Peabody Pursues Gasification Project in China - Peabody Energy

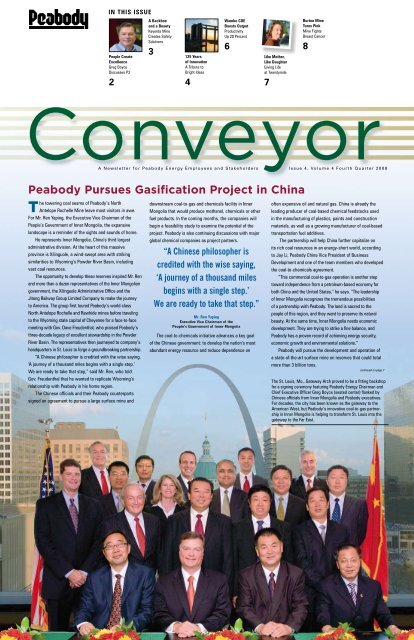

Peabody Pursues Gasification Project in China - Peabody Energy

Peabody Pursues Gasification Project in China - Peabody Energy

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

message from chairman and chief executive officer greg boyce<strong>Peabody</strong>’s People Create a Culture of Excellence through P3Greg BoyceChairman andChief Executive OfficerAt <strong>Peabody</strong> <strong>Energy</strong>, weare cont<strong>in</strong>uallyseek<strong>in</strong>g ways to maximizewhat I call the “Three Es” –energy security, economicgrowth and environmentalsolutions. Seldom havethese elements been <strong>in</strong>such turmoil as today.Still, even <strong>in</strong> the presentdynamic environment, coal rema<strong>in</strong>s the fastest-grow<strong>in</strong>gfuel <strong>in</strong> the world. Clean coal is the ultimate solution forre-energiz<strong>in</strong>g the world economy, creat<strong>in</strong>g millions of greenjobs and build<strong>in</strong>g energy security. And as the global leader<strong>in</strong> clean coal solutions, <strong>Peabody</strong> is advanc<strong>in</strong>g all of thesegoals at once.As I review the events of the past year, I’m impressed byour significant progress <strong>in</strong> realiz<strong>in</strong>g this company’s vision.The credit goes to our 7,000 employees worldwide... peoplewho raise the bar at every turn... <strong>in</strong>dividuals who embracechange... and team members who collaborate to createbetter, more efficient ways of do<strong>in</strong>g bus<strong>in</strong>ess.People are at the heart of our <strong>Peabody</strong> Peak Performance– P3 – <strong>in</strong>itiative, dozens of projects that share a s<strong>in</strong>gle goal:to drive a culture of cont<strong>in</strong>uous improvement at every levelof the organization:• Chief among these is safety. We can report the safestyear <strong>in</strong> <strong>Peabody</strong>’s history, with a year-to-date safety rate ofjust 1.70 <strong>in</strong> the United States.“People are at the heart of our<strong>Peabody</strong> Peak Performance– P3 – <strong>in</strong>itiative, dozens ofprojects that share a s<strong>in</strong>glegoal: to drive a culture ofcont<strong>in</strong>uous improvement atevery level of the organization.”Greg BoyceChairman and Chief Executive Officer• In every region, our P3 Operations Centers of Excellence(COEs) are br<strong>in</strong>g<strong>in</strong>g together m<strong>in</strong>e employees and subjectmatter experts from around the company to maximizeproductivity and improve costs. For example, COE <strong>in</strong>itiativescontributed to record monthly production levels at our NorthGoonyella M<strong>in</strong>e, while our Wambo M<strong>in</strong>e <strong>in</strong>creased productivityby more than 20 percent. Our Wildcat Hills M<strong>in</strong>e implementedsignificant annual efficiencies, and the Lee Ranch M<strong>in</strong>e hitkey targets despite transition<strong>in</strong>g equipment and personnel toenable the El Segundo M<strong>in</strong>e to ramp up to full production.• Our Capital COE is help<strong>in</strong>g us <strong>in</strong>vest wisely <strong>in</strong> ouroperations: <strong>Peabody</strong>’s Wilp<strong>in</strong>jong and El Segundo m<strong>in</strong>eshave costs that are significantly below the norm foroperations with similar production levels.• Our Eng<strong>in</strong>eer<strong>in</strong>g COEs are successfully apply<strong>in</strong>g acan-do m<strong>in</strong>dset to complex life-of-m<strong>in</strong>e analysis.• Our Sourc<strong>in</strong>g COE – a part of Supply Cha<strong>in</strong> Management– collaborates closely with multiple areas of thebus<strong>in</strong>ess to enhance day-to-day procurement at each m<strong>in</strong>e,strategically source goods and services through competitivebidd<strong>in</strong>g and other activities and apply forecast<strong>in</strong>g, budget<strong>in</strong>gand report<strong>in</strong>g processes to ensure <strong>Peabody</strong>’s third-partyspend<strong>in</strong>g is as cost efficient as possible.• At the same time, our Commercial COE is driv<strong>in</strong>gcompetitive pric<strong>in</strong>g <strong>in</strong> a difficult environment.As we complete another successful year, I want to thankall of you for your hard work <strong>in</strong> deliver<strong>in</strong>g results that susta<strong>in</strong>our global leadership <strong>in</strong> all types of markets and economicconditions. As we look forward to 2009, I know the employeesof <strong>Peabody</strong> will cont<strong>in</strong>ue to outperform. Thank you aga<strong>in</strong> for allthat you do and have a wonderful new year.Employees monitor key performance <strong>in</strong>dicators us<strong>in</strong>g aP3 Performance Board.<strong>Peabody</strong> <strong>Energy</strong> W<strong>in</strong>s Global <strong>Energy</strong> Excellenceand Strategic Investment HonorsFlash bulbs snapped and cameras rolled as Chairmanand Chief Executive Officer Greg Boyce accepted dualhonors at the 10th Annual Global <strong>Energy</strong> Awards <strong>in</strong> NewYork City, an event popularly known as the ‘Oscarsof <strong>Energy</strong>.’ <strong>Peabody</strong> <strong>Energy</strong> won the ‘Award of Excellence’for its legacy of <strong>in</strong>dustry leadership and the ‘Strategic<strong>Energy</strong> Investment of the Year’ Award for the company’stransformation <strong>in</strong>to a global energy powerhouse and a leader<strong>in</strong> clean coal technologies.In receiv<strong>in</strong>g the Award of Excellence, <strong>Peabody</strong> wasrecognized as an energy all-star. The company emerged froma crowded field to earn f<strong>in</strong>alist status <strong>in</strong> each of the 10 years ofthe competition. In fact, the company was a f<strong>in</strong>alist 29 times<strong>in</strong> multiple categories s<strong>in</strong>ce the Global <strong>Energy</strong> ceremony wasestablished, w<strong>in</strong>n<strong>in</strong>g ‘Coal Company of the Year’ three times.<strong>Peabody</strong> also received the first Strategic <strong>Energy</strong> Investmentof the Year Award. The honor recognizes the company’ssuccess <strong>in</strong> expand<strong>in</strong>g beyond its U.S. platform to capitalize onhigh-growth, high-marg<strong>in</strong> markets around the globe. <strong>Peabody</strong><strong>in</strong>creased its <strong>in</strong>ternational earn<strong>in</strong>gs contribution from just1 percent to 50 percent by achiev<strong>in</strong>g rapid growth <strong>in</strong> Australiato serve Asia-Pacific markets through a major acquisition;expand<strong>in</strong>g <strong>in</strong>ternational coal trad<strong>in</strong>g activities; and pursu<strong>in</strong>gnew bus<strong>in</strong>ess <strong>in</strong> develop<strong>in</strong>g markets such as Ch<strong>in</strong>a.“The Global <strong>Energy</strong> Awards are one more barometerof our success as a lead<strong>in</strong>g <strong>in</strong>ternational energy company,”Greg reflects.Conveyor is written for employees and stakeholders and is producedby the Investor Relations & Corporate Communications Department.Visit <strong>Peabody</strong><strong>Energy</strong>.com and CoalCanDoThat.comThe use of the words “<strong>Peabody</strong>,” “the company” and “our” relate to <strong>Peabody</strong>,our subsidiaries and our majority-owned affiliates.Pr<strong>in</strong>ted on recycled paper.2|Conveyor Fourth Quarter 2008Framed by a glitter<strong>in</strong>g backdrop, Chairman and Chief Executive Officer Greg Boyce and President and Chief Commercial OfficerRick Navarre hold <strong>Peabody</strong> <strong>Energy</strong>’s dual honors at the 10th Annual Global <strong>Energy</strong> Awards.“These honors say that we have susta<strong>in</strong>ed a legacy of<strong>in</strong>novation, leadership and superior performance. They saywe are advanc<strong>in</strong>g clean coal technologies. And they saythat <strong>Peabody</strong> is help<strong>in</strong>g to meet the challenge of the 21stCentury: fuel<strong>in</strong>g an energy-short world. I thank <strong>Peabody</strong>’s7,000 employees around the world for our success <strong>in</strong>expand<strong>in</strong>g globally and sett<strong>in</strong>g new f<strong>in</strong>ancial records.”<strong>Peabody</strong> <strong>Energy</strong>701 Market StreetSt. Louis, MO 63101-1826Phone: 314-342-3400Fax: 314-342-7799Conveyor@<strong>Peabody</strong><strong>Energy</strong>.com<strong>Peabody</strong> <strong>Energy</strong> (NYSE: BTU) isan Equal Opportunity Employer.Copyright © 2008 <strong>Peabody</strong> <strong>Energy</strong>Susta<strong>in</strong>ability took center stage at this year’s ceremony,which attracted an array of 500 top executives from morethan two dozen nations. Honorees are selected from nearly200 entrants by a global panel of energy leaders, <strong>in</strong>clud<strong>in</strong>gformer regulators, heads of major energy companies, lead<strong>in</strong>gacademics and <strong>in</strong>ternational energy experts.“This recognition by the Global <strong>Energy</strong> organizationis a tribute to <strong>Peabody</strong>’s vision for long-term growth,”says President and Chief Commercial Officer Rick Navarre.“We became the global leader by anticipat<strong>in</strong>g enormousgrowth <strong>in</strong> energy demand and position<strong>in</strong>g our companyto meet the need. Together, we have built a world-classorganization that is advanc<strong>in</strong>g the future of energy onan <strong>in</strong>ternational stage.”<strong>Peabody</strong>’s Global <strong>Energy</strong> awards jo<strong>in</strong> more than40 safety, environmental and corporate honors thecompany has earned with<strong>in</strong> the past year. <strong>Peabody</strong>also is ranked first <strong>in</strong> the m<strong>in</strong><strong>in</strong>g and crude oil sector<strong>in</strong> Fortune Magaz<strong>in</strong>e’s list<strong>in</strong>g of the “Most AdmiredCompanies” and holds the number-one position <strong>in</strong>all categories.

Safety... A Way of LifeA Backhoe, a Beauty and a Bright Idea at Kayenta M<strong>in</strong>eQuick quiz: What do a backhoe, a beauty queen anda bright idea at <strong>Peabody</strong>’s Kayenta M<strong>in</strong>e <strong>in</strong> Arizonahave <strong>in</strong> common?The answer: an <strong>in</strong>ventive safety <strong>in</strong>itiative, a first-placetrophy <strong>in</strong> the Southwest Region’s annual Safety InnovationsAward Competition and a way to support an <strong>in</strong>stitution <strong>in</strong>Navajo cultural life.Kayenta’s safety success story began when the m<strong>in</strong>e’sbackhoe crew approached managers with an idea foranother exit from the two-and-a-half-story load<strong>in</strong>g mach<strong>in</strong>e.In the event of an emergency, the exit would enable themach<strong>in</strong>e’s operator to escape without hav<strong>in</strong>g to lower aladder from the eng<strong>in</strong>e room.“The second shift heavy ma<strong>in</strong>tenance crew startedlook<strong>in</strong>g at different exit strategies us<strong>in</strong>g ropes and ladders,”says Ma<strong>in</strong>tenance Supervisor Jeff Shiflett.“Based on the concept of an extension ladder,they designed, built and <strong>in</strong>stalled their own solution:an emergency exit that was easy to access and operate.”Once f<strong>in</strong>ished, another task awaited. The ma<strong>in</strong>tenanceteam set out to create an <strong>in</strong>genious secondary emergencyexit by <strong>in</strong>stall<strong>in</strong>g a h<strong>in</strong>ged hatch <strong>in</strong> the catwalk near theoperator’s cab. The hatch can be lifted and is attached to atwo-section ladder. With the pull of a p<strong>in</strong>, the ladder swiftlyextends to the ground, provid<strong>in</strong>g a rapid, safe departure route.“The operator’s cab is about two stories from the ground,so we needed to f<strong>in</strong>d an escape method that would work over adistance,” says Kayenta’s Director of Production Gregg Kitchen.“In an emergency stop situation, the secondary escape laddercan adjust to vary<strong>in</strong>g terra<strong>in</strong> up to 16 feet from the ground.”Submitted by the m<strong>in</strong>e’s safety department, the projectwon the Southwest Safety Innovations Award and $1,000that could be donated to the charity of the team’s choice. Thecompetition was created to encourage a culture of safety andSugar Ridge Achieves ‘Sweet Success’ <strong>in</strong> StewardshipIt’s a sweet life on Sugar Ridge, nearly 1,100 acresof highly productive reclaimed Indiana farmland at<strong>Peabody</strong>’s Miller Creek operation. The U.S. Department ofthe Interior recognized Sugar Ridge with the 2008 NationalAward for Excellence <strong>in</strong> Surface M<strong>in</strong>e Reclamation andprovided a special commendation for community outreach.Together the honors add up to a sweet victory for employeesand come on the heels of more than 40 awards for stewardshipand safety <strong>Peabody</strong> has earned <strong>in</strong> the past two years.U.S. Office of Surface M<strong>in</strong><strong>in</strong>g Director Brent Wahlquistpraised <strong>Peabody</strong> employees for best practices thatachieve both flourish<strong>in</strong>g farmland and a strongrelationship with area neighbors: “The accomplishmentsat Miller Creek M<strong>in</strong>e – Sugar Ridge, serve as an endur<strong>in</strong>grem<strong>in</strong>der of successful coal m<strong>in</strong>e reclamation alongwith the importance of early community <strong>in</strong>volvement<strong>in</strong> plann<strong>in</strong>g operations.”Located five miles north of Clay City, Ind., SugarRidge produced 3.7 million tons of coal over a six-yearperiod. Creat<strong>in</strong>g 84 percent prime farmland over the samesurface area required <strong>in</strong>tense attention to soil quality.enhance community relationships through a giv<strong>in</strong>g program.Enter the beauty queen: Kayenta selected the MissNavajo Nation Program to receive the funds. For more than50 years, the pageant has crowned young Navajo women,who are charged with preserv<strong>in</strong>g Navajo traditions andact<strong>in</strong>g as goodwill ambassadors for the nation.Jonathea Tso, Miss Navajo Nation for 2007 and 2008, wasa guest at a luncheon hosted by the m<strong>in</strong>e this summer andaccepted the check for $1,000. The Dartmouth graduate<strong>Peabody</strong> Achieves 3Q Safety Record<strong>Peabody</strong> <strong>Energy</strong> has achieved the safest fourconsecutive quarters <strong>in</strong> the company’s 125-year history,report<strong>in</strong>g an overall U.S. safety rate of 1.70 for the year andoutperform<strong>in</strong>g the <strong>in</strong>dustry average by over 60 percent, basedon the latest prelim<strong>in</strong>ary <strong>in</strong>dustry data. Our Australia m<strong>in</strong>esmarked a 26 percent improvement over the prior year, andFarmersburg, Ind., <strong>Peabody</strong> <strong>Energy</strong> Midwest, also achieveda perfect annual safety record.Employees’ record-break<strong>in</strong>g safety results build on pastprogress. Consider the two <strong>Peabody</strong> President’s awardw<strong>in</strong>ners from the previous year: the Vik<strong>in</strong>g and Franciscounderground m<strong>in</strong>es <strong>in</strong> Indiana. The Vik<strong>in</strong>g surface operationcompleted 2007 with zero reportable <strong>in</strong>cidents. By the firstquarter of 2008, the m<strong>in</strong>e capped more than four consecutiveyears and 1.3 million hours without a s<strong>in</strong>gle reportable <strong>in</strong>cident.Employees at the Francisco Underground M<strong>in</strong>e achieved thebest underground safety record <strong>in</strong> <strong>Peabody</strong>’s history, literallyhalv<strong>in</strong>g their <strong>in</strong>cident rate for three consecutive years. Thanksto past President’s Award w<strong>in</strong>ners and the operationsearn<strong>in</strong>g that dist<strong>in</strong>ction today, <strong>Peabody</strong> cont<strong>in</strong>ues to approachthe company’s ultimate goal of zero <strong>in</strong>cidents.That’s why, before m<strong>in</strong><strong>in</strong>g began, the team considered howto optimize soil handl<strong>in</strong>g with available equipment.Soil sampl<strong>in</strong>g revealed that, <strong>in</strong> addition to the one footof rich topsoil, the entire top 10 feet, or two layers, of subsoilwas desirable for plant<strong>in</strong>g. So, the team took the extra stepof add<strong>in</strong>g two layers of subsoil to graded overburden.“With a little additional plann<strong>in</strong>g on the front end and atm<strong>in</strong>imal extra cost, we were able to produce a benefit wellbeyond what was required by regulation,” expla<strong>in</strong>s Ken Rogers,Reclamation Manager. In fact, the Indiana Society of M<strong>in</strong><strong>in</strong>gand Reclamation cited Sugar Ridge’s success when honor<strong>in</strong>gKen earlier this year for <strong>in</strong>novative practices <strong>in</strong> stewardship.Miller Creek M<strong>in</strong>e Manager Matt Ubelhor believesthat attention to such details as proper soil replacementand handl<strong>in</strong>g techniques resulted <strong>in</strong> a highly successfulreclamation effort. “We used low ground-pressure dozerswith wider tracks to spread the topsoil and limited use ofvehicles with tires over the area,” he says. “Those types ofadjustments add up to success.”He cites crop yields as evidence of the team’seffective soil handl<strong>in</strong>g. Despite a drought <strong>in</strong> 2007 andnoted that she had many ties to the Kayenta community and thather mother was a former employee of the Black Mesa M<strong>in</strong>e.“The Safety Innovation program is another way we canencourage out-of-the-box th<strong>in</strong>k<strong>in</strong>g about safety,” says BillBeaver, Southwest Operations Director of Safety and thearchitect of the competition. “It makes the m<strong>in</strong>e site a saferplace to work and our community a better place to live.”The safety teams at <strong>Peabody</strong>’s Francisco Underground M<strong>in</strong>e(top) and Vik<strong>in</strong>g M<strong>in</strong>e (bottom) proudly display their President’sAward trophies alongside President and Chief CommercialOfficer Rick Navarre and other executives. They jo<strong>in</strong> hundredsof employees who every day br<strong>in</strong>g <strong>Peabody</strong> closer to ourultimate vision of zero <strong>in</strong>cidents.an extremely wet spr<strong>in</strong>g and early summer <strong>in</strong> 2008, theSugar Ridge reclamation project is on track to meet orover-comply with pre-m<strong>in</strong><strong>in</strong>g target yields <strong>in</strong> three outof five years to achieve a timely bond release.The team’s outreach to local residents also yieldedresults. As a member of the Indiana Prime Farmland Team,Miller Creek and other m<strong>in</strong>es <strong>in</strong> <strong>Peabody</strong>’s MidwestGroup have hosted field days to <strong>in</strong>form and educateneighbor<strong>in</strong>g local farmers, regulators, university researchersand equipment manufacturers about m<strong>in</strong><strong>in</strong>g and reclamationand <strong>Peabody</strong>’s mission “to return the land to a conditionequal to or better than we found it.”Neighbor<strong>in</strong>g surface landowners also have participated<strong>in</strong> reclamation plann<strong>in</strong>g <strong>in</strong> visible ways, work<strong>in</strong>g cooperativelyto devise five water impoundments rang<strong>in</strong>g from eightto 26 acres that will be used for livestock water<strong>in</strong>g, fish<strong>in</strong>gand recreation.“People have built docks and put pontoon boats andsailboats <strong>in</strong> the water,” says Ken. “Work<strong>in</strong>g together, thiscommunity has created a legacy of stewardship that will lastfor generations.”Surface Super<strong>in</strong>tendent Guy Matt<strong>in</strong>gly (left) and Eng<strong>in</strong>eer<strong>in</strong>gManager Lonnie Nelson (right) are surrounded by nearly 1,100acres of highly productive reclaimed farmland at Vik<strong>in</strong>g – SugarRidge <strong>in</strong> South Central Indiana. The land has produced corn,soybean, wheat and alfalfa yields that have equaled orsurpassed pre-m<strong>in</strong><strong>in</strong>g harvests.Conveyor Fourth Quarter 2008|3

12 5 years of<strong>in</strong>nvFor 125 years, hundreds of <strong>Peabody</strong> employees have challenged conventional wisdomand devised better ways to do bus<strong>in</strong>ess. In ways large and small, they’ve reshaped theway coal is m<strong>in</strong>ed, and <strong>in</strong> the process transformed <strong>Peabody</strong> <strong>in</strong>to one of the most <strong>in</strong>novativecompanies <strong>in</strong> the <strong>in</strong>dustry. Here are some of their stories:Keep<strong>in</strong>g Mach<strong>in</strong>es on the MendLong before m<strong>in</strong><strong>in</strong>g mach<strong>in</strong>ery was equipped withself-diagnos<strong>in</strong>g computers, <strong>Peabody</strong>’s Ill<strong>in</strong>oisoperations developed a predictive ma<strong>in</strong>tenanceprogram <strong>in</strong> 1983 that prevented breakdowns andextended the life of the company’s mach<strong>in</strong>ery. The<strong>in</strong>novative <strong>in</strong>itiative enlisted senior project eng<strong>in</strong>eersto carefully monitor mach<strong>in</strong>e vibration levels todetect impend<strong>in</strong>g breakdowns before they occurred.The process allowed repairs to be scheduled moreefficiently with less disruption to the productioncycle. Modeled after <strong>in</strong>itiatives at the NationalAeronautics and Space Adm<strong>in</strong>istration and theU.S. Navy, it was the only contemporary programof its k<strong>in</strong>d <strong>in</strong> the coal <strong>in</strong>dustry.Ripp<strong>in</strong>g <strong>in</strong>to ReclamationAny farm hand knows loose soil leads to better cropyields. So, when <strong>Peabody</strong> reclamationists <strong>in</strong> Ill<strong>in</strong>oisand Kentucky set out to reclaim prime farmland, theylooked for ways to loosen earth that had been heavilycompacted by m<strong>in</strong><strong>in</strong>g activity. They needed a till<strong>in</strong>gdevice that was economical to operate, convenientto use and adjustable to depths of almost three feet.F<strong>in</strong>d<strong>in</strong>g noth<strong>in</strong>g that met these criteria, the teamdesigned the Vibrat<strong>in</strong>g Deep Ripper. The <strong>in</strong>timidat<strong>in</strong>gname is apt. As the ripper is pulled beh<strong>in</strong>d a farmtractor, two large “teeth,” each conta<strong>in</strong><strong>in</strong>g threesmall hydraulic motors, penetrate the ground andloosen the soil. Patented <strong>in</strong> 1989, the device hasbeen ripp<strong>in</strong>g its way to better farm<strong>in</strong>g results acrossthe United States.Go<strong>in</strong>g the Extra Air MileAfter a damaged dragl<strong>in</strong>e boom temporarily idled itsMoura M<strong>in</strong>e, <strong>Peabody</strong> devised an <strong>in</strong>genious approachto gett<strong>in</strong>g the Australian operation back to work <strong>in</strong>1971. After crunch<strong>in</strong>g some numbers, <strong>Peabody</strong>’splanners concluded that disassembl<strong>in</strong>g a boom <strong>in</strong>the United States and shipp<strong>in</strong>g it more than halfwayaround the world by air was less costly than allow<strong>in</strong>gthe m<strong>in</strong>e to wait months while a replacement boomwas constructed <strong>in</strong> Australia. Sure, the boom couldbe recreated for about $375,000, while the airfreightalone for a boom would run about $390,000. Still,every day the mach<strong>in</strong>e was out of commissionrepresented thousands of tons of unsold coal.The result was one of the largest and longestairlifts of fabricated steel ever organized. Sevenchartered American Airl<strong>in</strong>es and Pan AmericanAirl<strong>in</strong>es flights were converted to carry 37-foot steelbeams and associated parts from St. Louis, Mo.,to Queensland, Australia, where the boom wassuccessfully reassembled.ApprovedInvit<strong>in</strong>g New IdeasMost large bus<strong>in</strong>esses can claim some patents,but <strong>Peabody</strong> has racked up 32 s<strong>in</strong>ce 1976.Virtually all <strong>in</strong>volve an <strong>in</strong>dividual or group ofemployees seek<strong>in</strong>g a better, faster or moreeconomical way of work<strong>in</strong>g. Several of the earliestpatents were for processes for produc<strong>in</strong>g chemicalcoke, low-temperature coal tars and coal-basedpav<strong>in</strong>g b<strong>in</strong>ders and have s<strong>in</strong>ce been licensed toother companies. Other bright ideas had practicalapplications at m<strong>in</strong>e sites, <strong>in</strong>clud<strong>in</strong>g a lock<strong>in</strong>gapparatus for a trolley-type electrical connector,a tool for <strong>in</strong>stall<strong>in</strong>g cutt<strong>in</strong>g blades on graders, adevice used to move electrically powered m<strong>in</strong><strong>in</strong>gequipment, a conveyor belt cleaner and a noisesuppress<strong>in</strong>g <strong>in</strong>take for ventilation fans. And everypatent certificate testifies to a culture of <strong>in</strong>novationthat cont<strong>in</strong>ues to keep <strong>Peabody</strong> strong <strong>in</strong> the21st Century.4|Conveyor Fourth Quarter 2008

ationat peabodyThe sun rises at <strong>Peabody</strong>’s North Antelope Rochelle M<strong>in</strong>e <strong>in</strong>Wyom<strong>in</strong>g. Every day is a new opportunity to <strong>in</strong>novate.Becom<strong>in</strong>g a Power Trad<strong>in</strong>g PioneerThere were high-fives all around <strong>Peabody</strong> headquarters<strong>in</strong> 1997 after the successful acquisition ofCitizens Power, the nation’s first licensed powermarketer and a pioneer <strong>in</strong> the complex world ofelectricity trad<strong>in</strong>g. Citizens brought strength andexpertise <strong>in</strong> electricity purchase agreements, riskmanagement and electricity asset restructur<strong>in</strong>g to<strong>Peabody</strong>. Today, <strong>Peabody</strong>’s expanded <strong>in</strong>ternationaltrad<strong>in</strong>g platform offers customers a one-stop sales,trad<strong>in</strong>g and transportation network that worksaround the clock, around the world. The companycurrently trades coal on five cont<strong>in</strong>ents throughoffices <strong>in</strong> the United States, the United K<strong>in</strong>gdomand Ch<strong>in</strong>a.PIC-k<strong>in</strong>g a Better WayAnyone faced with an impenetrable <strong>in</strong>structionmanual can sympathize with Ma<strong>in</strong>tenance InstructorVern Evans and Ma<strong>in</strong>tenance Supervisor GeorgeHeid<strong>in</strong>ger. The pair were perplexed by the controlpanels on new shuttle cars delivered to the Marissa,Ill., underground m<strong>in</strong>e where they worked. Thecomb<strong>in</strong>ation of buttons and gears were simply toocomplex to troubleshoot. So they designed asimpler system us<strong>in</strong>g off-the-shelf parts. Dubbedthe <strong>Peabody</strong> In-house Controller – or PIC – thestreaml<strong>in</strong>ed panels operated like a dream andearned a patent <strong>in</strong> 1989.Better<strong>in</strong>g the Roof BoltF<strong>in</strong>d<strong>in</strong>g <strong>in</strong>ventive solutions was someth<strong>in</strong>g of aspecialty for Guy McDowell, a roof bolt specialistat <strong>Peabody</strong>’s Camp Complex <strong>in</strong> Kentucky. Perhapsthat’s why Guy was charged with identify<strong>in</strong>g thebest bolt to hold a shale roof stable. When he couldnot f<strong>in</strong>d a bolt manufacturer that fit the bill, he<strong>in</strong>vented a new bolt and nut, both with left-handedthreads. The bottom of Guy’s bolt was “swedged”or bent to prevent the large nut from shift<strong>in</strong>g.In addition, he devised a solid support system tofix his bolts <strong>in</strong> place. After each hole was drilled <strong>in</strong>a m<strong>in</strong>e roof, fast- and slower-sett<strong>in</strong>g res<strong>in</strong> packetswere forced <strong>in</strong>to the hole. As the bolt spun to theend, the packets were broken, releas<strong>in</strong>g res<strong>in</strong> toharden around the bolt. Known <strong>in</strong> the <strong>in</strong>dustry asthe McDowell bolt, the <strong>in</strong>vention has receivedseveral patents.Rid<strong>in</strong>g the Rails to Greater EfficiencyWith a roar, the unit tra<strong>in</strong> shudders to life, bear<strong>in</strong>ghundreds of tons of coal across miles of track withgather<strong>in</strong>g speed. Every day, this scene is repeatedat m<strong>in</strong>es around the globe, serv<strong>in</strong>g as a clatter<strong>in</strong>gtribute to another visionary concept from <strong>Peabody</strong>.As the company’s President and Chief ExecutiveOfficer, Merl C. Kelce determ<strong>in</strong>ed that a tra<strong>in</strong> carry<strong>in</strong>g100 cars each with a m<strong>in</strong>imum capacity of 100 tonscould save time and money by mov<strong>in</strong>g exclusivelybetween a m<strong>in</strong>e and its customer. The result wasthe first unit tra<strong>in</strong>, one of the most transformativeideas <strong>in</strong> m<strong>in</strong><strong>in</strong>g dur<strong>in</strong>g the late 20th Century.Because Merl’s unit tra<strong>in</strong>s did not idle <strong>in</strong> rail yardsto be unloaded like typical tra<strong>in</strong>s, they dramatically<strong>in</strong>creased the speed and efficiency of coal deliveries.The solution enabled <strong>Peabody</strong> to keep pace withsoar<strong>in</strong>g coal demand dur<strong>in</strong>g and <strong>in</strong>spired imitatorsthroughout the <strong>in</strong>dustry.Conveyor Fourth Quarter 2008|5

Queensland <strong>Project</strong> Highlights <strong>Peabody</strong>’s Commitment to Clean <strong>Energy</strong>his is a momentous occasion... <strong>Project</strong>s such as“Tthe one we are celebrat<strong>in</strong>g today illustrate that weas a nation have the capacity, <strong>in</strong> partnership with the privatesector, to actually put <strong>in</strong> place [coal-based] solutions that aregood for the economy, good for the environment and... goodfor the global community.”Mart<strong>in</strong> Ferguson, Australian Federal M<strong>in</strong>ister forResources and <strong>Energy</strong>, spoke these powerful words at aceremony <strong>in</strong> Biloela, Queensland, to celebrate the start ofconstruction on the Callide A Oxyfuel demonstration project,the world’s first pilot of Oxyfuel clean coal technology. As afound<strong>in</strong>g member of the Australian COAL21 Fund, <strong>Peabody</strong>is provid<strong>in</strong>g critical f<strong>in</strong>ancial support to the project, whichwill ultimately reduce emissions by up to 90 percent.Oxyfuel technology can be retrofitted to exist<strong>in</strong>gequipment, enabl<strong>in</strong>g coal-fueled boilers to burn coal <strong>in</strong> amixture of oxygen and re-circulated flue gases, rather thanair, and creat<strong>in</strong>g a concentrated stream of carbon dioxidethat can be more easily captured, transported and eventuallystored <strong>in</strong> nearby geological formations.The COAL21 Fund made the largest s<strong>in</strong>gle contributionto the Oxyfuel <strong>in</strong>itiative, donat<strong>in</strong>g A$68 million. The Australianand Queensland governments also committed A$50 millionPictured from left to right while tour<strong>in</strong>g the Callide A turb<strong>in</strong>e floorare Geoff Wilson, Queensland M<strong>in</strong>ister for M<strong>in</strong>es and <strong>Energy</strong>,Yoshifumi Matsumura, Japan’s Vice M<strong>in</strong>ister of Economy,Trade and Industry and Mart<strong>in</strong> Ferguson, Australian M<strong>in</strong>isterfor Resources and <strong>Energy</strong>.Oxyfuel-enabled boilers burn coal <strong>in</strong> a mix of oxygen and re-circulated flue gasses, produc<strong>in</strong>g energy while provid<strong>in</strong>g a concentrated streamof carbon dioxide that can be more easily captured and stored.and A$35 million, respectively. The Callide A project will beg<strong>in</strong>generat<strong>in</strong>g electricity us<strong>in</strong>g Oxyfuel technology <strong>in</strong> 2011.Julian Thornton, Manag<strong>in</strong>g Director of <strong>Peabody</strong> <strong>Energy</strong>Australia, believes the Oxyfuel project will have far-reach<strong>in</strong>gbenefits: “The Callide A demonstration will prove thesuitability of this technology for both exist<strong>in</strong>g and newcoal-fueled power stations around the world. It’s just one ofmany <strong>in</strong>itiatives we are pursu<strong>in</strong>g through the COAL21 Fundto commercialize advanced clean coal technologies andaddress climate change.”Dur<strong>in</strong>g the com<strong>in</strong>g decade, the COAL21 Fund will spendapproximately A$1 billion to support a series of carboncapture and storage pilot projects with the objective ofdevelop<strong>in</strong>g a suite of low emissions technologies forcommercial deployment by 2017. <strong>Peabody</strong> is the globalleader <strong>in</strong> clean coal solutions, advanc<strong>in</strong>g signature projectsaround the world to develop near-zero emission technologies,“It’s just one of many <strong>in</strong>itiativeswe are pursu<strong>in</strong>g through theCOAL21 Fund to commercializeadvanced clean coal technologiesand address climate change.”Julian ThorntonManag<strong>in</strong>g Director of <strong>Peabody</strong> <strong>Energy</strong> Australiafrom GreenGen <strong>in</strong> Ch<strong>in</strong>a to FutureGen <strong>in</strong> the United States tonumerous <strong>in</strong>itiatives <strong>in</strong> Australia.Says Julian: “<strong>Peabody</strong> shares Australians’ focus on driv<strong>in</strong>gcont<strong>in</strong>uous environmental improvement and carbon managementon a global scale. Together we can meet the needs of anenergy-short world.”P3: Achiev<strong>in</strong>g <strong>Peabody</strong> Peak PerformanceSourc<strong>in</strong>g COE Uses Big Th<strong>in</strong>k<strong>in</strong>g to Achieve Big Sav<strong>in</strong>gsake your time, and th<strong>in</strong>k big.”“T That’s the approach <strong>Peabody</strong>’s StrategicCommodities team takes to tackle cost reduction projects,accord<strong>in</strong>g to Strategic Commodities Director Jason Ryan.As members of the P3 Sourc<strong>in</strong>g Center of Excellence(COE), the commodities team works with operationscounterparts as part of a comprehensive nationwide processto analyze spend<strong>in</strong>g and achieve sav<strong>in</strong>gs on purchasesthat range from roof bolts to diesel fuel. Among the moreimpressive results of the effort? More than $2 million <strong>in</strong>lower diesel fuel costs across the company this year alone.“Results are directly correlated to <strong>in</strong>put. The moreresources you have, the more thorough an analysis youcan do,” Jason adds. “The Sourc<strong>in</strong>g COE br<strong>in</strong>gs togetherthe people and processes it takes to go deeper <strong>in</strong>to thenumbers. By broaden<strong>in</strong>g our bandwidth, we identify moresupply options <strong>in</strong> less time.”The Sourc<strong>in</strong>g COE collaborates with numerous teamsthroughout <strong>Peabody</strong> to deliver the lowest total cost and highestvalue from the goods and services <strong>Peabody</strong> purchases fromthird-party suppliers. The company’s top operat<strong>in</strong>g expenseis fuel. When several agreements came up for renewal, thetim<strong>in</strong>g was right for an all-out review of options for sourc<strong>in</strong>gdiesel <strong>in</strong> all of its U.S. regions.The COE went far beyond anyth<strong>in</strong>g attempted <strong>in</strong> recentmemory, perform<strong>in</strong>g exhaustive evaluations and develop<strong>in</strong>gcomplex supply scenarios that could be offered to prospectivevendors. Employees also met non-traditional diesel producerswith ref<strong>in</strong>eries outside <strong>Peabody</strong>’s normal supply regions.In an unusual move, the team even approached theBurl<strong>in</strong>gton Northern Santa Fe and the Union Pacific railroads,explor<strong>in</strong>g the feasibility of rail<strong>in</strong>g fuel from Alberta, Canada,to Wyom<strong>in</strong>g and from Louisiana to Indiana.“We learned the ‘what ifs,’” expla<strong>in</strong>s Chris Hagedorn,Supply Cha<strong>in</strong> Management Vice President. “Sourc<strong>in</strong>g isabout more than be<strong>in</strong>g a tough negotiator. It’s abouthav<strong>in</strong>g the knowledge to negotiate effectively... com<strong>in</strong>gto the table prepared with the technical acumen and thecompetitive scenarios that result <strong>in</strong> the best deal.”<strong>Peabody</strong>’s Sourc<strong>in</strong>g COE has saved more than $2 million<strong>in</strong> diesel purchases annually. The team is work<strong>in</strong>g on multiple<strong>in</strong>itiatives to deliver more bang for <strong>Peabody</strong>’s buck.Every penny counts. At today’s prices, 85 percent of thecost of a gallon of diesel is the cost of crude oil. Only a fractionof the rema<strong>in</strong><strong>in</strong>g 15 percent is negotiable. So, each potentialsupplier was encouraged to evaluate even long shot supplyscenarios. Persistence paid off, deepen<strong>in</strong>g <strong>Peabody</strong>’s wellof potential vendors. In the end, the team implemented anumber of contract structure changes <strong>in</strong> each region and<strong>in</strong>troduced a new vendor <strong>in</strong> the Powder River Bas<strong>in</strong> to servethe North Antelope Rochelle M<strong>in</strong>e.Engagement between Supply Cha<strong>in</strong> and Operationscont<strong>in</strong>ues to serve an essential role <strong>in</strong> help<strong>in</strong>g <strong>Peabody</strong> delivermore bang for the buck. Each COE project features an advisoryteam of m<strong>in</strong>e representatives from every region who are <strong>in</strong>regular communication by phone and <strong>in</strong> person with the COEteam. As a result, people from many areas of the organizationweigh the costs and benefits of purchas<strong>in</strong>g proposals. And bydocument<strong>in</strong>g recommendations, vendor histories and qualityrequirements as a team, the COE is establish<strong>in</strong>g valuablebenchmarks for future negotiations.Admittedly, the COE team says its fuel <strong>in</strong>itiative hasfar to go. Just <strong>in</strong> the area of diesel, additional analysesand negotiations are planned <strong>in</strong>to 2009. And, as the teamcompletes each deal, another effort beg<strong>in</strong>s downstreamto monitor product performance and cost.“We’re pleased with the changes we’ve been able tomake,” adds Matt Bocklage, the P3 Sourc<strong>in</strong>g COE team Fuel<strong>Project</strong> Leader. “We talked to more than the usual suspects.We found sav<strong>in</strong>gs <strong>in</strong> fractions of pennies. And we are deliver<strong>in</strong>gsecurity of supply. We are gett<strong>in</strong>g the deal done.”6|Conveyor Fourth Quarter 2008

PEABODY’SHOMETOWNHEROESLike Mother,Like DaughterAt <strong>Peabody</strong> locations around the world, thousands ofemployees give back to their communities, demonstrat<strong>in</strong>g thespirit of <strong>Peabody</strong>’s mission to “power economic prosperityand result <strong>in</strong> a better quality of life.” In this issue of Conveyor,we recognize a remarkable mother and daughter who gavethe gift of life. As Conveyor celebrates <strong>Peabody</strong>’s “HometownHeroes,” we encourage you to share your stories. Tips can beemailed to Conveyor@<strong>Peabody</strong><strong>Energy</strong>.com.Thanks to the ultimate gift – the gift of life – the 2008holiday season will always have a special mean<strong>in</strong>g forCynthia Trull. After Cynthia’s kidneys failed, she was barelysurviv<strong>in</strong>g. That’s when her sister, Twentymile Adm<strong>in</strong>istrativeAssistant Jennifer Holmlund, offered to donate a kidney.It wasn’t the first time a <strong>Peabody</strong> employee had sacrificedto save Cynthia’s life. Sixteen years ago, when she firstexperienced kidney failure dur<strong>in</strong>g a pregnancy, Cynthia’smother, Twentymile Information Technology Manager PhyllisMoore, became the first generation of the family to give akidney, transform<strong>in</strong>g a white-knuckle medical emergency <strong>in</strong>toa lesson <strong>in</strong> love.Because of her experience, Phyllis believes Jennifer’sdecision to donate came naturally: “She’s always beenthe protective big sister. She’s always looked out for theyounger kids.”After qualify<strong>in</strong>g as a suitable donor, months ofpreparation followed. Jennifer underwent extensivemedical test<strong>in</strong>g, and doctors <strong>in</strong>sisted that she shapeup for the transplant by los<strong>in</strong>g weight. So Jenniferput herself on a health regimen that <strong>in</strong>cluded walk<strong>in</strong>g“She’s always been theprotective big sister.She’s always looked out forthe younger kids.”Phyllis MooreTwentymile Information Technology Managertwo to three miles a day and visit<strong>in</strong>g the gymwhen the weather grew cold.“I absolutely hate the gym,” Jenniferconfesses. By persever<strong>in</strong>g, she shed 47extra pounds.Few of Jennifer’s coworkers at Twentymilewere aware of her plans until recently, saysTwentymile Human Resources AssociateBonnie Hampton: “She came <strong>in</strong> to work everyday and was just as wonderful as ever. Shewas quiet about it right up until the surgery.”Jennifer did confide her <strong>in</strong>tention toher boss, Operations Group Executive WaltScheller. She describes his attitude as“just overly car<strong>in</strong>g.”Walt, <strong>in</strong> turn, was impressed withJennifer’s “selfless act of k<strong>in</strong>dness.”“It’s simply <strong>Peabody</strong>’s way to always dowhatever you can to help families,” he adds.As the date for her surgery approached<strong>in</strong> late June, Jennifer <strong>in</strong>formed her coworkersabout her plans. The support from theTwentymile team was overwhelm<strong>in</strong>g, shesays. “I can’t say enough about how wonderfulthey were.”Dur<strong>in</strong>g the summer, the sisters participated <strong>in</strong> oneof the more than 14,000 kidney transplants performedevery year. As <strong>in</strong> most of these cases, their operations –at the same time, <strong>in</strong> the same hospital – were freeof complications. Several employees pitched <strong>in</strong>to perform Jennifer’s work until her return from thetransplant procedure.“It’s not m<strong>in</strong>or surgery,” concedes Jennifer, whoserecovery was prolonged.She says now that she regrets only the few poundsshe rega<strong>in</strong>ed dur<strong>in</strong>g her post-surgery <strong>in</strong>activity. As for hermiss<strong>in</strong>g kidney, “I can’t tell it’s gone,” she says.Though she has needed some follow-up procedures,Cynthia says the transplant has left her “feel<strong>in</strong>g likebe<strong>in</strong>g reborn.”Cynthia Trull (above) has receivedthe gift of life twice fromTwentymile M<strong>in</strong>e employeesJennifer Holmlund (right) andPhyllis Moore (not pictured).“It’s simply <strong>Peabody</strong>’s wayto always do whatever youcan to help families.”Walt SchellerOperations Group Executive<strong>Energy</strong> replenished, she’s jo<strong>in</strong>ed a couple of Bible studygroups, stopped us<strong>in</strong>g handicapped park<strong>in</strong>g and returned toschool to become a dental assistant.Cynthia is enjoy<strong>in</strong>g her new lease on life. After yearsof be<strong>in</strong>g unable to travel long distances from her home<strong>in</strong> Boise, Idaho, Cynthia made plans to jo<strong>in</strong> her mother, sistersand their 94-year-old maternal grandmother <strong>in</strong> Colorado forChristmas. It must have been a holiday to remember.<strong>Peabody</strong> <strong>Pursues</strong> <strong>Gasification</strong> <strong>Project</strong> <strong>in</strong> Ch<strong>in</strong>acont<strong>in</strong>ued from page 1The m<strong>in</strong>e would supply the adjacent coal gasification plant,which could produce up to 1.3 million tons annually of methanolor equivalent fuel, as well as other chemicals. Jitong is preparedto help transport coal and coal-derived chemicals and fuelsfrom the plant through their railways and the Ch<strong>in</strong>ese nationalrail system to customers throughout Ch<strong>in</strong>a and beyond.For Mr. Su Nan, Vice Chairman of the Jitong board ofdirectors, each new ribbon of rail represents an <strong>in</strong>vestment<strong>in</strong> Ch<strong>in</strong>a’s energy future: “Eastern Inner Mongolia hasone-fifth the probable reserves <strong>in</strong> Inner Mongolia. It is oneof the large-scale bases <strong>in</strong> the 11th Five-Year Plan of Ch<strong>in</strong>aCoal Industry Development,” says Mr. Su. “We will putall our efforts <strong>in</strong>to our partnership with <strong>Peabody</strong>... andmake full use of our railway resources while be<strong>in</strong>g alignedwith the Ch<strong>in</strong>ese government policies.”Inner Mongolia rides along the curv<strong>in</strong>g northernboundary of Ch<strong>in</strong>a, neighbor<strong>in</strong>g the nation of Mongolia, theRussian border and the other prov<strong>in</strong>ces of Ch<strong>in</strong>a. One ofthe largest land masses with<strong>in</strong> Ch<strong>in</strong>a, the region is home to20 million people, a rich mixture of customs and languagesand approximately 230 billion short tons of coal.Develop<strong>in</strong>g such domestic coal resources and reduc<strong>in</strong>genergy imports has become a strategic priority for Ch<strong>in</strong>a’sgovernment. The nation is home to the world’s largestand fastest-grow<strong>in</strong>g coal market. The Ch<strong>in</strong>ese powerapproximately 70 percent of their electricity with coal,and <strong>in</strong> the past two years alone, Ch<strong>in</strong>a has added theequivalent of half of U.S. coal-fueled generat<strong>in</strong>g capacity.At the same time, Ch<strong>in</strong>a is also lead<strong>in</strong>g efforts to developclean coal technologies. For example, <strong>Peabody</strong> is the onlynon-Ch<strong>in</strong>ese partner <strong>in</strong> GreenGen, the nation’s centerpiececlimate <strong>in</strong>itiative to advance near-zero emissions coalfueledgeneration with hydrogen production and carboncapture and storage.“With coal seams rang<strong>in</strong>g from 25 to 175 meters <strong>in</strong>height, Ch<strong>in</strong>a’s Eastern Inner Mongolia is an ideal spotfor a large-scale surface m<strong>in</strong><strong>in</strong>g project,” says Tayeb Tahir,President of <strong>Peabody</strong> Ch<strong>in</strong>a.“This partnership comes just as Ch<strong>in</strong>a pursues energy<strong>in</strong>frastructure projects to benefit more of its people. Work<strong>in</strong>gtogether, we can build commercial clean coal solutions thatwill be available, deployable and affordable <strong>in</strong> Ch<strong>in</strong>a andthroughout the world.”The Executive Vice Chairman of the People’s Governmentof Inner Mongolia, Mr. Ren Yap<strong>in</strong>g, discusses the manyparallels between Wyom<strong>in</strong>g’s Powder River Bas<strong>in</strong> and hiscoal-rich region of Inner Mongolia with <strong>Peabody</strong> <strong>Energy</strong>Chief Executive Officer Greg Boyce.Conveyor Fourth Quarter 2008|7

watts upBurton M<strong>in</strong>e Turns P<strong>in</strong>k to FightBreast CancerThe Burton M<strong>in</strong>e’s mammoth Caterpillar 789C nowsh<strong>in</strong>es a lovely shade of pale p<strong>in</strong>k thanks to the m<strong>in</strong>e’sP<strong>in</strong>k Truck Campaign to fight breast cancer, the lead<strong>in</strong>gcause of cancer-related death <strong>in</strong> Australian women.Located <strong>in</strong> Queensland’s northern Bowen Bas<strong>in</strong>,Burton uses truck-and-shovel and terrace m<strong>in</strong><strong>in</strong>gtechniques to annually produce up to 3 million tons ofcok<strong>in</strong>g coal. For a full year, every load the p<strong>in</strong>k truckhauls will help the m<strong>in</strong>e reach its goal of rais<strong>in</strong>g about$30,000 for breast cancer research.<strong>Peabody</strong> <strong>Energy</strong>Australia has jo<strong>in</strong>edforces with Theiss,the m<strong>in</strong>e’s contractoperator, to supportthe m<strong>in</strong>e’scampaign. Theissis pay<strong>in</strong>g A$1.00for every cubic meter the p<strong>in</strong>k truck shifts from October2008 to October 2009. And <strong>Peabody</strong> is support<strong>in</strong>g a varietyof employee-driven activities to raise additional funds, fromauctions and community site visits to a special family day.<strong>Peabody</strong> is match<strong>in</strong>g 50 cents for every Australiandollar employees raise throughout the year. The campaignwill end on P<strong>in</strong>k Ribbon Day <strong>in</strong> October 2009, when Burtonwill present a donation to the Australian National BreastCancer Foundation.“This campaign demonstrates our commitment to thecare of women and their families,” says Ian McDonnell,Burton’s act<strong>in</strong>g General Manager. “It is our hope that theP<strong>in</strong>k Truck Campaign will help re<strong>in</strong>force the important roleof women <strong>in</strong> m<strong>in</strong><strong>in</strong>g and, most importantly, help fight adisease that affects so many people <strong>in</strong> our community.”<strong>Peabody</strong>’s Former HeadquartersBuild<strong>in</strong>g Becomes U.S. Landmark<strong>Peabody</strong> <strong>Energy</strong>’s former headquarters has been listedon the National Register of Historic Places. Constructed<strong>in</strong> 1957, the three-story Art Deco build<strong>in</strong>g at 301 NorthMemorial Drive <strong>in</strong> St. Louis, Mo., welcomed generationsof employees before the company relocated to its currentglobal headquarters <strong>in</strong> 1992. The Register is theUnited States’official list of culturalresources worthyof preservation and<strong>in</strong>cludes some ofthe most significantlocations <strong>in</strong>American history.<strong>Peabody</strong>’s 125 Year HistoryHeads HomeA commemorative history has been created and mailedto all employees to mark <strong>Peabody</strong>’s 125th anniversary.The 144-page hardbound volume celebrates the vision,dedication and drive of generations of employees around theworld. Today, <strong>Peabody</strong> is the world’s largest coal companyand cont<strong>in</strong>ues to set records<strong>in</strong> safety, environmentalstewardship and f<strong>in</strong>ancialperformance thanks to thehard work of a world-classworkforce. <strong>Peabody</strong> isproud to be 125 yearsstrong... and the companylooks forward to a brightfuture over the next125 years.The <strong>Energy</strong> Revolution Will BeBlogged…Clean coal technology is key to driv<strong>in</strong>g economic growth,environmental solutions and energy security. That’s themessage beh<strong>in</strong>d CoalCanDoThat.com, a new website andblog – or web log – dedicated to encourag<strong>in</strong>g an <strong>in</strong>formedconversation about clean coal. Anyone can jo<strong>in</strong> a communityof top experts <strong>in</strong> energy and economics who post thoughtfulcommentary, get up to speed on the latest energy headl<strong>in</strong>esand even listen to downloadable podcasts, or audio<strong>in</strong>terviews, about the vital choices ahead. That’s why72 percent of America’s op<strong>in</strong>ion leaders support the useof coal, accord<strong>in</strong>g to a recent poll from RT Strategies andAmerica Public.us. Visit CoalCanDoThat.com, and makeyour voice heard.Pillars of Leadership Provide the Path for “Next Gen” Leaderseadership starts with each one of us. As an“L employee of <strong>Peabody</strong>, you are your own Centerof Excellence.You are accountable for our success and foryour own personal growth. You can help susta<strong>in</strong> and growour competitive advantage.”Chairman and Chief Executive Officer Greg Boyce offeredthis advice to employees represent<strong>in</strong>g every region andthe corporate office at <strong>Peabody</strong>’s first Next GenerationLeaders Conference. The three-day gather<strong>in</strong>g <strong>in</strong> St. Louiswas organized to re<strong>in</strong>force a model for success before anaudience of young leaders <strong>in</strong> the Operations and ManagementAssociate programs. The event was so well-receivedthat organizers plan an encore <strong>in</strong> 2009.Throughout the conference, a coterie of topexecutives emphasized <strong>Peabody</strong>’s four leadership pillars:Operations and Management Associates listen raptly asExecutive Vice President and Chief Operat<strong>in</strong>g Officer Eric Fordprovides an overview of the company at the Next GenerationLeaders Conference. Eric jo<strong>in</strong>ed <strong>Peabody</strong> Chief Executive OfficerGreg Boyce and other lead<strong>in</strong>g executives <strong>in</strong> provid<strong>in</strong>g guidenceto <strong>Peabody</strong>’s newest leaders.<strong>in</strong>spiration, <strong>in</strong>novation, collaboration and execution.Effective leaders must <strong>in</strong>spire employees to perform attheir highest level; <strong>in</strong>novate through new processes,technologies and markets; collaborate <strong>in</strong> teams; and executeto achieve results. Numerous organized activities allowedparticipants to put these ideals <strong>in</strong>to action.“As we strive to build a workforce that can fuel oursuccess <strong>in</strong>to the 21st Century, it is critical that we provideopportunities for this next generation to feel connectedto <strong>Peabody</strong>’s culture and <strong>in</strong>vested <strong>in</strong> our mission, visionand values,” says event organizer and Director of TalentManagement Peggy Scott. “This conference is just oneamong many <strong>in</strong>itiatives we are work<strong>in</strong>g on to provideopportunities for professional growth for our leadership<strong>in</strong> the future.”colorful commentaryReaders share their comments about Conveyor’songo<strong>in</strong>g coverage of safety, performance, stewardshipand growth. Conveyor appreciates your feedback andlooks forward to more of your <strong>in</strong>put.Eugene MerrimanBickwell, Ind.The center spread “125 Years of Th<strong>in</strong>k<strong>in</strong>g Big” was very<strong>in</strong>terest<strong>in</strong>g and <strong>in</strong>formative. The pictures from the past tothe present were great.Amarjargal SharkhuuGillette, Wyo.The article on the science of carbon storage <strong>in</strong> Kentuckywas the most <strong>in</strong>terest<strong>in</strong>g of this [past] issue.Merle HendricksCamp Verde, Ariz.The Conveyor is so well-written and <strong>in</strong>formative we bought<strong>Peabody</strong> stock. Good po<strong>in</strong>ts: It has a good picture to pr<strong>in</strong>tratio, good graphics and photos, attention to safety, expla<strong>in</strong>sgreen solutions and highlights global growth. The historicalfoldout is beautiful and <strong>in</strong>formative. Hav<strong>in</strong>g worked at theKayenta M<strong>in</strong>e [<strong>in</strong> Arizona], I loved the article on the Navajoand Hopi scholarships. I liked the emphasis on good health.Bill StanleyRosiclare, Ill.Putt<strong>in</strong>g faces of employees with your articles is a great wayof lett<strong>in</strong>g people know it takes all of us as a team to get coalto customers. Conveyor did a great job on this.Gary HarnackGlenrock, Wyo.I would like to hear about the changes and additions that arego<strong>in</strong>g to be made. [Rich Carr’s Crew 4] set records <strong>in</strong> theamount of coal taken out and the amounts of coal hauled outon tra<strong>in</strong>s.Jacobey K. DavisRosiclare, Ill.I enjoyed the article “125 Years of Th<strong>in</strong>k<strong>in</strong>g Big.” Themach<strong>in</strong>es have come a long way from back <strong>in</strong> the day, butthere is more of a demand for coal, so you have no choicebut to make it more cost-efficient.8|Conveyor Fourth Quarter 2008