Gardner-Denver Aire Hoist Catalog - Tecno Italia s.r.l

Gardner-Denver Aire Hoist Catalog - Tecno Italia s.r.l

Gardner-Denver Aire Hoist Catalog - Tecno Italia s.r.l

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

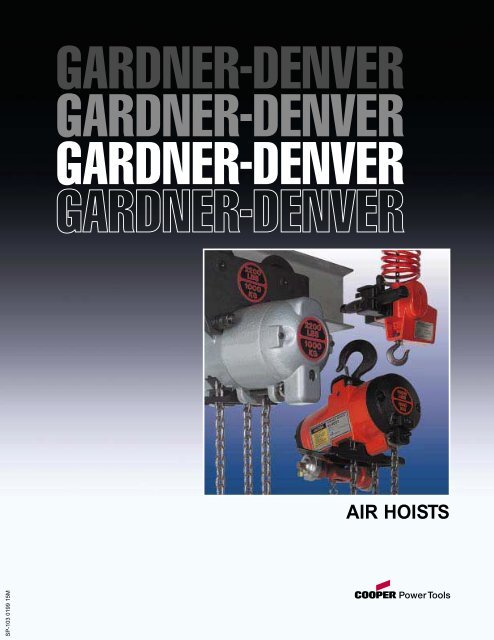

SP-103 0199 15MAIR HOISTS

Model Number IndexMODEL NUMBER PAGE7 Series75250AC5 9K1 SeriesK1CA22LPEP010AAA22 42K1CA33LPEP010AAA33 42K1CA44LPEP010AAA44 42K1CA66LPEP010GCA66 42K1CA88LPEP010GCA88 42K1HA22LPEP010AAA22 12K1HA22LREP010AAA22 12K1HA33LPEP010AAA33 12K1HA33LREP010AAA33 12K1HA44LPEP010AAA44 12K1HA44LREP010AAA44 12K1HA66LPEP010CCA66 12K1HA66LREP010CCA66 12K1HA88LPEP010CCA88 12K1HA88LREP010CCA88 12K1TA22LPEP010AAA22 30K1TA22LREP010AAA22 30K1TA33LPEP010AAA33 30K1TA33LREP010AAA33 30K1TA44LPEP010AAA44 30K1TA44LREP010AAA44 30K1TA66LPEP010BCA66 30K1TA66LREP010BCA66 30K1TA88LPEP010BCA88 30K1TA88LREP010BCA88 30K5 SeriesK5HA05LPEL010AAA05 10K5HA05LREL010AAA05 10K5HA05RPER010ACA05 10K5HA05RRER010ACA05 10K5HA11LPEL010AAA11 10K5HA11LREL010AAA11 10K5HA11RPER010ACA11 10K5HA11RRER010ACA11 10K5HA22LPEL010CEA22 10K5HA22LREL010CEA22 10K5HA22RPER010CGA22 10K5HA22RRER010CGA22 10K5LA05LPEL010AAA05 22K5LA05LREL010AAA05 22K5LA11LPEL010AAA11 22K5LA11LREL010AAA11 22K5LA22LPEL010CEA22 22K5LA22LREL010CEA22 22K5TA05LPEL010AAA05 28K5TA05LREL010AAA05 28K5TA11LPEL010AAA11 28K5TA11LREL010AAA11 28K5TA22LPEL010ACA22 28K5TA22LREL010ACA22 28P1 SeriesP1HA03LPEL010AAA03 14P1HA03LREL010AAA03 14P1HA03RPER010AGA03 14P1HA03RRER010AGA03 14P1HA05LPEL010AAA05 14P1HA05LREL010AAA05 14P1HA05RPER010AGA05 14P1HA05RRER010AGA05 14P1HA10LPEL010AAA10 14P1HA10LREL010AAA10 14P1HA10RPER010AGA10 14P1HA10RRER010AGA10 14P1HA20LPEL010EHA20 14P1HA20LREL010EHA20 14P1HA04RPEN010CCA05 14MODEL NUMBER PAGEP1HA04RREN010CCA05 14P1HA09RPEN010CCA10 14P1HA09RREN010CCA10 14P1LA03LPEL010AAA03 24P1LA03LREL010AAA03 24P1LA05LPEL010AAA05 24P1LA05LREL010AAA05 24P1LA10LPEL010AAA10 24P1LA10LREL010AAA10 24P1LA20LPEL010BHA20 24P1LA20LREL010BHA20 24P1TA03LPEL010AAA03 32P1TA03LREL010AAA03 32P1TA05LPEL010AAA05 32P1TA05LREL010AAA05 32P1TA10LPEL010AAA10 32P1TA10LREL010AAA10 32P2 SeriesP2CA11LPEL010AAA11 44P2CA22LPEL010AAA22 44P2CA44LPEL101AGA44 44P2CA15LPEQ010CCA15 44P2CA30LPQ010CEA30 44P2HA11LPEL010AAA11 16P2HA11LREL010AAA11 16P2HA11RPER010AKA11 16P2HA11RRER010AKA11 16P2HA22LPEL010AAA22 16P2HA22LREL010AAA22 16P2HA22RPER010AKA22 16P2HA22RRER010AKA22 16P2HA44LPEL010GGA44 16P2HA44LREL010GGA44 16P2HA44RPER010GIA44 16P2HA44RRER010GIA44 16P2HA10LPEQ010AAA10 16P2HA10LREQ010AAA10 16P2HA15LPEQ010CCA15 16P2HA15LREQ010CCA15 16P2HA30LPEQ010EEA30 16P2HA30LREQ010EEA30 16P2TA10LPEQ010BCA10 34P2TA10LREQ010BCA10 34P2TA11LPEL010AAA11 34P2TA11LREL010AAA11 34P2TA15LPEQ010BCA15 34P2TA15LREQ010BCA15 34P2TA22LPEL010AAA22 34P2TA22LREL010AAA22 34P2TA30LPEQ010CEA30 34P2TA30LREQ010CEA30 34P2TA44LPEL010DGA44 34P2TA44LREL010DGA44 34P3 SeriesP3CA22LPEP010AAA22 46P3CA43LPEP010AAA43 46P3CA80LPEP010ACA80 46P3HA22LPEP010AAA22 18P3HA43LPEP010AAA43 18P3HA80LPEP010CCA80 18P3NA22LPEP010AAA22 48P3NA43LPEP010AAA43 48P3TA22LPEP010AAA22 36P3TA43LPEP010AAA43 36P3TA80LPEP010BCA80 36HOISTRACTORSTATA04NPESXAXA 40TATA04OAEGXAXA 40TATA04PBEPXAXA 40MODEL NUMBER PAGETATA12NPESXAXA 40TATA12OAEGXAXA 40TATA12PBEPXAXA 40TATA24NPESXAXA 40TATA24OAEGXAXA 40TATA24PBEPXAXA 40TATA04NDESCAXA 40TATA04OEEGCAXA 40TATA04PFEPCAXA 40TATA12NDESCAXA 40TATA12OEEGCAXA 40TATA12PFEPCAXA 40TATA24NDESCAXA 40TATA24OEEGCAXA 40TATA24PFEPCAXA 40TATA04NDESKAXA 40TATA04OEEGKAXA 40TATA04PFEPKAXA 40TATA12NDESKAXA 40TATA12OEEGKAXA 40TATA12PFEPKAXA 40TATA24NDESKAXA 40TATA24OEEGKAXA 40TATA24PFEPKAXA 40TATA04NDESDAXA 40TATA04OEEGDAXA 40TATA04PFEPDAXA 40TATA15NDESDAXA 40TATA12OEEGDAXA 40TATA12PFEPDAXA 40TATA24NDESDAXA 40TATA24OEEGDAXA 40TATA24PFEPDAXA 40TATA04NDESEAXA 40TATA04OEEGEAXA 40TATA04PFEPEAXA 40TATA12NDESEAXA 40TATA12OEEGEAXA 40TATA12PFEPEAXA 40TATA24NDESEAXA 40TATA24OEEGEAXA 40TATA24PFEPEAXA 40TATA04NDESFAXA 40TATA04OEEGFAXA 40TATA04PFEPFAXA 40TATA12NDESFAXA 40TATA12OEEGFAXA 40TATA12PFEPFAXA 40TATA24NDESFAXA 40TATA24OEEGFAXA 40TATA24PFEPFAXA 40TATA04NPESXBXA 40TATA12NPESXBXA 40TATA24NPESXBXA 40TATA04NDESEBXA 40TATA12NDESEBXA 40TATA24NDESEBXA 40TATA04NDESFBXA 40TATA12NDESFBXA 40TATA24NDESFBXA 40TATA04NDESHAXA 40TATA04OEEGHAXA 40TATA04PFEPHAXA 40TATA12NDESHAXA 40TATA12OEEGHAXA 40TATA12PFEPHAXA 40TATA24NDESHAXA 40TATA24OEEGHAXA 40TATA24PFEPHAXA 402

<strong>Hoist</strong> OverviewFueled by endless numbers of varying applications, and the desire to provide greater flexibility, <strong>Gardner</strong>-<strong>Denver</strong> offers an extensive list ofhoist options, and accessories. As you begin to define the hoist configuration which best suits your unique application, utilize the criteriaoutlined here to obtain the optimum operator/hoist/task relationship.6Mounting Options■ Hook MountAlthough requiring more headroom than lugmounts,the flexibility of hook mounted hoistsmake them the more popular choice. Easier tohang and relocate, hook mounted hoists rotateat both the upper and lower hooks, allowingthe operator greater flexibility whenmanipulating a load into a desired position or angle. In addition,many hook mounted hoists offer the option of link or roller chain,and when hung from the appropriate <strong>Gardner</strong>-<strong>Denver</strong> trolley, allowhorizontal movement of the load.■ Lug MountThe compact, low headroom design oflug mounted hoists make them ideal forapplications where space is at a premium.This semi-permanent mount provides thegreatest benefits in tight working situationswhere the non-rotating, non-swinging lug allows preciseplacement of the load. Lug mounted hoists are available with linkchain only, to allow side movement of the load, and can bemounted on the appropriate <strong>Gardner</strong>-<strong>Denver</strong> trolley for horizontalmovement of the load.■ Trolley MountFor semi-permanent applicationsrequiring horizontal load movement,trolley mounted hoists provide thegreatest benefits. This compact, non-rotating configuration holdsthe load in constant alignment, as ball bearing constructedwheels provide smooth movement along the beam. <strong>Gardner</strong>-<strong>Denver</strong> trolleys adapt to many “I” beam sizes and are offered inlink chain only, to allow side movement of the load.Motor Options■ Rotary VaneThe industry standard in air hoists, rotary vanemotors provide an economical, easy tomaintain solution for the majority of fast,rugged applications. The <strong>Gardner</strong>-<strong>Denver</strong> 7,K5, and K1 series of easy to operate hoistsincorporate rotary vane motors which can be removed withoutdisturbing brakes, valving, or gearing, while highly reliable springloaded vanes insure immediate response start after start.■ Axial Piston (manufactured exclusively by <strong>Gardner</strong>-<strong>Denver</strong>)For applications where precise load control is essential, <strong>Gardner</strong>-<strong>Denver</strong> offers the P1, P2, and P3 series of axial piston hoists.These motors operate using multiple air driven pistons providingaxial force; this force is converted to rotarymotion through the use of a socket plate anddriveshaft assembly, all within a small,compact package. Axial piston motors provideseveral advantages including precise loadcontrol, quiet operation, low air consumption,and greater resistance to adverse airconditions.Control Options■ RopeRope control provides a simple, directlink to the hoist control valve, allowingthe operator to “feather” the operation ofthe hoist, making starts and stops moreaccurate and predictable. Because thereare no moving parts, rope controls require minimum maintenanceand are economical to replace.■ Pendant<strong>Gardner</strong>-<strong>Denver</strong> hoist control pendantsprovide a versatile, one-handed method ofhoist control. With varying length options, theoperator can safely control both lifting andlowering of the hoist as well as horizontalmovement of a hoistractor, from 5 to 25 ftaway. With the required cable assembly, thependant control provides a means for pullinga trolley, and the ergonomic handle design provides operatorcomfort while preventing accidental operation.Chain Options■ LinkLink chain, with its relatively low cost, is available on all hoistmodels, and is practical for use in a wide variety ofapplications. Its capacity for rotation allows the operator torotate the load slightly to assist with precise placement. Forapplications requiring rust and spark resistance, <strong>Gardner</strong>-<strong>Denver</strong> offers zinc plated chain on all models of hoists, andstainless steel chain on hoists with capacities up to 3000 lbs.■ RollerFor smother operation and extended life, <strong>Gardner</strong>-<strong>Denver</strong>offers roller chain on the K5, P1, and P2 series of hookmounted hoists. In addition, roller chain manufactured withstainless steel is available for applications requiring sparkresistant or clean room operation.Single or Double Reeved■ Single ReevedWhen speed is of more importance than capacity,the single reeved hoist is the best choice. Throughthe direct connection of the lower hook to the chain,and then to the hoist, all available drive speed istransferred to the load.■ Double ReevedFor extra lifting capacity, the doublereeved configuration increases the amount of weightthe motor can lift. By routing the chain around asprocket on the lower hook before connecting it tothe hoist drive, lifting capacity is doubled. In turn, thespeed of the lift is reduced by half. For heavy andsensitive loads, this slower action could bepreferable.

Selecting the Proper <strong>Hoist</strong>General <strong>Hoist</strong> Selection<strong>Hoist</strong> Mounting (page 6):■ Hook (pages 8-19) ■ Lug (pages 21-25) ■ Trolley (pages 27-37)■ <strong>Hoist</strong>ractor (pages 40-41) ■ <strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination Units (pages 44-51)<strong>Hoist</strong> Motor Type (page 6):■ Rotary Vane■ Axial PistonCapacity Requirement (see appropriate hoist page):Control Type (page 6):Rope: ■ Standard 5 feet __________________ Specify optional lengthPendent: ■ Standard 5 feet __________________ Specify optional lengthChain Type (page 6):■ Link ■ Roller ■ Spark ResistantLift (see appropriate <strong>Hoist</strong> page):■ Standard 10 feet ______________ Specify optional length ____________ Lifting speedHook Type: (optional hooks, page 54)Upper: ■ Standard ■ BullardLower: ■ Standard ■ BullardBeam Specifications (page 50):Trolley Mounted <strong>Hoist</strong>s, <strong>Hoist</strong>ractors & Combination Units____________________ Width ____________________ HeightWheel Type:Trolley (pages 20 & 26): ■ Tapered (Standard) ■ Flat ■ Narrow Flat*<strong>Hoist</strong>ractor (page 40): ■ Tapered (Standard) ■ Flat ■ Narrow Flat*<strong>Hoist</strong>/<strong>Hoist</strong>ractor Comb. Unit (pages 42-49): ■ Tapered (Standard) ■ Flat ■ Narrow Flat**NOTE: Suitable for American Std., American Monorail, Cleveland Tramrail, Spanmaster, Whiting,and Louden patented “I” beams<strong>Hoist</strong>ractor Engagement (Page 40):■ Spring (Standard) ■ Free Wheel to Positive Drive ■ Positive Drive to Free Wheel<strong>Hoist</strong>ractor Engaging Wheel Type (Page 40):■ Neoprene (Standard)■ AdipreneExtra Equipment■ Chain Container (Pg. 54-55) ■ Auxiliary Cable (Pg. 57) ■ Hose Trolley (Pg. 57) ■ Piped Exhaust Adapter ■ Flow Control Valve (Pg. 57)7

Hook Mounted <strong>Hoist</strong>s<strong>Gardner</strong>-<strong>Denver</strong> hook mountedhoists are designed to provide theultimate in high strength andflexibility. Hook mounted hoistscan quickly be hung from virtuallyany structure including trolleys,and their portability make themideal for maintenance applicationsor on construction sites. Ballbearing constructed upper andlower hooks allow full 360˚rotation of the hoist and load forprecision load placement, whileoptional roller chain, availableexclusively on hook mountedhoists, provides longer chain lifeand smoother lifting and loweringmotion. With load lifting capacitiesranging from 275 to 8800 lbs.,choice of rotary vane or axialpiston configurations, and manyspark resistant options, matchingone of these industrial gradehoists to your shop or clean roomapplication will not be a problem.Rotary Vane <strong>Hoist</strong>s7 Series . . . . . . . . . . . . . . .9K5 Series . . . . . . . . . . .10-11K1 Series . . . . . . . . . . .12-13Axial Piston <strong>Hoist</strong>sP1 Series . . . . . . . . . . .14-15P2 Series . . . . . . . . . . .16-17P3 Series . . . . . . . . . . .18-19Trolleys for hookmounted hoists . . . . . . . . . .208

Hook Mounted <strong>Hoist</strong>sGARDNER-DENVER ®7 SeriesCapacity:275 lbs.125 kg■ Compact, Lightweight Design makes the7 series the ideal portable, plug-n-go hoists.■ Self-Cooling, Self-Adjusting Disc Brakeprovides smooth stops and starts through8 ft. of lift.■ Conveniently Positioned Thumb Controlsallow right or left hand operation.The smooth running <strong>Gardner</strong>-<strong>Denver</strong> 7 serieshoists feature a built in chain container and loadcapacity up to 275 lbs., making this lightweight(only 19 lbs), compact hoist the perfect solutionfor an endless number of light duty, low lift heightapplications. Often found on loading docks, inshipping or receiving areas, or mounted aboveparts washers or tooling fixtures, this simple touse, portable hoist provides an economicalsolution for increasing worker productivity.Model Number Lifting & Lowering Speeds LiftChain Capacity Maximum Lift Maximum LowerDistanceWeightUnit Mounted Control Typelbs. kg fpm mpm fpm mpm ft m lbs. kg75250AC5 LINK 275 125 38 12 60 18 8.0 2.4 24 11GENERAL:Air Inlet: 3/8" NPT (use 1/2" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa).Air Consumption 40 cfm (1.13m 3 /min.) at rated load.STANDARD EQUIPMENT:Hook mounted air hoist with built-in chain containerEXTRA EQUIPMENT:Trolley – page 20Air strainer intake fitting – A9P14509

Hook Mounted <strong>Hoist</strong>sGARDNER-DENVER ®K5 SeriesCapacity:550-2200 lbs.250-1000 kg■ Rotary Vane Air Motor■ Rope or Pendent Control■ Link or Roller ChainSingle Reeved550 lbs. (250 kg) & 1100 lbs. (500 kg) CapacityDouble Reeved2200 lbs. (1000 kg) Capacity5.62"14.0" 14.0"6.3"6.5"15.21"20.84"8.62"13.0"10

Hook Mounted <strong>Hoist</strong>sK5 H A 05 L PE L --- A A A 05SERIESK5TYPE MOUNTH = HookFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY05 = 550 lbs.11 = 1100 lbs.22 = 2200 lbs.CHAIN TYPEL = LinkR = RollerCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)R = RopeS = Pendent (<strong>Hoist</strong> /<strong>Hoist</strong>ractor/Axial Motor-6LVR)T = Pendent (<strong>Hoist</strong> /<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6LVR)W = None-Pendent ReadyX = None*See page 39CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkP = Zinc Plated LinkR = Standard RollerX = No ChainZ= NoneCAPACITY RATING05 = 550 lbs. (05)06 = 550 lbs. (22)11 = 1100 lbs. (11)12 = 1100 lbs. (22)22 = 2200 lbs. (22)VINTAGEALOWER HOOKA = Standard Link (05/11)B = Bullard Link (05/11)C = Standard Roller (05/11)D = Bullard Roller (05/11)E = Standard Link (22)F = Bullard Link (22)G = Standard Roller (22)H = Bullard Roller (22)X = No HookUPPER HOOKA = Standard (05/11)B = Bullard (05/11)C = Standard (22)D = Bullard (22)X = No HookAMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Lifting Lowering Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgK5HA05LPEL010AAA05 K5HA05LREL010AAA05 Link 550 250 40-67 12-20 110-147 33-44 1 42 19K5HA05RPER010ACA05 K5HA05RRER010ACA05 Roller 550 250 40-67 12-20 110-147 33-44 1 42 19K5HA11LPEL010AAA11 K5HA11LREL010AAA11 Link 1100 500 20-50 6-15 80-120 24-36 1 42 19K5HA11RPER010ACA11 K5HA11RRER010ACA11 Roller 1100 500 20-50 6-15 80-120 24-36 1 42 19K5HA22LPEL010CEA22 K5HA22LREL010CEA22 Link 2200 1000 10-25 3-7 40-60 12-18 2 54 25K5HA22RPER010CGA22 K5HA22RRER010CGA22 Roller 2200 1000 10-25 3-7 40-60 12-18 2 54 25GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6.2 bar/620 kPa) air pressure.Air Consumption 75 cfm (2.12m 3 /min.) at rated load.STANDARD EQUIPMENT:Hook mounted air hoist with 10 ft. (3.0m) liftRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 54-55<strong>Hoist</strong> trolleys – page 20Auxiliary cable (Backup suspension) – page 57Air strainer intake fitting – A10161Piped exhaust adapter (3/4"NPT) – 536567Models marked for rapid delivery include standard optionsonly, with the following exceptions:Rope Control Length: Any available Pendent Control Length: 5, 10 or 15 ft.Capacity Rating: 05, 11 or 22 Amount of Lift: Any available11

Hook Mounted <strong>Hoist</strong>sGARDNER-DENVER ®K1 SeriesCapacity:2200-8800 lbs.1000-4000 kg■ Rotary Vane Air Motor■ Rope or Pendent Control■ Link ChainSingle Reeved2200 lbs. (1000 kg), 3300 lbs. (1500 kg) &4400 lbs. (2000 kg) CapacityDouble Reeved6600 lbs. (3000 kg) & 8800 lbs. (4000 kg) Capacity12

Hook Mounted <strong>Hoist</strong>sK1 H A 22 L PE P--- A A A 22SERIESK1TYPE MOUNTH = HookFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY22 = 2200 lbs. 66 = 6600 lbs.33 = 3300 lbs. 88 = 8800 lbs.44 = 4400 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)R = RopeS = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/Axial Motor-6LVR)T = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6LVR)W = None-Pendent ReadyX = None*See page 39CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkP = Zinc Plated LinkX = No ChainZ= NoneVINTAGEALOWER HOOKA = Standard Link (22/33/44)B = Bullard Link (22/33/44)C = Standard Link (66/88)D = Bullard Link (66/88)X = No HookUPPER HOOKA = Standard (22/33/44)B = Bullard (22/33/44)C = Standard (66/88)D = Bullard (66/88)X = No HookAMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010CAPACITY RATING11 = 1100 lbs. (11/22/33/44)22 = 2200 lbs. (22/33/44)33 = 3300 lbs. (33/44)34 = 3300 lbs. (66)44 = 4400 lbs. (44)45 = 4400 lbs. (66/88)66 = 6600 lbs. (66)88 = 8800 lbs. (88)Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgK1HA22LPEP010AAA22 K1HA22LREP010AAA22 Link 2200 1000 33 10 52 16 1 107 49K1HA33LPEP010AAA33 K1HA33LREP010AAA33 Link 3300 1500 21 6 34 10 1 107 49K1HA44LPEP010AAA44 K1HA44LREP010AAA44 Link 4400 2000 15 5 24 7 1 107 49K1HA66LPEP010CCA66 K1HA66LREP010CCA66 Link 6600 3000 10 3 17 5 2 130 59K1HA88LPEP010CCA88 K1HA88LREP010CCA88 Link 8800 4000 7 2 12 4 2 130 59GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 75 cfm (2.12m 3 /min.) at rated load.STANDARD EQUIPMENT:Hook mounted air hoist with 10 ft. (3.0m) liftRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55<strong>Hoist</strong> trolleys – page 20Auxiliary cable (Backup suspension) – page 57Piped exhaust adapter (3/4"NPT) – 536567Tractor connection kit – 51671013

Hook Mounted <strong>Hoist</strong>sGARDNER-DENVER ®P1 SeriesCapacity:300-2000 lbs.136-907 kg■ Axial Piston Air Motor■ Rope or Pendent Control■ Link or Roller ChainSingle Reeved300 lbs. (136 kg), 500 lbs. (227 kg) &1000 lbs. (454 kg) CapacityDouble Reeved2000 lbs. (907 kg) Capacity14

Hook Mounted <strong>Hoist</strong>sP 1 H A 03 L P E L --- A A A 03SERIESP1TYPE MOUNTH = HookFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY03 = 300 lbs. 09 =*1000 lbs.04 = *500 lbs. 10 = 1000 lbs.05 = 500 lbs. 20 = 2000 lbs *Spark ResistantCHAIN TYPEL = LinkR = RollerCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to postive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)R = Rope*See page 39S = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/Axial Motor-6LVR)T = No Control Type (Rope Ready)W = None-Pendent ReadyA = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6LVR)CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSZ = No Control LengthL = Standard Link N = Spark Resistant RollerP = Zinc Plated Link X = No ChainR = Standard RollerCAPACITY RATING03 = 300 lbs. (03/04/05/09/10)05 = 500 lbs. (04/05/09/10)10 = 1000 lbs. (09/10)11 = 1000 lbs. (20)15 = 1500 lbs. (20)20 = 2000 lbs. (20)VINTAGEALOWER HOOKA = Standard (03/05/10)B = Bullard (03/05/10)C = S.R. Standard Roller (04/09)D = S.R. Bullard Roller (04/09)E = Standard Roller w/mod. lift (03/05/10)F = Bullard Roller w/10ft. lift (03/05/10)G = Standard Roller w/10ft. lift (03/05/10)H = Standard Link (20)I = Bullard Link (20)P = Bullard Roller w/mod. lift (03/05/10)X = No Lower HookUPPER HOOKA = Standard (03/05/10)B = Bullard (03/05/10)C = S.R. Standard (04/09)D = S.R. Bullard (04/09)E = Standard (20)F = Bullard (20)X = No Upper HookAMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Lifting Lowering Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgP1HA03LPEL010AAA03 P1HA03LREL010AAA03 Link 300 136 80 24 88 27 1 28 13P1HA03RPER010AGA03 P1HA03RRER010AGA03 Roller 300 136 80 24 88 27 1 28 13P1HA05LPEL010AAA05 P1HA05LREL010AAA05 Link 500 227 47 14 115 35 1 28 13P1HA05RPER010AGA05 P1HA05RRER010AGA05 Roller 500 227 47 14 115 35 1 28 13P1HA10LPEL010AAA10 P1HA10LREL010AAA10 Link 1000 454 19 6 49 15 1 28 13P1HA10RPEL010AGA10 P1HA10RRER010AGA10 Roller 1000 454 19 6 49 15 1 28 13P1HA20LPEL010EHA20 P1HA20LREL010EHA20 Link 2000 907 9.5 324 7 2 31 14Spark Resistant UnitsP1HA04RPEN010CCA05 P1HA04RREN010CCA05 Roller 500 227 47 14 115 35 1 28 13P1HA09RPEN010CCA10 P1HA09RREN010CCA10 Roller 1000 454 19 6 49 15 2 28 13GENERAL:Air Inlet: 3/8" NPT (use 1/2" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 25 cfm (.71 m 3 /min.) at rated load.STANDARD EQUIPMENT:Hook mounted air hoist with 10 ft. (3.0m) liftRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – pages 54-55<strong>Hoist</strong> trolleys – page 20Auxiliary cable (Backup suspension) – page 57Piped exhaust adapter (1/2"NPT) – 500344Models marked for rapid delivery include standard optionsonly, with the following exceptions:Rope Control Length: Any available Pendent Control Length: 5, 10 or 15 ft.Capacity Rating: 03, 05 or 10 Amount of Lift: Any available15

Hook Mounted <strong>Hoist</strong>sGARDNER-DENVER ®P2 SeriesCapacity:1100-4400 lbs.500-2000 kg■ Axial Piston Air Motor■ Rope or Pendent Control■ Link or Roller ChainSingle Reeved1100 lbs. (500 kg), 1500 lbs. (680 kg) &2200 lbs. (1000 kg) CapacityDouble Reeved3000 lbs. (1360 kg) & 4400 lbs. (2000 kg) Capacity7.6"10.3"18.1"25.8"16

SERIESP2TYPE MOUNTH = HookHook Mounted <strong>Hoist</strong>sP 2 H A 11 L P E L --- A A A 11FEATURESA = Standard UnitE = Edible greaseH = Hi Temp GreaseP = Epoxy PaintR = Epoxy Paint/Edible GreaseS = Epoxy Paint/Hi Temp GreaseCAPACITY10 = 1000 lbs.11 = 1100 lbs. 30 =*3000 lbs. 44= 4400 lbs.15 =*1500 lbs. 22 = 2200 lbs. *Spark ResistantCHAIN TYPEL = LinkR = RollerCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-Free wheel positive drive-4LVR)*N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel positive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)*See page 39R = RopeS = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/Axial Motor-6LVR)T = No Control (Rope Ready)W = None-Pendent ReadyA = Pendant (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6LVR)CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSZ = No Control LengthL = Standard Link R = Standard RollerP = Zinc Plated Link X = No ChainQ = S.R. LinkGENERAL:Air Inlet: 3/8" NPT (use 1/2" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 44 cfm (1.3 m 3 /min.) at rated load.STANDARD EQUIPMENT:Hook mounted air hoist with 10 ft. (3.0m) liftRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthCAPACITY RATING03 = 300 lbs. (10/11/15)05 = 500 lbs. (10/11/15)10 = 1000 lbs. (10/11/15)11 = 1000 lbs. (10/15/22)15 = 1500 lbs. (15/22)20 = 2000 lbs. (22)22 = 2200 lbs. (22)30 = 3000 lbs. (30/44)31 = 1100 lbs. (30/44)32 = 2200 lbs. (30/44)40 = 4000 lbs. (44)44 = 4400 lbs. (44)VINTAGEALOWER HOOKA = Standard (11/22)B = Bullard (11/22)C = S.R. Standard Link (10/15)D = S.R. Bullard (10/15)E = S.R. Standard Link (30)F = S.R. Bullard Link (30)G = Standard Link (44)H = Bullard Link (44)I = Standard Roller (44)J = Bullard Roller (44)K = Standard Roller (11/22)L = Bullard Roller (11/22)X = No HookUPPER HOOKA = Standard (11/22)B = Bullard (11/22)C = S.R. Standard (10/15)D = S.R. Bullard (10/15)E = S.R. Standard (30)F = S.R. Bullard (30)G = Standard (44)H = Bullard (44)X = No HookAMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, represent the hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Lifting Lowering Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgP2HA11LPEL010AAA11 P2HA11LREL010AAA11 Link 1100 500 34 10 107 33 1 94 43P2HA11RPER010AKA11 P2HA11RRER010AKA11 Roller 1100 500 34 10 107 33 1 94 43P2HA22LPEL010AAA22 P2HA22LREL010AAA22 Link 2200 1000 17 5 56 17 1 94 43P2HA22RPER010AKA22 P2HA22RRER010AKA22 Roller 2200 1000 17 5 56 17 1 94 43P2HA44LPEL010GGA44 P2HA44LREL010GGA44 Link 4400 2000 9 328 9 2 126 57P2HA44RPER010GIA44 P2HA44RRER010GIA44 Roller 4400 2000 9 328 9 2 126 57Spark Resistant UnitsP2HA10LPEQ010AAA10 P2HA10LREQ010AAA10 Link 1000 454 38 12 107 33 1 94 43P2HA15LPEQ010CCA15 P2HA15LREQ010CCA15 Link 1500 680 237 58 18 1 94 43P2HA30LPEQ010EEA30 P2HA30LREQ010EEA30 Link 3000 1360 11 3 26 8 2 126 57EXTRA EQUIPMENT:Chain container – pages 54-55<strong>Hoist</strong> trolleys – page 20Auxiliary cable (Backup suspension) – page 57Piped exhaust adapter (3/4"NPT) – 535779Models marked for rapid delivery include standard optionsonly, with the following exceptions:Rope Control Length: Any available Pendent Control Length: 5, 10 or 15 ft.Capacity Rating: 11, 22 or 44 Amount of Lift: Any available17

Hook Mounted <strong>Hoist</strong>sGARDNER-DENVER ®P3 SeriesCapacity:2200-8000 lbs.1000-3629 kg■ Axial Piston Air Motor■ Pendent Control■ Link ChainSingle Reeved2200 lbs. (1000 kg) & 4300 lbs. (1950 kg) CapacityDouble Reeved8000 lbs. (3629 kg) Capacity18

Hook Mounted <strong>Hoist</strong>sP 3 H A 22 L P E P --- A A A 22SERIESP3TYPE MOUNTH = HookFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY22 = 2200 lbs.43 = 4300 lbs.80 = 8000 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (<strong>Hoist</strong> w/<strong>Hoist</strong>ractor-4LVR))P = Pendent Standard (STD-2LVR)X = None-Pendent readyCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = LinkZ = No Control LengthP = Zinc Plated LinkX = No ChainCAPACITY RATING11 = 1100 lbs. (22)20 = 2000 lbs. (22/43)22 = 2200 lbs. (22/43)40 = 4000 lbs. (43)43 = 4300 lbs. (43)50 = 5000 lbs. (80)60 = 6000 lbs. (80)80 = 8000 lbs. (80)VINTAGEALOWER HOOKA = Standard (22/43)B = Bullard (22/43)C = Standard (80)D = Bullard (80)X = No HookUPPER HOOKA = Standard (22/43)B = Bullard (22/43)C = Standard (80)D = Bullard (80)X = No HookAMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberPendent ControlLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightTypelbs. kg fpm mpm fpm mpm lbs. kgP3HA22LPEP010AAA22 Link 2200 1000 30 9 80 24 1 135 61P3HA43LPEP010AAA43 Link 4300 1950 15 5 40 12 1 135 61P3HA80LPEP010CCA80 Link 8000 3629 7 2 20 6 2 180 82GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 83 cfm (2.35 m 3 /min.) at rated load.STANDARD EQUIPMENT:Hook mounted air hoist with 10 ft. (3.0) liftPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55<strong>Hoist</strong> trolleys – page 20Auxiliary cable (Backup suspension) – page 57Tractor connection kit – 51671019

Trolleys for hook mounted hoistsTURNING RADIUS:Trolleys may be required to operateon curved beams. Determine theamount of curve (turning radius)involved and list this information onthe order. The diagram to the leftillustrates the proper method ofmeasuring turning radius.20Beam Width<strong>Hoist</strong> CapacityMinimumPart NumberHookLoad BarMin.Max.Radius Turning Clearance** Diameterlbs. kg in. mm in. mm in. mm Taper Flat Drawbar* in. mm in. mmWheel Wheel<strong>Hoist</strong> Series 7275 125 2.33 59 4.66 118 18 457 532992 1.50 38 0.75 19<strong>Hoist</strong> Series K5550 250 2.66 68 4.66 118 18 457 534925 534926 A60165 1.88 48 0.88 221100 500 2.66 68 4.66 118 18 457 527431 528235 A60165 1.88 48 0.88 222200 1000 3.00 76 5.25 133 21 533 527432 528236 A60164 2.25 57 1.12 28<strong>Hoist</strong> Series K12200* 1000 3.00 76 5.25 133 21 533 527432 528236 A60164 2.25 57 1.12 283300 1498 3.31 84 6.00 152 42 1067 534451 534709 A60164 2.25 57 1.25 324400 2000 3.31 84 6.00 152 42 1067 532274 534710 A60164 2.25 57 1.25 326600 3000 4.00 102 6.25 159 72 1829 531040 531040 516710 3.00 76 1.75 448800 4000 4.00 102 6.25 159 72 1829 531041 531041 516710 3.00 76 1.75 44<strong>Hoist</strong> Series P1300 136 2.66 68 4.66 118 18 457 539383 539384 A60165 1.88 48 0.88 22500 227 2.66 68 4.66 118 18 457 534923 534924 A60165 1.88 48 0.88 221000 454 2.66 68 4.66 118 18 457 527491 528161 A60165 1.88 48 0.88 222000 908 3.00 76 5.25 133 21 533 527492 528166 A60164 2.25 57 1.12 28<strong>Hoist</strong> Series P21100 500 2.66 68 4.66 118 18 457 527431 528235 A60165 1.88 48 0.88 222200 1000 3.00 76 5.25 133 21 533 527432 528236 A60164 2.25 57 1.12 284400 2000 3.31 84 6.00 152 42 1067 532274 534710 A60164 2.25 57 1.12 32<strong>Hoist</strong> Series P32200 1000 3.00 76 5.25 133 21 533 527432 528236 A60164 2.25 57 1.12 284300 1950 3.31 84 6.00 152 42 1067 528234 528237 A60164 2.25 57 1.25 328000 3629 4.00 102 6.25 159 72 1829 533578 533578 516710 3.00 76 1.75 44Spark Resistant Trolleys<strong>Hoist</strong> Series P1500 227 2.66 68 4.66 118 18 457 539388 539389 A60165 1.88 48 0.88 221000 454 3.00 76 5.25 133 21 533 539376 539377 A60164 2.25 57 1.12 28<strong>Hoist</strong> Series P21500 680 3.00 76 5.25 133 21 533 528186 528179 A60164 2.25 57 1.12 283000 1361 3.31 84 6.00 152 42 1067 528187 528188 A60164 2.25 57 1.12 32*NOTE: Drawbar for <strong>Hoist</strong>ractor**NOTE: Dimensions are for smallest size track

Lug Mounted <strong>Hoist</strong>sThe compact, low headroomdesign of lug mounted hoistsmake them ideal for applicationswhere space is at a premium.This semi-permanent mountprovides the greatest benefits intight working situations where thenon-rotating, non-swinging lugallows precise placement of theload. Lug mounted hoists areavailable with link chain only, toallow side movement of the load,and can be mounted on theappropriate <strong>Gardner</strong>-<strong>Denver</strong>trolley for horizontal movement ofthe load.Rotary Vane <strong>Hoist</strong>sK5 Series . . . . . . . . . .22-23Axial Piston <strong>Hoist</strong>sP1 Series . . . . . . . . . .24-25Trolleys for lugmounted hoists . . . . . . . . .2621

Lug Mounted <strong>Hoist</strong>sGARDNER-DENVER ®K5 SeriesCapacity:550-2200 lbs.250-1000 kg■ Rotary Vane Air Motor■ Rope or Pendent Control■ Link ChainSingle Reeved550 lbs. (250 kg) & 1100 lbs. (500 kg) CapacityDouble Reeved2200 lbs. (1000 kg) Capacity14.0"14.0"5.62"6.3"1.97"2.06"6.3"13.03"17.98"8.62"13.0"22

Lug Mounted <strong>Hoist</strong>sK5 L A 05 L PE L --- A A A 05SERIESK5TYPE MOUNTL = LugFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY05 = 550 lbs.11 = 1100 lbs.22 = 2200 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)R = RopeS = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/Axial Motor-6LVR)T = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6LVR)W = None-Pendent ReadyX = None*See page 39CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN TYPEL = Standard LinkZ = NoneP = Zinc Plated LinkX = No ChainCAPACITY RATING05 = 550 lbs. (05/11)06 = 550 lbs. (22)11 = 1100 lbs. (11)12 = 1100 lbs. (22)22 = 2200 lbs. (22)VINTAGEALOWER HOOKA = Standard Link (05/11)B = Bullard Link (05/11)E = Standard Link (22)F = Bullard Link (22)X = No HookUPPER LUGA = Standard (05/11)B = Standard (22)X = No ChainLIFT LENGTHSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgK5LA05LPEL010AAA05 K5LA05LREL010AAA05 Link 550 250 40-67 12-20 110-147 33-44 1 42 19K5LA11LPEL010AAA11 K5LA11LREL010AAA11 Link 1100 500 20-50 6-15 80-120 24-36 1 42 19K5LA22LPEL010CEA22 K5LA22LREL010CEA22 Link 2200 1000 10-25 3-7 40-60 12-18 2 54 25GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 75 cfm (2.12 m 3 /min.) at rated load.STANDARD EQUIPMENT:Lug mounted air hoist with 10 ft. (3.0m) liftRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55<strong>Hoist</strong> trolleys – page 26Auxiliary cable (Backup suspension) – page 57Air strainer intake fitting – A10161Piped exhaust adapter (3/4"NPT) – 53656723

Lug Mounted <strong>Hoist</strong>sGARDNER-DENVER ®P1 SeriesCapacity:300-2000 lbs.136-907 kg■ Axial Piston Air Motor■ Rope or Pendent Control■ Link ChainSingle Reeved300 lbs. (136 kg), 500 lbs. (227 kg) &1000 lbs. (454 kg) CapacityDouble Reeved2000 lbs. (907 kg) Capacity24

Lug Mounted <strong>Hoist</strong>sP 1 L A 03 L P E L --- A A A 03SERIESP1TYPE MOUNTL = LugFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY03 = 300 lbs.05 = 550 lbs.10 = 1000 lbs.20 = 2000 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)R = RopeS = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/Axial Motor-6LVR)A = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6LVR)W = None-Pendent ReadyT = No Control Type (Rope Ready)*See page 39CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkZ = No Control LengthP = Zinc Plated LinkX = No ChainCAPACITY RATING03 = 300 lbs. (03/05/10)05 = 500 lbs. (05/10)10 = 1000 lbs. (10)11 = 1000 lbs. (20)15 = 1500 lbs. (20)20 = 2000 lbs. (20)VINTAGEALOWER HOOKA = Standard Link (03/05/10)B = Bullard Link (03/05/10)H = Standard Link (20)I = Bullard Link (20)X = No Lower HookUPPER LUGA = Standard (03/05/10)B = Standard (20)X = No LugLIFT LENGTHSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgP1LA03LPEL010AAA03 P1LA03LREL010AAA03 Link 300 136 80 24 88 27 1 28 13P1LA05LPEL010AAA05 P1LA05LREL010AAA05 Link 500 227 47 14 115 35 1 28 13P1LA10LPEL010AAA10 P1LA10LREL010AAA10 Link 1000 454 19 6 49 15 1 28 13P1LA20LPEL010BHA20 P1LA20LREL010BHA20 Link 2000 907 9.5 324 7 2 31 14GENERAL:Air Inlet: 3/8" NPT (use 1/2" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 25 cfm (.71 m 3 /min.) at rated load.STANDARD EQUIPMENT:Lug mounted air hoist with 10 ft. (3.0m) liftRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55<strong>Hoist</strong> trolleys – page 26Auxiliary cable (Backup suspension) – page 57Piped exhaust adapter (1/2"NPT) – 50034425

Trolleys for Lug Mounted <strong>Hoist</strong>sTURNING RADIUS:Trolleys may be required to operateon curved beams. Determine theamount of curve (turning radius)involved and list this information onthe order. The diagram to the leftillustrates the proper method ofmeasuring turning radius.Beam Width<strong>Hoist</strong> CapacityMinimumPart NumberHookLoad BarMin.Max.Radius Turning Clearance** Diameterlbs. kg in. mm in. mm in. mm Taper Flat Drawbar* in. mm in. mmWheel Wheel<strong>Hoist</strong> Series K5550 250 2.66 68 4.66 118 18 457 534925 534926 A60165 1.88 48 0.88 221100 500 2.66 68 4.66 118 18 457 527431 528235 A60165 1.88 48 0.88 222200 1000 3.00 76 5.25 133 21 533 527432 528236 A60164 2.25 57 1.12 28<strong>Hoist</strong> Series P1300 136 2.66 68 4.66 118 18 457 539383 539384 A60165 1.88 48 0.88 22500 227 2.66 68 4.66 118 18 457 534923 534924 A60165 1.88 48 0.88 221000 454 2.66 68 4.66 118 18 457 527491 528161 A60165 1.88 48 0.88 222000 908 3.00 76 5.25 133 21 533 527492 528166 A60164 2.25 57 1.12 28*NOTE: Drawbar for <strong>Hoist</strong>ractor**NOTE: Dimensions are for smallest size track26

Trolley Mounted <strong>Hoist</strong>sTrolley mounted air hoists offera low hook-to-beam dimensionfor low headroom or permanentinstallations. The heavy-dutytrolleys will adapt to almostevery size “I” beam. Trolleyshave ball bearing constructionfor easy movement and longlife. Trolley mounted hoistsfeature link chain only, to allowside movement of load, and allare adaptable for use with the<strong>Gardner</strong>-<strong>Denver</strong> <strong>Hoist</strong>ractor.Rotary Vane <strong>Hoist</strong>sK5 Series . . . . . . . . . .28-29K1 Series . . . . . . . . . .30-31Axial Piston <strong>Hoist</strong>sP1 Series . . . . . . . . . .32-33P2 Series . . . . . . . . . .34-35P3 Series . . . . . . . . . .36-3727

Trolley Mounted <strong>Hoist</strong>sGARDNER-DENVER ®K5 SeriesCapacity:550-2200 lbs.250-1000 kgBeam flange width:3.0-6.0 in76-162 mmMinimum turning radius:34 in864 mm■ Rotary Vane Air Motor■ Rope or Pendent Control■ Link ChainSingle Reeved5500 lbs. (250 kg) & 1100 lbs. (500 kg) CapacityDouble Reeved2200 lbs. (1000 kg) Capacity28

Trolley Mounted <strong>Hoist</strong>sK5 T A 05 L PE L --- A A A 05SERIESK5TYPE MOUNTT = TrolleyFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY05 = 550 lbs.11 = 1100 lbs.22 = 2200 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free Wheel to Positive Drive-5LVR)O = Pendent (w/<strong>Hoist</strong>ractor-Positive Drive to Free Wheel-5LVR)P = Pendent (Standard-2LVR)R = RopeS = Pendent (w/<strong>Hoist</strong>ractor & Axial Motor-6LVR)T = Pendent (w/2 <strong>Hoist</strong>ractor-6LVR)W = None-Pendent Ready*See page 39X = NoneCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN TYPEL = Standard LinkZ = No Control LengthP = Zinc Plated LinkX = No ChainCAPACITY RATING05 = 550 lbs. (05/11)06 = 550 lbs. (22)11 = 1100 lbs. (11)12 = 1100 lbs. (22)22 = 2200 lbs. (22)VINTAGEALOWER HOOKA = Standard Link (05/11)B = Bullard Link (05/11)C = Standard Link (22)D = Bullard Link (22)X = No HookTROLLEYA = 3-5" Tapered for (05/11/22)B = 5-6" Tapered for (05/11/22)C = 3-5" Tapered w/<strong>Hoist</strong>ractor bracket (05/11/22)D = 5-6" Flat for (05/11/22)E = 3-5" Flat for (05/11/22)F = 3-5" Flat w/<strong>Hoist</strong>ractor bracket (05/11/22)G = 2" Nrw Flat for (05/11/22)H = 2" Nrw Flat w/<strong>Hoist</strong>ractor bracket (05/11/22)AMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgK5TA05LPEL010AAA05 K5TA05LREL010AAA05 Link 550 250 40-67 12-20 110-147 33-44 1 82 37K5TA11LPEL010AAA11 K5TA11LREL010AAA11 Link 1100 500 20-50 6-15 80-120 24-36 1 82 37K5TA22LPEL010ACA22 K5TA22LREL010ACA22 Link 2200 1000 10-25 3-7 40-60 12-18 2 93 42GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 75 cfm (2.12 m 3 /min.) at rated load.STANDARD EQUIPMENT:Trolley mounted air hoist with 10 ft. (3.0m) liftTapered WheelsRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55Air strainer intake fitting – A10161Piped exhaust adapter (3/4"NPT) – 536567Tractor connection kit – 530388 (Used to modify existing <strong>Hoist</strong>)29

Trolley Mounted <strong>Hoist</strong>sGARDNER-DENVER ®K1 SeriesCapacity:2200-8800 lbs.1000-4000 kgBeam flange width:2200 lbs., 3300 lbs., 4400 lbs. capacity3.00-6.25 in76-159 mm6600 lbs., 8800 capacity4.00-6.25 in102-159 mmMinimum turning radius:2200 lbs., 3300 lbs., 4400 lbs. capacity60 in1524 mm6600 lbs., 8800 lbs. capacity72 in1829 mm■ Rotary Vane Air Motor■ Rope or Pendent Control■ Link ChainSingle Reeved2200 lbs. (1000 kg), 3300 lbs. (1500 kg) &4400 lbs. (2000 kg) CapacityDouble Reeved6600 lbs. (3000 kg) & 8800 lbs. (4000 kg) Capacity30

Trolley Mounted <strong>Hoist</strong>sK1 T A 22 L PE P--- A A A 22SERIESK1TYPE MOUNTT = TrolleyFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY22 = 2200 lbs. 66 = 6600 lbs.33 = 3300 lbs. 88 = 8800 lbs.44 = 4400 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)R = RopeS = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/Axial Motor-6 LVR)T = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6 LVR)W = None-Pendent Ready*See page 39X = NoneCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkZ = No Control LengthP = Zinc Plated LinkX = No ChainVINTAGEALOWER HOOKA = Standard Link (22/33/44)B = Bullard Link (22/33/44)E = Standard Link (66/88)F = Bullard Link (66/88)X = No HookTROLLEYA = 3-6.25" Tapered (22/33/44)B = 4-6.25" Tapered (66/88)C = 3.25" Nrw Flat (66/88)D = 3-6.25" Flat (22/33/44)E = 4-6.25" Flat (66/88)F = 2" Nrw Flat (22/33/44)AMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010CAPACITY RATING11 = 1100 lbs. (22/33/44)22 = 2200 lbs. (22/33/44)33 = 3300 lbs. (33/44)34 = 3300 lbs. (66)44 = 4400 lbs. (44)45 = 4400 lbs. (66/88)66 = 6600 lbs. (66)88 = 8800 lbs. (88)Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgK1TA22LPEP010AAA22 K1TA22LREP010AAA22 Link 2200 1000 33 10 52 16 1 270 123K1TA33LPEP010AAA33 K1TA33LREP010AAA33 Link 3300 1500 21 6 34 10 1 270 123K1TA44LPEP010AAA44 K1TA44LREP010AAA44 Link 4400 2000 15 5 24 7 1 270 123K1TA66LPEP010BCA66 K1TA66LREP010BCA66 Link 6600 3000 10 3 17 5 2 278 140K1TA88LPEP010BCA88 K1TA88LREP010BCA88 Link 8800 4000 7 2 12 4 2 278 140GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 75 cfm (2.12 m 3 /min.) at rated load.STANDARD EQUIPMENT:Trolley mounted air hoist with 10 ft. (3.0m) liftTapered WheelsRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55Piped exhaust adapter (3/4"NPT) – 536567Tractor connection kit – 516710 (Used to modify existing <strong>Hoist</strong>)31

Trolley Mounted <strong>Hoist</strong>sGARDNER-DENVER ®P1 SeriesCapacity:300-1000 lbs.136-454 kgBeam flange width:2.63-5.00 in67-127 mmMinimum turning radius:26 in660 mm■ Axial Piston Air Motor■ Rope or Pendent Control■ Link ChainSingle Reeved300 lbs. (136 kg), 500 lbs. (227 kg) & 1000 lbs. (454 kg) Capacity10.5"8.8"(218)32

Trolley Mounted <strong>Hoist</strong>sP 1 T A 05 L P E L --- A A A 05SERIESP1TYPE MOUNTT = TrolleyFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY03 = 300 lbs.05 = 500 lbs.10 = 1000 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-4LVR)N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-5LVR)O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)P = Pendent (Standard-2LVR)R = RopeS = Pendent (Combo w/Axial Motor-6LVR)A = Pendent (Combo w/<strong>Hoist</strong>ractor-6LVR)W = None-Pendent ReadyT = No Control Type (Rope Ready)*See page 39CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkZ = No Control LengthP = Zinc Plated LinkX = No ChainVINTAGEALOWER HOOKA = Standard (03/05/10)B = Bullard (03/05/10)X = No HookCAPACITY RATING03 = 300 lbs. (03/05/10)05 = 500 lbs. (05/10)10 = 1000 lbs. (10)TROLLEYA = 2.63-5" Tapered (03/05/10) (standard)B = 5-7" Tapered (03/05/10)C = 2.63-5" Tapered w/<strong>Hoist</strong>ractor bracket (03/05/10)D = 5-7" Flat (03/05/10)E = 2.63-5" Flat (03/05/10)F = 2.63-5" Flat w/<strong>Hoist</strong>ractor bracket (03/05/10)G = 2" Nrw Flat (03/05/10)H = 2" Nrw Flat w/<strong>Hoist</strong>ractor bracket (03/05/10)AMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberLifting & Lowering SpeedsChain Capacity Lifting Lowering Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgP1TA03LPEL010AAA03 P1TA03LREL010AAA03 Link 300 136 80 24 88 27 1 50 23P1TA05LPEL010AAA05 P1TA05LREL010AAA05 Link 500 227 47 14 115 35 1 50 23P1TA10LPEL010AAA10 P1TA10LREL010AAA10 Link 1000 454 19 6 49 15 1 50 23GENERAL:Air Inlet: 3/8" NPT (use 1/2" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 25 cfm (.71 m 3 /min.) at rated load.STANDARD EQUIPMENT:Trolley mounted air hoist with 10 ft. (3.0m) liftTapered WheelsRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55Piped exhaust adapter (1/2"NPT) – 500344Tractor connection kit – 502953 (Used to modify existing <strong>Hoist</strong>)Models marked for rapid delivery include standard optionsonly, with the following exceptions:Rope Control Length: Any available Pendent Control Length: 5, 10 or 15 ft.Capacity Rating: any available Amount of Lift: Any available33

Trolley Mounted <strong>Hoist</strong>sGARDNER-DENVER ®P2 SeriesCapacity:1100-4400 lbs.500-2000 kgBeam flange width:3.00-5.00 in76-127 mmMinimum turning radius:1100 lbs., 1500 lbs., 2200 lbs. capacity36 in914 mm6600 lbs., 8800 lbs. capacity60 in1524 mm■ Axial Piston Air Motor■ Rope or Pendent Control■ Link ChainSingle Reeved1100 lbs. (500 kg), 1500 lbs. (680 kg) &2200 lbs. (1000 kg) CapacityDouble Reeved3000 lbs. (1360 kg) & 4400 lbs. (2000 kg) Capacity34

SERIESP2TYPE MOUNTT = TrolleyTrolley Mounted <strong>Hoist</strong>sP 2 T A 11 L P E L --- A A A 11FEATURESA = Standard UnitE = Edible GreaseH = Hi Temp GreaseP = Epoxy PaintR = Epoxy Paint/Edible GreaseS = Epoxy Paint/Hi Temp GreaseCAPACITY10 = 1000 lbs. 22 = 2200 lbs.11 = 1100 lbs. 30 =*3000 lbs.15 =*1500 lbs. 44 = 4400 lbs.*Spark ResistantCHAIN TYPEL = LinkCONTROL TYPEL = Pendent (2 <strong>Hoist</strong>-4LVR)M = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-4LVR)*N = Pendent (w/<strong>Hoist</strong>ractor-Free wheel to positive drive-5LVR)*O = Pendent (w/<strong>Hoist</strong>ractor-Positive drive to free wheel-5LVR)*P = Pendent (Standard-2LVR)R =RopeS = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/Axial Motor-6LVR)A = Pendent (<strong>Hoist</strong>/<strong>Hoist</strong>ractor/<strong>Hoist</strong>ractor-6LVR)W = None-Pendent ReadyT = No Control (Rope Ready)*See page 39CONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSZ = No Control Length.L = Standard LinkQ = S.R. LinkP = Zinc Plated LinkX = No ChainNote: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.CAPACITY RATING03= 300 lbs. (10/11/15)05= 300 lbs. (10/11/15)10= 1000 lbs. (10/11/15)11= 1100 lbs. (11/15/22)15= 1500 lbs. (15/22)20= 2000 lbs. (22)22= 2200 lbs. (22)30= 3000 lbs. (30/44)31= 1100 lbs. (30)32= 2200 lbs. (30/44)40= 4000 lbs. (44)44= 4400 lbs. (44)VINTAGEALOWER HOOKA = Standard (11/22) F = S.R. Bullard (30)B = Bullard (11/22) G = Standard (44)C = S.R. Std. (10/15) H = Bullard (44)D = S.R. Bullard (10/15) X = No HookE = S.R. Std. (30)TROLLEYA = 3-5" Tapered (11/22)B = 3-5" Tapered S.R. (10/15)C = 3-5" Tapered S.R. (30)D = 3-5" Tapered (44)E = 3-5" Flat (11/22)F = 3-5" Flat S.R. (10/15)G = 3-5" Flat S.R. (30)H = 3-5" Flat (44)I = 2" Nrw Flat (11/22)J = 2" Nrw Flat S.R. (10/15)K = 2" Nrw Flat S.R. (30)L = 2" Nrw Flat (44)M = 5-7" Tapered (11/22)N = 5-7" Tapered (44)O = 5-7" Tapered S.R. (10/15)P = 5-7" Tapered S.R. (30)Q = 5-7" Flat (11/22)R = 5-7" Flat (44)S = 5-7" Flat S.R. (10/15)T = 5-7" Flat S.R. (30)AMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Model NumberLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightPendent Control Rope Control Typelbs. kg fpm mpm fpm mpm lbs. kgP2TA11LPEL010AAA11 P2TA11LREL010AAA11 Link 1100 500 34 10 107 33 1 113 51P2TA22LPEL010AAA22 P2TA22LREL010AAA22 Link 2200 1000 17 5 56 17 1 11351P2TA44LPEL010DGA44 P2TA44LREL010DGA44 Link 4400 2000 9 328 9 2 145 66Spark Resistant UnitsP2TA10LPEQ010BCA10 P2TA10LREQ010BCA10 Link 1000 454 38 12 107 33 1 113 51P2TA15LPEQ010BCA15 P2TA15LREQ010BCA15 Link 1500 680 237 58 18 1 11351P2TA30LPEQ010CEA30 P2TA30LREQ010CEA30 Link 3000 1360 11 3 26 8 2 145 66GENERAL:Air Inlet: 3/8" NPT (use 1/2" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 44 cfm (1.2 m 3 /min.) at rated load.STANDARD EQUIPMENT:Trolley mounted air hoist with 10 ft. (3.0m) liftTapered WheelsRope Control: 5 ft. (1.5m) rope lengthPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Modified lift length (specify when ordering)Chain container – page 55Piped exhaust adapter (3/4"NPT) – 535779Tractor connection kit: (Used to modify existing <strong>Hoist</strong>)(1100, 1500, 2200 cap.) – 534919(3000, 4400 cap.) – 53492035

Trolley Mounted <strong>Hoist</strong>sGARDNER-DENVER ®P3 SeriesCapacity:2200-8000 lbs.1000-3629 kgBeam flange width:2200 lbs., 4300 lbs. capacity3.38-6.25 in86-159 mm8800 lbs. capacity4.00-6.25 in102-159 mmMinimum turning radius:2200 lbs., 4300 lbs. capacity60 in1524 mm8800 lbs. capacity72 in1829 mm■ Axial Piston Air Motor■ Pendent Control■ Link ChainSingle Reeved2200 lbs. (1000 kg) & 4300 lbs. (1950 kg) CapacityDouble Reeved8000 lbs. (3629 kg) Capacity36

Trolley Mount <strong>Hoist</strong>sP 3 T A 22 L P E P --- A A A 22SERIESP3TYPE MOUNTT = TrolleyFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY22 = 2200 lbs.43 = 4300 lbs.80 = 8000 lbs.CHAIN TYPEL = LinkCONTROL TYPEL = Pendent (w/<strong>Hoist</strong>ractor-4LVR)P = Pendent Standard (2LVR)X = None-Pendent ReadyCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkZ = No Control LengthP = Zinc Plated LinkX = No ChainVINTAGEALOWER HOOKA = Standard (22/43)B = Bullard (22/43)C = Standard (80)D = Bullard (80)X = No HookTROLLEYA = 3.38-6.25" Tapered (22/43)B = 4-6.25" Tapered (80)C = 3.25-3.33" Nrw Flat (80)D = 3.38-6.25" Flat (22/43)E = 4-6.25" Flat (80)AMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010CAPACITY RATING11 = 1100 lbs. (22)20 = 2000 lbs. (22/43)22 = 2200 lbs. (22/43)40 = 4000 lbs. (43)43 = 4300 lbs. (43)50 = 5000 lbs. (80)60 = 6000 lbs. (80)80 = 8000 lbs. (80)Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberPendent ControlLifting & Lowering SpeedsChain Capacity Maximum Lift Maximum Lower Reeves WeightTypelbs. kg fpm mpm fpm mpm lbs. kgP3TA22LPEP010AAA22 Link 2200 1000 30 9 80 24 1 270 123P3TA43LPEP010AAA43 Link 4300 1950 15 5 40 12 1 270 123P3TA80LPEP010BCA80 Link 8000 3629 7 2 20 6 2 335 152GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 83 cfm (2.35 m 3 /min.) at rated load.STANDARD EQUIPMENT:Trolley mounted air hoist with 10 ft. (3.0m) liftTapered WheelsPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 5537

<strong>Hoist</strong>ractor and <strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination Units<strong>Hoist</strong>ractorWhen used with a hoist, thepowerful, lightweight <strong>Hoist</strong>ractormoves heavy loads quickly andwithout operator fatigue. The<strong>Hoist</strong>ractor may be attached to avariety of different styles of trolleymounted hoists, and speed of travelis variable from a slow creep to fullspeed. With a single one-handcontrol for <strong>Hoist</strong>ractor and hoist, theoperator can raise, lower or moveloads with positive control. Whilesensitive piston-actuated air controlspermit smooth acceleration anddeceleration, the mechanical brakeprovides positive stopping to spotloads precisely.Combination Units<strong>Gardner</strong>-<strong>Denver</strong> <strong>Hoist</strong>/<strong>Hoist</strong>ractorUnits combine a hoist and<strong>Hoist</strong>ractor within a common frameto provide a powerful and versatilemeans of handling materials. Theseunits fit a wide variety of “I” beams,cover an extensive range of liftingcapacities and speeds, andeliminated extra sideplates, wheels,drawbars, etc., required byconventional arrangements.Low HeadroomDesigned with hoist and <strong>Hoist</strong>ractorcombined as one unit, <strong>Gardner</strong>-<strong>Denver</strong> low headroom hoists areideal where maximum use must bemade of available space. They fit avariety of beam sizes and are theultimate in compact design withminimum hook-to-beam dimensions.<strong>Hoist</strong>ractorTA Series . . . . . . . . . . .40-41Rotary Vane <strong>Hoist</strong>sK1 Combination Series . .42-43Axial Piston <strong>Hoist</strong>sP2 Combination Series . .44-45P3 Combination Series . .46-47P3 Low Headroom Series 48-4938

<strong>Hoist</strong>ractor OverviewWheel Options<strong>Gardner</strong>-<strong>Denver</strong> <strong>Hoist</strong>ractors comestandard with a neoprene drive wheel,however for improved wear resistanceand extended life, a molded adiprenewheel is also available. Please contacta <strong>Gardner</strong>-<strong>Denver</strong> service technician forapplications involving high temperature.Drive OptionsFor added flexibility and safety, <strong>Gardner</strong>-<strong>Denver</strong><strong>Hoist</strong>ractors are available with your choice of threedifferent drive options. As described below,each option has its advantages whether itbe ease of operation or positive stoppingcharacteristics.Standard Drive■ Even number of leversThe standard <strong>Hoist</strong>ractor drive utilizes apowerful compression spring to hold thedrive wheel in engagement with the beam.This type of drive requires only twopendent levers to control horizontalmovement in forward and reverse. Wheneither the forward or reverse lever isdepressed, the <strong>Hoist</strong>ractor immediatelymoves in the corresponding direction untilthe lever is released. Upon releasing thelever, a brake engages, and the loadcomes to an immediate stop.This type of drive provides the simplestmethod for movement and precisionlocation of a load.Free Wheel to Positive Drive■ Even number of leversRequiring only two pendant levers to control horizontalmovement, forward and reverse, this drive feature utilizesa drive wheel that is normally disengaged from the beam,allowing free movement of the load. When either theforward or reverse lever is depressed, the drive wheel isautomatically moved into engagement with the beam bymeans of an air cylinder. Upon engagement, the load willmove in the corresponding direction until the lever isreleased. When the lever is released, the drive wheelgradually disengages from the beam; this action will slowthe horizontal movement of the load somewhat, beforecoasting to a stop. Because the drive wheel is normallydisengaged, this type of drive allows the operator tomanually position the load.■ Odd number of levers onlyRequiring at least three pendent levers for operation, oneto engage the wheel, and two to control forward andreverse horizontal movement, this drive feature utilizes adrive wheel that is normally disengaged from the beam,allowing free movement of the load, To advance the<strong>Hoist</strong>ractor the operator must depress one lever to movethe wheel into engagement with the beam, and a secondlever to impart horizontal movement. The load willcontinue to move along the beam as long as both leversremain depressed. If the movement lever is releasedwhile the beam engagement lever remains depressed,the <strong>Hoist</strong>ractor brake will engage, and the unit will cometo an immediate stop. However, if the beam engagementlever is released before the motion lever, the drive wheelwill move out of engagement with the beam, and the loadwill coast to a stop.This drive type allows greater control over the horizontalmovement of the load because the operator manuallycontrols the engagement of the drive wheel with the beam.Positive Drive to Free Wheel■ Odd number of levers onlyThis type of drive is very similar to the previous exceptthat the drive wheel is normally held in engagement withthe beam by an air cylinder, and will remain so untilpressure is bled from the cylinder by depressing theappropriate lever. Available only with an odd number oflevers, two to control horizontal movement and one todisengage the drive wheel for manual movement, thisdrive provides the added safety feature of an immediatestop upon release of the levers.To advance the <strong>Hoist</strong>ractor, the operator must depresseither the forward or reverse lever, the load will continueto move along the beam as long as the lever remainsdepressed. Upon release of the lever, the brake willengage, and the load will come to an immediate stop. Ifthe lever to disengage the drive wheel is depressed whilethe load is in motion, the drive wheel will disengage fromthe beam, and the load will coast freely.The benefit of this type of drive is that the <strong>Hoist</strong>ractorbrake will not allow movement of the load unless the oneof the levers is depressed, or air pressure is bled off.However, if the operator wishes to manually move theload for precise positioning, he has but to depress thelever to disengage the drive wheel.39

<strong>Hoist</strong>ractorGARDNER-DENVER ®TA SeriesTraversing Speed (no load):40-240 fpm12-73 mpmBeam flange width:2.60-6.00 in66-152 mmMinimum turning radius:21 in533 mm■ Axial Piston Air Motor■ Pendent Control■ Neoprene Wheel Drive40Model NumberTraversing SpeedStandard Unit*No Load4000 lb. LoadFree Wheel toPositive Drive toPositive Drive Free Wheel fpm mpm fpm mpmUniversal UnitsTATA04NPESXAXA TATA04OAEGXAXA TATA04PBEPXAXA 40 12 40 12TATA12NPESXAXA TATA12OAEGXAXA TATA12PBEPXAXA 120 37 90 27TATA24NPESXAXA TATA24OAEGXAXA TATA24PBEPXAXA 240 73180 55K5 – AllTATA04NDESCAXA TATA04OEEGCAXA TATA04PFEPCAXA 40 12 40 12TATA12NDESCAXA TATA12OEEGCAXA TATA12PFEPCAXA 120 37 90 27TATA24NDESCAXA TATA24OEEGCAXA TATA24PFEPCAXA 240 73180 55K1 – AllTATA04NDESKAXA TATA04OEEGKAXA TATA04PFEPKAXA 40 12 40 12TATA12NDESKAXA TATA12OEEGKAXA TATA12PFEPKAXA 120 37 90 27TATA24NDESKAXA TATA24OEEGKAXA TATA24PFEPKAXA 240 73180 55P1 – AllTATA04NDESDAXA TATA04OEEGDAXA TATA04PFEPDAXA 40 12 40 12TATA15NDESDAXA TATA12OEEGDAXA TATA12PFEPDAXA 120 37 90 27TATA24NDESDAXA TATA24OEEGDAXA TATA24PFEPDAXA 240 73180 55P2 – 1100 & 2200TATA04NDESEAXA TATA04OEEGEAXA TATA04PFEPEAXA 40 12 40 12TATA12NDESEAXA TATA12OEEGEAXA TATA12PFEPEAXA 120 37 90 27TATA24NDESEAXA TATA24OEEGEAXA TATA24PFEPEAXA 240 73180 55P2 – 4400TATA04NDESFAXA TATA04OEEGFAXA TATA04PFEPFAXA 40 12 40 12TATA12NDESFAXA TATA12OEEGFAXA TATA12PFEPFAXA 120 37 90 27TATA24NDESFAXA TATA24OEEGFAXA TATA24PFEPFAXA 240 73180 55Universal Spark Resistant UnitsTATA04NPESXBXA 40 12 40 12TATA12NPESXBXA 120 37 90 27TATA24NPESXBXA 240 73180 55P2 – 1500 Spark ResistantTATA04NDESEBXA 40 12 40 12TATA12NDESEBXA 120 37 90 27TATA24NDESEBXA 240 73180 55P2 – 3000 Spark ResistantTATA04NDESFBXA 40 12 40 12TATA12NDESFBXA 120 37 90 27TATA24NDESFBXA 240 73180 55P3 – AllTATA04NDESHAXA TATA04OEEGHAXA TATA04PFEPHAXA 40 12 40 12TATA12NDESHAXA TATA12OEEGHAXA TATA12PFEPHAXA 120 37 90 27TATA24NDESHAXA TATA24OEEGHAXA TATA24PFEPHAXA 240 73180 55*NOTE: Spring engagementGENERAL:Air Inlet: 3/8" NPT (use 1/2" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption 30 cfm (.80 m 3 /min.) at rated load.Nominal weight: 70 lbs. (32 kg)STANDARD EQUIPMENT:<strong>Hoist</strong>ractor with Pendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Piped exhaust adapter (1/2" NPT) – 500344Flow Control Valve (3/8" NPT) – 502905

TA T A 04 N PE S X A X A<strong>Hoist</strong>ractorSERIESTATYPE MOUNTT = TrolleyFEATURESA = Standard Unit P = Epoxy PaintE = Edible Grease R = Epoxy Paint/Edible GreaseH = Hi Temp Grease S = Epoxy Paint/Hi Temp GreaseTRANSVERSING SPEED04 = 40 fpm12 = 120 fpm24 = 240 fpmDRIVE WHEEL TYPENeoprene Drive WheelN = Spring engagementM = Free wheel to positive drive*(2 or 4 lever pendent control handle)O = Free wheel to positive drive*(3 or 5 lever pendent control handle)P = Positive drive to free wheel*(3 or 5 lever pendent control handle)Adiprene Drive WheelA = Spring engagementB = Free wheel to positive drive*(2 or 4 lever pendent control handle)C = Free wheel to positive drive*(3 or 5 lever pendent control handle)D = Positive drive to free wheel*(3 or 5 lever pendent control handle)*See page 39CONTROL TYPEA = Free to positive (3/LVR)*P = Standard (2/LVR)**B = Positive to free (3/LVR)*R = Rope StandardD = Standard hoist w/<strong>Hoist</strong>ractor (4 LVR)** T = None (Rope ready)E = Free to positive (5/LVR)*W = None (Pendent Ready)F = Positive to free (5/LVR)* *See page 39I = P3 Models (4/LVR)* **Excluding P3 <strong>Hoist</strong>s & P3 Combination unitsCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTZ = No Control Length.VINTAGEAEXHAUSTX = Standard MufflerP = Piped ExhaustTROLLEYA = 2.62-6" TaperedB = 2.62-6" S.R. TaperedC = 2.62-6" FlatD = 2.62-6" S.R. FlatE = 2" Nrw FlatF = 2" S.R. Nrw FlatG = 6-8” TaperedH = 6-8” S.R. TaperedI = 6-8” FlatJ = 6-8" S.R. FlatCONNECTING LINKA = 300-1100 lbs. 2.66-4.66" H/T*B = 1500-4400 lbs. 3-6" H/T*C = K5 Series 2-5" TrolleyD = P1 Series 2-5" TrolleyE = P2 (11/15/22) 2-5" TrolleyF = P2 (30/44) 2-5" TrolleyL = P2 (11/15/22) 5-7" TrolleyM = P2 (30/44) 5-7" TrolleyG = K1 (66/88) & P3 (80) 4-6-25" TrolleyH = P3 (22/43) 3.33-6.25" TrolleyK = K1 (22/33/44) 2-6.25" TrolleyX = Standard Connecting Link*H/T = Hook type trolley**Code ‘G’ can be used with both Hook-typeand trolley mounted <strong>Hoist</strong>s (3.25-6.25"). CodesC-M to be used with existing trolley mountedhoists; A&B used with hook type trolleysNote: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.DRIVE ENGAGEMENTS = Spring for (04A/04N/12A/12N/24A/24N)F = Free to Positive (2 or 4 lever)*for (04B/04M/12B/12M/24B/24M)G = Free to Positive (3 or 5 lever)*for (04C/04O/12C/12O/24C/24O)P = Positive to Free (3 or 5 lever)*for (04D/04P/12D/12P/24D/24P) *See page 39Note: Numbers and letters in parentheses following a DriveEngagement option, represent the Traversing Speed and DriveWheel Type for which that Drive Engagement option is available.12.1"(307)41

<strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination UnitsGARDNER-DENVER ®K1 SeriesCapacity:2200-8800 lbs.1000-4000 kgBeam flange width:2200 lbs., 3300 lbs., 4400 lbs. cap.3.00-6.25 in76-159 mm6600 lbs., 8800 lbs. cap.4.00-6.25 in102-159 mmMinimum turning radius:2200 lbs., 3300 lbs., 4400 lbs. cap.60 in1254 mm6600, 8800 lbs. cap.72 in1829 mm■ Rotary Vane Air Motor■ Pendent Control■ Link ChainSingle Reeved2200 lbs. (1000 kg), 3300 lbs. (1500 kg) &4400 lbs. (2000 kg) CapacityDouble Reeved6600 lbs. (3000 kg) & 8800 lbs. (4000 kg) Capacity7.7"(196)42

<strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination UnitsK1 C A 22 L PE P--- A A A 22SERIESK1TYPE MOUNTC = CombinationFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY22 = 2200 lbs. 66 = 6600 lbs.33 = 3300 lbs. 88 = 8800 lbs.44 = 4400 lbs.CHAIN TYPEL = LinkCONTROL TYPEP = Pendent (w/<strong>Hoist</strong>ractor-4LVR)S = Pendent (Combo w/Axial Motor-6LVR)T = Pendent (Combo w/<strong>Hoist</strong>ractor-6LVR)W = Pendent ReadyCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN TYPEZ = No Control Length.L = Standard LinkP = Zinc Plated LinkX = No ChainVINTAGEALOWER HOOKA = Standard Link (22/33/44)B = Bullard Link (22/33/44)C = Standard Link (66/88)D = Bullard Link (66/88)X = No Lower HookCAPACITY RATING11 = 1100 lbs. (22/33/44)22 = 2200 lbs. (22/33/44)33 = 3300 lbs. (33/44)34 = 3300 lbs. (66)44 = 4400 lbs. (44)45 = 4400 lbs. (66/88)66 = 6600 lbs. (66/88)88 = 8800 lbs. (88)TROLLEYA = 3-6.25" Standard Speed, Tapered (22/33/44)B = 3-6.25" Standard Speed, Flat (22/33/44)C = 3-6.25" Slow Speed, Tapered (22/33/44)D = 3-6.25" Slow Speed, Flat (22/33/44)E = 3-6.25" High Speed, Tapered (22/33/44)F = 3-6.25" High Speed, Flat (22/33/44)G = 4-6.25" Standard Speed, Tapered (66/88)H = 4-6.25" Standard Speed, Flat (66/88)I = 3.25" Standard Speed, Nrw (66/88)J = 4-6.25" Tapered (66/88)K = 4-6.25" Flat (66/88)L = 3.25" Nrw Flat (66/88)M = 4-6.25" High Speed, Tapered (66/88)N = 4-6.25" High Speed Flat (66/88)O = 3.25" High Speed Nrw (66/88)AMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.Model NumberPendent ControlLifting & Lowering SpeedsTraversingChain Capacity Maximum Lift Maximum LowerSpeedReeves WeightTypelbs. kg fpm mpm fpm mpm fpm mpm lbs. kgK1CA22LPEP010AAA22 Link 2200 1000 33 10 52 16 69 21 1 325 147K1CA33LPEP010AAA33 Link 3300 1500 21 6 34 10 67 20 1 325 147K1CA44LPEP010AAA44 Link 4400 2000 15 5 24 7 65 20 1 325 147K1CA66LPEP010GCA66 Link 6600 3000 10 3 17 5 57 17 2 390 177K1CA88LPEP010GCA88 Link 8800 4000 7 2 12 4 50 15 2 390 177GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption:<strong>Hoist</strong> – 75 cfm (2.12 m 3 /min.) at rated load.<strong>Hoist</strong>ractor – 30 cfm (.8 m 3 /min.) at rated load.STANDARD EQUIPMENT:<strong>Hoist</strong>/<strong>Hoist</strong>ractor combination unit with 10 ft. (3.0m) liftPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55Piped exhaust adapter (1/2 " NPT) – 500344(3/4" NPT) – 53656743

<strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination UnitsGARDNER-DENVER ®P2 SeriesCapacity:1100-4400 lbs.500-2000 kgBeam flange width:3.00-5.25 in76-133 mmMinimum turning radius:1100 lbs., 1500 lbs., 2200 lbs. cap.26 in660 mm3000 lbs., 4000 lbs. cap.42 in1067 mm■ Axial Piston Air Motor■ Pendent Control■ Link ChainSingle Reeved1100 lbs. (500 kg), 1500 lbs. (680 kg) &2200 lbs. (1000 kg) CapacityDouble Reeved3000 lbs. (1360 kg) & 4400 lbs. (2000 kg) Capacity44

<strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination UnitsP 2 C A 11 L P E L --- A A A 11SERIESP2TYPE MOUNTC = CombinationFEATURESA = Standard UnitE = Edible GreaseH = Hi Temp GreaseP = Epoxy PaintR = Epoxy Paint/Edible GreaseS = Epoxy Paint/Hi Temp GreaseCAPACITY10 = 1000 lbs. 22 = 2200 lbs.11 = 1100 lbs. 30 = 3000 lbs.15 = 1500 lbs. 44 = 4400 lbs.CHAIN TYPEL = LinkCONTROL TYPEP = Pendent (w/<strong>Hoist</strong>rator-4LVR))S = Pendent (Combo w/Axial Motor-6LVR)A = Pendent (Combo w/<strong>Hoist</strong>ractor-6LVR)W = None-Pendent ReadyCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkZ = No Control Length.P = Zinc Plated LinkQ = S.R. LinkX = No ChainAMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' Lift 010Note: Numbers in parentheses following an option, representthe hoist capacities for which that option is available.CAPACITY RATING03 = 300 lbs. (10/11/15)05 = 500 lbs. (10/11/15)10 = 1000 lbs. (10/11/15)11 = 1100 lbs. (10/11/15)15 = 1500 lbs. (15/22)20 = 2000 lbs. (22)22 = 2200 lbs. (22)30 = 3000 lbs. (30/44)31 = 1100 lbs. (30)32 = 2200 lbs. (30/44)40 = 4000 lbs. (44)44 = 4400 lbs. (44VINTAGEALOWER HOOKA = Standard (11/22) F = S.R. Bullard (30)B = Bullard (11/22) G = Standard (44)C = S.R. Std. (10/15) H = Bullard (44)D = S.R. Bullard (10/15) X = No HookE = S.R. Std. (30)TRACTOR/TROLLEYA = 3-5.25" Std. Speed Tapered (11/22/44)B = 3-5.25" Std. Speed Flat (11/22/44)C = 3-5.25" Std. Speed S.R. Tapered (10/15/30)D = 3-5.25" Std. Speed S.R. Flat (10/15/30)E = 3-5.25" Slow Speed Tapered (11/22/44)F = 3-5.25" Slow Speed Flat (11/22/44)G = 3-5.25" Slow Speed S.R. Tapered (10/15/30)H = 3-5.25" Slow Speed S.R. Flat (10/15/30)I = 3-5.25" High Speed Tapered (11/22/44)J = 3-5.25" High Speed Flat (11/22/44)K = 3-5.25" High Speed S.R. Tapered (10/15/30)L = 3-5.25" High Speed S.R. Flat (10/15/30)M = 5-7" Std. Speed Tapered (11/22/44)N = 5-7" Std. Speed Flat (11/22/44)O = 5-7" Std. Speed S.R. Tapered (10/15/30)P = 5-7" Std. Speed S.R. Flat (10/15/30)Q = 5-7" Slow Speed Tapered (11/22/44)R = 5-7" Slow Speed Flat (11/22/44)S = 5-7" Slow Speed S.R. Tapered (10/15/30)T = 5-7" Slow Speed S.R. Flat (10/15/30)U = 5-7" High Speed Tapered (11/22/44)V = 5-7" High Speed Flat (11/22/44)W = 5-7" High Speed S.R. Tapered (10/15/30)Y = 5-7" High Speed S.R. Flat (10/15/30)Model NumberPendent ControlLifting & Lowering SpeedsTraversingChain Capacity Maximum Lift Maximum LowerSpeedReeves WeightTypelbs. kg fpm mpm fpm mpm fpm mpm lbs. kgP2CA11LPEL010AAA11 Link 1100 500 34 10 107 33 70 21 1 145 66P2CA22LPEL010AAA22 Link 2200 1000 17 5 56 17 69 21 1 170 77P2CA44LPEL010AGA44 Link 4400 2000 9 328 9 65 20 2 202 92Spark Resistant UnitsP2CA15LPEQ010CCA15 Link 1500 680 237 58 18 70 21 1 170 77P2CA30LPEQ010CEA30 Link 3000 1360 11 3 26 8 65 20 2 202 92GENERAL:Air Inlet: 3/8" NPT (use 5/8" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption:<strong>Hoist</strong> – 44 cfm (1.2 m 3 /min.) at rated load.<strong>Hoist</strong>ractor – 30 cfm (.8 m 3 /min) at rated load.STANDARD EQUIPMENT:<strong>Hoist</strong>/<strong>Hoist</strong>ractor combination unit with 10 ft. (3.0m) liftPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 55Additional Pendent Control hose lengths (specify when ordering)Piped exhaust adapter (1/2 " NPT) – 500344(3/4" NPT) – 53577945

<strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination UnitsGARDNER-DENVER ®P3 SeriesCapacity:2200-8000 lbs.1000-3629 kgBeam flange width:2200 lbs., 4300 lbs. capacity3.38-6.25 in86-159 mm8000 lbs. capacity4.00-6.25 in102-159 mmMinimum turning radius:2200 lbs., 4300 lbs. capacity60 in1524 mm8800 lbs. capacity72 in1829 mm■ Axial Piston Air Motor■ Pendent Control■ Link ChainSingle Reeved2200 lbs. (1000 kg) & 4300 lbs. (1950 kg) CapacityDouble Reeved8000 lbs. (3629 kg) Capacity46

<strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination UnitsP 3 C A 22 L P E P --- A A A 22SERIESP3TYPE MOUNTC = CombinationFEATURESA = Standard UnitH = Hi Temp GreaseP = Epoxy PaintS = Epoxy Paint/Hi Temp GreaseCAPACITY22 = 2200 lbs.43 = 4300 lbs.80 = 8000 lbs.CHAIN TYPEL = LinkCONTROL TYPEP = Pendent StandardX = None-Pendent ReadyCONTROL LENGTHE =5 FT L = 12 FT S = 19 FTF =6 FT M =13 FT T = 20 FTG =7 FT N = 14 FT U = 21 FTH =8 FT O = 15 FT V = 22 FTI =9 FT P = 16 FT W = 23 FTJ = 10 FT Q = 17 FT X = 24 FTK = 11 FT R = 18 FT Y = 25 FTCHAIN OPTIONSL = Standard LinkZ = No Control Length.P = Zinc Plated LinkX = No ChainVINTAGEALOWER HOOKA = Standard (22/43)B = Bullard (22/43)C = Standard (80)D = Bullard (80)X = No Lower HookCAPACITY RATING11 = 1100 lbs. (22)20 = 2000 lbs. (22/43)22 = 2200 lbs. (22/43)40 = 4000 lbs. (43)43 = 4300 lbs. (43)50 = 5000 lbs. (80)60 = 6000 lbs. (80)80 = 8000 lbs. (80)TROLLEYA = 4-6.25" Standard Speed Tapered (22/43/80)B = 4-6.25" Standard Speed Flat (22/43/80)C = 3.25-3.33" Nrw Flat (22/43/80)D = 4-6.25" Slow Speed Tapered (22/43/80)E = 4-6.25" Slow Speed Flat (22/43/80)F = 3.25-3.33" Slow Speed Nrw Flat 922/43/80)G = 4-6.25" High Speed Tapered (22/43/80)H = 4-6.25" High Speed Flat 922/43/80)I = 3.25-3.33" High Speed Nrw Flat (22/43/80)AMOUNT OF LIFTSpecify Length in Feet, 3 digitsExample: 10' Lift 010Note: Numbers in parentheses following an option, representthe hoist capabilities for which that option is available.Model NumberPendent ControlLifting & Lowering SpeedsTraversingChain Capacity Maximum Lift Maximum LowerSpeedReeves WeightTypelbs. kg fpm mpm fpm mpm fpm mpm lbs. kgP3CA22LPEP010AAA22 Link 2200 1000 30 9 80 24 69 21 1 325 147P3CA43LPEP010AAA43 Link 4300 1950 15 5 40 12 65 20 1 325 147P3CA80LPEP010ACA80 Link 8000 3629 7 2 20 6 55 17 2 365 166GENERAL:Air Inlet: 1/2" NPT (use 3/4" I.D. Hose)Performance rated at 90 psig (6 bar/620 kPa) air pressure.Air Consumption:<strong>Hoist</strong> – 83 cfm (2.35 m 3 /min.) at rated load.<strong>Hoist</strong>ractor – 30 cfm (.8 m 3 /min) at rated load.STANDARD EQUIPMENT:<strong>Hoist</strong>/<strong>Hoist</strong>ractor combination unit with 10 ft. (3.0m) liftPendent Control: 5 ft. (1.5m) hose lengthEXTRA EQUIPMENT:Chain container – page 5547

<strong>Hoist</strong>/<strong>Hoist</strong>ractor Combination (Low Headroom)GARDNER-DENVER ®P3 SeriesCapacity:2200-4300 lbs.1000-1950 kgBeam flange width:3.00 - 4.00 in76 - 102 mmMinimum turning radius:60 in1524 mm■ Axial Piston Air Motor■ Pendent Control■ Link Chain48