Gardner-Denver Aire Hoist Catalog - Tecno Italia s.r.l

Gardner-Denver Aire Hoist Catalog - Tecno Italia s.r.l

Gardner-Denver Aire Hoist Catalog - Tecno Italia s.r.l

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

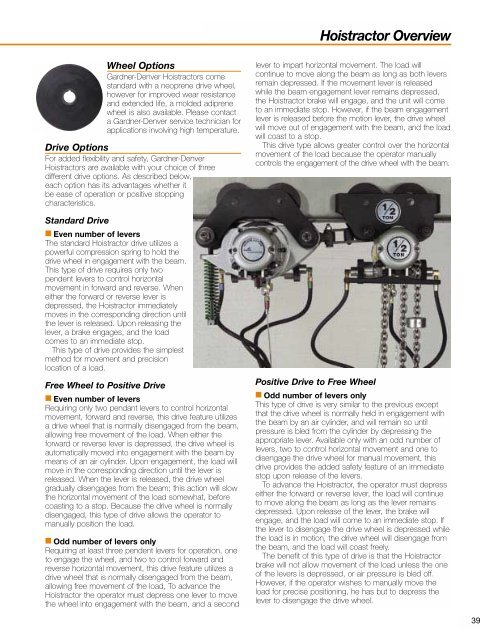

<strong>Hoist</strong>ractor OverviewWheel Options<strong>Gardner</strong>-<strong>Denver</strong> <strong>Hoist</strong>ractors comestandard with a neoprene drive wheel,however for improved wear resistanceand extended life, a molded adiprenewheel is also available. Please contacta <strong>Gardner</strong>-<strong>Denver</strong> service technician forapplications involving high temperature.Drive OptionsFor added flexibility and safety, <strong>Gardner</strong>-<strong>Denver</strong><strong>Hoist</strong>ractors are available with your choice of threedifferent drive options. As described below,each option has its advantages whether itbe ease of operation or positive stoppingcharacteristics.Standard Drive■ Even number of leversThe standard <strong>Hoist</strong>ractor drive utilizes apowerful compression spring to hold thedrive wheel in engagement with the beam.This type of drive requires only twopendent levers to control horizontalmovement in forward and reverse. Wheneither the forward or reverse lever isdepressed, the <strong>Hoist</strong>ractor immediatelymoves in the corresponding direction untilthe lever is released. Upon releasing thelever, a brake engages, and the loadcomes to an immediate stop.This type of drive provides the simplestmethod for movement and precisionlocation of a load.Free Wheel to Positive Drive■ Even number of leversRequiring only two pendant levers to control horizontalmovement, forward and reverse, this drive feature utilizesa drive wheel that is normally disengaged from the beam,allowing free movement of the load. When either theforward or reverse lever is depressed, the drive wheel isautomatically moved into engagement with the beam bymeans of an air cylinder. Upon engagement, the load willmove in the corresponding direction until the lever isreleased. When the lever is released, the drive wheelgradually disengages from the beam; this action will slowthe horizontal movement of the load somewhat, beforecoasting to a stop. Because the drive wheel is normallydisengaged, this type of drive allows the operator tomanually position the load.■ Odd number of levers onlyRequiring at least three pendent levers for operation, oneto engage the wheel, and two to control forward andreverse horizontal movement, this drive feature utilizes adrive wheel that is normally disengaged from the beam,allowing free movement of the load, To advance the<strong>Hoist</strong>ractor the operator must depress one lever to movethe wheel into engagement with the beam, and a secondlever to impart horizontal movement. The load willcontinue to move along the beam as long as both leversremain depressed. If the movement lever is releasedwhile the beam engagement lever remains depressed,the <strong>Hoist</strong>ractor brake will engage, and the unit will cometo an immediate stop. However, if the beam engagementlever is released before the motion lever, the drive wheelwill move out of engagement with the beam, and the loadwill coast to a stop.This drive type allows greater control over the horizontalmovement of the load because the operator manuallycontrols the engagement of the drive wheel with the beam.Positive Drive to Free Wheel■ Odd number of levers onlyThis type of drive is very similar to the previous exceptthat the drive wheel is normally held in engagement withthe beam by an air cylinder, and will remain so untilpressure is bled from the cylinder by depressing theappropriate lever. Available only with an odd number oflevers, two to control horizontal movement and one todisengage the drive wheel for manual movement, thisdrive provides the added safety feature of an immediatestop upon release of the levers.To advance the <strong>Hoist</strong>ractor, the operator must depresseither the forward or reverse lever, the load will continueto move along the beam as long as the lever remainsdepressed. Upon release of the lever, the brake willengage, and the load will come to an immediate stop. Ifthe lever to disengage the drive wheel is depressed whilethe load is in motion, the drive wheel will disengage fromthe beam, and the load will coast freely.The benefit of this type of drive is that the <strong>Hoist</strong>ractorbrake will not allow movement of the load unless the oneof the levers is depressed, or air pressure is bled off.However, if the operator wishes to manually move theload for precise positioning, he has but to depress thelever to disengage the drive wheel.39