PERIOD ENDED DECEMBER 31, 2003 Annual ... - Peabody Energy

PERIOD ENDED DECEMBER 31, 2003 Annual ... - Peabody Energy

PERIOD ENDED DECEMBER 31, 2003 Annual ... - Peabody Energy

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

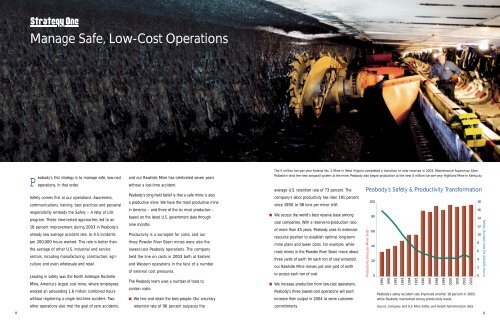

Manage Safe, Low-Cost Operations<strong>Peabody</strong>’s first strategy is to manage safe, low-costoperations, in that order.Safety comes first at our operations. Awareness,communications, training, best practices and personalresponsibility embody the Safety – A Way of Lifeprogram. These time-tested approaches led to an18 percent improvement during <strong>2003</strong> in <strong>Peabody</strong>’salready low average accident rate, to 4.5 incidentsper 200,000 hours worked. This rate is better thanthe average of other U.S. industrial and servicesectors, including manufacturing, construction, agricultureand even wholesale and retail.Leading in safety was the North Antelope RochelleMine, America’s largest coal mine, where employeesworked an astounding 1.6 million combined hourswithout registering a single lost-time accident. Twoand our Rawhide Mine has celebrated seven yearswithout a lost-time accident.<strong>Peabody</strong>’s long-held belief is that a safe mine is alsoa productive mine. We have the most productive minein America – and three of the six most productive –based on the latest U.S. government data throughnine months.Productivity is a surrogate for costs, and ourthree Powder River Basin mines were also thelowest-cost <strong>Peabody</strong> operations. The companyheld the line on costs in <strong>2003</strong> both at Easternand Western operations in the face of a numberof external cost pressures.The <strong>Peabody</strong> team uses a number of tools tocontain costs:■ We hire and retain the best people. Our voluntaryThe 5 million ton-per-year Federal No. 2 Mine in West Virginia completed a transition to new reserves in <strong>2003</strong>. Maintenance Supervisor AllenPollastrini tests the new longwall system at the mine. <strong>Peabody</strong> also began production at the new 4 million ton-per-year Highland Mine in Kentucky.average U.S. retention rate of 73 percent. Thecompany’s labor productivity has risen 191 percentsince 1990, to 98 tons per miner shift.■ We access the world’s best reserve base amongcoal companies. With a reserve-to-production ratioof more than 45 years, <strong>Peabody</strong> uses its extensiveresource position to establish optimal long-termmine plans and lower costs. For example, whilemost mines in the Powder River Basin move aboutthree yards of earth for each ton of coal extracted,our Rawhide Mine moves just one yard of earthto access each ton of coal.■ We increase production from low-cost operations.<strong>Peabody</strong>’s three lowest-cost operations will eachincrease their output in 2004 to serve customer<strong>Peabody</strong>’s Safety & Productivity TransformationProductivity (Tons per Miner Shift)1001816806040200199019911992199<strong>31</strong>99419951996199719981999200020012002<strong>2003</strong><strong>Peabody</strong>’s safety accident rate improved another 18 percent in <strong>2003</strong>,while <strong>Peabody</strong> maintained strong productivity levels.14121086420Safety (Accident Rate Per 200,000 Hours)other operations also met the goal of zero accidents,retention rate of 96 percent outpaces thecommitments.Source: Company and U.S. Mine Safety and Health Administration data.89