Download brochure - Renold plc

Download brochure - Renold plc

Download brochure - Renold plc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

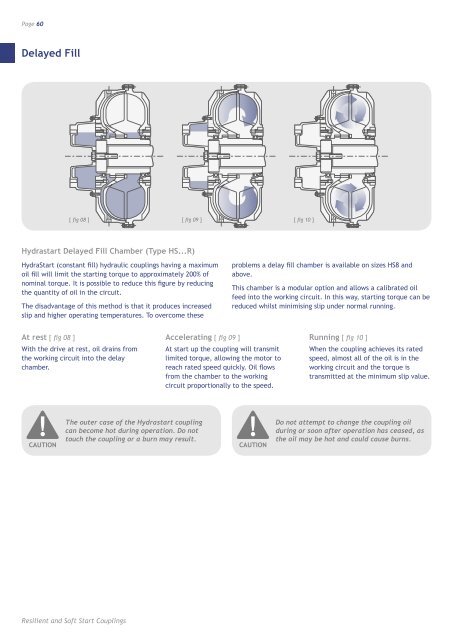

Page 60Delayed Fill[ fig 08 ][ fig 09 ] [ fig 10 ]Hydrastart Delayed Fill Chamber (Type HS...R)HydraStart (constant fill) hydraulic couplings having a maximumoil fill will limit the starting torque to approximately 200% ofnominal torque. It is possible to reduce this figure by reducingthe quantity of oil in the circuit.The disadvantage of this method is that it produces increasedslip and higher operating temperatures. To overcome theseproblems a delay fill chamber is available on sizes HS8 andabove.This chamber is a modular option and allows a calibrated oilfeed into the working circuit. In this way, starting torque can bereduced whilst minimising slip under normal running.At rest [ fig 08 ]With the drive at rest, oil drains fromthe working circuit into the delaychamber.Accelerating [ fig 09 ]At start up the coupling will transmitlimited torque, allowing the motor toreach rated speed quickly. Oil flowsfrom the chamber to the workingcircuit proportionally to the speed.Running [ fig 10 ]When the coupling achieves its ratedspeed, almost all of the oil is in theworking circuit and the torque istransmitted at the minimum slip value.!CAUTIONThe outer case of the Hydrastart couplingcan become hot during operation. Do nottouch the coupling or a burn may result.!CAUTIONDo not attempt to change the coupling oilduring or soon after operation has ceased, asthe oil may be hot and could cause burns.Resilient and Soft Start Couplings