Pressure Piping Construction Requirements QMS MANUAL ... - ABSA

Pressure Piping Construction Requirements QMS MANUAL ... - ABSA

Pressure Piping Construction Requirements QMS MANUAL ... - ABSA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

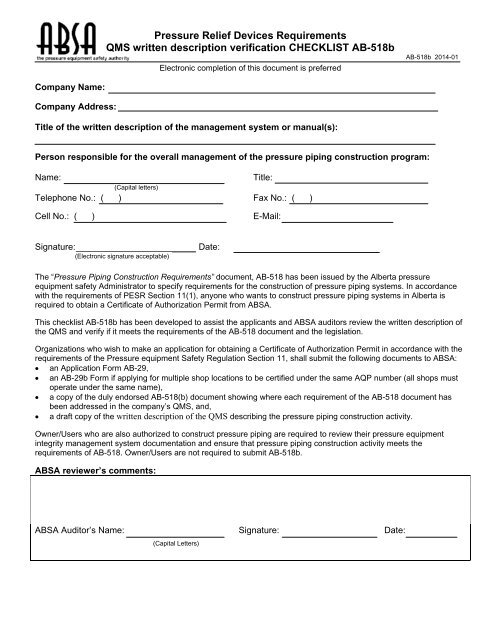

<strong>Pressure</strong> Relief Devices <strong>Requirements</strong><strong>QMS</strong> written description verification CHECKLIST AB-518bElectronic completion of this document is preferredAB-518b 2014-01Company Name:Company Address:Title of the written description of the management system or manual(s):Person responsible for the overall management of the pressure piping construction program:Name:Title:(Capital letters)Telephone No.: ( ) Fax No.: ( )Cell No.: ( ) E-Mail:Signature:(Electronic signature acceptable)Date:The <strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong> document, AB-518 has been issued by the Alberta pressureequipment safety Administrator to specify requirements for the construction of pressure piping systems. In accordancewith the requirements of PESR Section 11(1), anyone who wants to construct pressure piping systems in Alberta isrequired to obtain a Certificate of Authorization Permit from <strong>ABSA</strong>.This checklist AB-518b has been developed to assist the applicants and <strong>ABSA</strong> auditors review the written description ofthe <strong>QMS</strong> and verify if it meets the requirements of the AB-518 document and the legislation.Organizations who wish to make an application for obtaining a Certificate of Authorization Permit in accordance with therequirements of the <strong>Pressure</strong> equipment Safety Regulation Section 11, shall submit the following documents to <strong>ABSA</strong>:an Application Form AB-29,an AB-29b Form if applying for multiple shop locations to be certified under the same AQP number (all shops mustoperate under the same name),a copy of the duly endorsed AB-518(b) document showing where each requirement of the AB-518 document hasbeen addressed in the company s <strong>QMS</strong>, and,a draft copy of the written description of the <strong>QMS</strong> describing the pressure piping construction activity.Owner/Users who are also authorized to construct pressure piping are required to review their pressure equipmentintegrity management system documentation and ensure that pressure piping construction activity meets therequirements of AB-518. Owner/Users are not required to submit AB-518b.<strong>ABSA</strong> reviewer s comments:<strong>ABSA</strong> Auditor s Name: Signature: Date:(Capital Letters)

3.3.1Scope<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAB-518b 2014-01Does this section:describe the scope of the activities to be undertaken?If a company has no shop and undertakes field activities only, the followingrequirement does not apply. The company shall indicate that the activitiesundertaken are at field sites in Alberta controlled from an office address ofthe company.list the shop locations covered under the same registered name, describescope of work undertaken at each shop location, address of each shop,indicate whether field activities are also undertaken and controlled fromthis location, title of a person designated to perform QC function at eachsite, and, the title of a person who is overall responsible for maintenanceand assuring effective implementation of the <strong>QMS</strong> at all locations?Is the scope of workundertaken within the scope ofwork applied for?Yes ; NoIs all information as required bythis section provided?Yes; NoReviewer s Comments:3.3.2Definitions of Terms and AcronymsAre terms and acronyms used within the <strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong>written quality management system defined?N/AReviewer s Comments:Page 4 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferreda statement that the quality system has the full support of themanagement who will ensure that adequate resources, includingcompetent personnel, are provided to implement the program. State thetitle of the person responsible for the development and maintenance ofthe pressure piping construction program, with an explanation that thisperson has the defined authority and responsibility for implementation ofthe program and has direct access to, and support from, topmanagement to resolve any implementation barriers?signature (with date) of an executive manager?Is there evidence that themanagement has providedadequate and competentresources for the constructionactivities?Yes ; NoDoes the person responsiblefor the program have directaccess to the top manager?Yes ; NoN/AAB-518b 2014-01Reviewer s Comments:3.3.5Management s ResponsibilitiesDoes this section:include a statement and evidence that the management is committed tothe development and implementation of a successful pressure pipingconstruction program and that it will continually improve itseffectiveness?This question should beanswered by the auditor uponcompletion of the audit.establish that management will review the pressure piping constructionprogram at appropriate intervals to ensure its continued suitability andeffectiveness?Is there evidence ofowner/management conductingthe review?Yes ; NoPage 6 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredinclude a statement that the management shall determine and provideadequate competent human resources and the necessary facilities andequipment to effectively implement the pressure piping constructionactivities?Is there evidence ofowner/management providingleadership, adequateinfrastructure, competentresources, effective <strong>QMS</strong>,training?Yes ; NoAB-518b 2014-01Reviewer s Comments:3.3.6Contract ReviewAre/is the:responsibilities for contract review and agreement defined?pressure piping construction requirements documented? Yes ; Noscope of work defined? Yes ; NoReview the contract documentfor the project and verify thatthe requirements areaddressed.Yes ; Noresponsibilities for the supply of materials, construction drawings,design, design registration with <strong>ABSA</strong>, PWHT and pressure test definedin the contract?Yes; Nopiping lot sizes for the purpose of NDE specified by the owner andagreed upon between the contracting parties before the start of theconstruction activities?Yes; NoPage 7 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredrequirement for a turnover package and contents thereof defined? Yes ; NoAB-518b 2014-01responsibilities for certifying the construction using AB-83 or AB-83Partial or AB-83F as the case may be defined?Yes; Noresponsibilities for certifying the installation and readiness for operationusing an AB-81 Form defined?Yes; NoReviewer s Comments:3.3.7Document & Data ControlAre the controls needed for the development, identification, storage,revision, protection, retrieval, retention time, and disposition of recordsaddressed?Are these controls beingimplemented?Yes; NoHas a document revision control process been developed andamendments to the documents are covered by an appropriateauthorization, and processed in a manner which will ensure timelyavailability at the appropriate location?Is a controlled copy of an up todate <strong>QMS</strong> manual available atthe site?Yes ; NoIs a current version of the quality manual provided and accepted by<strong>ABSA</strong>?Yes; NoPage 8 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAre all changes to documents managed appropriately includingnotification to the affected parties?Yes; NoAB-518b 2014-01Are the current issues of the appropriate documentation available at allrelevant locations and to all relevant persons?Yes; NoAre superseded documents removed from use throughout theorganization or are appropriately identified as superseded documents?Yes; NoIs the current revision status of documents identified? Yes ; NoAre the documents legible, readily identifiable and retrievable? Yes ; NoAre documents of external origin identified and their distributioncontrolled?Yes; NoReviewer s Comments:Page 9 of 25

3.3.8<strong>Piping</strong> Design<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAB-518b 2014-01Scenario 1If a pressure piping design is undertaken in-house by a manufacturer or by anowner who is also a manufacturer:Are design requirements such as the operating conditions, servicerequirements and other information needed to facilitate the safe design,construction, and inspection of the pressure piping system identified anddocumented?Check N/Aapply to you.Yes ; Noif scenario 1 does notAre the personnel assigned to engineer the piping systems competent,and do they meet the qualification requirements of the company and ofthe applicable ASME B31 Code(s)?Yes; NoAre the design documents stamped by a P.Eng when a pressure pipingsystem is required to be registered with <strong>ABSA</strong>?Yes; NoAre piping design documents prepared, verified and approved by theowner?Yes; NoDo the design documents provide information about the code ofconstruction including edition, proper material specifications, designpressure, maximum and minimum design temperatures, ASME B31.3fluid category for process piping, type and extent of NDE required, hydrotest pressure and medium, Pre Heat and PWHT treatmentrequirements, joint design details, WPS and dimensions?Yes; NoAre the design code edition and addenda of the applicable ASMEconstruction codes, standards and other related documents available todesign personnel and applied for pressure piping design?Yes; NoPage 10 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredDo all design documents, including any revisions, have the requiredapproval and are the revised documents made available at the point ofuse?Yes; NoAB-518b 2014-01Is an appropriate management of change process utilized to managechanges to the design?Yes; NoIf the piping system s internal volume exceeds 500 liters, are the designregistration requirements with <strong>ABSA</strong> specified?Yes; NoAre the drawings reviewed and approved by engineering prior to releasefor construction?Yes; NoScenario 2If a pressure piping design is contracted out by an owner:Are competent in-house engineering resources assigned to preparedesign basis memorandum (DBM) that identifies the design andoperating conditions, the service requirements and other informationneeded to facilitate a safe design, construction and inspection of thepressure piping system. When no in-house engineering resources areavailable, is a process for contracting out the preparation of the DBMdescribed?Is the DBM reviewed, approved and provided to the designer by theowner prior to the start of the design activity?Check N/Aapply to you.Yes ; NoYes ; Noif scenario 2 does notIs the designer competent and meets the pressure piping design, codeknowledge and qualification requirements of the owner, and of theapplicable ASME B31 Code(s)?Yes; NoPage 11 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAre current ASME Codes available to the designer? Yes ; NoAB-518b 2014-01Do the design documents prepared by the designer provide informationabout the code of construction including edition, proper materialspecifications, design pressure, maximum and minimum designtemperatures, ASME B31.3 fluid category for process piping, type andextent of NDE required, hydro test pressure and medium, preheat andPWHT treatment requirements, joint design details, WPS anddimensions?Yes; NoAre the owner s responsibilities assigned for the verification andacceptance of the design documents received back from the designer?Yes; NoIf the piping system s internal volume exceeds 500 liters, is responsibilityfor the registration of the design with <strong>ABSA</strong> assigned?Yes; NoAre the drawings reviewed and approved by the owner prior to releasefor construction?Yes; NoScenario 3If pressure piping design is supplied to the manufacturer by the owner:Do the construction drawings and/or other engineering documentsreceived from the owner include information about the code ofconstruction including edition, proper material specifications, designpressure, maximum and minimum design temperatures, ASME B31.3fluid category for process piping, type and extent of NDE required, hydrotest pressure and medium, preheat and PWHT treatment requirements,joint design details, WPS and dimensions, or, the information needed forconstruction of the piping is made available through appropriatedocumentation by the owner?Check N/Aapply to you.Yes ; Noif scenario 3 does notPage 12 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredWhen spool drawings or cut sheets are prepared by the manufacturer,are the drawings or cut sheets controlled and referenced by the ownersuppliedconstruction or design drawings?N/A ; Yes ; NoAB-518b 2014-01Are the drawings reviewed and approved by the manufacturer prior torelease for construction?Yes; NoReviewer s Comments:3.3.9Purchasing and Material ControlPurchasing: Has the manufacturer:specified purchasing responsibilities?Is purchasing being done byqualified personnel?Yes ; Nospecified the process for the purchasing of materials and forensuring conformance to the material requirements of theengineering design and requirements of the owner?Are the materials properlyspecified in the P.O. and meetthe requirements of theengineering design?Yes ; Noensured that the fittings ordered are registered with <strong>ABSA</strong> (havevalid CRN for installation in Alberta)?Is documentation confirmingCRN available?Yes ; Nospecified the process for controlling purchase documents?Are the specified controls inpractice?Yes ; NoPage 13 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredControl of Owner supplied materials: Has the manufacturerestablished a process for verification, storage and maintenance ofowner supplied materials?Is the process in practice?Yes ; NoAB-518b 2014-01Receiving of materials: Has the manufacturer ensured that:Yes; Noreceived materials conform to the correct specifications andquantity, and are not damaged?a process is established for identifying and disposing of nonconformingitems?Materials Identification and Traceability:Has the manufacturer established a process for identification of pipes,fittings, bolting, welding consumables and other materials used forpiping fabrication while in storage and during construction activities?Is the process in practice?Yes ; NoIs the process in practice?Yes; NoReviewer s Comments:3.3.10<strong>Construction</strong> of <strong>Pressure</strong> <strong>Piping</strong>Has the manufacturer ensured that:a fabrication plan is developed and reviewed with personnel?Yes; Noan ITP (and/or a <strong>Construction</strong> Travel Sheet) and a project file are initiatedprior to the start of the project and maintained?Yes; NoPage 14 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredthe owner s inspector assigned to the job by the owner is informed priorto the start of the project for the purpose of reviewing ITP (and/or a<strong>Construction</strong> Travel Sheet), for construction documents and forassignment of inspection hold points?Yes; NoAB-518b 2014-01up to date and approved (by the QC manager) drawing(s) is/are availablefor the construction. When no design drawings or spool drawings aresupplied by the owner and the spool drawings are prepared by thecontractor, documented approval shall be obtained from the owner toensure that the design, material, fabrication, NDE, PWHT, hydrotest andany other requirements are specified?Yes; Nothe materials are available, issued for construction and checked forconformance with the engineering design prior to start of fabrication?Yes; Nowelding and other fabrication activities are monitored and documentedduring production?Yes; Nothe WPS specified in the engineering design are suitable for the job.When no WPS are specified by the designer, is the process for assigningthe WPS in coordination with the owner specified?Yes; Nocopies of the registered WPS are available to the welders, and areunderstood and implemented effectively.Yes; Nothe welders are qualified for the job and records of the welders aremaintained?the inspection and examination stages are identified, carried out inaccordance with the acceptance standards, documented, verified andrecords maintained?YesYes; No; NoPage 15 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredthe process for defining the extent of NDE, identification of spools, supplyof NDE instructions to the NDE company, review of radiographs andreports and acceptance is defined and documentation maintained?Yes; NoAB-518b 2014-01for ASME B31.1 Boiler External piping, <strong>ABSA</strong> inspection and certificationis achieved?N/A ; Yes ; Nothe PWHT is completed in accordance with the requirements of theengineering design, verified and documented?N/A ; Yes ; Nothe pressure testing is accomplished in accordance with requirements ofthe engineering design and codes, and documented?Yes; Nothe completed job is certified using an AB-83 Form, a copy is supplied tothe owner and records maintained. When a job partially meets therequirements of the SCA, Regulations and applicable ASME B31 code(s)a partial AB-83 Form shall be completed and provided to the primarycontractor?Yes; Nowhen specified by the contract, and, when the piping system wasoriginally registered with <strong>ABSA</strong>, an AB-81 Form is completed uponinstallation and prior to the operation and submitted to <strong>ABSA</strong>?Reviewer s Comments:Yes; NoPage 16 of 25

3.3.11Post Weld Heat Treatment (PWHT)<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAB-518b 2014-01Has the manufacturer:assigned responsibilities for the implementation and maintenance of thePWHT procedures?Yes; Noverified that the PWHT requirements are defined in the engineeringdesign/drawings or otherwise made available by the owner?Yes; Noensured that the PWHT activities are executed in accordance with therequirements of the engineering design?Yes; Noensured that the piping spools designated for PWHT are identified? Yes ; Noensured that the PWHT instructions for the piping are prepared andsupplied to the heat treatment contractor?Yes; Noensured that upon completion of the PWHT of the piping, it is inspectedand the documentation verified?Yes; Nomaintained PWHT documentation? Yes ; NoReviewer s Comments:Page 17 of 25

3.3.12Nondestructive Examinations and Testing<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAB-518b 2014-01Has the manufacturer ensured that:the NDE required for the pressure piping fabrication is determined fromthe documents issued for construction by the manufacturer?Yes; Noa lot size is established in agreement with the owner? Yes ; Noprocedures used for performing NDE are documented and meetrequirements of the current Regulations, ASME Section V and theapplicable ASME B31 Code of construction?the NDE interpretations are performed by CGSB/SNT-TC-IA Level II orIII technicians?Has the manufacturer verifiedthat the procedures used bythe NDE company meet therequirements of the regulationsand the codes?Yes ; NoVerify Radiographic reports.Yes ; Nothe written instructions for performing NDE are provided to thetechnicians performing NDE?Yes; Nothe process for identifying the welding joints requiring NDE isdocumented?Is the process in practice?Yes ; Nothe NDE is performed to meet the specified NDE for each lot? Yes ; Nothe radiographic film and reports are reviewed and accepted by his/herQC personnel?Yes; Nothe NDE documents are kept on file for a specified period of time?Review past files.Yes ; NoPage 18 of 25

Reviewer s Comments:<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAB-518b 2014-013.3.13Examination(Examination and inspections activities performed by the manufacturer)Are the responsibilities for the examination activities and qualificationsof an examiner defined?Yes; NoAre the examinations specified for various stages of constructionconducted?Yes; NoAre <strong>QMS</strong> examination requirements and associated proceduresavailable and understood by the personnel responsible for theexamination activities?Confirm availability ofdocuments at the point of useand verify understandingthrough personnel interviews.Yes ; NoAre the materials received from the owner(s) and supplier(s) examinedto assure conformance with the requirements of the engineeringdesign?Are the partial piping systems and documents received from thesubcontractors examined prior to release for further processing?Are the partial piping turnover packages received from manufacturerswithin Alberta accompanied by Partial AB-83 forms?YesYesYes; No; No; NoAre the piping systems and documentation received from manufacturersoutside of Alberta accompanied by AB-83F forms and examined priorto release?Yes; NoPage 19 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAre completed piping systems and documents received frommanufacturers from within Alberta accompanied by AB-83 forms andare examined prior to release.Yes; NoAB-518b 2014-01Is the final examination carried out in accordance with the documentedprocedures, to complete the evidence of conformance of the finishedproduct to the specified requirements?Yes; NoAre the examination records maintained? Yes ; NoFor ASME B31.1 Boiler External <strong>Piping</strong>, is <strong>ABSA</strong> s inspectionrequirement addressed?Reviewer s Comments:<strong>ABSA</strong> s inspection enabledwhen required?N/A ; Yes ; No3.3.14<strong>Pressure</strong> TestingIs a documented procedure in place and understood by the personnelresponsible for conducting the pressure tests?Confirm availability of theprocedure and verifyunderstanding throughpersonnel interviews.Yes ; NoIs over pressure prevented during the pressure test? Yes ; NoAre the pressure test areas secure and safe for all personnel? Yes ; NoPage 20 of 25

Is the procedure effective and meets the requirements of theengineering design and the code of construction?<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredYes; NoAB-518b 2014-01Is the procedure being complied with? Yes ; NoAre the pressure gauges calibrated and of proper range? Yes ; NoAre the required examinations carried out by qualified personnel? Yes ; NoAre the pressure test records maintained? Yes ; Nofor ASME B31.1 Boiler External <strong>Piping</strong>, are prior arrangements madewith <strong>ABSA</strong> to enable a SCO to inspect and witness the pressure test?Yes; NoReviewer s Comments:3.3.15Control of Monitoring and Measuring DevicesHas the manufacturer ensured that:a process is developed for determining which measurements arerequired to be taken during the construction, examination and testing ofpressure piping and for selecting the appropriate equipment that iscapable of providing the necessary accuracy and precision?Yes; Noinspection, measuring and test equipment is identified, calibrated andadjusted at prescribed intervals, and that the equipment is verified to bein good condition prior to use?Sample the equipment.Yes ; NoPage 21 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredthe equipment is calibrated against internationally or nationallyrecognized standards?Yes; NoAB-518b 2014-01the process employed for the calibration, and for keeping details ofequipment, unique identification, location, frequency of calibrations andchecks, calibration method, acceptance criteria and action to be takenwhen the results are unsatisfactory, is defined?Yes; Nocalibration records of the equipment are maintained?Sample records.Yes ; Nothe handling, preservation and storage of the equipment is such that theaccuracy and fitness for purpose could be assured?a method for safeguarding the equipment from unauthorizedadjustments is defined?Reviewer s Comments:YesYes; No; No3.3.16Competency and TrainingHas the manufacturer established and is continuing to maintain adocumented plan for the training of personnel responsible for theconstruction of pressure piping?Verify records and note theresults below.Does the training plan include requirement for identifying training needs,providing training, making assessment to assure competency andmaintenance of records?Reviewer s CommentsPage 22 of 25

3.3.17Corrective and Preventive Action<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAB-518b 2014-01Has the manufacturer:ensured that a documented procedure for Corrective and PreventiveAction program is in place?Verify records and note theresults below:ensured that the procedure identifies the Forms and includes steps toidentify the non-conformity, immediate action to dispose of the nonconformity,root cause analysis to determine the action in order toprevent it from happening again, and, to verify the effectiveness of thecorrective action taken?ensured that training is provided for the implementation of the Correctiveand Preventive Action program?reviewed the Corrective Action and Preventive Action Reports/Formsand logs on a periodic basis, evaluated, established trends and initiatedimprovement measures?controlled the Corrective and Preventive Action documents?ensured that the records are available for review to the management?Reviewer s CommentsPage 23 of 25

3.3.18Internal Audits<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferredAB-518b 2014-01Has the manufacturer:developed an Internal Audit process and/or procedures?Verify records and note theresults below:prepared a schedule for conducting the Internal Audits?carried out the Internal Audits?documented the audit results?communicated the audit results to the appropriate personnel andmanagement?ensured that timely action is taken as a result of the audit findings?assured that follow-up action to verify the success of the correctiveaction taken is defined?defined maintenance of the records?conducted a periodic review of the audit system and reported the resultsto the management?Reviewer s Comments:Page 24 of 25

<strong>Pressure</strong> <strong>Piping</strong> <strong>Construction</strong> <strong>Requirements</strong><strong>QMS</strong> <strong>MANUAL</strong> & AUDIT CHECKLIST AB-518(b)Electronic completion of this document is preferred3.4 Are the quality management system personnel knowledgeable, meet the requirements of section3.4 of AB-518 document and provide competent services at the construction site?Reviewer s Comments:Yes; NoAB-518b 2014-01Page 25 of 25