Alert - Use of Registered Fittings - ABSA

Alert - Use of Registered Fittings - ABSA

Alert - Use of Registered Fittings - ABSA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

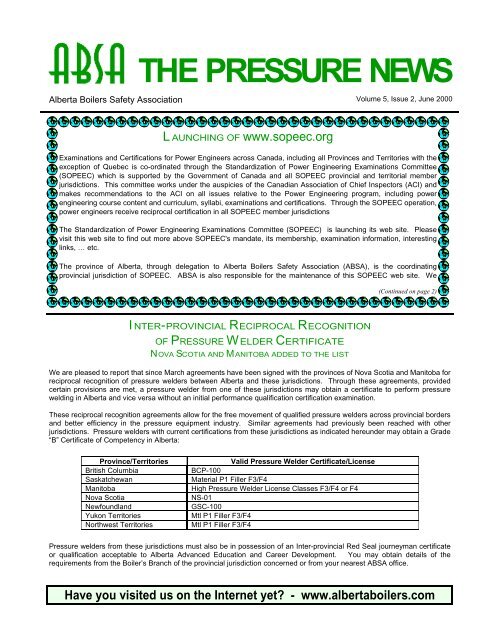

THE PRESSURE NEWSAlberta Boilers Safety Association Volume 5, Issue 2, June 2000L AUNCHING OF www.sopeec.orgExaminations and Certifications for Power Engineers across Canada, including all Provinces and Territories with theexception <strong>of</strong> Quebec is co-ordinated through the Standardization <strong>of</strong> Power Engineering Examinations Committee(SOPEEC) which is supported by the Government <strong>of</strong> Canada and all SOPEEC provincial and territorial memberjurisdictions. This committee works under the auspicies <strong>of</strong> the Canadian Association <strong>of</strong> Chief Inspectors (ACI) andmakes recommendations to the ACI on all issues relative to the Power Engineering program, including powerengineering course content and curriculum, syllabi, examinations and certifications. Through the SOPEEC operation,power engineers receive reciprocal certification in all SOPEEC member jurisdictionsThe Standardization <strong>of</strong> Power Engineering Examinations Committee (SOPEEC) is launching its web site. Pleasevisit this web site to find out more above SOPEEC's mandate, its membership, examination information, interestinglinks, etc.The province <strong>of</strong> Alberta, through delegation to Alberta Boilers Safety Association (<strong>ABSA</strong>), is the coordinatingprovincial jurisdiction <strong>of</strong> SOPEEC. <strong>ABSA</strong> is also responsible for the maintenance <strong>of</strong> this SOPEEC web site. We(Continued on page 2)I NTER-PROVINCIAL RECIPROCAL RECOGNITIONOF PRESSURE W ELDER CERTIFICATENOVA SCOTIA AND MANITOBA ADDED TO THE LISTWe are pleased to report that since March agreements have been signed with the provinces <strong>of</strong> Nova Scotia and Manitoba forreciprocal recognition <strong>of</strong> pressure welders between Alberta and these jurisdictions. Through these agreements, providedcertain provisions are met, a pressure welder from one <strong>of</strong> these jurisdictions may obtain a certificate to perform pressurewelding in Alberta and vice versa without an initial performance qualification certification examination.These reciprocal recognition agreements allow for the free movement <strong>of</strong> qualified pressure welders across provincial bordersand better efficiency in the pressure equipment industry. Similar agreements had previously been reached with otherjurisdictions. Pressure welders with current certifications from these jurisdictions as indicated hereunder may obtain a GradeB Certificate <strong>of</strong> Competency in Alberta:Province/TerritoriesBritish ColumbiaSaskatchewanManitobaNova ScotiaNewfoundlandYukon TerritoriesNorthwest TerritoriesValid Pressure Welder Certificate/LicenseBCP-100Material P1 Filler F3/F4High Pressure Welder License Classes F3/F4 or F4NS-01GSC-100Mtl P1 Filler F3/F4Mtl P1 Filler F3/F4Pressure welders from these jurisdictions must also be in possession <strong>of</strong> an Inter-provincial Red Seal journeyman certificateor qualification acceptable to Alberta Advanced Education and Career Development. You may obtain details <strong>of</strong> therequirements from the Boiler s Branch <strong>of</strong> the provincial jurisdiction concerned or from your nearest <strong>ABSA</strong> <strong>of</strong>fice.Have you visited us on the Internet yet? - www.albertaboilers.com

The Pressure News Page 2 Volume 5, Issue 2, June 2000(Continued from page 1)would like to hear your comments asto what we could improve on in orderto help make this web site more usefulfor all power engineers andeveryone associated with powerengineering across Canada.ALERTUSE OF REGISTERED FITTINGSAn incident occurred recently at a drycleaning facility due to an unsuitableand unregistered fitting s beinginstalled on a high pressure steamboiler. The fitting has been purchasedat a hardware store and installed onthe boiler water column drainassembly.A contractor was working on the boilerin the vicinity <strong>of</strong> the water columnwhile the boiler was in operation. Heinadvertently knocked the drain piping.The stress caused the fitting to breakat the transition between the inletbottom threads and the body. Theboiler water flashed into steam andthe contractor was burnt about hisbody, necessitating hospitaltreatment.Only suitably rated, registered fittingsshall ever be installed on pressureequipment.ASME SECTION IX2000 ADDENDAThere is a proposal to revise ASMESection IX to permit the use <strong>of</strong> someAWS Standard Welding ProcedureSpecifications. This proposal will likelybe included in the 2000 Addendawhich is scheduled for publication inJuly 2000. We will provide informationon the <strong>ABSA</strong> web-site relative to thisproposed revision to ASME Section IXas soon as this Addenda becomesavailable and detials <strong>of</strong> the revisionare confirmed. We will also try toinclude further information in theSeptember issue <strong>of</strong> the <strong>ABSA</strong>Newsletter.PRESSURE RELIEF VALVES ON BOILERSMany questions arise about theselection, sizing and installation <strong>of</strong>safety or safety relief valves onboilers. The term pressure reliefvalve (PRV) used here means safetyvalve or safety relief valve asappropriate to the service. This articlewill address some <strong>of</strong> the issues weencounter.1) Is the boiler a heating boiler or apower boiler? A hot water (or glycol)boiler stamped for a maximumallowable working pressure <strong>of</strong> 160psig or less may be a heating boiler.Those bearing the ASME H stampare definitely heating boilers but forboilers built under the CSA B51 Codeit may be necessary to examine theManufacturer s Data Report todetermine whether the code <strong>of</strong>construction is ASME Section I (PowerBoilers) or ASME Section IV (HeatingBoilers.) Experienced personnel maybe able to determine the differencefrom the layout <strong>of</strong> the nameplate. Asteam boiler with an MAWP <strong>of</strong> notmore than 15 psig and marked withthe ASME H stamp is a low pressuresteam boiler, also called a steamheating boiler. As with the hot waterboilers, it may be a little less obviouswhether ASME Section I or Section IVapplies to the construction <strong>of</strong> a steamboiler built and marked under the CSAB51 Code. If the steam boiler has anMAWP above 15 psig or a water boilerhas an MAWP greater than 160 psig itwould have to have been built inaccordance with ASME Section I, i.e.it would be a power boiler.2) Determine the type <strong>of</strong> safety orsafety relief valve that must be usedon the boiler. For a heating boiler, i.e.a boiler built in accordance with ASMESection IV rules, the PRV must havethe ASME HV or V on thenameplate. If the boiler is power boilerbuilt in accordance with ASME SectionI the PRV must have the ASME Vsymbol on the nameplate.3) The PRV must be capable <strong>of</strong>relieving the full output <strong>of</strong> the boilerwithout a pressure rise <strong>of</strong> more than alimited amount above the MAWP. Fora hot water heating boiler, the limit is10% above the set pressure <strong>of</strong> thesafety relief valve; for a steam heatingboiler it is 5 psig above the setpressure <strong>of</strong> the safety valve. Powerboiler PRVs are required to relievetheir rated capacities at not more thanthe greater <strong>of</strong> 2 psi or 3% <strong>of</strong> their setpressure.4) Power boilers that have more than500 sq. ft. <strong>of</strong> bare tube water-heatingsurface or more than 1100 kW electricpower input must have more than onePRV.The above are only some <strong>of</strong> theconsiderations for proper selection <strong>of</strong>PRVs on heating boilers (ASMESection IV construction) and powerboilers (ASME Section I construction.)For complete details the readershould refer to ASME Section IV, PartHG, Article 4 for heating boilers and toASME Section I paragraphs PG-67through PG-72.4 for power boilers.Here are some <strong>of</strong> the violations wehave encountered on power boilers:- The PRV is found installed in thehorizontal position. PG-71.2 statesthat PRVs are to be installedupright with their spindles in thevertical position.- The PRV has a bushing in the inletor outlet to adapt the boiler openingto the valve or the vent pipe to thevalve. PG-71.3 states that theopening between the safety valveand the boiler shall have at leastthe area <strong>of</strong> the valve inlet and thatwhen a discharge pipe is used, thecross-sectional area <strong>of</strong> that pipeshall be not less than the full area<strong>of</strong> the valve outlet or <strong>of</strong> the total <strong>of</strong>the areas <strong>of</strong> the valve outletsdischarging through that pipe.- PRVs are found mounted on pipingat some distance from the boiler.PG-71.2 states that the PRV mustbe mounted as close as possible tothe boiler or the normal steam flowpath and in no case further than theface-to-face dimension <strong>of</strong> thecorresponding tee fitting <strong>of</strong> the(Continued on page 3)

The Pressure News Page 3 Volume 5, Issue 2, June 2000D ESIGN CALCULATION CONTROLWhat follows is a partial list <strong>of</strong>nonconformances associated withdesign calculations, which haverecently been identified in ASME jointreviews and routine audits.Paragraph 10-5 <strong>of</strong> Appendix 10 <strong>of</strong>ASME Section VIII, Division 1 (andparallel clauses in other CodeSections) requires that TheManufacturer s or Assembler s QualityControl System shall provideprocedures which will ensure that thelatest applicable drawings, designcalculations, specifications andinstructions, required by the Code, aswell as authorized changes, are usedfor manufacture, examination,inspection and testing.1) Vessel design calculations arefound to be lacking page control orrevision control. The cover sheetshould show the total number <strong>of</strong>pages attached. The pages shallbe consecutively numbered andshall provide for a revisionindicator. There shall be a record<strong>of</strong> the revisions to the calculationsand there shall also be a means <strong>of</strong>showing that the calculations havebeen determined to still beapplicable or have been revisedwhenever the drawings have beenrevised.2) Calculations are not provided forall applicable loadings. Loadingsthat are specified in Codeparagraph UG-22 must beconsidered. For example, if thevessel has support lugs, theremust be calculations for the loadsimposed on the vessel by thoselugs. See UG-22 for otherloadings that must be consideredwhen they are applicable. If thereare no nozzle loads specified orno other UG-22 loadings apply, astatement such as Vesselcalculations have considered allapplicable loadings in accordancewith UG-22 should be acceptable.3) The Manufacturer has failed tosign <strong>of</strong>f the calculations orrevisions to the calculations.There shall be approval <strong>of</strong> thecalculations by signature and dateby the person specified as beingresponsible for this function in theQuality Control Manual.4) There is no indication in thecalculations <strong>of</strong> whether or notimpact tests are required and, ifnot, what specific Code paragraphand subparagraph permits theexemption. For example, ASMEB16.5 ferritic steel flanges for useat an MDMT not colder than minus20 degrees F could be exemptedfrom impact testing by paragraphUCS-66(c), but just invokingparagraph UCS-66 would beinadequate. Likewise, notindicating any exemptionparagraph would be a deficiency.Note that when the exemption isbased on UG-20(f), all five <strong>of</strong> thecriteria <strong>of</strong> UG-20(f) must besatisfied and there shall be astatement to this effect in thecalculations.5) Design calculations do notindicate the Code Edition andAddenda to which they areperformed. It is essential thatthese be identified on thecalculations.6) Old calculations used for a newvessel do not indicate that theyhave been verified as complyingwith the Code Edition andAddenda under which the vesselmust be built. This commonlyapplies to vessels <strong>of</strong> a standarddesign that are built repeatedly.Once a new set <strong>of</strong> addenda or anew Code Edition becomesmandatory, the calculations mustreflect that they comply with thatEdition and Addenda.(Continued from page 2)same diameter as the valve inlet.- Mufflers with diameters smallerthan the outlet <strong>of</strong> the safety valvehave been found. PG-71.4 statesthat if a muffler is used it must havesufficient outlet area to preventback pressure from interfering withthe proper operation and dischargecapacity <strong>of</strong> the valve.There are many elements to beconsidered when selecting andinstalling safety or safety relief valves.Please refer to appropriate codes andstandards prior to starting such aproject. Remember that pressurerelief valves are the last line <strong>of</strong>defense from overpressure andpotential catastrophic failure <strong>of</strong> theboiler.NEWS FROM NATIONAL BOARDNATIONAL BOARD REGISTRATION OF CSA B51BOILERS AND PRESSURE VESSELSRegistration <strong>of</strong> boilers and pressurevessels built to CSA B-51 with theNational Board has been a possibilitysince 1998. This is due to a documenttitled "Criteria for Registration whichwas developed by the National Boardat the request <strong>of</strong> the jurisdictionmembers. CSA B-51 was the firststandard to be determined to be incompliance with the criteria.Since the development <strong>of</strong> the criteria,some jurisdictions have amended theirlaws and rules to allow the use <strong>of</strong>boilers and pressure vessels built tovarious standards so long asregistration with the National Boardwas completed.Questions have been asked <strong>of</strong> theNational Board regarding theimplementation <strong>of</strong> the applicationprocess leading to authorization toregister boilers and pressure vesselsbuilt to CSA B-51. In an attempt torespond to these questions, thefollowing has been prepared.The process leading to authorizationto register CSA B-51 boilers andpressure vessels begins with themanufacturer submitting anapplication to the National Board.(Continued on page 4)