>and</strong> <strong>and</strong> system of conveyors<strong>and</strong> tables for material h<strong>and</strong>ling.The remote operator control st<strong>and</strong> enables the operator to sitehimself in the optimum sawing position. From this remote station,the operator can easily control all aspects of the mill, from logh<strong>and</strong>ling, to determining board thickness <strong>and</strong> controlling thecutting <strong>and</strong> return movement of the head.Transfer Deck(for more details, please see page 33)Incline Conveyor(for more details, please see page 32)Edger MultiRip(for more details, please see page 36)Log Deck(for more details, please see page 32)Equipment28PLC Setworks(st<strong>and</strong>ard on LT70 Remote)(for more details,please see page 42)SW Setworks(st<strong>and</strong>ard on LT40 Remote)(for more details,please see page 42)Lube<strong>Mizer</strong>(st<strong>and</strong>ard on LT70 Remote,LT40 Remote optional)(for more details,please see page 44)Debarker (optional)(for more details,please see page 43)

The addition of an optional log deck, inclined conveyor for boardremoval <strong>and</strong> transfer table or the use of the st<strong>and</strong>ard (3 m)modular tables make the LT40/LT70 Remote easy to integrateinto any new or existing installation.The LT40/LT70 Remote is the most productive mill in the“orange” range of <strong>Wood</strong>-<strong>Mizer</strong> products. In terms of the overallmethod of operation, the LT40/LT70 Remote is similar to theindustrial WM3000 but for the lower volume user the reducedinitial cost of the LT40/LT70 Remote means that the marginreturned per sawn cubic meter is similar.LT70 Remote with modular tables<strong>and</strong> log deck <strong>and</strong> optional Edger• Roller, Double Block BladeGuides: Accurate cutting withincreased blade stability(only with LT70 Remote).• Roller, Single Block BladeGuides: Combine maximum bladestability with minimalmaintenance(only with LT40 Remote).• Hinged blade wheel covers:Facilitate quick bladechanges <strong>and</strong> are easy to close<strong>and</strong> fasten.• Idler pulley clutch system: Easyaccess to drive belt for routinemaintenance.• Air bag blade tensioning:Improved blade tensionconsistency in all cuttingconditions.• Large throat capacity:Allows for cuts up to73 cm wide (LT70 Remote) <strong>and</strong>72 cm wide (LT40 Remote).Plenty of space for cutting bigdiameter logs.29

The Super Hydraulic Log H<strong>and</strong>ling for the LT40/70 RemoteProductivity in any sawmill depends to a large extent on the time needed to manipulatethe log <strong>and</strong> h<strong>and</strong>le the sawn material, as opposed to the actual sawing time.In designing the LT40/LT70 Remote the emphasis was placed primarily on reducing the timespent on log h<strong>and</strong>ling <strong>and</strong> dealing with the sawn material. Additionally, the new versionis equipped with an operator console, enabling the user place the console in the optimumposition for their application.LT70 Remote with the Roller System of Outfeed Tables30

Super Hydraulic Log H<strong>and</strong>lingChain TurnerTurns logs quickly<strong>and</strong> effortlessly ineither direction.Power RollerEasily enables youto position the log onthe bedrails.Also can assistin removing sawn cants.Vertical Side SupportsPerfect referencepoints for accurate,square cuts.Hold Down ClampsInvaluable when cuttinglogs which havecompression ortension wood.Central ClampSpecial two-planeclamping systemsimplifies sawingof stressed logs. Cuts asclose as 2.5 cm from thebed are possible.Roller Toe BoardAllows taper settingof logs for gradesawing, boxedhearts, <strong>and</strong> more.Remote Operator St<strong>and</strong>The operator consoleis fitted with everythingneeded to controlthe sawing head,full hydraulic controlsfor log h<strong>and</strong>ling,<strong>and</strong> setworksfor automaticdimensioning.31

Material H<strong>and</strong>lingfor the LT40/70 RemoteLog DeckThe log deck is an essential part of the LT40 Remote <strong>and</strong> LT70 Remote. Controlled from the operators st<strong>and</strong>, it allowsthe operator to easily load logs onto the mill. The Log Deck is available in two st<strong>and</strong>ard lengths (3.6 m <strong>and</strong> 6 m).Driven by 4.5 kW electric motor <strong>and</strong> the loader ensures that only a single log is loaded during one cycle.The entry angle is steep enough to load low grade, knotty logs, but shallow enough to smoothly load any log.The hydraulicstop <strong>and</strong> loader ispowerful <strong>and</strong> fastIncline ConveyorThe inclined conveyor is designed to work in combination with the integral board removal system on the LT40 Remote <strong>and</strong> LT70 Remote.Originally designed to fit with our industrial WM3000, the Inclined Conveyor has been adopted to mate with the LT40 Remote <strong>and</strong> LT70 Remote<strong>and</strong> quickly transport sawn material onto the Transfer Deck or the Roller System Outfeed Tables.The Incline Conveyor works inconjunction with the Transfer Deckor the Three Way Conveyor32

Transfer DeckThe Transfer Deck helps to h<strong>and</strong>le sawn material transferred by the Inclined Conveyor. After the material movesonto the Transfer Deck, the operator can move the cut piece to a stop location or remove it as a waste slabor for further processing.Roller System of Outfeed TablesThe Roller System of Outfeed Tables is a manual solution based on manual tables, <strong>and</strong> can be a cost effectivealternative to the incline conveyor <strong>and</strong> Transfer Deck options.33

SECONDARY PROCESSINGPerformance SpecificationsEdger EG300Minimum Board Length700 mmMaximum Board Thickness60 mmMaximum Edging Width420 mmMaximum Board Width550 mmMinimum Cutting Width for the board– MultiRip (up to 5 blades)– Edger20 mm60 mmPower Options15 kW Electric18.5 kW ElectricFeed Speed0-25 m/minBlade Size350/76/18St<strong>and</strong>ard Features• 2 circular blades• SW Setworks• In-feed <strong>and</strong> out-feed tables• Adjustable speed• Powered alignment of the edging width• Adjustable side fenceTypical Options• MultiRip (up to 5 blades)• Lasers34

SECONDARY PROCESSING

EDGER EG300SECONDARY PROCESSINGEdger MultiRip –available in orange(on request).3615 kW Electric engine(18.5 kW optional)Top rollersFacilitates the returnof boards that requirea second pass.Powered alignment ofthe edging widthSW SetworksIncreases productivity<strong>and</strong> accuracy using ruggedelectronics to quickly positionthe adjustable blade to presetsizes.

ACCESSORIESmillsSegmented Bed SawmillsClassic Bed SawmillsRemote SawmillsLT10LT15LT20BLT20LT40LT70LT40RLT70RSW SetworksAccusetPLC Setworks٧٧٧٧٧٧٧٧٧AutoClutch٧٧DebarkerAC٧AC/DC٧AC/DC٧AC/DC٧AC/DC٧AC٧AC٧Remote OperatorStation٧ ٧ ٧Wireless Remote(selected models)٧ ٧ ٧ ٧Lube<strong>Mizer</strong>٧٧٧٧Bed Extensions1.8 m3.6 m7.2 m٧٧٧٧٧٧٧٧٧Bed Sections1.95 m2.00 m2.70 m٧٧٧٧Loading Ramps٧٧٧٧٧٧40

accesSories

Debarker – LT40 & LT70 sawmillsSay good-bye to the days of power-washingyour logs. A <strong>Wood</strong>-<strong>Mizer</strong> debarker cleans upthe log before each cut, preventing yourblades from hitting mud, rocks, or thick bark.The debarker’s 0.75 kW motor will help youkeep your blades in great shape betweensharpenings <strong>and</strong> extend overall blade life.And the less time you spend changing yourblades, the more time you’ll spend sawing.Debarker – LT15 & LT20 sawmillsEvery LT15 (AC models) <strong>and</strong> LT20 sawmillcomes prewired <strong>and</strong> ready to fit the optionaldebarker, which extends blade life bypre-cleaning the log.Remote Operator St<strong>and</strong>The operator console is fitted with everythingneeded to control the sawing head,full hydraulic controls for log h<strong>and</strong>ling,<strong>and</strong> setworks for automatic dimensioning.Only available for LT40 <strong>and</strong> LT70 M beds.Cant HookYou may not be able to move the world, but if you want to move logs – you’ll definitelyneed cant hooks. These traditional logger’s tools are used to roll, lift, move, <strong>and</strong> pivotlogs. Until you’ve tried them, you won’t believe how much leverage they can provide.Our cant hook is made from special hardened steel <strong>and</strong> feature 1.2 m hickory h<strong>and</strong>les.You’ll need two for basic log h<strong>and</strong>ling.43

ACCESSORIESWireless RemoteThe NEW <strong>Wood</strong>-<strong>Mizer</strong> Wireless Remote conveniently operates threeof the company's thin-kerf sawmills. The LT20, 40 & 70 are now availablewith the optional Wireless Remote on new mills only. With this unit,sawyers operate the up/down, forward/reverse, blade guide arm,debarker, <strong>and</strong> autoclutch head controls from any practical viewingdistance around the mill; ensuring the best view of the work area.The remote is designed to be worn either around the waist or with thest<strong>and</strong>ard break-a-way shoulder strap; placing the joystick <strong>and</strong> togglecontrols at the user's fingertips. It has rechargeable batteries, protectedin a weatherproof box, <strong>and</strong> features armored & robust technology thatprevents interference from "frequency hopping." <strong>Wood</strong>-<strong>Mizer</strong>'s newWireless Remote offers the operator Dual Controls: the flexibility<strong>and</strong> versatility to use the st<strong>and</strong>ard controls <strong>and</strong> walk with the millor switch to the wireless control unit for improved visibility <strong>and</strong> thefreedom to operate from any position around the mill.Ask your representative for more information <strong>and</strong> list of models available with the Wireless Remote.Lube<strong>Mizer</strong> High Performance Sawing SystemThe Lube<strong>Mizer</strong> system helps melt away sap with ease. It featuresan adjustable electronic flow controller <strong>and</strong> pump that applies a speciallubricating solution to both sides of the blade. Lube<strong>Mizer</strong> additive canbe used in small amounts for a little sap <strong>and</strong> used in the continuousmode to tackle blades with encrusted sap.(Currently, the Lube<strong>Mizer</strong> High Performance Sawing Systemis available as an option on new <strong>Wood</strong>-<strong>Mizer</strong> mills, <strong>and</strong> as a retrofit kitfor our non-remote, 12-volt mills built after April 1997).Lube<strong>Mizer</strong> AdditiveThis pre-mix solution is pouredinto the water bottle <strong>and</strong> intensifiesblade cleaning.No measuring required.Loading RampsProvides easy loading of logs when used with the optional manual winch.LT10LT20 <strong>and</strong> LT20B44

Bed ExtensionsMost <strong>Wood</strong>-<strong>Mizer</strong> portable sawmills can h<strong>and</strong>le just about any log length imaginable.• Professional Bed Extensions (LT20, LT40, LT70):You can add 1.8 m or 3.6 m or 7.2 m extensions to the existingbed, <strong>and</strong> tackle super-long logs with ease.1.8 m Extensions3.6 m Extensions7.2 m Extensions(Not available on the LT10, LT15 <strong>and</strong> LT20B.)TOP VIEW1.8 m or 3.6 m or 7.2 mSAWMILLBED EXTENSION• Segmented Bed Extensions (LT10, LT15, LT20B):Increases cutting length by 1.95 m each.No practical limit to maximum length.Bed Section: 1.95 m (LT10 only)Bed Section: 1.95 m or 2.7 mNo practical limit to maximum length.Bed Section: 1.95 m or 2.7 m (LT15 only)Increases cutting length by 2.00 m each.No practical limit to maximum length.Bed Section: 2.00 m (LT20B only)45

BLADE PARAMETERSmillsHOW TO READ THE BLADE PART NUMBERBLADE PARAMETERSB S 2 7 5 IH741030 -401 -F10How sold:B = BOX OF BLADESHow read:S = STELLITE BLADESThickness:1 = 1.00 mm2 = 1.07 mm3 = 1.14 mm4 = 1.40 mm5 = 1.27 mmTooth spacing:5 = 12,7 mm7 = 7/8” = 22.2 mmWidth:20 = 20 mm5 = 32 mm35 = 35 mm6 = 38 mm7 = 45 mm8 = 50 mm75 = 75 mmDetails:IH = INDUCTION HARDENED TEETH (DoubleHard)74 = TYPE OF MATERIAL (Silver Tip)432 = BLADE PROFILE 4°/32°929 = BLADE PROFILE 9°/29°1030 = BLADE PROFILE 10°/30°1329 = BLADE PROFILE 13°/29°734 = BLADE PROFILE 7°/34°Length:LENGTH IN CENTIMETERSType of box <strong>and</strong> quality of blades:(not used for S = single blade)F = FLAT BOXS = SQUARE BOX8 = 8 PCS PER BOX10 = 10 PCS PER BOX15 = 15 PCS PER BOX20 = 20 PCS PER BOX30 = 30 PCS PER BOXhts– Hook Angle– Back Angle– Tooth Height (Depth of Gullet)– Tooth spacing– Thickness of bladeWe are offering five tooth profiles:TOOTH PROFILES• 4/32 this profile is for very hard or frozen wood• 9/29 this profile is for hard or frozen wood• 10/30 the most popular profile for cuttingsoftwoods or easy-to-saw hardwoods• 13/29 this profile is recommended for softwoods• 7/34 this profile is recommended for hardwood;works best with engines over 15 kW46

lades & ACCESORIES

BladesA History of QualityBLADESSoon after <strong>Wood</strong>-<strong>Mizer</strong> had pioneered the portable sawmill business, it became evident that improvements were needed in the quality <strong>and</strong>performance of blades. After having limited success with other manufacturers, we decided to make our own.Today, <strong>Wood</strong>-<strong>Mizer</strong> is still the only sawmill manufacturer that produces its own blades. We have an entire team of blade researchers who rigorouslytest the steel used in our blades. We use the best equipment available to manufacture the blades, including our very own CBN grinder, <strong>and</strong>sophisticated computerized setter. Our technology brings greater accuracy <strong>and</strong> longer life to every blade that leaves <strong>Wood</strong>-<strong>Mizer</strong>.We offer blades in a wide variety of lengths <strong>and</strong> profiles, but we’ll customize blades for customers who want something not found on our list.<strong>Wood</strong>-<strong>Mizer</strong> blades come in three distinct br<strong>and</strong>s: RazorTip, DoubleHard <strong>and</strong> SilverTip.All <strong>Wood</strong>-<strong>Mizer</strong> blades are produced internally <strong>and</strong> are subject to rigorous Quality Control processes. Each tooth is individually measured <strong>and</strong> setby computer-controlled equipment during the manufacturing process. We supply a wide range of lengths <strong>and</strong> profiles suited to the most commonapplications <strong>and</strong> to more specialised cutting needs. Custom lengths are also available upon request.48

STELLITE ® BANDSAW BLADESOne word that sums up the new <strong>Wood</strong>-<strong>Mizer</strong> RazorTip blade is TOUGH. When you need a bladewith excellent wear power <strong>and</strong> multiple resharpenings, this blade sets the st<strong>and</strong>ard. When otherblades dull with only a few cuts, the RazorTip tipped blade is just getting started. When you needa blade for tough, abrasive woods, <strong>Wood</strong>-<strong>Mizer</strong>'s new blade meets the challenge.TOUGHHIGH TECHQUALITYRESHARPEN– Stays sharp when cutting abrasive, kiln-dried, tropical, specialty,<strong>and</strong> other tough wood <strong>and</strong> beams– Stellite ® tipped technology that keeps an edge long after other blades dull– Each tooth is set <strong>and</strong> profile ground to exact specifications thatensure long life <strong>and</strong> quality cut– Easy to resharpen with conventional sharpening equipmentor <strong>Wood</strong>-<strong>Mizer</strong>'s Resharp service.INDUSTRIAL BANDSAW BLADESThere's a reason these are called „DoubleHard” blades.DoubleHard blades have up to twice the sharp life of most st<strong>and</strong>ard blades.<strong>Wood</strong>-<strong>Mizer</strong> DoubleHard blades are tough, non-brittle, <strong>and</strong> won't chip or wear down prematurely.DoubleHard blades offer unmatched cutting flexibility, whether you want to cut frozen orkiln-dried timber, softwoods, hardwoods or knotty woods. DoubleHard Blades have "IH"in the part number.Raw material ProfileThickness / Width(mm)BS275 10/30 1.07 x 32BS376 7/34 1.14 x 38BS376 10/30 1.14 x 38Raw materialB475IHB476IHB476IHB476IHB476IHB576IHB576IHProfileB275IH 10/30B2735IHB278IHB375IHB375IHB376IHB376IHB376IHB376IH10/3010/30Thickness / Width(mm)1.07 x 321.07 x 351.07 x 5010/30 1.14 x 329/29 1.14 x 3213/29 1.14 x 3810/30 1.14 x 384/321.14 x 387/341.14 x 3810/30 1.40 x 3213/29 1.40 x 3810/30 1.40 x 384/321.40 x 387/341.40 x 3813/29 1.27 x 3810/301.27 x 38BANDSAW BLADESIn recent years <strong>Wood</strong>-<strong>Mizer</strong> has applied their world famous narrow b<strong>and</strong> technology to thesecondary processing market. Our Industrial Horizontal resaws are operating in manycountries throughout the world <strong>and</strong> the addition of the new Professional Single Head Resawrange consolidates our presence in this market place. Resawing applications havedifferent blade requirements than the primary break-down of logs. The cut width is typicallymuch smaller, the timber is clean, <strong>and</strong> ideally the saw should be in the timber the whole shift.The <strong>Wood</strong>-<strong>Mizer</strong> SilverTip b<strong>and</strong>saw blade has been designed specifically for this task.We use a st<strong>and</strong>ard, very flexible base material to give maximum possible flex-life, <strong>and</strong> thenwe apply our unique induction hardening process (as used in our Industrial DoubleHard range)to each tooth. This gives exceptional sharp life to our SilverTip blades. In this way we havecombined excellent sharp life with maximum total flex-life for the secondary processingenvironment. SilverTip Blades have "IH74" in the part number.Raw materialB1520IH74B1735IH74B275IH74B2735IH74B278IH74B2775IH74Profile10/3010/3010/3010/3010/3010/30Thickness / Width(mm)1.00 x 201.00 x 351.07 x 321.07 x 351.07 x 501.07 x 75B2775IH74 13/291.07 x 75B376IH74 10/30 1.14 x 38B376IH74 4/32 1.14 x 38B477IH74 13/29 1.40 x 45B477IH74 10/30 1.40 x 4549

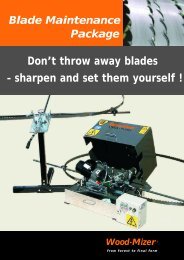

Basic Blade MaintenanceCustomer Blade Maintenance PackageFor customers unable to benefit from a Re-Sharp Service, we have designed a Blade Maintenance Package that will allow you to reconditionyour own blades. Ours is not the cheapest solution available – but rest assured, it is made to our exacting st<strong>and</strong>ards, fully documented <strong>and</strong> certifiedfor use in your country. When used properly, our blade maintenance system will give you “near” factory results. Our sharpening <strong>and</strong> settingequipment has been carefully designed to be the best balance between low cost, excellent results <strong>and</strong> long life under difficult working conditions.BLADESCleaning your bladesCleaning blades is the first <strong>and</strong> most important step to sharpening <strong>and</strong> setting your blades. It is very important to remove any residue fromcutting <strong>and</strong> inspect each blade for possible damage that can lead to premature blade breakage. Don't forget this important step when yourecondition your blades!Sharpener<strong>Wood</strong>-<strong>Mizer</strong> sharpeners feature a 0.18 kW single phaseAC motor with a nominal speed of 2800 rpm.It is an ideal solution for sharpeners wherethe presence of abrasive materials suchas oil <strong>and</strong> metal filings would quickly ruinother motors. The <strong>Wood</strong>-<strong>Mizer</strong> design also facilitatesthe easy insertion <strong>and</strong> removal of the blade. Wheninstalling the blade, the head lifts up <strong>and</strong> out of the wayso the blade can be inserted into the clamp. The electriccontrol box is mounted in such a position to alloweasy access to the controls. Incorporated into the hingedlid is a venting pipe that can be connected to an exhaustsystem to remove any fumes generated duringthe sharpening process. This is especially importantin saw shops where multiple units are being used.CBN wheels<strong>Wood</strong>-<strong>Mizer</strong> supplies specially designed borazon grinding wheels (5”, 127 mm for the basic sharpener)in four profiles which exactly match our factory set profiles.• 10/30 our most popular <strong>and</strong> versatile tooth profile• 9/29 ideal in frozen or especially hard timbers• 13/29 ideal for fresh softwoods such as Pine or Spruce• 4/32 this profile is for very hard or frozen wood• 7/34 this profile is recommended for hardwood;works best with engines over 15 kWSetterOf equal importance is the process of setting teeth.Our screw based setting system is very accurate, easierto use than the old “over-center” lever system <strong>and</strong> is lesstiring for the operator allowing for faster, precise settingof your blades. Our setter comes complete with a floorst<strong>and</strong> <strong>and</strong> arms for holding the blade while setting.The angle of the setter on the st<strong>and</strong> can be adjustedso that it is easy to read the set gage. Accurate <strong>and</strong>repeatable setting from tooth to tooth ensures accurate,straight cutting.50

Advanced PackagesIndustrial sharpenerThe industrial sharpener, from its very beginning,has been designed to suit the requirementsof bigger sawmills. It is also equippedwith a system for the easy installation<strong>and</strong> removal of the blade. As a st<strong>and</strong>ardfeature, the new sharpener hasan electronic tooth counter whichcan be pre-set <strong>and</strong> will thenautomatically turn off the sharpeningprocess after the full cycle.Our industrial sharpener is powered by 0.75 kW(2820 rpm main motor) which runs an 8” (203 mm)CBN wheel with 4280 rpm.All the functions of the Sharpener are controlled fromthe operator panel <strong>and</strong> we have added an inspectionwindow <strong>and</strong> LED lighting to complete the picture.<strong>Wood</strong>-<strong>Mizer</strong>’s tests indicate that the new motor <strong>and</strong> largerdiameter CBN wheel <strong>and</strong> precise feeding system doublesthe speed of sharpening in comparison to its smaller brother.CBN wheels (8") 203 mmCBN wheels 8”, 203 mm for the Industrial sharpener.Available - all profiles:• 10/30 our most popular <strong>and</strong> versatile tooth profile• 9/29 ideal in frozen or especially hard timbers• 13/29 ideal for fresh softwoods such as Pine or Spruce• 4/32 this profile is for very hard or frozen wood• 7/34 this profile is recommended for hardwood;works best with engines over 15 kWAutomatic setterAn industrial, computerized pneumatic setter givesvery high accuracy of the tooth-set <strong>and</strong> ensuresa high level of repeatability. The computer “learns”from the first few teeth exactly how much pressureshould be applied to ensure accurate setting.It also incorporates an electronic control panel givingaccess to all the setting parameters required <strong>and</strong> alsodiagnostics should there be a failure.The Industrial equipment (sharpener <strong>and</strong> setter) is designedfor enterprises where three, five or more narrow b<strong>and</strong> sawmillsoperate as well as for Re-Sharp Service centres whose businessis based on blade maintenance.51