Image brochure - Trapo AG

Image brochure - Trapo AG

Image brochure - Trapo AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Solutions for...

We focus on the requirements of our customers<br />

and on the benefits our products offer to them.<br />

We work with know-how and highly specialised<br />

technologies at individual solutions for intralogistics<br />

and automation.<br />

TRAPO | Range | 02 / 03<br />

Services Page<br />

Expertise 04 / 07 We perceive our service as a process! We always feel<br />

committed to the overall result during every work step.<br />

...Materials handling<br />

... Robotics and<br />

handling systems<br />

... Service and<br />

maintenance<br />

08 / 11 We support your success applying all our expertise and<br />

knowledge; completely independent from the fact if you<br />

require individual conveying elements or a complex system<br />

including assembly, control and commissioning.<br />

12 / 15 We take control of your handling! We understand what<br />

your situation requires and suggest the suitable solution as<br />

system modules. During this process our thinking and work<br />

is focused on practicality and flexibility.<br />

16 / 19 We ensure smooth procedures! Within the scope of a<br />

maintenance contract we ensure that production<br />

downtimes can be avoided in your company. Our vertical<br />

range of manufacture permits us to react to last-minute<br />

requests in a quick and flexible manner.<br />

The company 20 / 23 We deliver quality! Quality developed and produced<br />

exclusively in Germany, more precisely in North Rhine-<br />

Westphalia.

Expertise<br />

We see the efficiency in processes before<br />

they become real.<br />

TRAPO | Expertise | 04 / 05<br />

Solutions development in dialogue<br />

Project management<br />

Simulation<br />

Every project starts with a talk. You describe your product to us, your requirement<br />

and your objective and we present you the corresponding possibilities and solutions<br />

so that we can reach this objective together. You will receive support from the same<br />

employee, who will be at your disposal at any time throughout the entire development<br />

of the product. This permits short paths and a close contact without information<br />

loss. It is important to us that that you receive the best support possible!<br />

Prior to the implementation the following have to be determined and decided<br />

about; requirement, possibilities and the volume of your project. In the project<br />

design phase the procedure and goals are determined, individual work steps to the<br />

implementation are mapped out and carefully planned. We do not leave anything to<br />

chance and at the same time we maintain the freedom and flexibility that are<br />

required to react to unexpected events and changes in the course of the project in<br />

an appropriate and relaxed manner. Planning foresight permits us to implement<br />

deviations at short notice.<br />

Already during the planning phase we have the goal in mind. The functions of your<br />

systems are developed in 3D and, if required, we will present it in a simulation.<br />

We exclusively use modern software for this purpose. Sequences, cycle times and<br />

interfaces can thus already be visualised before the start of the production and<br />

are continuously optimised during the development. Already in the planning phase<br />

we create the conditions for highest possible effectiveness and contribute to<br />

strengthening your market position in the long term.

TRAPO | Expertise | 06 / 07<br />

Design<br />

Control engineering<br />

Production<br />

Commissioning and assembly<br />

During the design phase ideas take shape. Our strong team consisting of engineers<br />

and technicians is characterised by both its creativity and its specialist technical<br />

knowledge and cross-industry experience. We design your system layout in<br />

three-dimensional views and permit the testing of the individual components in a<br />

coherent system using simulation. The aim is to optimise existing processes and<br />

to smoothly integrate new modules in the work process; completely independent<br />

from the size and volume of the respective project.<br />

Control engineering connects process and machine and turns your system into an<br />

intelligent one. Therefore it is obvious and sensible to purchase design and control<br />

engineering from one source. Our team of electrical planning engineers, electronics<br />

technicians and programmers deal with software development, preparation of circuit<br />

diagrams and systems automation; from the simple motor control via all SPS controls<br />

and robot programming to the connection to existing ERP systems. We see your<br />

system in context. This avoids costly interfaces and unnecessary information loss<br />

We attach great importance to the standardisation of procedures and products in<br />

order to smoothly integrate individual elements into existing processes, if required,<br />

and to be able to transfer existing solutions to related tasks. This saves us and our<br />

customers time and costs. Apart from different versions, sizes and colour and<br />

depending on the sector and application area, we offer even material alternatives,<br />

develop specialised grippers, cells and safety concepts so that a large whole in<br />

terms of profitability and efficiency is created.<br />

We only leave once your system is up and running! Trained fitters carry out the<br />

professional installation and the integration of the individual elements and they<br />

monitor the commissioning on site. If requested the approval inspection can also be<br />

carried out in our premises. For this purpose your system is set up in our assembly<br />

hall, all specific components and functions are tested and released. Only then the<br />

individual parts are taken to their point of destination and integrated in the running<br />

operation, if required. Like this we avoid unnecessary assembly-related downtimes.<br />

During commissioning an extensive introduction to handling the system is given.<br />

Expertise<br />

Complex projects are the sum of many<br />

details. We concentrate on every single<br />

one of them.

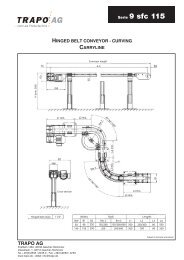

TRAPO | Materials handling | 08 / 09<br />

Conveyor technique<br />

Enclosures<br />

TRAPO develops individual material<br />

handling systems<br />

We plan and develop solutions for individual complete systems,<br />

completely independent from complexity and volume of the respective<br />

company and its production processes. In close cooperation with you<br />

as customer, we create customised material flow systems that are the<br />

basis for economical production methods and that can give you a<br />

significant advantage in terms of competition.<br />

Besides planning and development, our range of services also comprises<br />

the production, assembly and control of the conveying and handling<br />

systems. Being at your disposal as full service provider when it comes<br />

to conveying and handling, we are able to react to different requests<br />

and demands in a competent manner. Your personal contact person will<br />

advise you in all issues and will forward your requests without any<br />

information getting lost. This is comfortable and above all saves time<br />

and costs.

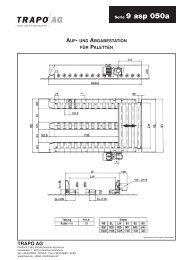

TRAPO | Materials handling | 10 / 11<br />

Conveyor technique<br />

Materials handling elements<br />

TRAPO optimises existing processes<br />

Our standardised materials handling elements are manufactured in<br />

accordance with the modular design principle and can be integrated<br />

into a new or existing system in a fast and smooth manner. They<br />

offer all features that are required to enhance the processes within<br />

your system:<br />

Speed – The quality of our conveying elements and technical<br />

solutions make the planning of deadlines easier and safer.<br />

Flexibility – Our products are available in various models. Thanks to<br />

this they can be variably used and randomly extended by using add-on<br />

components.<br />

Reliability – Our multi-directional roller conveyors, chain and belt<br />

conveyors handle even heavy loads with high speed in a uniform and<br />

safe manner.<br />

Optimum utilisation of space – Our conveyor systems offer powerful<br />

solutions for both large and small areas.<br />

Vertical conveyors<br />

Multi-directional roller conveyors<br />

Belt conveyors<br />

Discharge and distribution stations<br />

Modular and slat conveyors<br />

Rotary collecting tables<br />

Accessories<br />

Pallet conveyor range<br />

Chain and belt conveyors<br />

Roller conveyors<br />

Roller conveyor curves

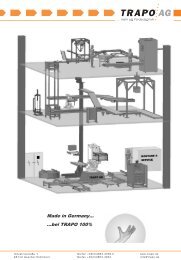

TRAPO | Robotics and handling systems | 12 / 13<br />

Robotics and handling systems<br />

TRAPO develops complex<br />

handling systems<br />

The requirements for robotics and handling systems are as diverse as<br />

the goods to be transported. Our product range meets this diversity.<br />

Our experience permits us the use and handling of robots of all<br />

leading manufacturers and makes. The heart of a robot cell, however,<br />

is the gripper. Only the gripper eventually permits the execution of the<br />

specific handling tasks that might have very different and individual<br />

requirements, depending on the transport material.<br />

The central transport material within the process is the product. The<br />

grippers can also handle the change of pallets, loading of intermediate<br />

layers and test and inspection tasks. We develop grippers for a variety<br />

of possible materials, application areas and ambient conditions.<br />

Depending on what you want to move, what space is available and how<br />

many work steps are to be carried out simultaneously, we shall choose<br />

the appropriate gripper together with you. Key criteria here can be the<br />

gripper weight and the precision of the gripper, size, service life, safety<br />

conditions, changeover times and connection options.

TRAPO | Robotics and handling systems | 14 / 15<br />

We always find a solution, independent from the shape, weight and<br />

surface of the respective transport material. Our gripper range permits the<br />

handling of solid, smooth materials and soft, porous materials, cartons,<br />

sacks and pallets to very small thin and fragile parts. Even delicate goods<br />

are effectively handled by us whilst avoiding any damage to the material.<br />

Combination grippers are particularly suited for small areas, where<br />

several work steps are to be carried out simultaneously.<br />

Fork grippers cannot only hold flimsy carton boxes or sacks, but also suck<br />

intermediate layers or grip empty pallets.<br />

Mechanical grippers grip smooth surfaces securely and safely whilst<br />

preventing deformations.<br />

Vacuum grippers are suited for smooth, air impermeable goods<br />

of any shape.<br />

Magnetic grippers take up relatively little space and work even in<br />

the event of a power-cut.<br />

Needle grippers grip and carefully transport soft, porous products<br />

where suction is not possible.<br />

Combination grippers<br />

Fork grippers<br />

Mechanical grippers<br />

Vacuum grippers<br />

Magnetic grippers<br />

Needle grippers

TRAPO | Service and maintenance | 16 / 17<br />

Service and maintenance<br />

TRAPO keeps your production running<br />

After the successful commissioning of your system we shall continue to<br />

be at your disposal as contact person and as responsible company we<br />

naturally offer you the maintenance of the system we installed. For this<br />

purpose we will draw up an individual maintenance contract together<br />

with you, depending on the type of system and your applications.<br />

Regular maintenance of a system is essential to ensure safety and<br />

efficiency. Downtimes are reduced to a minimum and best possible<br />

use is made of the utilisation capabilities. For system concepts can<br />

greatly differ depending on their size, volume and purpose, we shall<br />

specify individual maintenance intervals for your system in the<br />

maintenance contract.

TRAPO | Service and maintenance | 18 / 19<br />

Our customer care can be reached by phone at any time which puts us<br />

in a position to immediately react to urgent requests or incidents and, if<br />

required, to assist you at your premises as quickly as possible. Our<br />

extensive stock of original spare parts guarantees a quick delivery and<br />

ensures that your system continues to run with the usual efficiency<br />

after wear-related repairs.<br />

All consulting service, maintenance works and repairs are carried out by<br />

our qualified specialists. You may always rest assured that the high<br />

standard of your systems is maintained.<br />

24/7 Service<br />

Spare parts service Maintenance<br />

Our extensive stock of original spare parts guarantees a<br />

prompt delivery.<br />

Our customer care can be reached by phone at any time.<br />

The maintenance intervals for your system will be<br />

specified in an individual maintenance contract.

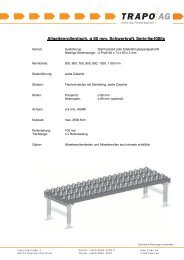

TRAPO | The company | 20 / 21

TRAPO | The company | 22 / 23<br />

The company<br />

TRAPO has been setting standards - for 55 years<br />

Quality „made in Germany“<br />

Ever since the foundation in 1957, TRAPO <strong>AG</strong> has been playing a decisive<br />

role in shaping the market for materials handling. Our range of services<br />

comprises the planning and development, the production, the assembly<br />

and the sale of individual conveying elements and complex fully automated<br />

conveyor and handling systems. This is complemented and<br />

rounded off by the development of state-of-the-art control engineering.<br />

Our versatile range of grippers helped us make a name for ourselves as<br />

motivated and competent partner even at international levels.<br />

Certificates<br />

A distinctive sign for the successful implementation for our high<br />

quality demand is the certification by the TÜV Cert. Since 1995 we have<br />

been certified in accordance with DIN EN ISO 9001. This certifies<br />

that our work and products are safety-tested, reliable and meet high<br />

quality standards.<br />

Facts and figures<br />

Affiliate: TRAPOROL GmbH<br />

Industriestr. 1<br />

48712 Gescher-Hochmoor<br />

www.traporol.de<br />

Business division: Planning, production, sales and<br />

assembly of conveyor systems<br />

and handling systems and robotic<br />

systems<br />

Board: Kai Hermann, Alfred Palm<br />

Number of employees in the group: 220<br />

Sales volume of the group: approx. 26 Mio. Euro<br />

We exclusively produce in our production halls in Gescher-Hochmoor<br />

in North Rhine-Westphalia. Since 2006 we have been working in three<br />

production halls, one of which is used exclusively for the production of<br />

stainless steel systems.<br />

The TRAPO team now consists of 220 qualified employees. Their<br />

knowledge and experience are the basis for continually new<br />

developments and innovations.

TRAPO | Pharma und Healthcare<br />

TRAPO <strong>AG</strong><br />

Industriestraße 1<br />

48712 Gescher-Hochmoor<br />

Tel. +49 2863 2005-0<br />

Fax +49 2863 4264<br />

info@trapo.de<br />

www.trapo.de