HAZET – Safety Spring Vice 4900

HAZET – Safety Spring Vice 4900

HAZET – Safety Spring Vice 4900

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

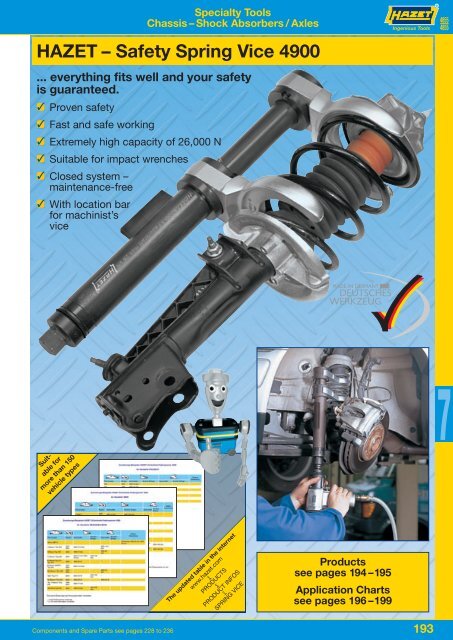

Proven safetyFast and safe workingExtremely high capacity of 26,000 NSuitable for impact wrenchesClosed system <strong>–</strong>maintenance-freeWith location barfor machinist’sviceSpecialty ToolsChassis <strong>–</strong> Shock Absorbers / Axles<strong>HAZET</strong> <strong>–</strong> <strong>Safety</strong> <strong>Spring</strong> <strong>Vice</strong> <strong>4900</strong>... everything fits well and your safetyis guaranteed.Ingenious Tools485548557Suitableformore than 150vehicle typesThe updated table in the internetwww.hazet.comîPRODUCTSîPRODUCT INFOSîSPRING VICEProductssee pages 194 <strong>–</strong>195Application Chartssee pages 196 <strong>–</strong>199Components and Spare Parts see pages 228 to 236 193

Ingenious ToolsSpecialty ToolsChassis <strong>–</strong> Shock Absorbers / Axles<strong>Safety</strong> <strong>Spring</strong> <strong>Vice</strong> <strong>–</strong> Basic ApplianceCZFor installing and removing the coil spring when changing shock absorbersLocation bar for machinist’s vice• Basic appliance <strong>–</strong> also suitable for new BMW 3-series andMERCEDES-BENZ C-Class, max. span 309 mm• High capacity of 26,000 N even under tough conditionsup to -20°C• Suitable for impact operation, e.g. <strong>HAZET</strong> 9012 MGin conjunction with impact socket <strong>HAZET</strong> 900 S-27or 900 S Lg-27• Closed system <strong>–</strong> maintenance-free!• Variable system due to easiliy replaceable tensioningjaws (DBGM <strong>–</strong> German registered utility model)• Plastic inserts for the protection of the lacqueredspring surfaces preventing coil damage due to corrosion.• With location bar for machinist’s vice• Proven safety• Tempered cylindrical and guiding tube• Forged and tempered tensioning jaws• European Patent applied, DBGM <strong>–</strong> German registered utility model1 4<strong>4900</strong>-2 A 077267<strong>Safety</strong> <strong>Spring</strong> <strong>Vice</strong>Spare PartsTensioning Jaws (Price per piece)(Application see above mentioned classification table)Tensioning Jaws (Price per piece)(Application see above mentioned classification table)1 t 4<strong>Safety</strong> Shearing Pin for <strong>4900</strong>-1<strong>4900</strong>-01 7 0561257Replacement set for <strong>Spring</strong> <strong>Vice</strong> <strong>4900</strong>-2consisting of: 5 straight pins and 2 O-rings<strong>4900</strong>-02/7 6 063437Spare part set for <strong>Spring</strong> <strong>Vice</strong> <strong>4900</strong>-1 A and -2 Aconsisting of 2 straight pins and 1 O-ring<strong>4900</strong>-02A/3 7 069415Tensioning Jaws (Price per piece)(Application see above mentioned classification table)1 4<strong>4900</strong>-12 059720Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-120 0611501 4<strong>4900</strong>-15 A 1214721 4<strong>4900</strong>-10 059706Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-100 0611361 4<strong>4900</strong>-13 0597371 4<strong>4900</strong>-16 062164Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-130 0611671 4<strong>4900</strong>-11 059713Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-110 0611431 4<strong>4900</strong>-14 A 0646491 4<strong>4900</strong>-17 062171194 Components and Spare Parts see pages 228 to 236

Specialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesIngenious Tools<strong>4900</strong><strong>4900</strong>Tensioning Jaws (Price per piece)(Application see above mentioned classification table)Tensioning Jaws (Price per piece)(Application see above mentioned classification table)Tensioning Jaws (Price per piece)(Application see above mentioned classification table)1 41 4<strong>4900</strong>-18 100378<strong>4900</strong>-24 062201Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-240 0610371 4<strong>4900</strong>-30 100514Plastic plugsfor the codification of the tensioning jawsas well as for the prevention of damageat the threads of the strut mounting<strong>4900</strong>-30/03 100507&1 41 4For driver’s cabin MB Actros (MP-1)<strong>4900</strong>-25 121670<strong>4900</strong>-19 085842Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-190 0861531 4<strong>4900</strong>-31 1380361 4&For driver’s cabin with steel springs MB-Actros (MP-1)<strong>4900</strong>-26 1216871 4<strong>4900</strong>-22 062188Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-220 0610131 41 4<strong>4900</strong>-33 1380437<strong>4900</strong>-28 100545Plastic plugsfor the codification of the tensioning jawsas well as for the prevention of damageat the threads of the strut mounting<strong>4900</strong>-28/06 1004841 4<strong>4900</strong>-34 1217311 4<strong>4900</strong>-23 062195Plastic <strong>Spring</strong> Protection Insert<strong>4900</strong>-230 061020Plastic <strong>Spring</strong> Protection InsertSpecial insert in conjunctionwith <strong>HAZET</strong> Tensioning Jaws <strong>4900</strong>-23and <strong>Safety</strong> <strong>Spring</strong> <strong>Vice</strong> <strong>4900</strong>-2 Afor the operation of the front axle springson BMW since 2001E 65: 735i, 745i, 730d, 740dE 66: 7<strong>4900</strong>-231 0889591 4<strong>4900</strong>-29 100538Plastic plugsfor the codification of the tensioning jawsas well as for the prevention of damageat the threads of the strut mounting<strong>4900</strong>-29/02 1275661 4<strong>4900</strong>-35 121212Components and Spare Parts see pages 228 to 236 195

Ingenious ToolsClassification examples:ALFA ROMEOSpecialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesFor more information see www.hazet.com in the internetTechnical modifications of the vehicle manufacturers are subject to change without notice<strong>–</strong> = no spring vice necessary* = no information available** = Use on BMW coil springs only in conjunction with the corresponding plastic spring protection inserts.BMW prescription: <strong>Spring</strong> vices must be operated with hand tools only!Alfa 156 <strong>4900</strong>-10 (2x) *Alfa 164 Super 1996 <strong>4900</strong>-13 (2x) *AUDI80 1989 <strong>4900</strong>-11 (2x) *100 Quattro <strong>4900</strong>-13 (2x) <strong>4900</strong>-11 12100C4 <strong>4900</strong>-13 (2x) <strong>4900</strong>-11 (2x)80B4 1992 <strong>4900</strong>-11 (2x) *A100 1991 <strong>4900</strong>-13 (2x) *A2 2000 <strong>4900</strong>-11 (2x) *A3 2000 <strong>4900</strong>-11 (2x) *A4 1996 <strong>4900</strong>-11 (2x) *A4 Vario 1996 <strong>4900</strong>-11 (2x) *A6 1996 <strong>4900</strong>-11 (2x) *A8 1996 <strong>4900</strong>-11 (2x) *BMWYear of Tensioning Plastic <strong>Spring</strong> Tensioning Plastic <strong>Spring</strong> FurtherType Construction Jaws Protection Inserts Jaws Protection Inserts Applications3 (E36) ** 1989-1998 <strong>4900</strong>-12 (2x) <strong>4900</strong>-120 (2x) *3 (E46) ** 1998- <strong>4900</strong>-22 24 <strong>4900</strong>-220 240 *3 (E90)** 2005- <strong>4900</strong>-22 24 <strong>4900</strong>-220 (1x) <strong>–</strong>5 (E34) ** 1994 <strong>4900</strong>-11 (2x) <strong>4900</strong>-110 (2x) <strong>–</strong>5 (E39) ** : 528i 1995-2000 <strong>4900</strong>-12 (2x) <strong>4900</strong>-120 (2x) *75 (E39) ** : 530i / 540i 1996- <strong>4900</strong>-23 (2x) <strong>4900</strong>-230 (2x) *5 (E60) ** 2004- <strong>4900</strong>-22 24 <strong>4900</strong>-220 (1x) -7 (E32) ** : 730i 1986-1994 <strong>4900</strong>-11 (2x) <strong>4900</strong>-110 (1x) <strong>–</strong>7 (E38) ** 1993-2000 <strong>4900</strong>-23 (2x) <strong>4900</strong>-230 (2x) *7 (E65) ** : 735i / 745i / 730d / 740d 2001- <strong>4900</strong>-23 (2x) <strong>4900</strong>-231 (2x) <strong>4900</strong>-19 (2x) <strong>4900</strong>-190 (2x)7 (E66) ** : 735Li / 745Li 2001- <strong>4900</strong>-23 (2x) <strong>4900</strong>-231 (2x) <strong>4900</strong>-19 (2x) <strong>4900</strong>-190 (2x)X3 (E83) 2006- <strong>4900</strong>-31 33Z3 ** 1996- <strong>4900</strong>-12 (2x) <strong>4900</strong>-120 (2x) *CHRYSLER300M (LH) <strong>4900</strong>-12 (2x) <strong>4900</strong>-11 (2x)Cherokee (XJ) <strong>4900</strong>-11 (2x) *Grand Cherokee (ZJ, ZG, WJ) <strong>4900</strong>-11 (2x) *Neon (PL) <strong>4900</strong>-12 (2x) <strong>4900</strong>-17 (2x)Stratus (JA/JX) <strong>4900</strong>-16 (2x) *Voyager (GS) <strong>4900</strong>-13 (2x) *Wrangler (TJ) <strong>4900</strong>-11 (2x) *DACIALogan 1.6i 2005- <strong>4900</strong>-11 (2x) *DAEWOONexia 1997 <strong>4900</strong>-11 (2x) *196 Components and Spare Parts see pages 228 to 236

Specialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesIngenious ToolsDAEWOONubira <strong>4900</strong>-11 (2x) *FIATBarchetta 1995 <strong>4900</strong>-12 (2x) *Ducato 1995 <strong>4900</strong>-13 (2x) *Marea 1997 <strong>4900</strong>-13 (2x) *Panda 1993 <strong>4900</strong>-10 (2x) *Punto 1997 <strong>4900</strong>-10 12 *Seicento Sporting 1998 <strong>4900</strong>-12 (2x) *Stilo 2002 <strong>4900</strong>-11 (2x) *Tempra 1993 <strong>4900</strong>-12 (2x) *Tipo 1990 <strong>4900</strong>-13 (2x) *Ulysse 1994 <strong>4900</strong>-13 (2x) *FORDEscort 1988 <strong>4900</strong>-10 (2x) *Escort 1.4i 1988 <strong>4900</strong>-10 (2x) *Fiesta * <strong>4900</strong>-10 (2x)Fiesta 1996 <strong>4900</strong>-11 (2x) *Focus 1998 <strong>4900</strong>-11 (2x) *Mondeo 1996 * <strong>4900</strong>-11 12Puma <strong>4900</strong>-11 (2x) <strong>4900</strong>-10 (2x)Sierra 1991 <strong>4900</strong>-11 (2x) *HONDAAccord Coupé <strong>4900</strong>-12 (2x) <strong>4900</strong>-12 (2x)ISUZUYear of Tensioning Plastic <strong>Spring</strong> Tensioning Plastic <strong>Spring</strong> FurtherType Construction Jaws Protection Inserts Jaws Protection Inserts ApplicationsGemini 1988 <strong>4900</strong>-11 (2x) *MAZDA626 1992 <strong>4900</strong>-13 (2x) <strong>4900</strong>-11 (2x)MERCEDES-BENZActros (MP-1) Driver’s cabin <strong>4900</strong>-25 26A-Class / type 168 1997-2004 <strong>4900</strong>-15 A (2x) <strong>4900</strong>-14 A (2x)A-Class type 169 2004- <strong>4900</strong>-17 (2x) <strong>4900</strong>-35 (2x)C-Class / type 203 2000- <strong>4900</strong>-17 18 <strong>4900</strong>-180 (1x) *E-Class type 211/ type 219 2003- <strong>4900</strong>-19 30 *7E-Class 4MATIC / type 210 1997-2002 <strong>4900</strong>-14 A (2x) <strong>–</strong>ML-Class / type 163 1997-2005 <strong>–</strong> <strong>4900</strong>-16 (2x)ML-Class / type 164 2005- <strong>4900</strong>-35 (2x)SLK type 171 2004- <strong>4900</strong>-18 34 <strong>4900</strong>-180 (1x) *SL-Class type 230 2003- <strong>4900</strong>-28 19 <strong>4900</strong>-29 19Vito, V-Class / type 638 1996-2002 <strong>4900</strong>-17 (2x) <strong>–</strong>Vito/Viano type 639 2003- <strong>4900</strong>-23 (2x) <strong>4900</strong>-230 (2x) *NISSANAlmera (N15) 1996 <strong>4900</strong>-11 (2x) <strong>4900</strong>-10 (2x)Bluebird (T12) <strong>4900</strong>-13 (2x) <strong>4900</strong>-12 (2x)Laurel (C32) <strong>4900</strong>-12 (2x) <strong>4900</strong>-10 (2x)Micra (K10) <strong>4900</strong>-10 (2x) <strong>4900</strong>-10 (2x)Components and Spare Parts see pages 228 to 236 197

Specialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesIngenious ToolsRENAULTKangoo 1.5 2004 <strong>4900</strong>-15 A (2x)Laguna 2.0 dci 2005 <strong>4900</strong>-12 (2x) -Mégane 1996- <strong>4900</strong>-12 (2x) *Mégane 1.5 dci 2005 <strong>4900</strong>-12 (2x) <strong>4900</strong>-120 (2x) -R19 1990 <strong>4900</strong>-12 (2x) *R21 1991 <strong>4900</strong>-13 (2x) *R5 1992 <strong>4900</strong>-11 (2x) *Rapid 1994 <strong>4900</strong>-11 (2x) *Scénic 1.5 dci 2005 <strong>4900</strong>-12 (2x) <strong>4900</strong>-120 (2x) -Twingo 1998- <strong>4900</strong>-11 (2x) -Vel Satis 2.2 dci 2005 <strong>4900</strong>-33 (2x) -SEATIbiza 2002 <strong>4900</strong>-11 (2x) <strong>4900</strong>-10 (2x)León 2002 <strong>4900</strong>-11 (2x) <strong>4900</strong>-10 (2x)Toledo 1996 <strong>4900</strong>-11 (2x) *SKODAFabia 2001 <strong>4900</strong>-11 (2x) *Octavia 1999 <strong>4900</strong>-11 (2x) *Superb 2002 <strong>4900</strong>-11 (2x) *SUZUKIAlto 1993 <strong>4900</strong>-10 (2x) *Ignis 2000 <strong>4900</strong>-10 (2x) *Wagon R+ 2000 <strong>4900</strong>-10 (2x) *TOYOTAYear of Tensioning Plastic <strong>Spring</strong> Tensioning Plastic <strong>Spring</strong> FurtherType Construction Jaws Protection Inserts Jaws Protection Inserts ApplicationsCamri 3.0 1992 <strong>4900</strong>-12 (2x) *Corolla 1999 * <strong>4900</strong>-11 12Picnic 1996 <strong>4900</strong>-11 (2x) *VOLKSWAGENGolf I + II <strong>4900</strong>-10 (2x) *Golf II 1.3 <strong>4900</strong>-10 (2x) <strong>4900</strong>-11 (2x)Golf III <strong>4900</strong>-11 (2x) *7Golf IV 1998 <strong>4900</strong>-11 (2x) <strong>4900</strong>-10 (2x)Jetta 1989 <strong>4900</strong>-11 (2x) *Lupo 1999 <strong>4900</strong>-11 (2x) <strong>4900</strong>-10 (2x)Passat 1986 <strong>4900</strong>-11 (2x) *Passat 1990 <strong>4900</strong>-11 (2x) *Passat 1992 <strong>4900</strong>-11 (2x) *Passat B5 1997 <strong>4900</strong>-11 (2x) *Passat Variant 1993 <strong>4900</strong>-11 (2x) <strong>4900</strong>-10 (2x)Polo 1994 <strong>4900</strong>-11 (2x) *Polo I <strong>4900</strong>-11 (2x) *Sharan 1996 * <strong>4900</strong>-12 (2x)T5 1.9D and 2.5D<strong>4900</strong>-13 (2x)VOLVOS 80 <strong>4900</strong>-12 (2x) <strong>4900</strong>-12 (2x)Components and Spare Parts see pages 228 to 236 199

Ingenious ToolsInside <strong>Spring</strong> <strong>Vice</strong> Set6 Parts,in Assortment Case• Optimally suited to the limited spaces wheninstalling and removing coil springs at the rear axleof the following vehicles:BMW1-series E87 (since 2003): 116i, 118d, 120i, 120dE87 (since 2004): 118i3-series E90 (since 2004): 320i, 320d, 325i, 330i lim.E91 (since 2005): 320, 325, 330 Touring• Pendulum 6-point head with integrated anti-twistprotection providing a uniform distribution of power• Internal guidance of the tensioning jaws preventsthe spring from sliding out, protected by utilitymodel• Both-sided spindle operation possible• DGBM <strong>–</strong> German registered utility model, EP1 4Set of 6 parts consisting of:<strong>–</strong> Inside <strong>Spring</strong> <strong>Vice</strong> 4902-1<strong>–</strong> Tensioning Jaw 4902-10<strong>–</strong> Tensioning Jaw 4902-11<strong>–</strong> Tubular Box Wrench, size 10 4902-210<strong>–</strong> Tubular Box Wrench, size 24 4902-224<strong>–</strong> Reversible Ratchet 4910-14902/6 121694Inside <strong>Spring</strong> <strong>Vice</strong>4902-1 122639Tensioning Jaw4902-10 1226464902-11 122653Tubular Box Wrench, size 104902-210 122677Tubular Box Wrench, size 244902-224 122660Reversible Ratchet4910-1 062133Specialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesZ7Shock Absorber ToolAssortment/Z344 x 188 x 56 mm• For repair work at the spring strut,e.g. shock absorber, bearings of shock absorberlegs, coil springs• For retaining the piston rod when installing orremoving strut units• Caution: Follow vehicle manufacturer’s specificationsconcerning torque values. Always use a torquewrench, e.g. <strong>HAZET</strong> 6291-1 CT in conjunctionwith Box-End Insert Tool 6630 d-21!BShock Absorber ToolAssortmentC• Caution:Application of an impact wrench may damagethe thrust bearing and the piston rod• Set of 13 partsin plastic caseContents:4910-14910-6 7 84910-16 17 18 19 21 22 244910-58 681 S 44910/13 <strong>–</strong> 061495Reversible Ratchet4910-1 <strong>–</strong> 062133Repair Set consisting of:ratchet wheel, pawl, shift lever,2 screws, ball and compression springfor 4910-14910-1/7 <strong>–</strong> 064533Extensions4910- 6 b 6 0620894910- 7 b 7 0620964910- 8 b 8 0621024910-58 Y 5 x 8 0621194910-68 Y 6 x 8 062126For PORSCHE Cayenne S, VW-Touareg4910-71 Y 7,1 x 9,6 0911956-Point Sockets4910-16 16 0620104910-17 17 0620274910-18 18 062034/ZBShock Absorber ToolAssortmentC1 S 46-Point Wrenches4910-19 19 0620414910-21 21 0620584910-22 22 0620654910-24 24 062072For OPEL Astra H4910-T 50 N T 50 120598Sockets (6-Point)• For repair work at the spring strut, especiallyfor retaining the piston rod when installing orremoving strut units• In conjunction with Shock Absorber Tool Set<strong>HAZET</strong> 4910/131 S 4/Z/ZÄ 7 mm for MERCEDES-BENZ Vaneo screws at thejoint rod4911-7 c 7 100620Ä 8 mm for BMW4911-8 c 8 085644Ä 9 mm for OPEL Corsa B, Astra F, G, Vectra B4911-9 c 9 100804200 Components and Spare Parts see pages 228 to 236

Specialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesWheel Bearing ExtractorModular System in Assortment CaseIngenious Tools49024911Including operating instructions with 3-dimensional illustrationsSoft-foam insertRecess for ABS-sensorSpacer platesHousing7Thrust washerO-ring-clamping (DBGM <strong>–</strong> Germanregistered utility model) developed by<strong>HAZET</strong> retains the thrust washer onthe centring bushing when installingand removing the wheel hub.Spindle nutReduction ringThreadedspindleCentering bushingHigher axial forces in spite of lowerapplication of force (due to highcapacitythreaded spindle with specialtrapezoidal fine thread in conjunctionwith the axial cylinder roller bearing)Optimal centring when inserting thewheel hub into the new wheel bearing• For installing and removing wheel bearings as well as for installing wheel hubs• Change of built-in wheel bearings• Removing the strut unit as well as camber adjustment are not necessary:<strong>–</strong> time-saving (approx. 30 min)<strong>–</strong> money-saving repair for the customer• Vehicles with Anti-Lock Braking System (ABS):<strong>–</strong> Due to the recess at the housing dismounting the ABS-sensor is not necessary<strong>–</strong> No risk of damaging the ABS-sensor<strong>–</strong> Money and time-saving• Centring aid due to calotte (spherical recess) at the housingComponents and Spare Parts see pages 228 to 236 201

Ingenious ToolsSpecialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesApplication of Wheel Bearing Tools1VW/AUDI RENAULT, VW/AUDI MERCEDES- BMW OPEL FORD PEUGEOT RENAULTSEAT, SKODA PEUGEOT, SEAT, SKODA BENZOPEL, FORD CITROËN (PSA)4930-1/16 4930-2/15 4930-25/15 4930-27/12 4930-29/13 4930-30/12 4930-34/11 4930-37/10 4930-38/124930-1 4930-2 4930-3 4930-4 4930-5 4930-6*4930-7 4930-34 x 40 4930-35 x 40 4930-35 x 42 4930-37 x 45 4930-39 x 41 4930-604930-62 4930-64 4930-66 4930-68 4930-72 4930-74 4930-80 4930-82 4930-84 4930-720 4930-820 4930-850 * Optionally for VW Polo C since 1991, PEUGEOT 106 since 1989+7Wheel Bearing ExtractorCCWheel Bearing Extractor• For the change of built-in wheel bearings <strong>–</strong> removing the strut unitas well as camber adjustment are not necessary• Patented function of adapters• Axial guidance due to centering bushing• Centering aid due to calotte (spherical recess) of the housing• High-quality threaded spindle with high capacity• In tool case (expandable)• Detailed operating instructions• DBGM <strong>–</strong> German registered utility model1 4CThreaded spindleincl. thrust bearing, 6-point drive Ä 224930-1 080755Spindle nut Ä 304930-2 080762BSpacer plates4930-3 0811584930-4 0811414930-5 082834Reduction ring4930-6 for VW Polo C since 1991, PEUGEOT 106 since 1999in conjunction with housing 4930-7204930-6 083633in conjunction with housing 4930-8504930-7 083640Inside ? 45 mm in conjunction with 4930-82454930-8 097890Centering disc for installing new wheel bearing on AUDI A4, A64930-9 121465Centering bushings4930-34 x 40 0810424930-35 x 40 0810664930-35 x 42 0810354930-37 x 45 081073B202 Components and Spare Parts see pages 228 to 236

Specialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesIngenious Tools49304930Wheel Bearing ExtractorWheel Bearing ExtractorC1 4Centering bushings4930-39 x 41 0810284930-43 x 45 097739Thrust washers burnished,outside ? 60 mm4930-60 081011outside ? 62 mm4930-62 080854outside ? 64 mm4930-64 080939outside ? 66 mm4930-66 080946outside ? 68 mm4930-68 080953CC• For the change of built-in wheel bearings <strong>–</strong> removing the strut unitas well as camber adjustment are not necessary• Patented function of adapters• Axial guidance due to centering bushing• Centering aid due to calotte (spherical recess) of the housing• High-quality threaded spindle with high capacity• In tool case (expandable)• Detailed operating instructions• DBGM <strong>–</strong> German registered utility model1 416 parts for VW/AUDI, OPEL, FORDContents:4930-1 2 3 4 54930-34 x 40 35 x 40 39 x 414930-62 64 66 68 72 744930-720 8204930-1/16 121328Coutside ? 72 mm4930-72 080960outside ? 74 mm4930-74 080977outside ? 80 mm4930-80 081004outside ? 82 mm4930-82 08099115 parts for RENAULT, PEUGEOT, CITROËN (PSA)Contents:4930-1 2 3 4 54930-35 x 40 35 x 42 37 x 454930-64 72 82 844930-720 820 8504930-2/15 08276615 parts for VW/AUDI, SEAT, SKODAin conjunction with 4930-84930-8245 097746outside ? 84 mm4930-84 081448Housings, burnished,72 mm ?4930-720 08108082 mm ?4930-820 08109785 mm ?4930-850 082179Contents:4930-1 2 3 4 54930-34 x 40 35 x 40 39 x 414930-62 66 68 72 744930-720 8204930-25/15 12131112 parts for MERCEDES-BENZContents:4930-1 2 3 4 5 74930-35 x 42 37 x 454930-64 74 84 8504930-27/12 084234Wheel Bearing ExtractorC13 parts for BMWContents:4930-1 2 3 4 54930-35 x 42 37 x 45 39 x 414930-72 74 804930-720 8204930-29/13 12130412 parts for OPELContents:4930-1 2 3 4 54930-34 x 40 39 x 414930-64 72 744930-720 8204930-30/12 121298711 parts for FORDContents:4930-1 2 3 4 54930-35 x 40 39 x 414930-72 744930-720 8204930-34/11 12143410 parts for PEUGEOTContents:4930-1 2 3 4 54930-35 x 424930-72 824930-720 8204930-37/10 082742B12 parts for RENAULTContents:4930-1 2 3 4 54930-35 x 40 37 x 454930-64 72 844930-720 8504930-38/12 082759Components and Spare Parts see pages 228 to 236 203

Ingenious ToolsSpecialty ToolsChassis <strong>–</strong> Shock Absorbers / AxlesWheel Hub and Drive Shaft (Half Shaft) Puller34 Parts, DBGM <strong>–</strong> German Registered Utility Modelwith hydraulic spindle suitable for impact operationIncluding operating instructions with 3-dimensional illustrationsSoft-foam insert7Drive Shaft /Half ShaftWithout O-RingInner O-RingSliding mechanismRemoving the drive shaft(half shaft) on vehicles onwhich the strut unit must notbe completely dismounted.Removing a wheel hubwith inner O-ringRemoving a wheel hubwithout O-ringThe sliding flange plate can be usedfor 4 and 5-bolt rimsThe hydraulic spindle can beoperated with impact wrench.Max. load 100 KN (^= 10 tons)Sectional View onImpact Socket<strong>Safety</strong>shearing pinSpecial<strong>HAZET</strong>driveThe safety shearing pin preventsoverload (overload protection).The special <strong>HAZET</strong> drive (DBGM)prevents the spindle from breakingaway when threading it completelyinto the hydraulic cylinder.• No pressing or impact forces <strong>–</strong> therefore damage-freeremoving of the wheel hub• Time-saving: 30 minutes less of work for removing the wheel hub ofthe built-in rear axle, as the following works are not necessary:removing the axle body / removing the hand brake cable/removing theABS-sensor / removing the brake lines and brake ventilation• Modular assortment consisting of 34 parts, suitable for:AUDI A4, A6, BMW E 36, E 46, E53, E60, E61, E83, E90, E91, E93,VW Golf III and IV, Passat, FORD Focus, Mondeo, RENAULT Mégane,Scénic, Clio, OPEL Astra F, PEUGEOT• Removing the drive shaft (half shaft) on all vehicle types on which thecomplete dismounting of the strut unit is not necessary• Saving money as camber adjustment is not necessary• Very sturdy, even for continuous use of impact wrenches1 44935-1/34 121441204 Components and Spare Parts see pages 228 to 236

Specialty ToolsChassis <strong>–</strong> Shock Absorbers / Axles / BrakesIngenious Tools49354955Wheel Hub Puller1 4C/BrakesBrake Fluid TesterAKR&Hydraulic spindle, mechanical Ä 17 mm, stroke 35 mm4935-1 119493Flange plate for mechanical spindle 4935-14935-2 119486Thrust bolts (2 pieces)4935-3 119479Pressure rail 4-bolt wheel hub4935-4 120505Pressure rail 5-bolt wheel hub4935-5 119974Thrust mandrel 65 mm4935-6 120031Thrust mandrel 115 mm4935-7 119820Thrust ring4935-8 119462Location bolt for machinist’s vice4935-9 120192Spindle drive j 12.5 = 1 ⁄2”4935-10 128778Thrust ring, complete, bearing diameter 82 mm4935-25 120185Thrust ring, complete bearing diameter 75 mm4935-25 A 120215Thrust ring, complete for BMW4935-29 120154Shells (pair) for VW, FORD, PEUGEOT, RENAULT, OPEL4935-72 119813Shells (pair) for FORD Mondeo4935-75 119806Shells (pair) for PEUGEOT4935-82 119790Threaded bolts (3 pieces)4935 IG- M 12 x 1,5 1197764935 AG-M 12 x 1,5 1197454935 AG-M 14 x 1,5 119769Fixation set4935-M 12/9 121458Additionally availableThrust ring, complete for FORD4935-34 120147Track Rod Wrench• Portable (for everywhere use) <strong>–</strong> to be connected to battery,replaces a stationary installation• Boiling point tester <strong>–</strong> higher testing accuracy in comparisonto other testing methods• Easy application <strong>–</strong> brake fluid remains in its fluid reservoir• Time saving <strong>–</strong> the test can be carried out directly in the fluid reservoir• Security for the user <strong>–</strong> no fluid loss (environmentally sound)• Approved by vehicle manufacturers• Approved by TÜV Austria• Dot 3 - 4 - 5.1 brake fluid• Operating voltage 12 V1 44954-1 129201Calliper Gauge for Brake DrumsMeasuring Temperatureup to 320° C (608° F)Brake Fluid:Dot 3 <strong>–</strong> 4 <strong>–</strong> 5.1SR7• For the operation of the track rod screwing• Double, spring-bearing jaw openingprevents slipping off, especially on seized or very tight screws• Forged design• Application on BMW 3 and 5-series,MERCEDES-BENZ C and E-Classes,OPEL Astra, Corsa, Kadett-E, Omega and Vectra,PEUGEOT 3/406, NISSAN, RENAULT, SEAT Ibiza,SKODA Fabia and Octavia,VW Bora, Golf I-IV, Jetta, Polo, Sharan, T4, VentoAUDI 80, 100, A4, A61 S 44950-13 13 0980334950-14 14 0980404950-17 17 0980574950-19 19 0980644950-22 22 100712• For the abrasion test at the drum brakes of passenger carsand commercial vehicles (follow vehicle manufacturer’s instructions)• Scale and slide made of aluminium profile• Jaws made of stainless steel, 150 mm long• Inside measuring with immediate reading• Vernier 1/20• With fixing screw• Measuring range up to 500 mm• In wooden box1 44955-1 073153Components and Spare Parts see pages 228 to 236 205

Ingenious ToolsCalliper Gauge for Brake DiscsSR• For measuring the thickness of the brake discs(wear/abrasion of the brake disc)Follow vehicle manufacturer’s instructions!• With fixing screw and sliding vernier(vernier 1 ⁄10)• With crowned measuring surfaces• In leather case1 4for passenger cars and motorcycles,measuring range: 60 mm,jaw length: 75 mm4956-1 073160for commercial vehicles and motorbusses,measuring range 100 mm, jaw length 115 mm4956-2 073177CSpecialty ToolsBrakesWheel Hub Grinder1 4for wheel hubs with stud bolts(grinding zone ? 40 or 50 mm),e.g. FORD, PORSCHE, VOLVO, Japanese carscontents: 2 grinding pads, 6 grinding wheels each:? 40 mm and 50 mm4960-45/14 132234&for wheel hubs on passenger carsup to a ? of 160 mmcontents: 1 grinding pad, 3 grinding wheels ? 160 mm4960-160/4 1322873 Replacement grinding wheels, ? 160 mm4960-0160/3 1322635 Replacement grinding wheels, ? 40 mm4960-040/5 1322945 Replacement grinding wheels, ? 50 mm4960-050/5 132300Mandrels with Abrasive RingsRAssembly Tool• For installing and removing the draw spring ofhand brake shoes, e.g. on MERCEDES-BENZpassenger cars with rear disc brakesas well as on VW LT since 1997• Hook with T-Handle• Special steel• Surface chrome-plated1 K 44964-1 162 055708Brake Adjusting ToolRa R7Wheel Hub Grinder&C• For removing rust and dust,e.g. from the fit drills of floating callipersor the ABS sensor location hole etc.• Operation with e.g. a hand drill orflexible extension• ? 16 mm, e.g. for floating callipers on VW Golf,Passat, Polo, etc.• ? 18 mm, e.g. the ABS sensor location hole onBMW, VW-AUDI, etc.• ? 22 mm, e.g. for the floating callipers on OPEL1 t 4Mandrel with 50 abrasive rings4961-16/51 16 0993134961-18/51 18 0993204961-22/51 22 099634Mandrel4961-16 16 0995284961-18 18 0995354961-22 22 09954225 abrasive rings4961-016/25 16 1115654961-018/25 18 1115724961-022/25 22 11158950 abrasive rings4961-016/50 16 0995594961-018/50 18 0995664961-022/50 22 099573• For adjusting hand brakes (brake cable)on different car models,especially for VW-AUDI, BMW, FORD,OPEL Astra G, Vectra B and MAZDA• Tubular box wrench Ä 10 mm• Plastic handle• Chrome-Vanadium• Surface chrome-platedNot suitable for vehicles withautomatic hand brake adjusting1 S K 44965-1 10 300 050598Brake Line Wrencha ROptimal cleaning of wheel hubs and brake discs• Prevents the falsification of the wheelbolt tightening torque originated by corrosion• Patented hook and loop fastener for fastchanging of grinding wheels• Wear-resistant grinding wheels<strong>–</strong> 4960-45/14: approx. 50 vehicles per wheel(40, 50 mm ?)<strong>–</strong> 4960-160/4: approx. 100 vehicles per wheel(160 mm ?)• Open pored abrasive material and cup formedgrinding pad reduce the formation of dust to aminimum• 10 mm 3-point pin, e.g. for the use in (air) drills• Max. 1,500 rpm• No formation of sparks (the lower the speed thebetter the grinding quality)BSpecial Tool for Brakes• For installing and removingspring plates the holding deviceof brake linings on drum brakes,e.g. on VW, SEAT, SKODA,OPEL and RENAULT with reardrum brakes• Push- and turn-part with carbidecoating layer in front working area• Plastic handle• Chrome-Vanadium• Surface chrome-plated1 K 44963-1 237 050383R• For screwing the union nuts on brake lineson BMW, VW-AUDI, FORD, MERCEDES-BENZ,MITSUBISHI, NISSAN, PEUGEOT, RENAULT,VOLVO<strong>–</strong> also on vehicles without anti-lock brake system• Flare nut insert tool• j drive 6.3 = 1 ⁄4”or square insert 9 x 12 mm• Chrome-Vanadium• Surface chrome-plated1 S 44966-11 11 0590104966-12 12 059027206 Components and Spare Parts see pages 228 to 236

Specialty ToolsBrakesIngenious Tools49564970Brake Calliper File/R• For removal of brake dust, rust and dirt from thebrake calliper• For vehicles with disc brakes• Coarse bevel cut on one side• One-sided cut prevents damage of thedust boot at the brake piston• Width: 12 mm• Plastic handle• Special steel1 M N 44968-1 165 275 084739Brake Calliper FileC• Extra slim style (width 10 mm),&Respecially appropriate for Japanese vehicles• For removal of brake dust,rust and dirt from the brake calliper• With integrated flat scraper at the frontend for removing crude residues1 M N 44968-5 155 265 129379Brake Bleeding WrenchesRBrake Piston Readjusting SetR/Brake Calliper Brush• For removal of brake dust and dirtfrom the brake calliper• For vehicles with disc brakes• Slim design• Plastic handle with suspension hole1 K 44968-2 225 084821Brass Brake Calliper BrushRR• For brake releasing without removing the wheels,replacement of wheel brake cylinder, master brakecylinder and tube connections• Bent and offset• Equal hexagon span on both sides• Chrome-Vanadium• Surface chrome-plated1 K 44968- 7 190 0857054968- 8 208 0856994968- 9 208 0856824968-10 236 0857124968-11 236 085729Brake Bleeding Wrench Set• For cleaning aluminium brake calipers• Soft brass bristles facilitate damage-freecleaning• Slim design <strong>–</strong> allows working in areaswith restricted access• Plastic handle with suspension hole1 44968-3 089147Brake Cable <strong>Spring</strong> Pliers• For installing and removing hand brake cables ofthe drum brake• With opening spring and stop• Front working area hardened• Special steel• Surface burnished1 K 44968-4 227 084760Brake Calliper FileR&RB5 parts, 7-11 mmContents:4968-7 8 9 10 111 44968/5 086535Application ChartsWith thrust bearing rotating to the left and right• For readjusting (pushing or turning)brake pistons on floating calliper systemswith or without locking device for hand brakes• Thrust bearing avoids damagingof the dust boot• With additional outside hexagon Ä 13 mmfor flexible application of operating tools,e.g. reversible ratchets• Universal application <strong>–</strong> suitable for all commonvehicle types1 G H K 4Set of 6 parts in plastic boxContents:4970-1 5 6 7 8 94970/6 <strong>–</strong> <strong>–</strong> <strong>–</strong> 088867Basic appliance4970-1 <strong>–</strong> <strong>–</strong> <strong>–</strong> 088874Adapter with 2 pinsAUDI 80 B4, Golf IV4970-5 35 5 29 052943Adapter VW-AUDI, inside hexagon 12 mm4970-6 30 6 24 052950Adapter with 2 pinsFORD Focus, OPEL Zafira, Astra, Astra G, CorsaGSI, SMART For Four4970-7 32 6 44 052967Adapter with 2 pinsCITROËN, VW-AUDI4970-8 55 5 22 052974Adapter with 4 pinsHONDA, SAAB4970-9 30 5 22 052981Adapter with 2 pinsOPEL Vectra C4970-10 35 6 20 126019Components and Spare Parts see pages 228 to 236 207SBMW 7CITROËN 8 9DAIHATSU 8FIAT 7 8FORD 7 8 9 10 11HONDA 8 10MAZDA 8MERCEDES-BENZ 9 11MITSUBISHI 10 11NISSAN 10 11OPEL 9PEUGEOT 7 8 9 10 11RENAULT 7 8 9 11SEAT 7 8SUZUKI 10TOYOTA 8 10VOLVO 8 10 11VW-AUDI 7 117

Ingenious ToolsTorque Tools<strong>HAZET</strong> <strong>–</strong> Torque WrenchesTorque Wrenches System 5000 CT“The classic workshop torque wrench”Robust and well-pricedProven a million timesIndispensable for the torquecontrolled screw tighteningRelease accuracy tolerance (in direction of actuation):± 4% of preset scale value according toDIN EN ISO 6789:2003 (D)With automatic close gap release <strong>–</strong> palpableand audible when torque setting is reachedTested andcertifiedSafe and fast adjustment of the desiredtorque value by turning the handleDGBM (German Registered Utility Model),EP (European Patent)Accuracy <strong>–</strong> fine scalegraduationErgonomicallyshapedIndividual serialnumber<strong>Safety</strong> lock at the handleSliding square tang allows reversing thedirection of actuation (according to DIN 3120 A, ISO1174-1 A),with plastic knob for manual pre-tighteningTorque Wrenches System 5000 CLT8“For higher demands”Click-Lens-Type with value readout in the display <strong>–</strong>security for the userRelease accuracy tolerance (in direction of actuation):± 4% of the preset scale value according toDIN EN ISO 6789Torque release <strong>–</strong> palpable by close gap release<strong>–</strong> audible by click-soundDGBM (German Registered Utility Model),EP (European Patent)User-friendlyreversible ratchetService-friendliy(do-it-yourself repairkits for ratchets available)Square drive solid tothe wrench <strong>–</strong> no risk of lossHard chrome-platedsteel tube <strong>–</strong> slim,but very sturdy andwear-resistantTested, withcertificateAwarded with theErgonomically shaped handle withcollar reducing the risk of slipping-offand injuryWith serial numberand certificateSafe locking of thehandle due to rotatingassembly <strong>–</strong> no risk ofjamming!Safe and fast adjustmentof the desired torque valueby turning the handleIntegrated shift lever with freerunningfunction ( 1 ⁄2” model)reducing the risk of injury andmalfunction<strong>–</strong> Safe box included in delivery! <strong>–</strong>Safe and exact adjustment of thedesired release torque. Optimal andeasy reading of the torque valueThree large digits for aneasy-to-read torque settingLarge convex display(interchangeable) optimizesthe readout208 Components and Spare Parts see pages 228 to 236

“High-precision measuring toolsfor highest demands”Release accuracy tolerance (in directionof actuation): ± 2% of the presetscale value according to DIN EN ISO 6789Tested, with certificate<strong>Safety</strong> lock at the handleAccuracy <strong>–</strong> fine scale graduationIndividual serial numberReversible ratchets 2, 3, 4Ergonomically shapedSafe torque release:• palpable (close gap release)• audible (“click” sound)• optical (signal transmitter, depending on model)Torque Tools<strong>HAZET</strong> <strong>–</strong> Torque WrenchesTorque Wrenches System 6000 CTWith serial numberand certificateErgonomically shapedhandle with collarreducing the riskof slipping-off and injuryIngenious Tools<strong>Safety</strong> lock atthe handleSafe and fast adjustmentof the desired torque valueby turning the handle50006000Integrated shift lever withfree-running function( 1 ⁄2” model) reducingthe risk of injury andmalfunctionUser-friendly reversibleratchetService-friendly(do-it-yourself repairkits for ratchets available)Hard chrome-platedsteel tube <strong>–</strong> slim, butvery sturdy and wear-resistantSquare drive solid to thewrench <strong>–</strong>no risk of loss<strong>–</strong> Safe box included in delivery! <strong>–</strong>Torque ScrewdriverSystem 6000 CTFor applications requiring low torque ranges(10<strong>–</strong>120 cNm and 1<strong>–</strong>6 Nm)Especially suitable for:• Screwed connections in plastic material• Connections in switch cabinets• Model makingFor applications requiring low torque rangesEspecially suitable for:• Engines• Gearboxes• Industry• Machine construction• Model making81Release accuracytolerance:± 2% of the presetscale valueComponents and Spare Parts see pages 228 to 236 209

Ingenious Tools<strong>HAZET</strong> Torque ToolsTorque Wrench ServiceOur Examination andCalibration Service offers:Adjustment, calibration and repairof your torque wrenchesGood preconditions for functionaltorque wrenchesRegular working quality,provable in the long termTest stickerExamination certificateindicating the test valuesTorque Tools07 0809 108210 Components and Spare Parts see pages 228 to 236

Torque ToolsTorque Wrenches • SYSTEM 5000 CT • Release Accuracy Tolerance ± 4%• Perfect for working on motorcycles and bicycles• Release accuracy tolerance (in direction of actuation) ± 4% of scale value according to DIN EN ISO 6789:2003 (D)• With automatic close gap release <strong>–</strong> palpable and audible when torque setting is reached• Safe and fast adjustment of the desired torque value by turning the handle• <strong>Safety</strong> lock at the handle• Fine scale graduation• With serial number and certificate• With reversible ratchet• DGBM <strong>–</strong> German registered utility model, EPGraduation1 o ! KNm 45108-2 CT 6,3 = 1 ⁄4” 2,5-25 232 0,2 119752• Release accuracy tolerance (in direction of actuation) ± 4% of scalevalue according to DIN EN ISO 6789:2003 (D)• Tightening at torque setting is possible both to the right and to the left• With automatic close-gap release, palpable and audible when torquesetting is reached• Easy and safe adjustment of the desired torquevalue by turning the handle• With lock at the handle• Fine scale graduation• With serial number and certificate• Ratchet with sliding square tang(according to DIN 3120 A, ISO 1174-1 A)with plastic turn-knob for manual pre-tightening• Changing the direction of actuation by inversing theratchet’s sliding square tang• DBGM <strong>–</strong> German registered utility model, EPIngenious Tools//51085128+ = Safe Boxes available, to be ordered separately, see page 219Graduation1 o ! KNm 45110-1 CT + 10 = 3 ⁄8” 10- 60 310 0,5 0223975121-1 CT + 12,5 = 1 ⁄2” 20-120 392 1,0 0224275122-1 CT + 12,5 = 1 ⁄2” 40-200 498 1,0 0224725123-1 CT 12,5 = 1 ⁄2” 60-320 615 2,0 022588Sliding square tang 10 = 3 ⁄8” ifor 5110-1 CT5110-01 049691Sliding square tang 12.5 = 1 ⁄2” ifor 5121-1 CT, 5122-1 CT 5123-1 CT5121-01 022410Torque Wrenches • SYSTEM 5000 CT • Release Accuracy Tolerance ± 4%• Click-Lens-TypeLarge digits for exact and easy-to-read torque setting• Safe and accurate adjusting of the desired torque valueExact and easy reading of the torque value• Triple-digit optomechanical value readout with largedigits on the display• Torque release<strong>–</strong> palpable <strong>–</strong> by close-gap release<strong>–</strong> audible <strong>–</strong> by click-sound• Release accuracy tolerance (in direction of actuation):±4% of scale valueaccording to DIN EN ISO 6789:2003 (D)• Large, convex display (exchangeable) simplifies reading• The desired torque value is adjusted easily and safelyby turning the handle• Reversible ratchet• Ergonomically shaped handle• <strong>Safety</strong> lock at the handle• With serial number and certificate• DBGM <strong>–</strong> German registered utility model, EPlbf.Graduation1 o !ft.KNm 45121-2 CLT 12,5 = 1 ⁄2” 20 <strong>–</strong> 120 <strong>–</strong> 435 1 1042155122-2 CLT 12,5 = 1 ⁄2” 40 <strong>–</strong> 200 <strong>–</strong> 545 1 1041925123-2 CLT 12,5 = 1 ⁄2” 60 <strong>–</strong> 320 <strong>–</strong> 660 2 104222• According to US standards• Scale graduation in lbf.ft5128-2 CLT 12,5 = 1 ⁄2” <strong>–</strong> 50 <strong>–</strong> 250 660 2 112296Components and Spare Parts see pages 228 to 236 211/8

Ingenious ToolsTorque ToolsDynamometric Screwdrivers • SYSTEM 6000 CT • Release Accuracy Tolerance ±5%• Release accuracy tolerance (in direction of actuation):± 5% of scale value according to DIN EN ISO 6789:2003 (D)• For screwdriver bits with 6.3 = 1 ⁄4” outside hexagon drive• Operation of sockets (j drive 6.3 = 1 ⁄4”) in conjunction with Adapter <strong>HAZET</strong> 2304• Application, e.g. on screwed connections in plastic materials and connectionson switch cabinets and model makingGraduation1 g % ! KNm 46002 CT 6,3 = 1 ⁄4” 10-120 <strong>–</strong> 170 0,1 0230046003 CT 6,3 = 1 ⁄4” <strong>–</strong> 1-6 230 0,1 023011Adapter• For the connection of sockets with square drive according to DIN 3120and operating tools with hexagon drive1 o g 42304 6,3 = 1 ⁄4” 6,3 = 1 ⁄4” 016020Torque Wrenches • SYSTEM 6000 CT • Release Accuracy Tolerance ± 2%• With automatic close-gap release,palpable and audible when torque setting is reached• Easy and safe adjustment of the desired torque value by turning the handle• Release accuracy tolerance (in direction of actuation):± 2% of scale value according to DIN EN ISO 6789:2003 (D)• Application: engines, gearboxes, machines, industry, model construction• Square drive according to DIN 3120 A, ISO 1174-1 AGraduation1 o ! KNm 46108-1 CT 6,3 = 1 ⁄4” 2 <strong>–</strong> 10 198 0,2 0622186109-2 CT 6,3 = 1 ⁄4” 4 <strong>–</strong> 40 256 0,4 080564• Release accuracy tolerance (in direction of actuation):± 2 % of scale value according to DIN EN ISO 6789:2003 (D)• With reversible ratchet• With turning knob for additional locking of the adusted torque value• Square drive according to DIN 3120 A, ISO 1174-1 A• 6110-1 CT to 6123-1 CT = DBP <strong>–</strong> German registered patent8+ = in Safe Box (more Safe Boxes see page 219)o = without signal transmitterGraduation1 o ! KNm 46110-1 CT + 10 = 3 ⁄8” 5 <strong>–</strong> 60 335 0,5 0250226111-1 CT + 10 = 3 ⁄8” 20 <strong>–</strong> 120 389 1,0 0250776121-1 CT + 12,5 = 1 ⁄2” 20 <strong>–</strong> 120 435 1,0 0252206122-1 CT + 12,5 = 1 ⁄2” 40 <strong>–</strong> 200 543 1,0 0252686123-1 CT 12,5 = 1 ⁄2” 60 <strong>–</strong> 320 659 2,0 0253676143-1 CT o 20 = 3 ⁄4” 100 <strong>–</strong> 400 803 2,5 0254666144-1 CT o 20 = 3 ⁄4” 200 <strong>–</strong> 500 1040 2,5 0255416145-1 CT o 20 = 3 ⁄4” 300 <strong>–</strong> 800 1280 2,5 025565Torque Wrenches • SYSTEM 6000 CT • US STANDARDS • Release Accuracy Tolerance ± 3%• According to US standards• Scale graduation in lbf.ft• Release accuracy tolerance (in direction of actuation):± 3% of scale value according to DIN EN ISO 6789:2003 (D)• With reversible ratchet• With turning knob for additional locking of the adjusted torque value• Square drive according to DIN 3120 A, ISO 1174-1 A+ = in Safe Box (more Safe Boxes see page 219)o = without signal transmitterlbf.Graduation1 o ft.! KNm 46114-1 CT 10 = 3 ⁄8” 5 <strong>–</strong> 40 6,8 <strong>–</strong> 54,2 333 0,5 0784246115-1 CT + 10 = 3 ⁄8” 20 <strong>–</strong> 100 27,1 <strong>–</strong> 135,6 390 0,5 0250846127-1 CT + 12,5 = 1 ⁄2” 40 <strong>–</strong> 200 54,2 <strong>–</strong> 271,2 545 1,0 0253816128-1 CT 12,5 = 1 ⁄2” 50 <strong>–</strong> 250 67,8 <strong>–</strong> 339 660 2,0 0761166132-1 CT 20 = 3 ⁄4” 120 <strong>–</strong> 600 162,7 <strong>–</strong> 813,5 1280 2,0 0784552MDE =212 Components and Spare Parts see pages 228 to 236

Torque ToolsIngenious Tools60026392Torque Wrenches • SYSTEM 6000 CT• With plug-and-socket connection to accomodate insert tools• Release accuracy tolerance (in direction of actuation):± 2% of scale value according to DIN EN ISO 6789:2003 (D)Graduation1 k ! KNm 46280-1 CT 9 x 12 2 <strong>–</strong> 10 180 0,2 0260056282-1 CT 9 x 12 4 <strong>–</strong> 40 240 0,4 080540• With plug-and-socket connection to accomodate insert tools• Release accuracy tolerance (in direction of actuation):± 2% of scale value according to DIN EN ISO 6789:2003 (D)+ = in Safe Box (more Safe Boxes see page 219)Graduation1 k ! KNm 46290-1 CT + 9 x 12 5 <strong>–</strong> 60 305 0,5 0260436291-2 CT + 9 x 12 20 <strong>–</strong> 120 388 1,0 0261046291-1 CT + 14 x 18 20 <strong>–</strong> 120 400 1,0 0260746292-1 CT + 14 x 18 40 <strong>–</strong> 200 510 1,0 0261356293-1 CT 14 x 18 60 <strong>–</strong> 320 620 2,0 026173• With plug-and-socket connection to accomodate insert tools• Release accuracy tolerance (in direction of actuation):± 2% of scale value according to DIN EN ISO 6789:2003 (D)• Without signal transmitterSafe-Boxen see page 219o = without signal transmitterGraduation1 k ! KNm 46294-1 CT o 14 x 18 100 <strong>–</strong> 400 715 2,5 0261976295-1 CT o 14 x 18 200 <strong>–</strong> 500 955 2,5 0262036296-1 CT o 14 x 18 300 <strong>–</strong> 800 1195 2,5 026210Data for effective length on Torque Wrenches with (different) Insert ToolsMDE = Torque to be selectedMDV = Prescribed torquelj = Standard length adjustment with adjusting devicel 1 = Effective length of torque wrenchl 2 = Gauge dimension of adjusting devicel w = Gauge dimension of extended insert tool(l 1 + l 2 ) x MDVMDE =l 1 + l wDimensions of various <strong>HAZET</strong> Torque Wrenches:Adjusted with1 M<strong>HAZET</strong>-No.N6280-1 CT 140 6401-1 (S) 19,56282-1 CT 200 6401-1 (S) 19,56290-1 CT 245 6402-1 (S) 306291-1 CT 330 6404-1 (S) 38,56291-2 CT 312 6402-1 (S) 306292-1 CT 432 6404-1 (S) 38,51 MAdjusted with<strong>HAZET</strong>-No.N 1 M N6293-1 CT 547 6404-1 (S) 38,5 6391- 35 130 <strong>–</strong>6294-1 CT 640 6406 44 6391- 50 190 <strong>–</strong>6295-1 CT 880 6406 44 6391- 85 260 <strong>–</strong>6296-1 CT 1120 6406 44 6392-200 345 <strong>–</strong>6391-12 100 <strong>–</strong> 6392-320 570 <strong>–</strong>6391-25 130 <strong>–</strong>Components and Spare Parts see pages 228 to 236 2138

Ingenious ToolsTorque Tools8Repair SetsPlease observe the following characteristics:1. Shift lever, burnished (black)2. Replaceable head3. since 1985 <strong>–</strong> ergonomic plastic handle1 4Repair Set for shift lever,consisting of: shift lever, screws, ball, compression springfor 1016, 1016/2,6132-1 CT, 6143 CT, 6143-1 CT, 6144 CT, 6144-1 CT,6145 CT, 6145-1 CT, 6146-1 CT1016/6 001972Repair Set for ratchet wheel 20 = 3 ⁄4” iconsisting of: ratchet wheel, pawl, shift lever, screws,ball, compression springfor 1016, 1016/2,6132-1 CT, 6143 CT, 6143-01, 6143-1 CT,6144 CT, 6144-01, 6144-1 CT,6145 CT, 6145-01, 6145-1 CT, 6146-1 CT1016/8 N 001989Repair Set for shift lever,consisting of: shift lever, screws, ball, compression springfor 8816 G, 8816 GK, 8816 P,8816 S, 8816 ST2264-1,6110 CT, 6110-1 CT, 6111-1 CT,6114-1 CT, 6115-1 CT6402-1, 6402-1 S, 6408-18816 P/5 042227Repair Set for ratchet wheel 10 = 3 ⁄8” iconsisting of: ratchet wheel, pawl, shift lever, screws,ball, compression springfor 8816 G, 8816 GK, 8816 P, 8816 ST,6110 CT, 6110-1 CT, 6111-1 CT,6114-1 CT, 6115-1 CT, 6402-18816 P/7 N 042234Repair Set for shift lever,consisting of: shift lever, screws, ball, compression springfor 6108-1 CT, 6109-1 CT, 6109-2 CT, 6401-1, 6401-1 S, 64086401-1/5 111176Repair Set for twist lock,consisting of: lock spring, twist lock with 2 headless screwsfor 6010-1 CT, 6110-1 CT, 6290-1 CT6110-27 025053Repair Set for twist lock,consisting of: lock spring, twist lockwith 2 headless screwsfor 5121-2 CLT, 5122-2 CLT, 5123-2 CLT6021-1 CT, 6022-1 CT, 6023-1 CT,6111-1 CT, 6115-1 CT, 6121-1 CT, 6122-1 CT, 6123-1 CT, 6127-1 CT, 6128-1 CT,6291-1 CT, 6292-1 CT, 6293-1 CT, 6722 TAC, 6291-2 CT6122-27 025299Repair Set for optical signal transmitter,consisting of: red button, compression spring, black housing, pin, screwfor 6021-1 CT, 6022-1 CT, 6023-1 CT,6110 CT, 6110-1 CT, 6111-1 CT, 6114-1 CT,6115-1 CT, 6121 CT, 6121-1 CT, 6122 CT, 6122-1 CT, 6123 CT, 6123-1 CT,6127-1 CT, 6128-1 CT, 6191-2 CT, 6290-1 CT, 6291 CT, 6292-1 CT, 6293-1 CT6122-29 025305Repair Set for shift lever,consisting of:shift lever, screws, ball, compression spring,spring washer, lockringfor 5121-2 CLT, 5121-2 CT,5122-2 CLT, 5122-2 CT, 5122 ST-15123-2 CLT, 5123-2 CT,6121-1 CT, 6121 CT, 6122-1 CT, 6122 CT, 6123-1 CT,6123 CT, 6127-1 CT, 6128-1 CT, 6722 TAC6122/7 025329Repair Set for ratchet wheel 12.5 = 1 ⁄2” iconsisting of: ratchet wheel, pawl, shift lever, screws, ball,compression spring, spring washer, lockringfor 5121-2 CLT, 5121-2 CT,5122-2 CLT, 5122-2 CT,6121 CT, 6121-1 CT, 6122-1 CT, 6122 CT, 6123-1 CT,6123 CT, 6127-1 CT, 6128-1 CT, 6722 TAC6122/9 N 025343BCRepair Sets1 4Reversible ratchet with screw, complete(exchangeable): 20 = 3 ⁄4” iuntil end of 2004for 6132-1 CT, 6143 CT, 6143-1 CT,6144 CT, 6144-1 CT,6145 CT, 6145-1 CT, 6146-1 CT6143-01 111190Repair Set for twist lock,consisting of: twist lock, lock springand cylinder screwfor 6132-1 CT, 6143-1 CT, 6144-1 CT, 6145-1 CT,6243-1 CT, 6244-1 CT, 6245-1 CT, 6246-1 CT,6294-1 CT, 6295-1 CT, 6296-1 CT6144-01/3 025527Reversible ratchet with pin, complete(exchangeable): 20 = 3 ⁄4” isince 2005for 6132-1 CT, 6144 CT, 6144-1 CT,6145 CT, 6145-1 CT, 6146-1 CT6145-01 111206Torque insert lock with screwfor 6243-1 CT, 6244-1 CT, 6245-1 CT, 6294-1 CT,6295-1 CT until end of 2004,6296-1 CT until end of 20046294-01 026180Torque insert lock with pinsince 2005for 6295-1 CT, 6296-1 CT6296-01 111213Torque Tool Assortments29 parts, in sheet metal box with plastic insertContents:6290-1 CT 6402-16450 c- 7 8 9 10 11 1213 14 15 16 176612 c-10 11 12 13 14 176630 c- 7 8 10 11 12 1314 15 16 171 46290-1 CT/29 026067//B214 Components and Spare Parts see pages 228 to 236

Torque Tool AssortmentsTorque ToolsC All Torque Wrenches of this line (<strong>HAZET</strong> 6391-6392)20 parts, in sheet metal box with plastic insertare without scale and without signal transmitter.Contents:6292-1 CT 6404-16450 d-13 14 15 16 1718 19 21 226630 d-13 14 15 16 1718 19 21 221 46292-1 CT/20 026159//Torque WrenchesIngenious Tools/1016881628 parts, in sheet metal box with plastic insertContents:6292-1 CT 6404-16450 d-13 14 15 16 17 18 1921 22 24 27 30 326630 d-13 14 15 16 17 18 1921 22 24 27 30 321 46292-1 CT/28 026166Dynamometric Screwdrivers• Especially appropriate for the application in series production• With inside hexagon drive 6.3 = 1 ⁄4”for screwdriver bits• Release accuracy tolerance (in direction of actuation):± 5% of scale value according to DIN EN ISO 6789:2003 (D)• Tightening at torque setting is possible only with screwswith right-handed threads• Without adjustment scaleAdjusting of the desired torque value with enclosed Hex Head Wrench <strong>HAZET</strong>2100 A-3/16 in conjunction with torque testing device1 ! K 46303 1 <strong>–</strong> 10 160 026678b• With lockable torque setting• Especially suitable for application in series production• With plug-and-socket connection to accommodate insert tools• Release accuracy tolerance in direction of actuation: ± 2% of scale value• DIN EN ISO 6789Adjusting the desired torque value with Adjustment Wrench<strong>HAZET</strong> 6399 in conjunction with Torque Tester <strong>HAZET</strong> 6903, 6905or any other suitable device.1 k ! K 46391-12 9 x 12 2 <strong>–</strong> 12 125 0270266391-25 9 x 12 2 <strong>–</strong> 25 180 0270406391-35 9 x 12 15 <strong>–</strong> 35 180 027057• With lockable torque setting• Especially suitable for application in series production• With plug-and-socket connection to accommodate insert tools• Release accuracy tolerance in direction of actuation: ± 2% of scale value• DIN EN ISO 6789Adjusting the desired torque value with Adjustment Wrench<strong>HAZET</strong> 6399 in conjunction with Torque Tester <strong>HAZET</strong> 6903, 6905or any other suitable device.All Torque Wrenches of this line (<strong>HAZET</strong> 6391-6392)are without scale and without signal transmitter.1 k ! K 46391-50 9 x 12 5 <strong>–</strong> 50 240 0270646391-85 9 x 12 15 <strong>–</strong> 85 315 027071//8Adapter• For the connection of sockets with square drive accordingto DIN 3120 and operating tools with hexagon drive• Chrome-Vanadium• Surface burnished1 o g 42304 6,3 = 1 ⁄4” 6,3 = 1 ⁄4” 016020• With lockable torque setting• Especially suitable for application in series production• With plug-and-socket connection to accommodate insert tools• Release accuracy tolerance in direction of actuation: ± 2% of scale value• DIN EN ISO 6789Adjusting the desired torque value with Adjustment Wrench<strong>HAZET</strong> 6399 in conjunction with Torque Tester <strong>HAZET</strong> 6903, 6905or any other suitable device.All Torque Wrenches of this line (<strong>HAZET</strong> 6391-6392)are without scale and without signal transmitter.1 k ! K 46392-200 14 x 18 50 <strong>–</strong> 200 400 0271186392-320 14 x 18 60 <strong>–</strong> 320 630 027125Components and Spare Parts see pages 228 to 236 215

Ingenious ToolsSpecial Levers• Without torque functionTorque ToolsInsert Reversible Ratchets/• Forged from solid steel• With plug-and-socket-connectionto accommodate insert tools• For loosening tight screwed connections1 k K 46396 9 x 12 405 0271326397 14 x 18 635 027149Adjustment Wrenchfor Torque Wrenches <strong>HAZET</strong> 6391-6392,to adjust and to lock the torque value1 K 46399 167 027170Insert Reversible Ratchets/• With locking device and quick release press button• Square drive according to DIN 3120 A, ISO 1174-1 A• 6401-1 S 20 teeth <strong>–</strong> max. 40 Nm6402-1 S 30 teeth <strong>–</strong> max. 120 Nm6403-1 S 32 teeth <strong>–</strong> max. 120 Nm6404-1 S 32 teeth <strong>–</strong> max. 300 Nm• Chrome-Vanadium• Drop forged• Surface chrome-plated1 o l Q K 46401-1S 6,3 = 1 ⁄4” 9 x 12 46,5 19,5 0274466402-1S 10 = 3 ⁄8” 9 x 12 61 30 0274776403-1S 12,5 = 1 ⁄2” 9 x 12 74,5 38,5 0275386404-1S 12,5 = 1 ⁄2” 14 x 18 83,5 38,5 027569Reversible Ratchets for Bits/ b8• Square drive DIN 3120 A, ISO 1174-1 A• 6401-1 20 teeth <strong>–</strong> max. 40 Nm 6403-1 32 teeth <strong>–</strong> max. 120 Nm6402-1 30 teeth <strong>–</strong> max. 120 Nm 6404-1 32 teeth <strong>–</strong> max. 300 Nm• Chrome-Vanadium• Drop forged• Surface chrome-plated1 o l Q K 46401-1 6,3 = 1 ⁄4” 9 x 12 19,5 46,5 0274396402-1 10 = 3 ⁄8” 9 x 12 30 61 0274606403-1 12,5 = 1 ⁄2” 9 x 12 38,5 74,5 0275216404-1 12,5 = 1 ⁄2” 14 x 18 38,5 83,5 027552• For screwdriver bits• Chrome-Vanadium• Drop-forged• Surface chrome-plated1 h l Q K 4i drive 6.3 = 1 ⁄4”20 teeth6408 6,3 = 1 ⁄4” 9 x 12 19,5 46,5 027583i drive 8 = 5 ⁄16”30 teeth6408-1 8 = 5 ⁄16” 9 x 12 30 61 027590Repair Sets• Fine tooth, 72 teeth, rotation angle 5°• Square drive according to DIN 3120 A, ISO 1174-1 A• Chrome-Vanadium• Drop forged• Surface chrome-plated• 6401 N max. 40 Nm6402 and 6403 max. 120 Nm6404 max. 300 Nm 6406 max. 800Nm1 o l Q K 46401 N 6,3 = 1 ⁄4” 9 x 12 17,5 46 1152046402 10 = 3 ⁄8” 9 x 12 26 58,5 0274536403 12,5 = 1 ⁄2” 9 x 12 26 58,5 0275146404 12,5 = 1 ⁄2” 14 x 18 27 70,5 0275456406 20 = 3 ⁄4” 14 x 18 44 101 027576Please observe the following characteristics:1. Shift lever, burnished (black)2. Replaceable head3. since 1985 <strong>–</strong> ergonomic plastic handle B216 Components and Spare Parts see pages 228 to 236

Torque ToolsIngenious Tools64018816CRepair Sets1 4Repair Set for shift lever,consisting of: shift lever, screws,ball, compression springfor 8816 G, 8816 GK, 8816 P,8816 S, 8816 ST2264-1,6110 CT, 6110-1 CT, 6111-1 CT,6114-1 CT, 6115-1 CT6402-1, 6402-1 S, 6408-18816 P/5 042227Repair Set for ratchet wheel 10 = 3 ⁄8” iconsisting of: ratchet wheel, pawl, shift lever, screws,ball, compression springfor 8816 G, 8816 GK, 8816 P, 8816 ST,6110 CT, 6110-1 CT, 6111-1 CT,6114-1 CT, 6115-1 CT, 6402-18816 P/7 N 042234Repair Set for shift lever,consisting of: shift lever, screws, ball,compression springfor 6108-1 CT, 6109-1 CT, 6109-2 CT,6401-1, 6401-1 S, 64086401-1/5 111176Repair Set for ratchet wheel 6.3 = 1 ⁄4” iconsisting of: ratchet wheel, pawl, shift lever,screws, ball, compression springfor 6108-1 CT, 6109-1 CT, 6109-2 CT, 6401-16401/7 111169Repair Set for ratchet wheel 6.3 = 1 ⁄4” iconsisting of: ratchet wheel, pawl, shift lever,screws, ball, compression springfor 6401-1 S6401-1 S/7 111152Repair Set for shift lever,consisting of: shift lever, screws, ball,compression spring, spring washer, lockringfor 6403-1, 6403-1 S, 6404-1, 6404-1 S6403-1/7 070756Repair Set for ratchet wheel 12.5 = 1 ⁄2” iconsisting of: ratchet wheel, pawl, shift lever,screws, ball, compression spring, spring washer, lockringfor 6403-1, 6404-16403-1/9 070749Repair Set for ratchet wheel 12.5 = 1 ⁄2” iconsisting of: ratchet wheel, pawl, shift lever,screws, ball, compression spring, spring washer, lockringfor 6403-1 S, 6404-1 S6403-1 S/9 070817Repair Set for ratchet wheel 6.3 = 1 ⁄4” iconsisting of: ratchet wheel, pawl, shift lever,screws, ball, compression springfor 64086408/7 111145Repair Set for ratchet wheel 10 = 3 ⁄8” iconsisting of: ratchet wheel, pawl, shift lever, screws,ball, compression springfor 8816 S, 6402-1 S8816 S/7 048465Insert Holder with Square DrivesSpare Parts1 o l Q K 4Holdersquare insert 9 x 12j drive 10 = 3 ⁄8”6413-1 <strong>–</strong> 9 x 12 17,5 43,5 027644Sliding square tangsi 10 = 3 ⁄8”6413-2 6,3 = 1 ⁄4” <strong>–</strong> <strong>–</strong> 22 0489086413-3 10 = 3 ⁄8” <strong>–</strong> <strong>–</strong> 26 0488926413-4 12,5 = 1 ⁄2” <strong>–</strong> <strong>–</strong> 30,4 048885Insert Square Drives• Square drive, DIN 3120 A, ISO 1174-1• Chrome-Vanadium• Surface chrome-plated1 o l Q K 46414 12,5 = 1 ⁄2” 14 x 18 25 63,5 0276686416 20 = 3 ⁄4” 14 x 18 25 70 027682Bit HolderDIN 3126, chrome-plated1 h l Q K 46420 b 6,3 = 1 ⁄4” 9 x 12 17,5 40,5 0279036420 c 8 = 5 ⁄16” 9 x 12 17,5 41,5 0279106420 d 8 = 5 ⁄16” 14 x 18 25 58 027927Insert Adapters8Set, 4 partsContents:6413-1 2 3 41 46413/4 027651chrome-plated1 k l Q K 4square insert 14 x 18 to 9 x 126423 c 14 x 18 9 x 12 34 50 027934square insert 9 x 12 to 14 x 186423 d 9 x 12 14 x 18 20 45 057559Components and Spare Parts see pages 228 to 236 217

Ingenious ToolsInsert Adapter with Hinge JointTorque ToolsOpen End Insert Tools• For the operation of screwed connections in areaswith restricted access or behind obstacles,e.g. with torque wrench or reversible ratchet• May be used as extension and adapter14 x 18 to 9 x 12• Alternatively to be operated with j 10 = 3 ⁄8”• Slender style• Chrome-Vanadium• Surface chrome-plated• DBGM <strong>–</strong> German registered utility modelNote: Tightening with precise torque valuesis possible only in straight, in-line position1 k l Q K 46423 g 9 x 12 14 x 18 46 68 096053Insert Adapters• DIN 899• Chrome-plated1 l Q K 46450 c- 7 9 x 12 17,5 36,5 0284296450 c- 8 9 x 12 17,5 37 0284366450 c- 9 9 x 12 17,5 37,5 0284436450 c-10 9 x 12 17,5 38 0283206450 c-11 9 x 12 17,5 38,5 0283376450 c-12 9 x 12 17,5 38,5 0283446450 c-13 9 x 12 17,5 39 0283516450 c-14 9 x 12 20 42 0283686450 c-15 9 x 12 20 42,5 0283756450 c-16 9 x 12 20 43 0283826450 c-17 9 x 12 20 43,5 0283996450 c-18 9 x 12 20 44 0284056450 c-19 9 x 12 20 45 0284126450 d-13 14 x 18 25 56,5 0284506450 d-14 14 x 18 25 57 0284676450 d-15 14 x 18 25 57,5 0284746450 d-16 14 x 18 25 58 0284816450 d-17 14 x 18 25 58,5 0284986450 d-18 14 x 18 25 59 0285046450 d-19 14 x 18 25 59,5 0285116450 d-21 14 x 18 25 60,5 0285286450 d-22 14 x 18 25 61 0285356450 d-24 14 x 18 25 62 0285426450 d-27 14 x 18 32,5 68,5 0285596450 d-30 14 x 18 32,5 70 0285666450 d-32 14 x 18 32,5 71,5 0285736450 d-34 14 x 18 32,5 73,2 0501786450 d-36 14 x 18 32,5 73,3 0725076450 d-38 14 x 18 32,5 72,7 0725146450 d-41 14 x 18 40 79 0285808• With plug-and-socket-connection to accommodate insert tools• j drive 10 = 3 ⁄8”• For the operation of screwed connections in areaswith restricted access (engine compartment)• Chrome-Vanadium• Surface chrome-plated1 l Q K 46424 c 9 x 12 26,5 33,5 053759Blank-End Inserts1 l Q K 46430 c 9 x 12 ** 25 0279586430 d 14 x 18 ** 38 027965** = Note: Welding on tools with a gauge dimension lw > 45 mmwill affect the release valuesh Box-End Insert Tools• For outside TORX ® screws• DIN 899• Chrome-plated1 l r Q K 46609 c-E 8 9 x 12 7,52 17,5 39 0747166609 c-E 10 9 x 12 9,42 17,5 40,0 0497386609 c-E 11 9 x 12 10,08 17,5 40,6 0497456609 c-E 12 9 x 12 11,17 17,5 42,1 0497526609 c-E 14 9 x 12 12,90 17,5 42,8 0497696609 c-E 16 9 x 12 14,76 17,5 44,3 0497766609 c-E 18 9 x 12 16,70 17,5 45 0497836609 c-E 20 9 x 12 18,49 17,5 46,5 0497906609 c-E 22 9 x 12 20,32 17,5 47 0498066609 c-E 24 9 x 12 22,16 17,5 48,8 0498136609 d-E 10 14 x 18 9,42 25 58 0547946609 d-E 11 14 x 18 10,08 25 58,5 0548006609 d-E 12 14 x 18 11,17 25 59 0548176609 d-E 14 14 x 18 12,90 25 60 0548246609 d-E 16 14 x 18 14,76 25 61 0548316609 d-E 18 14 x 18 16,70 25 62 0548486609 d-E 20 14 x 18 18,49 25 63,5 0548556609 d-E 22 14 x 18 20,32 25 64,3 0548626609 d-E 24 14 x 18 22,16 25 65,3 054879e218 Components and Spare Parts see pages 228 to 236

Torque ToolsIngenious Tools60606690Flare Nut Insert ToolsSafe Boxeschrome-plated1 l Q K 46612 c-10 9 x12 17,5 42,3 0287266612 c-11 9 x12 17,5 42,8 0287336612 c-12 9 x12 17,5 43,4 0287406612 c-13 9 x12 17,5 43,7 0287576612 c-14 9 x12 17,5 44,4 0287646612 c-16 9 x12 17,5 45,4 0287716612 c-17 9 x12 17,5 45,9 0287886612 c-18 9 x12 17,5 46,1 0287956612 c-19 9 x12 17,5 46,8 0288016612 c-21 9 x12 17,5 48 0288186612 c-22 9 x12 17,5 48,8 028825Box-End Insert Tools• DIN 899• Chrome-plated1 l Q K 46630 c- 7 9 x12 17,5 40 0289556630 c- 8 9 x12 17,5 40,6 0289626630 c-10 9 x12 17,5 42,1 0288326630 c-11 9 x12 17,5 42,8 0288496630 c-12 9 x12 17,5 43,5 0288566630 c-13 9 x12 17,5 43,8 0288636630 c-14 9 x12 17,5 45 0288706630 c-15 9 x12 17,5 45,5 0288876630 c-16 9 x12 17,5 46,5 0288946630 c-17 9 x12 17,5 47 0289006630 c-18 9 x12 17,5 47,8 0289176630 c-19 9 x12 17,5 48,8 0289246630 c-21 9 x12 17,5 50 0289316630 c-22 9 x12 17,5 50,8 0289486630 d-13 14 x 18 25 60,8 0289796630 d-14 14 x 18 25 61,5 0289866630 d-15 14 x 18 25 62 0289936630 d-16 14 x 18 25 62,9 0290066630 d-17 14 x 18 25 63,6 0290136630 d-18 14 x 18 25 64,3 0290206630 d-19 14 x 18 25 65,3 0290376630 d-21 14 x 18 25 66,5 0290446630 d-22 14 x 18 25 67,3 0290516630 d-24 14 x 18 25 68,8 0290686630 d-27 14 x 18 31 76,8 0290756630 d-30 14 x 18 31 78,5 0290826630 d-32 14 x 18 31 79,8 0290996630 d-34 14 x 18 31 81,3 0291056630 d-36 14 x 18 31 82,5 0291126630 d-41 14 x 18 31 85,5 029129• For safe storage of torque wrenches• Up to size BX 8 with window• Plastic, black1 K 4for <strong>HAZET</strong> 6110-1 CT 6114-1 CT 6290-1 CT6060 BX-2 420 024629for <strong>HAZET</strong> 5121-2 CLT 6111-1 CT 6115-1 CT6121-1 CT 6291-1 CT 6291-2 CT6060 BX-4 530 024636for <strong>HAZET</strong> 5122-2 CLT 6122-1 CT 6127-1 CT 6292-1 CT6060 BX-6 635 024643for <strong>HAZET</strong> 5123-2 CLT 5128-2 CLT 6123-1 CT6128-1 CT 6293-1 CT6060 BX-8 775 102907without windowfor 6143-1 CT 6294-1 CT6060 BX-10 830 116515without windowfor 6132-1 CT 6144-1 CT 6145-1 CT6295-1 CT 6296-1 CT6060 BX-12 1310 116522Mechanical Angle Dials• For tightening screws as a function of the torsion angle• To be used between all torque wrencheswith i drive 12.5 = 1 ⁄2” (resp. 20 = 3 ⁄4”) and toolswith j drive 12.5 = 1 ⁄2” (resp. 20 = 3 ⁄4”)• With flexible magnetic holder for the fixing point• Range 0 - 360°, graduation 1°, 95 mm ?1 r 46690 12,5 = 1 ⁄2” 0292666690-1 20 = 1 ⁄4” 029273K8Components and Spare Parts see pages 228 to 236 219

Ingenious ToolsTorque MultipliersTorque ToolsHydraulic Torque TestersK8• For tightening and looseningtight screwed connections• Avoids the application of impacttools, extensions, lever arms, etc.• No external power source necessary,low-maintenance• High accuracy: ± 5%• For building and agricultural machines, trucks,plant and engine construction and shipbuildingtorque ratio:6800-700 1:3.56800-1400 1:3.56800 Lg-1400 1:3.56800-2800 1:121 ! q o 46800- 700 700 12,5 = 1 ⁄2” 20 = 3 ⁄4” 0627756800-1400 1400 20 = 3 ⁄4” 25 = 1” 0627446800-2800 2800 20 = 3 ⁄4” 25 = 1” 062768extra long pattern,e.g. for deeply located wheel bolts/nuts on trucks6800 Lg-1400 1400 20 = 3 ⁄4” 25 = 1” 062751Torque wrenches and torque testers are high precision measuring tools. Theyhave to be checked with an appropriate tester after a certain period of timeand adjusted when required. The checking frequency depends on the usingfrequency.<strong>HAZET</strong> disposes of the corresponding torque testers. After testing andadjustment, the torque wrenches and torque testers sent to <strong>HAZET</strong> aresupplied with a test certificate.Conversion Chart · Torque Valueslbf.ft Nm lbf.ft Nm1 1.4 35 47.52 2.7 40 54.23 4.1 45 61.04 5.4 50 67.85 6.8 60 81.36 8.1 70 94.97 9.5 80 108.58 10.8 90 122.09 12.2 100 135.610 13.6 120 162.715 20.3 140 189.820 27.1 160 216.925 33.9 180 244.030 40.7 200 271.2• For torque wrench testing and adjustment• Tolerance ± 1% of scale value• Low mass acceleration• Reduced friction• Ball-bearing primary shaft• Motion of pointer damped, pointer does not swivelor move upon release of the Torque Wrench• Inside 8-point drive 12.5 = 1 ⁄2”additional adapter 10 = 3 ⁄8” and 20 = 3 ⁄4” (included)• Space-saving wall fixation with two heavy-duty dowels (included)1 ! 46903 10 <strong>–</strong> 200 0293106905 20 <strong>–</strong> 400 029327The <strong>HAZET</strong> torque testing devices are constantly supervised and calibratedby the German Calibration Service (DKD). This guarantees the existingessential competence in the field of controlled screw tightening as well as thehigh qualitity of the <strong>HAZET</strong> torque wrenches and torque testing devices.SYSTEM 5000 CT / CLT / 6000 CTNm lbf.ft Nm lbf.ft1 0.7 40 29.52 1.5 45 33.23 2.2 50 36.94 3.0 55 40.65 3.7 60 44.36 4.4 70 51.67 5.2 80 59.08 5.9 90 66.49 6.6 100 73.810 7.4 110 81.115 11.1 120 88.520 14.8 130 95.925 18.4 140 103.330 22.1 150 110.635 25.8 200 147.51 Nm 0.7376 lbf.ft 1 lbf.ft 12 lbf.in 1 Nm 0.1020 kpm1 lbf.ft 1.3558 Nm 1 lbf.in 0.0833 lbf.ft 1 kpm 9.807 NmNote:During continuous operation with Reversible Ratchets and square drive InsertTools (<strong>HAZET</strong> 6401-1 <strong>–</strong> 6416) the max. torque values are limited as follows:6401-1 = 40 Nm, 6402, 6402-1 = 120 Nm, 6403, 6403-1 = 120 Nm,6404, 6404-1 = 300 Nm, 6406 = 800 NmThe max. torque values of Open End-, Flare Nut- and Box Wrenches(<strong>HAZET</strong> 6450 <strong>–</strong> 6630) depend on the respective wrench size (DIN 899)and can be smaller than the max. torque value of the tool in operation. The audibleand palpable “click”-signal abates when torque value is lower.The release accuracy corresponds to a room temperature of 20 °C.Torque Wrench to be reset to smallest value after operation!220 Components and Spare Parts see pages 228 to 236

Pneumatic Tools<strong>HAZET</strong> <strong>–</strong> Range of Pneumatic ToolsExtensive range of pneumatic tools:Impact Wrenches 2345Air Ratchets 123Drill, Angle DrillDie Grinders, straight and angledChisel Hammer SetOrbital Sander, Belt Sander, AngleGrinderSabre SawNeedle ScalerAir Nibbler, Air ShearAir Blow Guns, Air Blow Pensand many more…Ingenious Tools680068009Components and Spare Parts see pages 228 to 236 221

Ingenious ToolsPneumatic ToolsImpact Wrenches• Ultra-light (1.2 kg) magnesium housinglighter than comparable aluminium housings• Powerful pin clutch mechanism• 3 power settings in forward• Best possible distribution of weightfor ergonomic working• Screw size: M 13• Recommended torque:up to 190 Nm• Max. loosening torque: 350 Nm• Air consumption: 71 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level Lp A: 90 dB(A)• Cold-insulated handle• Exhaust air is guided through the handle downwards• Reduced vibrations• Forward and reverse• Easy handling• Coupler plug, nominal size 7.2 included1 $ ( 5 49011 MG 250 10000 1200 109180CImpact Wrenches• Cold insulated handle• Exhaust air is guided through the handle downwards• Reduced vibrations• Forward and reverse• Easy handling• Coupler plug, nominal size 7.2 included1 $ ( 5 49013 MG 1490 5500 5200 109210• Ultra-light (2.6 kg) magnesium housinglighter than comparable aluminium housings• Powerful twin hammer mechanism• 3 power settings in forward• Screw size: M 16• Recommended torque: up to 542 Nm• Max. loosening torque: 1490 Nm• Air consumption: 133 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level Lp A: 88 dB(A)• Cold insulated handle• Exhaust air is guided through thehandle downwards• Reduced vibrations• Forward and reverse• Easy handling• Coupler plug, nominal size 7.2 included1 $ ( 5 49012 MG 740 7500 2600 109197• Ultra-light (8.8 kg) magnesium housinglighter than comparable aluminium housings• Powerful twin hammer mechanism• Multiple power settings in forward and reverse• Screw size: M 32• Recommended torque: up to 1355 Nm• Max. loosening torque: 2600 Nm• Air consumption: 300 l/min• Air inlet thread: 1 ⁄2”• Working pressure: 6.3 bar• Sound pressure level Lp A:111.4 dB(A)• Cold insulated handle• Exhaust air is guided downwards1 $ ( 5 49014 MG 2160 4500 8800 1092279• Ultra-light (5.2 kg) magnesium housinglighter than comparable aluminium housings• Powerful twin hammer mechanism• 3 power settings in forward• Screw size: M 30• Recommended torque: up to 1084 Nm• Max. loosening torque: 1800 Nm• Air consumption: 206 l/min• Air inlet thread: 3/8”• Working pressure: 6.3 bar• Sound pressure level Lp A: 87 dB(A)B• Ultra-light (9.9 kg) magnesium housinglighter than comparable aluminium housings• Long drive spindle (190 mm) <strong>–</strong>for the operation of deeply located screws• Powerful twin hammer mechanism• Multiple power settings in forward/reverse• Screw size: M 32• Recommended torque: up to 1355 Nm• Max. loosening torque: 2600 Nm• Air consumption: 300 l/min• Air inlet thread: 1 ⁄2”• Working pressure: 6.3 bar• Sound pressure level Lp A: 111.4 dB(A)• Cold-insulated handle• Exhaust air is guided downwards1 $ ( 5 49014 MG-Lg 2160 4500 9900 115853222 Components and Spare Parts see pages 228 to 236

Pneumatic ToolsIngenious Tools90119022Impact WrenchesAir RatchetsC• Forward and reverse• Continuous regulation• Air consumption: 180 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level Lp A: 83 dB(A)• Cold insulated handle• Reduced vibrations• Coupler plug, nominal size 7.2 included1 $ ( 5 K 4S9020-2 35 170 500 165 109432S• Especially for wheel mounting• For controlled screw tightening without impact effect at 50 Nm max.• Loosening of screws at max. 700 Nm, with automatic impact mechanism• Overload protection thanks to pressure limit at 6.3 bar• Max. loosening torque: 1250 Nm• Air consumption: 300 l/min• Air inlet thread: 3 ⁄8”• Working pressure: 6.3 bar• Noise level: 85.1 dB(A)• Cold-insulated handle• Reduced vibrations• Exhaust air is guided through the handle• i drive 12.5 = 1 ⁄2”, in conjunction with impact socket,e.g. <strong>HAZET</strong> 900 S1 $ ( 5 49012-50 50 / 700 7000 3000 083732S• Forward and reverse• Continuous regulation• Air consumption: 180 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level Lp A: 88 dB(A)• Cold insulated handle• Reduced vibrations• Coupler plug, nominal size 7.2 included1 $ ( 5 K 49021-2 70 160 1200 230 109449• Short design• Forward and reverse• Continuous regulation• Air consumption: 180 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level Lp A: 83 dB(A)• Cold insulated handle• Reduced vibrations• Coupler plug, nominal size 7.2 included1 $ ( 5 K 4S9021-3 35 170 500 165 116614S• Maximum performance at minimum weight (1.9 kg)• Shock resistant plastic housing• Powerful twin hammer mechanism• Multiple power settings in forward and reverse• Screw size: M 16• Recommended torque: up to 515 Nm• Max. loosening torque: 1490 Nm• Air consumption: 133 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level Lp A: 98.5 dB(A)• Cold-insulated handle, reduced vibrations• Exhaust air is guided to the handle downwards• Coupler plug, nominal size 7.2 included1 $ ( 5 49012 KS 690 7700 1900 109203• Forward and reverse• Continuous regulation• Air consumption: 180 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure levell Lp A: 88 dB(A)• Cold insulated handle• Reduced vibrations• Coupler plug, nominal size 7.2 included1 $ ( 5 K 49022-2 70 160 1200 230 1094569Components and Spare Parts see pages 228 to 236 223

Ingenious ToolsPneumatic ToolsAir DrillSXDie Grinder, straight design• Quick-change chuck, capacity 1-10 mm• Forward and reverse• Air consumption: 113 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level Lp A: 91 dB(A)• Cold insulated handle• Exhaust air is guided through the handle downwards• Robust housing• Suitable for continuous operation• Especially appropriate for car body works and industry• Coupler plug, nominal size 7.2 included1 ( 5 49030-1 2500 1350 109470• For grinding, polishing, burnishingand deburring• High ease of use• Ergonomic design• Straight design• Speed regulation with setting wheel• Power: 164 Watts• Air consumption: 113 l/min• Air inlet thread: 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level: 91 dB(A)• Collet chuck: 6 mm• Coupler plug, nominal size 7.2 included1 ( 5 K 49032-1 2000 <strong>–</strong> 25000 380 158 117055Angle Drill&SXAngle Die Grinder9For working in areas with difficult access• Quick change chuck, capacity 1-10 mm• Forward and reverse• Exhaust air is guided through the handle backwards• Air consumption: 113 l/min• Working pressure: 6.3 bar• Sound pressure level: 90 dB(A)• Coupler plug, nominal size 7.2 included1 ( 5 49030-5 1200 1100 132379• For grinding, polishing, burnishingand deburring• High ease of use• Ergonomically shaped• Angled design• Speed regulation with setting wheel• Power: 160 Watts• Air consumption: 113 l/min• Air inlet thread 1 ⁄4”• Working pressure: 6.3 bar• Sound pressure level: 90 dB(A)• Collet chuck: 6 mm• Coupler plug, nominal size 7.2 included1 ( 5 K 49032-5 2000 <strong>–</strong> 22000 560 160 117062224 Components and Spare Parts see pages 228 to 236