nsmms - Blue 52 Productions, LLC

nsmms - Blue 52 Productions, LLC

nsmms - Blue 52 Productions, LLC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Table of ContentsInside Cover BlankPlease see pages 6 & 7 for locations.Sponsors & Supporters .............................................................2Committees ..............................................................................3Staff ............................................................................................4Symposium Map ......................................................................5Week-At-A-Glance..................................................................6Tutorials & Workshops-At-A-Glance ......................................8Detailed AgendaSunday, 23 June 2013 - CRASTE & NSMMSPre-Registration .................................................................... 10 & 18Monday, 24 June 2013 - CRASTE & NSMMSTutorials & Workshops .......................................................... 10 & 18Small Business Forum ........................................................... 11 & 19Welcome Reception and Exhibit & Poster Kick-off ................ 11 & 19Tuesday, 25 June 2013 - CRASTEJoint Plenary Session ....................................................................11Systems Integration Session .........................................................12Happy Hour in the Exhibit Hall .....................................................13Tuesday, 25 June 2013 - NSMMSJoint Plenary Session ....................................................................19Hypersonics Session ......................................................................20Planetary Orbit & Exploration Session ........................................21Space Materials Experiments, Modeling, &Simulation Session .........................................................................22Happy Hour in the Exhibit Hall .....................................................23Wednesday, 26 June 2013 - CRASTEReducing Cost Increasing Safety Session ..................................13Sub-Orbital Concepts and Capabilities Session .......................14Poster Session and Reception .....................................................15Wednesday, 26 June 2013 - NSMMSHypersonics Session, Cntd. ..........................................................26Planetary Orbit & Exploration Technologies Session, Cntd. ....25Space Materials Experiments, Modeling, & SimulationSession Cntd.. ................................................................................26Space Access and Propulsion Session .......................................27Poster Session and Reception .....................................................28Thursday, 27 June 2013 - CRASTERocket Propulsion Accomplishments & Plans Session ..............15Pico/Nano Launch Session..........................................................16Hypersonic Vehicle & Propulsion Concepts & ThermalManagement Protection Session ..............................................17Grand Prize Give-Away ...............................................................32Thursday, 27 June 2013 - NSMMSMissiles & Missile Defense Session ................................................28Innovations in Materials Session ..................................................30Space Access & Propulsion Session, Cntd. ...............................32Grand Prize Give-Away ...............................................................32Friday, 28 June 2013 - CRASTE & NSMMSFuture of Flight Boeing Tour ................................................ 17 & 32Poster Session .........................................................................36Exhibit Map .............................................................................39Exhibitors .................................................................................39Notes ........................................................................................481Please see pages 6 & 7 for locations.

Sponsors & SupportersIndustry SponsorsAerojet RocketdyneATKThe Boeing CompanyNASA Tech BriefsPlasma Processes, <strong>LLC</strong>Scot Forge CompanySouthern Research InstituteUltramet CorporationSupportersAerospace CorporationAir Force Research LaboratoryAir Force Office of Scientific ResearchArmy Aviation & Missile Research Development & Engineering CenterArmy Space & Missile Defense CommandArnold Engineering Development CenterBall Aerospace and Technologies CorporationDefense Advanced Research Projects AgencyLockheed Martin Space SystemsMaterials Research & DesignMissile Defense AgencyNASA Ames Research CenterNASA HeadquartersNASA Johnson Space CenterNASA Langley Research CenterNASA Marshall Space Flight CenterNaval Surface Warfare Center Carderock DivisionNorthrop Grumman Aerospace SystemsOak Ridge National LaboratoryRice UniversitySouthern Research InstituteUSEC, Inc.Planning & Steering CommitteesCRASTE Steering CommitteeMr. Nicholas Demidovich, FAAMr. Robert Johnson, NASA KSCMr. Steve Nunez, NASA JSCMr. Dan Rasky, NASA ARCMr. Bruce Thieman, AFRLMr. Tom Engler, NASA KSCMr. Tom Jacobs, AFRLNSMMS Conference AdvisorsMr. Eric Becker, AFRLMr. Dave Brewer, GDITDr. Doug Deason, MDAMr. Shane Juhl, AFRLDr. Gerald Russell, Army RDECOMDr. Monica Stucke, AFRLDr. Andy Swanson, AFRLDr. Eric Wuchina, NSWCNSMMS Steering CommitteeGovernmentDr. Anthony Calomino, NASA GRCDr. Charles Camarda, NASA HQMr. Derek Doyle, AFRLDr. Brian Holloway, DARPAMr. Michael Huggins, AFRLDr. Sylvia Johnson, NASA ARCMs. Fabiola Martinez, Army SMDCMr. Curtis Martin, NSWCCDDr. John Rivard, ORNLMr. Wesley Sanderson, MDADr. John Schmisseur, AFOSRMr. Mark Smith, AEDCMr. John Vasquez, NRLMr. John Vickers, NASA MSFCMr. Richard Wegrich, NASA MSFCIndustry & UniversityDr. Jack Agee, Rice UniversityMr. Jerry Brockmeyer, UltrametMr. Alan Brown, Aerojet RocketdynePlease see pages 6 & 7 for locations.2 3Please see pages 6 & 7 for locations.

Steering Committee & StaffSymposium MapMr. Charles Frohlich, The Boeing CompanyMr. Mike Fuller, ATK Launch SystemsMr. Andrew Haaland, ATK Launch SystemsMr. Brian Hill, Northrop GrummanMs. Beth Kelsic, Ball Aerospace & Technologies Corp.Mr. John Koenig, Southern Research InstituteDr. Russell Lipeles, The Aerospace CorporationMr. Paul Marchol, AerojetMr. Tim McKechnie, Plasma Processes, <strong>LLC</strong>Mr. Ronald Ooten, USEC, Inc.Mr. Mitch Petervary, The Boeing CompanyDr. Suraj Rawal, Lockheed Martin Space SystemsMr. Pat Sisson, General Dynamics Information TechnologyDr. Brian Sullivan, Materials Research & DesignDr. Dianne Wiley, Independent ConsultantMs. Michelle Williams, <strong>Blue</strong><strong>52</strong> <strong>Productions</strong>, <strong>LLC</strong>Hyatt Regency BellevueBehind the Scenes & On-site StaffEvent CoordinatorMs. Michelle Williams, <strong>Blue</strong> <strong>52</strong> <strong>Productions</strong>On-site StaffMs. Elise Kirk, The Boeing CompanyRegistrarMs. Sherry Johnson, <strong>Blue</strong> <strong>52</strong> <strong>Productions</strong>Sponsorships & AdvertisingMs. Amy Voisard, <strong>Blue</strong> <strong>52</strong> <strong>Productions</strong>Webmaster & GraphicsMs. Susie Sanford, Insert Name Here, <strong>LLC</strong>04 10Registration: Birch Foyer (Sunday & Monday), GrandBallroom Foyer (Tuesday - Thursday)Exhibits & Posters: Evergreen BallroomTutorials, Workshops, and Small Business Forum: Cedar &Regency BallroomsTechnical Sessions: Grand BallroomSpeaker Breakfast: Regency G (Monday), Grand Ballroom K(Tuesday - Thursday)Please see pages 6 & 7 for locations.4 5Please see pages 6 & 7 for locations.

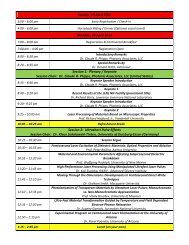

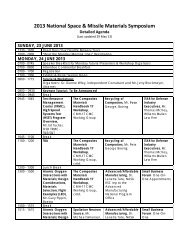

Week-At-A-GlanceWeek-At-A-GlanceSundayMondayNSMMS&CRASTEWednesdayNSMMSWednesdayCRASTERegencyAC CedarB CedarA RegencyEGGrandBallroomBC GrandBallroomE GrandBallroomF GrandBallroomIJTutorials&WorkshopsTutorials&WorkshopsTutorials&WorkshopsTutorials&WorkshopsHypersonicsPlanetaryOrbit&ExplorationTechnologiesSpaceMaterialsExperiments,Modeling,&SimulationReducingCost,IncreasingSafetySUNDAY/MONDAYPreRegistration&RoadDog'sTour(LocalBreweryTour)Tutorials&WorkshopsTutorials&WorkshopsTutorials&WorkshopsBreak(RegencyFoyer)Tutorials&WorkshopsTutorials&WorkshopsTutorials&WorkshopsTutorials&WorkshopsLunchBreak(OnYourOwn)Tutorials&WorkshopsBreak(RegencyFoyer)Tutorials&WorkshopsTutorials&WorkshopsSmallBusinessForumSmallBusinessForumWEDNESDAYHypersonicsHypersonicsHypersonicsBreak(GrandFoyer)PlanetaryOrbit&ExplorationTechnologiesSpaceAccess&PropulsionLunchBreak(OnYourOwn)PlanetaryOrbit&ExplorationTechnologiesPlanetaryOrbit&ExplorationTechnologiesSpaceAccess&PropulsionBreak(EvergreenBallroom)SpaceAccess&PropulsionReducingCost,IncreasingSafetySubOrbitalConceptsandCapabilitiesSubOrbitalConceptsandCapabilitiesWelcomeReceptioninEhibitHallPosterSession&ReceptioninExhibitHallTuesdayNSMMSGrandBallroomACTuesdayCRASTEThursdayNSMMSThursdayCRASTEFridayGrandBallroomBC GrandBallroomE GrandBallroomF GrandBallroomIJTUESDAYGrandBallroomAC GrandBallroomE GrandBallroomF GrandBallroomIJHypersonicsHypersonicsLunchBreak(OnYourOwn)PlanetaryOrbit&ExplorationTechnologiesPlanetaryOrbit&ExplorationTechnologiesPlenarySessionBreak(GrandFoyer)PlenarySessionSpaceMaterialsExperiments,Modeling,&SimulationBreak(EvergreenBallroom)SpaceMaterialsExperiments,Modeling,&SimulationSystemsIntegrationSystemsIntegrationTHURSDAY/FRIDAYMissiles&MissileDefenseMissiles&MissileDefenseMissiles&MissileDefenseMissiles&MissileDefenseInnovationsinMaterialsInnovationsinMaterialsInnovationsinMaterialsInnovationsinMaterialsSpaceAccess&PropulsionBreak(GrandFoyer)Pico/NanoLaunchLunchBreak(OnYourOwn)Break&GrandPrizeGiveaway(GrandFoyer)RocketPropulsionAccomplishments&PlansRocketPropulsionAccomplishments&PlansHypersonicVehicle&PropulsionConcepts&ThermalManagement/ProtectionHypersonicVehicle&PropulsionConcepts&ThermalManagement/ProtectionFutureofFlightBoeingEverettTourHappyHourinExhibitHallPlease see pages 6 & 7 for locations.6 7Please see pages 6 & 7 for locations.

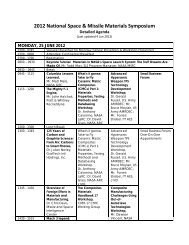

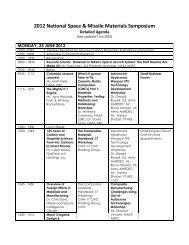

CRASTE & NSMMSTUTORIALS & WORKSHOPSMonday, 24 June 20130800 - 09300930 - 0945(Regency A-C)Keynote: Accelerated ManufacturingDr. Leo Christodoulou,Director, Structures and Materials, The Boeing CompanyBREAK (Regency Foyer)TRACK 1 TRACK 2TRACK 3TRACK 4(Regency A-C)(Cedar B)(Cedar A)(Regency E-F)0945 - 1045FAA LicensingTest ResourceManagement Center(TRMC), High SpeedSystems Test (HSST)Program OverviewRecycling of CompositesITAR for DefenseIndustry Executives1045 - 1100BREAK (Regency Foyer)BREAK (Regency Foyer)1100 - 1200High Heat Flux Testing - HotStuff: Design, Modeling an dTesting with Loads That Varyin Space and Time and HeatTransfer with Gas, PorousMedia and Two-phased FlowThe CompositesMaterialsHandbook 17WorkshopRecycling ofComposites,cntd.ITAR for Defense IndustryExecutives, cntd.1200 - 1300LUNCH BREAK (On Your Own)LUNCH BREAK (On Your Own)1300 - 1500Atomic Oxygen Interactionswith Materials; DesignConsiderations, MaterialsSelection, Flight Examples(LEO)The CompositesMaterialsHandbook 17Workshop, cntd.Advanced/AffordableManufacturingWorkshopSmall BusinessForum One-On-OneAppointments1500 - 1515BREAK (Regency Foyer)BREAK (Regency Foyer)1515 - 16151615 - 1715Atomic OxygenInteractions withMaterials; DesignConsiderations,Materials Selection,Flight Examples(LEO), cntd.Spallation NeutronSourceMaterialCharacterization– A BroadBrush View ofConsiderationsAdvanced/AffordableManufacturingWorkshopSmall BusinessForum One-On-OneAppointments, cntd.1715 - 1900Welcome Reception and Exhibit & Poster Kick-offSponsored by The Boeing Company(Evergreen Ballroom)Please see pages 6 & 7 for locations.8 9Please see pages 6 & 7 for locations.

CRASTESUNDAY, 23 JUNE 20131330 - 1630 Road Dogs Tour (Seattle Brewery Tour)1600 - 2000 RegistrationMONDAY, 24 JUNE 20130700 - 0745 Speaker Breakfast for Monday’s TutorialPresenters & Workshop Organizers0700 - 0800 Attendee Continental Breakfast0700 - 1700 Registration1715 - 1900 Exhibits & Poster Session OpenPlease see pages 6 & 7 for locations.JOINT CRASTE & NSMMSTUTORIALS & WORKSHOPS0800 - 0930 Keynote: Accelerated ManufacturingDr. Leo Christodoulou, Director, Structures andMaterials, Enterprise Technology Strategy,The Boeing Company0930 - 0945 Break0945 - 1045 FAA LicensingMr. Phil Brinkman, FAA0945 - 1045 Test Resource Management Center (TRMC),High Speed Systems Test (HSST) ProgramOverviewEd Tucker, OSD TRMC-T&E/S&T0945 - 1200 Recycling of Composites WorkshopMr. Pete George, The Boeing Company0945 - 1200 ITAR for Defense Industry ExecutivesMr. Thomas McVey, Williams Mullen Law Firm1045 - 1100 Break1100 - 1200 High Heat Flux Testing - Hot Stuff: Design,Modeling and Testing with Loads That Vary inSpace and Time and Heat Transfer with Gas,Porous Media and Two-phased FlowDr. Richard Nygren & Dr. Dennis Youchison,Sandia National Laboratory1100 - 1200 The Composites Materials Handbook 17(CMH-17), CMH-17 CMC Working GroupCRASTE1200 - 1300 Lunch Break (On Your Own)1300 - 1500 The Composites Materials Handbook 17(CMH-17), cntd.CMH-17 CMC Working Group1300 - 1715 Atomic Oxygen Interactions with Materials;Design Considerations, Materials Selection,Flight Examples (LEO)Mr. Gary Pippin, Independent Consultant1300 - 1715 Advanced/Affordable Manufacturing WorkshopDr. Lanetra Tate, NASA KSC rep to theAdvanced Manufacturing National ProgramOffice1300 - 1715 Small Business Forum - One-on-OneAppointments1500 - 1515 Break1515 - 1615 Spallation Neutron SourceMichael Simonson, Oak Ridge NationalLaboratory1615 - 1715 Material Characterization – A Broad Brush Viewof ConsiderationsMr. Samuel Causey, Southern Research Institute1715 - 1900 Welcome Reception and Exhibit & PosterKick-off (Sponsored by ATK)TUESDAY, 25 JUNE 20130700 - 0745 Speaker Breakfast for Tuesday’s Presenters0700 - 0800 Attendee Continental Breakfast(Sponsored by Aerojet Rocketdyne)0700 - 1700 Registration1330 - 1830 Exhibits & Poster Session OpenJOINT CRASTE & NSMMSPLENARY SESSIONSession Chairs: Dr. Doug Deason, MDA &Mr. Robert Johnson, NASA KSC0800 - 0815 Opening Remarks & National AnthemPlease see pages 6 & 7 for locations.10 11

CRASTECRASTE0815 - 0830 WelcomeDr. Doug Deason, Missile Defense Agency &Dr. Robert Johnson, NASA JSC0830 - 0930 Recycling of Composites and Other MaterialChallengesDr. Dianne Chong, The Boeing Company0930 - 1000 Break1000 - 1100 X-51Mr. Joe Vogel, The Boeing Company1100 - 1200 The Trillion Dollar Space Industry,Mr. Andrew Nelson, XCOR Aerospace1200 - 1330 Lunch Break (On Your Own)SYSTEMS INTEGRATION SESSION1330 - 1335 Session Intro1335 - 1400 Enabling Responsive Fabrication of SpacecraftStructures Using Additive ManufacturingTechniquesDr. Robert Hoyt, Tethers Unlimited, Inc.1400 - 1425 Futuristic Triboluminescent Damage SensorsDr. William Hollerman, University of Louisiana atLafayette1425 - 1450 Nanosatellite Clusters Enabled through RadioCommunication Crosslinks with Zero-overheadRelative NavigationMr. Nestor Voronka, Tethers Unlimited, Inc.1450 - 1515 Breaking Barriers to Increased RideshareMissions with the FANTM-RiDE SystemMr. Daniel Lim, TriSept Corporation1515 - 1545 Root Beer Float Break(Sponsored by Plasma Processes)1545 - 1610 Integrated Adaptive Guidance andAutonomous Flight SafetyMr. Dan Salluce, Northrop Grumman AerospaceSystems1610 - 1635 Autonomous Flight Safety SystemDr. George Papadopoulos, ATK Missile Defenseand ControlsPlease see pages 6 & 7 for locations.1635 - 1700 TERRIFC - Design Approach for Small andMedium Lift Reusable VehiclesMr. John Carpenter, Northrop Grumman1700 - 1725 Integrated Ground Operations Demonstrationfor Space AccessMr. Robert Johnson, NASA KSC1725 - 1830 Happy Hour in the Exhibit Hall(Sponsored by Scot Forge)WEDNESDAY, 26 JUNE 20130700 - 0745 Speaker Breakfast for Wednesday’sPresenters(Sponsored by Ultramet)0700 - 0800 Attendee Continental Breakfast(Sponsored by Southern Research Institute)1330 - 1900 Exhibits & Poster Session Open0700 - 1700 RegistrationREDUCING COST, INCREASINGSAFETY SESSION0800 - 0805 Session Intro0805 - 0830 Low Cost Large Scale Composite StructuresMr. Daniel Kletzli, ATK0830 - 0855 Low Cost Access to Near Space TestingMr. Tim Lachenmeier, Near Space Corporation0855 - 0920 Composite Overwrapped Pressure Vessel(COPV) for Space TransportationMr. Daniel Kletzli, ATK0920 - 0945 Hydrogen Properties for Energy Research(HYPER)Dr. Jacob Leachman, Washington StateUniversity0945 - 1015 Break1015 - 1040 Structural Health Monitoring using COTSEquipment during High Altitude StratosphericBalloon FlightDr. Andrei Zagrai, New Mexico Institute ofMining and Technology12 13Please see pages 6 & 7 for locations.

CRASTE1040 - 1105 Life Cycle Cost Assessment for Small GroundLaunch SystemsDr. John Bradford, SpaceWorks1105 - 1130 Rapid Mission Planning and Safety Analysisfor Air Launch Assisted Space AccessMr. Dan Salluce, Northrop Grumman AerospaceSystems1130 - 1155 Composite Cryotank Technology Developmentand Future ApplicabilityMr. Cataldo Mazzola, The Boeing Company1155 - 1300 Lunch Break (On Your Own)SUB-ORBITAL CONCEPTS ANDCAPABILITIES SESSION1300 - 1305 Session Intro1305 - 1330 FAST Airframe & SHM Ground ExperimentProgramMr. Robert Biggs, Lockheed Martin SpaceSystems Co.1330 - 1355 SpaceShipTwo: Revolutionary SuborbitalSpace Transport for Passengers and PayloadsMr. A.C. Charania, Virgin Galactic1355 - 1420 De-Orbit ModuleMr. Ryan VanHalle, MMA Design <strong>LLC</strong>1420 - 1445 Reusable Testbeds: Masten Suborbital VehicleDevelopment UpdateMr. Colin Ake, Masten Space Systems, Inc.1445 - 1510 Break1510 - 1535 Scaling Betavoltaic Technology for SpaceExplorationDr. Christopher Thomas, Widetronix, Inc.1535 - 1600 FAST Integrated Adaptive Guidance & ControlProgramMr. Darryl Busch, Honeywell International1600 - 1625 Government Utility of XCOR’s CommercialManned Reusable Suborbital Vehicles forNanosatellite LaunchMs. Katherine Rodway, XCOR AerospaceCRASTE1625 - 1650 NLV Development and Flight Testing StatusMr. John Garvey, Garvey SpacecraftCorporation1650 - 1900 Poster Session and Reception(Sponsored by The Boeing Company)THURSDAY, 27 JUNE 20130700 - 0745 Speaker Breakfast for Thursday’s Presenters0700 - 0800 Attendee Continental Breakfast0700 - 1530 RegistrationROCKET PROPULSIONACCOMPLISHMENTS & PLANSSESSION0800 - 0805 Session Intro0805 - 0830 Green Propellant Infusion Mission, ProgramConstruct, and Mission ObjectivesDr. Ron Spores, Aerojet0830 - 0855 Low-Energy Electronic Ignition System forNOFBX TM ThrustersDr. Blair Thompson, Firestar Technologies/Odyssey Space Research0855 - 0920 NOFBX Flight Engine Test Results andPerformance AssessmentMr. Greg Mungas, Innovative Space PropulsionSystems (ISPS)0920 - 0945 US Progress and Plans in ADN-based GreenPropellant Technology DevelopmentMr. Stephen Beckel, ATK(Alliant Techsystems)0945 - 1015 BreakPlease see pages 6 & 7 for locations.14 15Please see pages 6 & 7 for locations.

CRASTE-- Begin Two Concurrent CRASTE Sessions --ROCKET PROPULSIONACCOMPLISHMENTS & PLANS SESSION(Track 1)1015 - 1040 Development of Hot-Fire Subscale SLSRockets for Wind Tunnel TestingDr. Aaron Dufrene, CUBRC, Inc.1040 - 1105 Independent Assessment of Nitrous OxideFuel Blend (NOFBX) Monopropellants:Material CompatibilityDr. Brian Brady, The Aerospace Corporation1105 - 1130 Roadmap and Progress to Date of XCOR’s5K18 Propulsion SystemMr. Andrew Nelson, XCOR Aerospace1130 - 1155 ORBITEC’s Vortex Liquid Rocket Engines andTechnologiesMr. Paul Zamprelli, Orbital Technologies Corp.1155 - 1300 Lunch Break (On Your Own)PICO/NANO LAUNCH SESSION (Track 2)1015 - 1040 CubeSat Modular Propulsion SystemsProduct Lin Development Status andMission ApplicationsMr. Christian Carpenter, Aerojet1040 - 1105 Development of a Water-ElectrolysisThruster for the PowerCube, a ModuleOffering Integrated Power, Propulsion andAttitude Control for CubeSatsMr. Nestor Voronka, Tethers Unlimited, Inc.1105 - 1130 Programmable Picosatellite Transceiver forResponsive SpacecraftMr. Nestor Voronka,Tethers Unlimited, Inc.1130 - 1155 High Speed Structures for Space LaunchMr. Bill Beglin, University of Dayton ResearchInstitute1155 - 1300 Lunch Break (On Your Own)-- End Concurrent CRASTE Sessions --HYPERSONIC VEHICLE &PROPULSION CONCEPTS &THERMAL MANAGEMENTPROTECTION SESSIONCRASTE1300 - 1305 Session Intro1305 - 1330 Micro- and Nano-Scale Sensors for ExtremeHarsh EnvironmentsDr. Debbie Senesky, Stanford University1330 - 1355 Carbon-Silicon Carbide Design forAerospace Hot StructuresMr. Matthew Levesque, Fiber Materials, Inc.1355 - 1420 Experimental and Computational Studiesof Lifting Body and Capsule Based ReentryVehicles at Velocities from 1 to 9 km/secMr. Timothy Wadhams, CUBRC AerosciencesGroup1420 - 1445 Advances in Game Changing ThermalProtection System Technologies at NASA:Enabling Future Commercial and NASA’sRobotic and Human ExplorationDr. Margaret Stackpoole, NASA ARC1445 - 1510 Break & Grand Prize Give-away1510 - 1535 Heat Pipe Cooled Leading EdgesDr. Suraj Rawal, Lockheed Martin1535 - 1600 Vertical Air-breathing Launch Technology(VALT) for NanosatellitesMr. Karl Hoose, Applied Thermal Sciences, Inc.1600 - 1610 Grand Prize Give-Away & AdjournFRIDAY, 28 JUNE 20130800 - 1100 Steering Committee Meeting0830 - 1100 Future of Flight Boeing TourPlease see pages 6 & 7 for locations.16 17Please see pages 6 & 7 for locations.

NSMMSNSMMSTuesday, 25 June 2013 Tuesday, 25 June 2013SUNDAY, 23 JUNE 20131330 - 1630 Road Dogs Tour (Seattle Brewery Tour)1600 - 2000 RegistrationMONDAY, 24 JUNE 20130700 - 0745 Speaker Breakfast for Monday’s TutorialPresenters & Workshop Organizers0700 - 0800 Attendee Continental Breakfast0700 - 1700 Registration1715 - 1900 Exhibits & Poster Session OpenJOINT CRASTE & NSMMSTUTORIALS & WORKSHOPS0800 - 0930 Keynote: Accelerated ManufacturingDr. Leo Christodoulou, Director, Structures andMaterials, Enterprise Technology Strategy,The Boeing Company0930 - 0945 Break0945 - 1045 FAA LicensingMr. Phil Brinkman, FAA0945 - 1045 Test Resource Management Center (TRMC),High Speed Systems Test (HSST) ProgramOverviewEd Tucker, OSD TRMC-T&E/S&T0945 - 1200 Recycling of Composites WorkshopMr. Pete George, The Boeing Company0945 - 1200 ITAR for Defense Industry ExecutivesMr. Thomas McVey, Williams Mullen Law Firm1045 - 1100 Break1100 - 1200 High Heat Flux Testing - Hot Stuff: Design,Modeling and Testing with Loads That Vary inSpace and Time and Heat Transfer with Gas,Porous Media and Two-phased FlowDr. Richard Nygren & Dr. Dennis Youchison,Sandia National Laboratory1100 - 1200 The Composites Materials Handbook 17(CMH-17), CMH-17 CMC Working Group1200 - 1300 Lunch Break (On Your Own)1300 - 1500 The Composites Materials Handbook 17(CMH-17), cntd.CMH-17 CMC Working Group1300 - 1715 Atomic Oxygen Interactions with Materials;Design Considerations, Materials Selection,Flight Examples (LEO)Mr. Gary Pippin, Independent Consultant1300 - 1715 Advanced/Affordable Manufacturing WorkshopDr. Lanetra Tate, NASA KSC rep to theAdvanced Manufacturing National ProgramOffice1300 - 1715 Small Business Forum - One-on-OneAppointments1500 - 1515 Break1515 - 1615 Spallation Neutron SourceMichael Simonson, Oak Ridge NationalLaboratory1615 - 1715 Material Characterization – A Broad Brush Viewof ConsiderationsMr. Samuel Causey, Southern Research Institute1715 - 1900 Welcome Reception and Exhibit & PosterKick-off (Sponsored by ATK)TUESDAY, 25 JUNE 20130700 - 0745 Speaker Breakfast for Tuesday’s Presenters0700 - 0800 Attendee Continental Breakfast(Sponsored by Aerojet Rocketdyne)0700 - 1700 Registration1330 - 1830 Exhibits & Poster Session OpenJOINT CRASTE & NSMMSPLENARY SESSIONSession Chairs: Dr. Doug Deason, MDA &Mr. Robert Johnson, NASA KSC0800 - 0815 Opening Remarks & National AnthemPlease see pages 6 & 7 for locations.18 19Please see pages 6 & 7 for locations.

NSMMS0815 - 0830 WelcomeDr. Doug Deason, Missile Defense Agency &Dr. Robert Johnson, NASA JSC0830 - 0930 Recycling of Composites and Other MaterialChallengesDr. Dianne Chong, The Boeing Company0930 - 1000 Break1000 - 1100 X-51Mr. Joe Vogel, The Boeing Company1100 - 1200 The Trillion Dollar Space IndustryMr. Andrew Nelson, XCOR Aerospace1200 - 1330 Lunch Break (On Your Own)- Begin Three Concurrent NSMMS Sessions -HYPERSONICS SESSION (Track 1)Session Chair: Dr. Brian Sullivan, Materials Research & DesignSession Organizers: Mr. Dave Brewer, NASA LaRC;Mr. Andy Swanson, AFRL; Mr. Jim Ledesma, The BoeingCompany; Mr. Mitch Petervary, The Boeing Company1330 - 1335 Session Intro1335 - 1425 X-51Mr. George Thum, Aerojet Rocketdyne1425 - 1450 Hypersonic PropulsionMr. Chris Kogstrom, ATK Inc.1450 - 1515 Development and Analysis of ContinuousSiC Fiber-Reinforced HfB2-SiC Composites forHypersonic Flight ApplicationsDr. Clifford Leslie, AFRL & NRC ResearchAssociateship Program1515 - 1545 Root Beer Float Break(Sponsored by Plasma Processes)1545 - 1635 Overview of National Hypersonic ScienceCenter for Materials and StructuresDr. Dave Marshall, Teledyne1635 - 1700 Data Correlation of Impact Performanceof SiC/SiC MaterialsMr. Edward Klock-McCook, Materials Research& DesignNSMMS1700 - 1725 Ultra High Temperature Mechanical Testing ofZrB2-ZrC Based CeramicsMr. Eric Neuman, Missouri University of Science& Technology1725 - 1830 Happy Hour in the Exhibit Hall(Sponsored by Scot Forge)PLANETARY ORBIT & EXPLORATIONTECHNOLOGIES (Track 2)Session Chair: Dr. Anthony Calomino, NASA LaRCSession Organizers: Mr. Mike Fuller, ATK; Ms. Beth Kelsic, BallAerospace & Technologies Corp.; Dr. Sylvia Johnson, NASA ARC;Dr. Suraj Rawal, Lockheed Martin; Mr. Pat Sisson, GDIT; Mr. EricBecker, AFRL; Mr. Brian Hill, Northrop Grumman; Dr. Jack Agee,Rice University; Mr. John Vickers, NASA MSFC; Mr. Rich Wegrich,NASA MSFC; Dr. Charlie Camarda, NASA HQ1330 - 1335 Session Intro1335 - 1400 Advanced TPS Materials for Hypersonic GlideReentry VehiclesMr. Jean Doucette, Textron Defense Systems1400 - 1425 Thermal Insulation Performance of AerogelComposites for SatellitesDr. Nicholas Zafiropoulos, Aspen Aerogels, Inc.1425 - 1450 4-Meter Primary Reflector Demonstrator for theScanning Microwave Limb SounderMr. Eldon Kasl, Vanguard Space Technologies1450 - 1515 Development of PICA Gap Filler for HeatshieldAssembliesDr. Steven Violette, Fiber Materials Inc., GraftechInternational1515 - 1545 Root Beer Float Break(Sponsored by Plasma Processes)1545 - 1610 The Impact of Thermally Induced PropertyChanges of PICA on Ultrasonic AblationThermometry,Mr. Joseph Lloyd, Industrial MeasurementSystems, Inc.Please see pages 6 & 7 for locations.20 21Please see pages 6 & 7 for locations.

NSMMS1610 - 1635 Woven TPS – Enabling Missions BeyondHeritage Carbon PhenolicDr. Margaret Stackpoole, NASA ARC1635 - 1700 Viability of 3D Woven Carbon Cloth andAdvanced Carbon-Carbon Ribs for use inAdaptive Deployable Entry PlacementTechnology for Future NASA MissionsMr. Brandon Smith, NASA ARC1700 - 1725 Char Depth Measurements of Arc JetSamples for Comparison with HollowaErothermal Ablation and Temperature(HEAT) Sensor Data in Support of MEDLIDr. Erika Rodriguez, ERC, Inc./NASA ARC1725 - 1830 Happy Hour in the Exhibit Hall(Sponsored by Scot Forge)SPACE MATERIALS EXPERIMENTS,MODELING, & SIMULATION (Track 3)Session Chair: Dr. Alan Stewart, The Boeing CompanySession Organizers: Mr. Shane Juhl, AFRL; Mr. Chip Frohlich,The Boeing Company; Mr. John Vasquez, Naval ResearchLaboratory; and Mr. Derek Doyle, AFRL1330 - 1335 Session Intro1335 - 1400 MISSE-X - Status, Needs, and Path ForwardDr. Sheila Thibeault, NASA LaRC1400 - 1425 Design of Thermo-Structural Test for In-PlaneCompression Fracture under High ThermalGradientsMr. Hans Jensen, Materials Research & Design1425 - 1450 Further Analysis of Materials Exposed onMISSE-7BMr. Michael Kravchenko, The Boeing Company1450 - 1515 Adhesion Forces of Silicone Elastomer SealsPretreated with Atomic OxygenDr. Heather Oravec, The University of Akron1515 - 1545 Root Beer Float Break(Sponsored by Plasma Processes)NSMMS1545 - 1610 Use of Molecular Dynamics Simulations toModel Materials Damage Due to HyperthermalAtomic OxygenDr. Vanessa Oklejas, The Aerospace Corporation1610 - 1635 An Extensible Model for Environmental Effectsin Space and Test ChambersDr. Jason Cline, Spectral Sciences, Inc.1725 - 1830 Happy Hour in the Exhibit Hall(Sponsored by Scot Forge)-- End Concurrent NSMMS Sessions --Wednesday, 26 June 20130700 - 0745 Speaker Breakfast for Wednesday Presenters(Sponsored by Ultramet)0700 - 0800 Attendee Continental Breakfast(Sponsored by Southern Research Institute)1330 - 1900 Exhibits & Poster Session Open0700 - 1700 Registration- Begin Three Concurrent NSMMS Sessions -HYPERSONICS SESSION (Track 1)Session Chair: Dr. Brian Sullivan, Materials Research & DesignSession Organizers: Mr. Dave Brewer, NASA LaRC;Mr. Andy Swanson, AFRL; Mr. Jim Ledesma, The BoeingCompany; Mr. Mitch Petervary, The Boeing Company0800 - 0805 Session Intro0805 - 0855 HTV2Mr. Bob Wetherall, Lockheed Martin0855 - 0920 Passive Leading Edge TestingMr. James Ledesma, The Boeing Company0920 - 0945 A New Calibration-Based Inverse Method forEstimating Surface Heat FluxDr. Jay Frankel, University of Tennessee0945 - 1015 Break1015 - 1040 Mechanical Testing of Compliant ThermalBarriers for Multi-Purpose Crew VehicleMr. Jeffrey DeMange, University of Toledo /NASA GRCPlease see pages 6 & 7 for locations.22 23Please see pages 6 & 7 for locations.

NSMMSNSMMS1040 - 1105 Ceramic Matrix Composite Fracture ToughnessPost-Test Data CorrelationMr. Edward Klock-McCook, Materials Research &Design, Inc.1105 - 1130 FASTDr. Bill Garver, Lockheed Martin1130 - 1155 Ceramic Matrix Composites for HypersonicRadomes and AperturesMr. Steve Atmur, ATK COI Ceramics1155 - 1300 Lunch Break (On Your Own)1300 - 1325 LCWHS Missile StructuresDr. Bill Garver, Lockheed Martin1325 - 1350 Hypersonic Control Surfaces Using the HighDensity - Low Density Family of Integrated DualLayer MaterialsMr. James Crowley, Textron Systems Corporation1350 - 1415 High Temperature Structural Honeycombs,Hat Stiffeners and SiOC Fibrous TPS TechnologyMr. Thomas Rosengren, MATECH1415 - 1440 Bimetallic TPS Structure with Integrated Anti-Oxidation CoatingDr. George Ritter, EWI1440 - 1510 Break1510 - 1535 Thermal Protection System for Hypersonic Flightand High Velocity Earth Re-EntryMr. Scott Brown, Ultramet1535 - 1600 Tailorable Ceramic Micro-truss as a Panel CoreStructure for Thermal Protection SystemsDr. Daniel Driemeyer, The Boeing Company1600 - 1625 Innovative Materials & Processes Developmentfor Structurally Integrated Thermal ProtectionSystemsMs. Kerry Hopp, Materials Research & Design1625 - 1650 Summary of Pre-Test Predictions and Post-TestResults for Structurally Integrated ThermalProtection System Joint SubelementsMr. Daniel Howren, Materials Research & Design1650 - 1900 Poster Session and Reception(Sponsored by The Boeing Company)PLANETARY ORBIT & EXPLORATIONTECHNOLOGIES (Track 2)Session Chair: Dr. Anthony Calomino, NASA LaRCSession Organizers: Mr. Mike Fuller, ATK; Ms. Beth Kelsic, BallAerospace & Technologies Corp.; Dr. Sylvia Johnson, NASA ARC;Dr. Suraj Rawal, Lockheed Martin; Mr. Pat Sisson, GDIT; Mr. EricBecker, AFRL; Mr. Brian Hill, Northrop Grumman; Dr. Jack Agee,Rice University; Mr. John Vickers, NASA MSFC; Mr. Rich Wegrich,NASA MSFC; Dr. Charlie Camarda, NASA HQ0800 - 0805 Session Intro0805 - 0830 Interfacial Design of Ablative CompositeMaterialsDr. Tapan Desai, Advanced Cooling Technologies0830 - 0855 Spaced-Based (Lunar) Thin-Film DepositionTechnology for Solar Power, Astronomical andDirected Energy ApplicationsMr. Michael Fulton, Surface Optics Corporation0855 - 0920 Controlled Temperature Testing Techniques forComposite Materials and Metal Interfaces atSub-77 K Temperatures for Space ApplicationsMr. Mark Haynes, Composite TechnologyDevelopment, Inc.0920 - 1015 Break1015 - 1040 Low SWaP Semiconductor Laser TransmitterModules for Space Mission ApplicationsDr. Alex Rosiewicz, EM4, Inc.1040 - 1105 Materials Selection and Evaluation for Insulationof High Voltage Antennas for Space PropulsionPower, and CommunicationDr. John Slough, MSNW, <strong>LLC</strong>1105 - 1130 Development of Radiation Hard GaN Devicesand SystemsDr. Ke-Xun Sun, University of Nevada, Las Vegas1130 - 1155 Thermal Performance of Flexible, HighTemperature Aerogel Composite InsulationDr. Frances Hurwitz, NASA GRC1155 - 1300 Lunch BreakPlease see pages 6 & 7 for locations.24 25Please see pages 6 & 7 for locations.

NSMMSNSMMS1300 - 1325 New Nonflammable, High-Strength,Lightweight Structural Cryogenic CompositeMaterial in DevelopmentMs. Katherine Rodway, XCOR Aerospace1325 - 1350 Deployable Articulating Array forNanosatellitesMs. Dana Turse, Composite TechnologyDevelopment, Inc.1350 - 1415 Woven Thermal Protection System BasedHeat-Shield for Extreme Entry EnvironmentsTechnology (HEEET), Dr. Margaret Stackpoole,NASA ARC1415 - 1510 Break1510 - 1535 Inflatable Re-entry Vehicle ExperimentTechnology Development and DemonstratorFlight TestDr. Anthony Calomino, NASA LaRC1535 - 1600 Development of Large Scale HypersonicInflatable Atmospheric DeceleratorsDr. Anthony Calomino, NASA LaRC1600 - 1625 Aging of Flexible TPS MaterialsMr. Jacques Cuneo, Southern ResearchInstitute1625 - 1650 Hypersonic Inflatable Decelerator StudyDr. Suraj Rawal, Lockheed Martin1650 - 1900 Poster Session and Reception(Sponsored by The Boeing Company)SPACE MATERIALS EXPERIMENTS, MODELING, &SIMULATION (Track 3)Session Chair: Dr. Alan Stewart, The Boeing CompanySession Organizers: Mr. Shane Juhl, AFRL; Mr. Chip Frohlich, TheBoeing Company; Mr. John Vasquez, Naval Research Laboratory;and Mr. Derek Doyle, AFRL0800 - 0805 Session Intro0805 - 0830 A Bi-variate Distribution Function to ForecastProbability of Fatigue LifeMr. Brian Hardy, The Aerospace Corporation0830 - 0855 MISSE in MAPTISMr. DeWitt Burns, NASA MSFC0855 - 0920 Bent Panel Thermo-Structural Test DevelopmentMr. Michael Dion, Materials Research & Design0920 - 0945 Comments on Materials Interactions with AtomicOxygen and Other Environmental FactorsMr. Gary Pippin, Independent Consultant0945 - 1015 BreakSPACE ACCESS & PROPULSION (Track 3)Session Chair: Mr. Tim McKechnie, Plasma Processes, <strong>LLC</strong>Session Organizers: Mr. Alan Brown, Aerojet Rocketdyne; Mr. JohnKoenig, Southern Research Institute; Mr. Wes Sanderson, MissileDefense Agency; Mr. Jerry Brockmeyer, UltrametCorporation; and Dr. Diane Wiley, Ind. Consultant1015 - 1040 HydroCarbon Boost TPA Kick Pump ImpellerMaterials & Processes DevelopmentMr. Albert Contreras, Aerojet1040 - 1105 Carbon-Carbon Nozzle Extension for the RL10EngineMr. Raj Narayanan, Carbon Carbon AdvancedTechnologies, Inc.1105 - 1130 Domestically Available Lyocell C-C for NozzleExtensions and ComponentMs. Leslie Weller, Materials Research & Design1130 - 1155 TLyocell C/C Test Panel and Large ScaleDemonstration Article Mfg & EvaluationMr. Jacques Cuneo, Southern Research Institute1155 - 1300 Lunch Break1300 - 1325 High Performance Green Propulsion forImproved Responsiveness and Reduced LifeCycle CostMr. Stephen Beckel, ATK (Alliant Techsystems)1325 - 1350 Electro-formed Engineered Rhenium withImproved Mechanical PropertiesMr. Scott O’Dell, Plasma Processes, <strong>LLC</strong>Please see pages 6 & 7 for locations.26 27Please see pages 6 & 7 for locations.

NSMMS1350 - 1415 Low-Cost, High-Performance Materials forIn-Space PropulsionDr. Arthur Fortini, Ultramet1415 - 1440 Ceramic Matrix Composites for PropulsionStructures ApplicationsMr. Mitch Petervary, The Boeing Company1440 - 1510 Break1510 - 1535 Manufacturing Overview of a 2.4 MeterComposite CryotankMr. Carlos Guzman, The Boeing Company1535 - 1600 Hydrogen Permeation Testing and Analysis forComposite CryotanksMr. Michael Robinson, The Boeing Company1600 - 1625 Refractory Coated/Lined Low DensityStructuresMr. Joseph Pluscauskis, Materials Research &Design, Inc.1625 - 1650 Fiber Placement of an Out of Autoclave TankUsing Low Cost PlatformsMr. Brice Johnson, The Boeing Company1650 - 1900 Poster Session and Reception(Sponsored by The Boeing Company)-- End Concurrent NSMMS Sessions --Thursday, 27 June 20130700 - 0745 Speaker Breakfast for Thursday Presenters0700 - 0800 Attendee Continental Breakfast0700 - 1530 Registration- Begin Three Concurrent NSMMS Sessions -MISSILES & MISSILE DEFENSE SESSION(Track 1)Session Chair: Mr. Paul Marchol, AerojetSession Organizers: Dr. Doug Deason, MDA; Mr. Gerald Russell,RDECOM; Mr. Mark Smith, AEDC; and Dr. Curtis Martin,NSWCCDNSMMS0800 - 0805 Session Intro0805 - 0830 Technology Roadmap for Affordable andProducible EO/IR/RF Sensor Window MaterialsMr. Doug Freitag, USACA0830 - 0855 UHT CMCs for Propulsion ApplicationsMr. Steve Kirkwood, MATECH0855 - 0920 Survivable Broadband Optical Coating forBallistic Missile Defense MissionsDr. Bill Goodman, Trex Enterprises Corporation0920 - 0945 Improved Powder Towpreg Process forFabrication of Low-cost, High PerformanceMissile and Aircraft CompositesDr. Ronald Allred, Adherent Technologies, Inc.0945 - 1015 Break1015 - 1040 High Temperature Composites for MissileStructuresDr. Jason Lincoln, P2SI1040 - 1105 Development of Advanced C-C Composites forMissile TPS ApplicationsDr. Steven Violette, Fiber Materials Inc.,Graftech International1105 - 1130 Thermostructural Analysis and Design Supportfor Low-cost, Light-Weight, High-SpeedStructuresMr. Daniel Howren, Materials Research & Design1130 - 1155 A High-Performance Mid-Pressure Arc HeaterFacility for Improved Thermal Testing ofMaterials for Prompt Global Strike MissionsDr. Joseph Sheeley, Aerospace Testing Alliance/AEDC1155 - 1300 Lunch Break1300 - 1325 Development of Structural Insulators for MDAApplicationsMr. Kent Buesking, Materials Research & Design1325 - 1350 Materials Design Challenges for NextGeneration, Mr. Timothy Dominick, ATK MissileDefense & Controls Division1350 - 1415 Carbon-Carbon Structural Insulator forAdvanced Air-To-Air MissilesDr. Brian Sullivan, Materials Research & DesignPlease see pages 6 & 7 for locations.28 29Please see pages 6 & 7 for locations.

NSMMS1415 - 1440 Ta and Hf Carbide Alloys for SRM Nozzle viaField Assisted Sintering Technology (FAST)– Bulk verses Near Net Shaped ProcessingDr. Heedong Lee, AFRL1440 - 1510 Break & Grand Prize Give-Away1510 - 1535 Non-Eroding Nozzles for Aluminized SolidRocket Motors: Hot Fire Test Results inDual-Pulse and Vectored ConditionsDr. Daniel Butts, Plasma Processes, <strong>LLC</strong>1535 - 1600 A High Capacity Thermal Battery Based onNovel Electrodes and ElectrochemistryDr. Pyoungho Choi, CFD Research Corporation1600 - 1625 Rayon Replacement Materials for use in AblativeApplicationsMr. Carl Varnerin, Barrday Composite Solutions1625 - 1650 AdjournINNOVATIONS IN MATERIALS (Track 2)Session Chair: Dr. John Rivard, ORNLSession Organizers: Dr. Russ Lipeles, The Aerospace Corporation;Dr. Eric Wuchina, NSWC; Dr. Brian Holloway, DARPA; Dr. AnneFischer, DARPA; and Dr. John Schmisseur, AFOSR0800 - 0805 Session Intro0805 - 0855 Laser-Printed Silicon Carbide Fibers - A NationalGame-ChangerDr. Joseph Pegna, Free Form Fibers0855 - 0920 Injection Moldable Pressureless Sintered SiliconNitrideMr. Mark Hawthorne, ATC Materials0920 - 0945 In Situ Processing of Lunar Glass Fiber andCompositesDr. Edward Pope, MATECH0945 - 1015 Break1015 - 1040 Synthesis of Alloyed Nanocarbide/GrapheneNanocomposites by a Scalable ProcessDr. Baburaj Eranezhuth, Clarkson AerospaceCorporationNSMMS1040 - 1105 Mechanical Properties of Spark PlasmaSintered ZrB2 with Oxide Reducing AgentsMr. David Pham, University of Arizona1105 - 1130 Development of a Oxide Additive Free, SparkPlasma Sintered, High Strength Silicon NitrideSystemDr. William Pinc, University of Arizona1130 - 1155 Volumetric Imaging of CMCs by MicrowaveInterferometryMr. Karl Schmidt, Evisive, Inc.1155 - 1300 Lunch Break1300 - 1325 Ultra-High Temperature Ceramic OxidationBehavior Using Multiple High Temperatureand Oxygen Rich Testing FacilitiesDr. Erica Corral, University of Arizona1325 - 1350 Ultra Lightweight Structural MetalsMr. Brian Doud, Powdermet, Inc.1350 - 1415 Porous Shape Memory Effect Foams for Solid-State Actuation and Shock MitigationDr. Peter Jardine, Shape Change Technologies1415 - 1440 Plasma Electrolytic Treatment to ImprovePerformance of Titanium and Aluminum AlloysDr. Solomon Berman, IBC Materials &Technologies, Inc.1440 - 1510 Break & Grand Prize Give-away1510 - 1535 Electrical Conductivity and ElectromagneticCapabilities for Composites and PolymersDr. Nathan Hansen, Conductive CompositesCompany1535 - 1600 The Development of CNT Based Cellular Corefor Space PlatformsMr. Nicholas Patz, Patz Materials & Technologies1600 - 1625 Cellular Core Technology – A New Body ofKnowledge for Design and ManufacturingMr. William Rodman, JIT-inVision, <strong>LLC</strong>1625 - 1650 Nanosilicon and NanofuelsDr. David Irvin, Systems and Materials ResearchCorporationPlease see pages 6 & 7 for locations.30 31Please see pages 6 & 7 for locations.

NSMMSSPACE ACCESS & PROPULSION SESSION, Cntd.(Track 3)Session Chair: Mr. Tim McKechnie, Plasma Processes, <strong>LLC</strong>Session Organizers: Mr. Alan Brown, Aerojet Rocketdyne;Mr. John Koenig, Southern Research Institute;Mr. Wes Sanderson, Missile Defense Agency;Mr. Jerry Brockmeyer, Ultramet Corporation; andDr. Diane Wiley, Independent Consultant0800 - 0805 Session Intro0805 - 0830 Compression Analysis and Test of Fluted-CoreSandwich Composite PanelsDr. Marc Schultz, NASA LaRC0830 - 0855 Thin, Lightweight Aerogel Thermal Insulationfor Space ApplicationsDr. Shannon White, Aspen Aerogel,Inc.0855 - 0920 A Technical Evaluation of Direct Metal LaserSintering for Rocket Engine ComponentManufacturingMr. David Salazar, Sierra Lobo, Inc.0920 - 0945 Additive Manufactured Propulsion SystemsDevelopment Status and ApplicationsMr. Christian Carpenter, Aerojet Corporation-- End Concurrent NSMMS Sessions --Friday, 28 June 20130800 - 1100 Steering Committee Meeting0830 - 1100 Future of Flight Boeing TourGrand Prize RaffleCollect raffle tickets at the end of eachNSMMS & CRASTE session for a chanceto win a GoPro Camera. Winning ticket willbe drawn at the Thursday afternoon break.Must be present to win. Birmingham, Alabamawww.SouthernResearch.orgPlease see pages 6 & 7 for locations.32 33

LIMITLESSPOSSIBILITIESLEAD TOENDLESSINNOVATION.Boeing supports theNational Space & MissileMaterials Symposiumin its extraordinaryachievements in thedevelopment of advancedmaterials research.MetalsCeramicsCarbidesPolymersAdvanced Materials Technologyfor Demanding Applicationswww.plasmapros.com34 35

Poster SessionPoster SessionPoster SessionSession Organizers: Mr. Shane Juhl, AFRL; Dr. Todd Steyer, The BoeingCompany; and Dan Driemeyer, The Boeing CompanyHypersonics• Ceramic Matrix Composite Fracture ToughnessPost-Test Data Correlation, Mr. Craig Iwano, MaterialsResearch & Design• Development and Analysis of Continuous SiC Fiber-Reinforced HfB2-SiC Composites for Hypersonic FlightApplications, Dr. Clifford Leslie, AFRL (and NRC ResearchAssociateship Program)• Ultra High Temperature Mechanical Testing of ZrB2-ZrCBased Ceramics, Mr. Eric Neuman, Missouri University ofScience and Technology• High Temperature Structural Honeycombs, HatStiffeners and SiOC Fibrous TPS Technology,Mr. Thomas Rosengren, MATECHInnovations in Materials• Plasma Electrolytic Treatment to Improve Performanceof Titanium and Aluminum Alloys, Dr. Solomon Berman,IBC Materials & Technologies, Inc.• SynFoam TM Syntactic Ceramic Composites - Processing,Properties and Applications, Mr. Nicholas Farkas,Powdermet, Inc.• Woven TPS – Mechanical Property Evaluation,Mr. Gregory Gonzales, NASA ARC• Purification of Commercial CNT Sheet Material forComposite Fabrication, Dr. Alan Hopkins, The AerospaceCorporation• Nanosilicon and Nanofuels, Dr. David Irvin, Systems andMaterials Research Corporation• Synthetic Silicate Nano – Materials for AdvancedComposites and Coatings, Dr. Vijay Mathur, GR NanoMaterials• Multiple Use Precision Extractable Tooling forStreamlined Composite Manufacturing, Ms. Dana Turse,Composite Technology Development, Inc.Missiles & Missile Defense• Development of Structural Insulators for MDAApplications, Mr. Kent Buesking, Materials Research &Design• Hafnium-based Materials for DACS Propulsion Systems:Microstructural Characterization, Oxidation Behavior,and Mechanical Testing, Dr. Daniel Butts, PlasmaProcesses, <strong>LLC</strong>• Thermostructural Analysis and Design Support forLow-Cost, Light-Weight, High-Speed Structures,Mr. Daniel Howren, Materials Research & Design• UHT CMCs for Propulsion Applications,Mr. Steve Kirkwood, MATECHPlanetary Orbit & ExplorationTechnologies• Interfacial Design of Ablative Composite Materials,Dr. Tapan Desai, Advanced Cooling Technologies, Inc.• Spaced-Based (Lunar) Thin-Film Deposition Technologyfor Solar Power, Astronomical and Directed EnergyApplications, Mr. Michael Fulton, Surface OpticsCorporation• Materials Selection and Evaluation for Insulation of HighVoltage Antennas for Space Propulsion, Power andCommunication, Dr. John Slough, MSNW <strong>LLC</strong>• Woven Thermal Protection System Based Heat-shieldfor Extreme Entry Environments Technology (HEEET),Dr. Margaret Stackpoole, NASA ARC• Stiff Deployable Composite Structures for Lightweight,High Power Solar Arrays, Ms. Dana Turse, CompositeTechnology Development, Inc.• Thermal Distortion Testing of a Deployable, HighFrequency Composite Antenna Reflector, Ms. DanaTurse, Composite Technology Development, Inc.Please see pages 6 & 7 for locations.36 37Please see pages 6 & 7 for locations.

Poster SessionSpace Access & Propulsion• High Thermal Conductivity Reinforced AluminumComposite for Space Structures, Mr. Nicholas Farkas,Powdermet, Inc.• Data Correlation of Impact Performance of SiC/SiCMaterials, Mr. Edward Klock-McCook, Materials Research& Design• Refractory Coated/Lined Low Density Structures,Mr. Joseph Pluscauskis, Materials Research & Design• Monolithic Catalysts Based on Metal Foams,Dr. Anatoliy Shchetkovskiy, Plasma Processes, <strong>LLC</strong>• Maintaining Heritage Silver-Zinc Battery AvailabilityWhile Designing Replacement Lithium Ion Batteriesfor Launcher Applications, Mr. Darren Whelan, YardneyTechnical Products, Inc.Space Materials Experiments,Modeling, & Simulation• Fracture In Low Density Porous Carbon Ablators,Mr. Jose Chavez-Garcia, NASA ARC• Fracture Toughness (ENF) Specimen Design,Mr. Michael Dion, Materials Research & Design• Design of Thermo-Structural Test for In-PlaneCompression Fracture under High Thermal Gradients,Mr. Hans Jensen, Materials Research & Design• Visualization of Atomic Resolution Stresses in MolecularDynamics Simulations, Dr. Andrew Fenley, University ofCalifornia San Diego, Skaggs School of Pharmacy andPharmaceutical Sciences• Post-Flight Evaluation of PICA-X – the Dragon 1 ForebodyHeatshield Material, Dr. Margaret Stackpoole, NASA ARCExhibit Chairs:Mr. Ron Ooten, USEC, Inc. and Mr. Chip Frohlich,The Boeing CompanyNetworking AreaNetworkingAreaAerojet Rocketdyne – 309 & 311http://www.rocket.comExhibit MapAerojet Rocketdyne is a world-recognized provider of comprehensivepower & propulsion solutions for the defense and aerospace sectors.Built on a combined legacy of more than 130 years of mission success,the company is the only U.S. provider of all four types of power andpropulsion: solid, liquid, airbreathing and electric. For more information,visit www.rocket.comPlease see pages 6 & 7 for locations.38 39Please see pages 6 & 7 for locations.

ExhibitorsATK/ATK COI – 401 & 403http://www.atk.comATK is a premier advanced weapon and space systems companyproducing composite structures, propulsion systems, munitions, anddefense integration solutions. ATK is a world-class supplier of launchvehicle solid propulsion systems and a leader in the development andproduction of composite optical benches and dimensionally stableassemblies for satellites and propulsion products. ATK COI is apremier supplier of oxide and non-oxide ceramic matrix compositesfor military, commercial and industrial applications.Barrday – 111http://www.barrday.comBarrday is a Composite material Supplier with high performancematerials from fabric to prepregs for high end composite applications.The Boeing Company – 200 & 202http://www.boeing.comBoeing is the world’s leading aerospace company and the largestmanufacturer of commercial jetliners and military aircraft combined.Additionally, Boeing designs and manufactures rotorcraft, electronicand defense systems, missiles, satellites, launch vehicles andadvanced information and communication systems. As a majorservice provider to NASA, Boeing provides launch capability andInternational Space Station operations support. The company alsoprovides numerous military and commercial airline support services.Boeing has customers in more than 90 countries around the worldand is one of the largest U.S. exporters in terms of sales. Boeing hasa long tradition of aerospace leadership and innovation. We continueto expand our product line and services to meet emerging customerneeds. Our broad range of capabilities includes creating new, moreefficient members of our commercial airplane family; integratingmilitary platforms, defense systems and the warfighter throughnetwork-centric operations; creating advanced technology solutionsthat reach across business units; e-enabling airplanes and providingconnectivity on moving platforms; and arranging financing solutionsfor our customers. Headquartered in Chicago, Boeing employs morethan 173,000 people across the United States and in 70 countries.This represents one of the most diverse, talented and innovativeworkforces anywhere. More than 90,000 of our people hold collegedegrees--including nearly 29,000 advanced degrees--in virtuallyevery business and technical field from approximately 2,700 collegesand universities worldwide. Our enterprise also leverages the talentsof hundreds of thousands more skilled people working for Boeingsuppliers worldwide.ExhibitorsComposite Technology Development – 210http://www.ctd-materials.comCTD is a technology and product development company focused onthe development and application of advanced composite materials.The company produces deployable space structures, compositetanks, and other advanced composites, and provides mechanicaltesting and other engineering services to a variety of customers.Conductive Composites – 315http://www.conductivecomposites.com/Conductive Composites creates materials and delivers technologiesthat enable electrical conductivity and electromagnetic capabilities incomposites and plastics. Our products are the key components thatdeliver value to a broad range of applications. With a special focus onperformance, customer experience, and continual improvement, weprovide critical expertise in the partnered insertion of electrical andelectromagnetic properties in lightweight platforms. Our proprietarymaterials and products are domestically manufactured on commercialgrade production lines in ISO:9001-2008 compliant facilities.Damping Technologies, Inc. – 212http://www.damping.comNoise and Vibration Control Through Material Innovations. The “DTIDifference” consists of our ability to analyze/understand key structuraldynamics and environmental factors associated with a given noiseor vibration issue, develop appropriate innovative passive dampingsystem solutions, and then manufacture the best solution in a costeffectivemanner.EnUrga, Inc. – 204http://www.enurga.comOptical patternation for spray Nozzles, High speed visible or infraredspectrometor.Free Form Fibers – 319http://www.fffibers.comFree Form Fibers (FFF):• Early-Stage Company, Developer of Silicon Carbide, BoronCarbide, and Boron monofilament fibers, Up to 270 filaments/tow• Filament diameter adjustable from 10 to 30 µm,• Preliminary Young’s Modulus of SiC fibers: ~300 GPa,• Preliminary tensile strength of SiC fibers: >1.5 GPa,• High-purity ß-SiC, oxygen-free,• Availability of experimental quantities (300”) expected Q3 ’13,• Domestically produced SiC fibers.Please see pages 6 & 7 for locations.40 41Please see pages 6 & 7 for locations.

ExhibitorsExhibitorsGeneral Plastics Manufacturing Company – 101http://www.generalplastics.comFrom the deep sea to deep space, we shape great ideas into reality.For 70 years, General Plastics has been a leading plastics innovator.We specialize in unique chemistry-based solutions, centered on oursignature LAST-A-FOAM® rigid and flexible polyurethane foam. Wesupport engineers and design teams in diverse industries with unrivaledformulations and high-quality materials for the most demanding productapplications. Our customer service, chemistry, CNC design, testing andQA teams work closely with you from concept to completion.IMS, Inc. – 113http://www.imsysinc.comIndustrial Measurement Systems, Inc. is pioneering ultrasonicthermometry and ablation measurement technologies with the potentialof providing revolutionary non-intrusive measurements of recession,temperature distribution and heat flux.Loctronix Corporation – 207http://www.loctronix.comLoctronix provides navigation and tracking solutions GPS/GNSSchallenged environments. The company offers solutions for spacenavigation, payload recovery, GPS signal assurance, and indoor/outdoorpersonnel navigation using signals of opportunity.Luxel Corporation – 107http://www.luxel.comLuxel is the preeminent supplier of free standing sub-micron thin filters.Since 1973 we have produced Bandpass filters for use in the extremeultraviolet (EUV) and soft X-ray portion of the electromagnetic spectrumfor both laboratory and space research. With our history of supplyingthe highest quality products, customers have come to rely on Luxel’stechnical expertise when their experimental results are critical.MATECH – 206http://www.matechgsm.comMATECH has developed and produces 500 filament ceramic fiber towof two types of silicon-based fibers, silicon nitride/carbide (SiNC) andstoichiometric silicon carbide (SiC) for use in advanced ceramic matrixcomposites (CMCs). MATECH is a leader in ultra-high-temperature(UHT) CMCs for missile propulsion and aerothermal TPS applications.MATECH manufactures UHT C/ZrOC CMCs. MATECH manufacturesSiC-matrix CMCs by PIP, CVI, and hybrid processing. MATECH hasa dedicated CVI/CVD facility for both interface coatings and matrixdensification. MATECH has also recently launched its new weaving lab.MATECH is fully integrated, from the manufacture of fibers, weavingof fabric, deposition of interface coatings, and CMC densification.Materials, Research & Design, Inc. – 404http://www.m-r-d.comMaterials Research & Design (MR&D) is a small business thatprovides research and design services to the aerospace materialscommunity. Typical programs at MR&D focus on the simultaneousdesign of material and structure to optimize component cost,weight, or structural performance. Additional areas of interest focusupon research into the behavior of composite materials and thedevelopment of micromechanical models to analyze and understandobserved properties. The analytical approach employed by MR&D isbased upon a practical understanding of engineering issues foundedupon a strong background of theoretical mechanics.Missile Defense Agency – 312http://mdasbir.com/The Missile Defense Agency (MDA) Small Business InnovationResearch (SBIR) and Small Business Technology Transfer (STTR)programs participate within the Department of Defense (DoD) .2SBIR, .A STTR, and .B STTR solicitations. MDA makes SBIR PhaseI awards up to $100K with a $50k option. STTR Phase I awards areup to $100K – the $50K option only applies to SBIR Phase I awards.The nominal Phase II award amount is $1.0MOxy-Gon Industries Inc. – 317http://www.oxy-gon.comOxy-Gon Industries Inc. has been a high temperature controlledatmosphere and vacuum furnace manufacture for 25+ years. Pleasevisit our booth with your specific thermal processing needs!PLANSEE USA <strong>LLC</strong> – 321http://www.plansee-usa.comPLANSEE USA is the worldwide leader in the supply, machining andfabrication of high performance materials (Molybdenum, Tungsten,Tantalum, Niobium, Tungsten Heavy Metals, Super Alloys, Titanium).PLANSEE USA’s state-of-the-art facility provides innovativeand effective solutions in engineering, high precision machining,fabrication, thermal processing, brazing and cleanroom operations.PLANSEE USA offers a portfolio of components for space, civil, andmilitary aerospace applications. We are AS9100 Certified and ITARRegisteredPlease see pages 6 & 7 for locations.42 43Please see pages 6 & 7 for locations.

ExhibitorsExhibitorsPlasma Processes – 304http://www.plasmapros.comPlasma Processes is an ISO 9001:2008 certified small businessspecializing in the development and manufacture of high temperaturematerials, coatings, net-shape structures, and powder processingservices. Plasma develops, applies and validates coating solutions forthermal protection, electrical isolation, wear and corrosion resistanceand dimensional restoration, in addition to the manufacture ofnet-shape components by vacuum plasma and EL-Form® depositionprocesses. Plasma serves customers in the government, aerospace/defense and commercial sectors.P2SI – 306http://www.p2si.comP2SI is a supplier of high temperature structural prepregs andadhesives to the Defense and commercial industries. P2SI’s productline includes polyimides, epoxies, and bismaleimide materials. In2011, P2SI was awarded Lockheed Martin Supplier of the Year foran advanced development, high temperature composite structureprogram which utilized P2SI’s materials and process developmentcapabilities.Resodyn Acoustic Mixers – 105http://www.resodynmixers.comResodyn Acoustic Mixers (RAM) manufactures an innovative, unique,non-contact mixing technology that uses low frequency acousticenergy to mix a wide range of materials. RAM is able to mix powders,liquids and viscous materials with ease. Mixing is accomplished invirtually any sealed container, eliminating contamination or clean upconcerns. Mix a few grams to hundreds of kilos using RAM. Visit us fora live demonstration and DISCOVER WHAT YOU COULD BE MIXING!Scot Forge Company – 305 & 307http://www.scotforge.comScot Forge is a 100% employee-owned, AS9100C certifiedmanufacturer of custom open die and rolled ring forgings. ScotForge has over 100 years of experience, leading the industry as oneof the most modern and respected forging companies in the world.More than 650 employees operate within 1,000,000 square feet ofmanufacturing space in five plants. Output of these facilities is greaterthan 250 million pounds of material annually. Our 3,600 ton ringexpander compliments a large Wagner ring roller and drop-bottomfurnace. These assets work in tandem to provide large ring forgingsfor aircraft, missile and space applications. With the capability to formaluminum, magnesium and titanium rings up to 2<strong>52</strong>” diameter andover 42” tall, Scot Forge is a member an extremely small community ofdomestic corporations with these capabilities.Thermacore Incorporated – 213http://www.thermacore.com/Founded in 1970, Thermacore specializes in the custom design,development, and manufacturing of highly engineered thermalmanagement systems and components such as heat pipe/vaporchamber assemblies, loop heat pipe assemblies, k-Core® APG basedadvanced solid conduction assemblies and active pumped liquidthermal management systems for a variety of OEM applications acrossa diversified set of global markets that includes Military/Aerospace,Computer, Communication, Energy Conversion, Medical and TestEquipment. For information about Thermacore, visit www.thermacore.com.ULTRAMET – 205http://www.ultramet.comUltramet is an ISO 9001:2008-certified producer of flight-qualifiedcomponents, comprised of engineers, scientists, and supportpersonnel, production and R&D facilities particularly suited to theresearch, development and production of advanced materialsincluding high temperature capability, corrosion- and erosion-resistantmaterials. Ultramet personnel will be on hand to discuss your materialsrelated applications.Yardney Technical Products, Inc. – 209http://www.yardney.comYardney Technical Products is a Veteran Owned Small Businessthat has been in operation since 1944. We specialize in militaryand aerospace battery systems that cannot fail. Our currentbattery chemistries include Lithium Ion and Silver Zinc. We proudlymanufacture our cells and batteries in the United States using USmade materials whenever possible.Zircar Zirconia, Inc. – 308http://www.zircarzirconia.comZircar is a ceramic manufacturer of alumina, ceria, hafnia and zirconiamaterials for use in ablatives, catalyst supports, composites, gasketsand other high performance refractory applications.Please see pages 6 & 7 for locations.44 45Please see pages 6 & 7 for locations.

Photonics Tech BriefsImaging TechnologyNASA Invites Youto Explore theCutting EdgeSeptember 2012 www.techbriefs.com Vol. 36 No. 9Special SectionMars Science Laboratory: NASABegins a New Era of ExplorationSpecial SupplementSoftware Tech BriefsNovember 2012 www.techbriefs.com Vol. 36 No. 11The best new design ideas and engineering innovationsdeveloped under NASA’s $12 billion R&D budget are reportedFIRST in NASA Tech Briefs — America’s largest-circulationdesign engineering magazine.Keep pace with the latest breakthroughs in:• Electronics• Test & Measurement• Computing• Bio-medical• Mechatronics• Software• Green DesignJoin over 190,000 design engineers & managers throughout OEMindustries who rely on NASA Tech Briefs to stay on the cutting edge...and gain a competitive advantage.You may also qualify to receive Defense Tech Briefs,from the publishers of NASA Tech Briefs.Volume 6 • Number 5 • October 2012Special Awards Section:Create the Future DesignContest WinnersIndustry Update: Analysis &Simulation SoftwareNASA Spinoff CreatesUnique TreadmillPhotonics Tech BriefsAirflow and Thermal Analysis ofUAV Deicing SystemsDesigning a New Generation ofRugged Military ElectronicsSystemInterconnectsfor Today’s MilitaryVehiclesStart your subscription today at:www.techbriefs.com/subscribe/EXPO13INSIDE:Supplement to NASA Tech Briefswww.defensetechbriefs.comFor information on marketing to this audience of highly qualified BUYERS,visit www.techbriefsmedia.com or contact Joe Pramberger, publisher,at 917-286-3758; joe@techbriefs.com.46 47

ULTRAMET ENGINEERS AND MANUFACTURESrefractory metals, platinum group metals, andceramics for demanding applications that meetthe needs of the aerospace, defense, biomedical,and energy industries.Ultramet maintains a quality management systemtemperature capability, corrosion- and erosionresistantmaterials. Manufactured products Inside Cover BlankUnclassified Notes(No ITAR or Military Critical Data Allowed)48