TRITT CONTRACTING - TEC Tractor Times

TRITT CONTRACTING - TEC Tractor Times

TRITT CONTRACTING - TEC Tractor Times

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

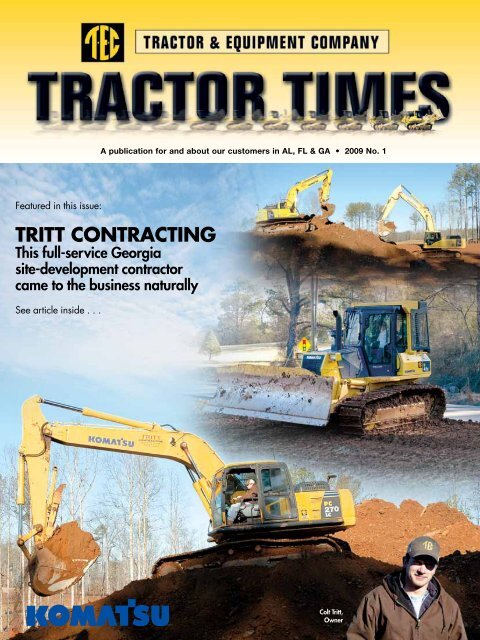

A publication for and about our customers in AL, FL & GA • 2009 No. 1Featured in this issue:<strong>TRITT</strong> <strong>CONTRACTING</strong>This full-service Georgiasite-development contractorcame to the business naturallySee article inside . . .Colt Tritt,Owner

A MESSAGE FROMTHE PRESIDENTDan StracenerDear Equipment User:We’re looking forward to the new year with optimism thatconstruction will rebound. One reason we’re hopeful is because ofthe recently approved economic stimulus package, which includesan estimated $130 billion in construction-related spending.No matter the conditions in the construction industry, we shouldall look for ways to be more efficient in our equipment use. Thatmeans using quality machinery that helps you produce more in lesstime with decreased fuel consumption and emissions. Komatsu hasa full line of construction, utility, mining and forestry equipment thatmeets those standards.You can find out about some of those products in this issueof <strong>Tractor</strong> <strong>Times</strong>. Among them are innovative machines, such asKomatsu’s largest utility excavator, the PC88MR-8; the PC200LC-8excavator with thumb spec; and D31 and D37 dozers, which nowfeature the super-slant nose design. If it’s mining equipment you’reinterested in, check out the MINExpo article to see products thathave made Komatsu the leader in mining machinery.If you need more information on any of these products, or if we canhelp you with any of your service needs, don’t hesitate to contact us.We’re here to help you in any way we can.Sincerely,Dan StracenerPresident

THE PRODUCTS PLUSTHE PEOPLE TO SERVE YOU!IN THIS ISSUE<strong>TRITT</strong> <strong>CONTRACTING</strong>See how a passion for the business has led to success for this Georgiasite-development contractor.VANTAGE CONSTRUCTIONProviding customers with value has helped this site-prep arm for FyffeConstruction stay busy.FIELD NOTESCheck out the photos from Komatsu’s recent Demo Days whereparticipants operated equipment and toured the ChattanoogaManufacturing Operation.INVESTING IN THE PRESENT AND THE FUTUREThe $787 billion American Recovery and Reinvestment Act was signedinto law in mid-February. See how infrastructure spending is a crucialelement of this economic stimulus plan.GUEST OPINIONDavid Seiders, former NAHB Chief Economist shares potential goodnews on the status of the housing market.DESIGN INNOVATIONKomatsu is at the forefront of design innovation with its award-winningsuper-slant design and other improvements to its D31 and D37 dozers.PRODUCT NEWSRead how the new PC200LC-8 Thumb Spec excavator offers greater liftcapacity and stability in a variety of applications.Published by Construction Publications, Inc. forTRACTOR & EQUIPMENT CO.Dan Stracener, PresidentLloyd Adams, Executive V.P./CFOLenn Morris, Executive V.P/General Manager – AL/FL operationsSteve McCondichie, V.P./General Manager – GA operationsGerald Carroll, V.P./General Service ManagerSteve Day, V.P./General Parts ManagerHugh Stith, V.P./Regional Sales Manager - GAMike Copeland, V.P./Regional Sales Manager – GADeVaughn Pettit, V.P./Regional Sales Manager – GAChuck Tullos, V.P./Regional Sales Manager – AL & FLBrett Bussman, V.P./Regional Sales Manager – ALJoe Patton, V.P./Regional Sales Manager – ALAutrey McMillan, V.P./Regional Sales Manager – AL & FLTim Tipton, V.P./Product Support MarketingChris Lucas, V.P./Data Processing ManagerMike Kemmerer, General Service Manager - GALarry Watkins, Service Manager –North ALMark Shoults, General Parts Manager - GAScott Deitz, Utility Division ManagerTim Thomas, Used Equipment ManagerJohn Pierce, New Equipment Rental ManagerBIRMINGHAM, ALTim Woods, Parts ManagerJeff Hodge, Service ManagerTUSCALOOSA, ALJody Thomason, Branch ManagerMichael Burkes, Service ManagerMcCay Harrison, Parts ManagerANNISTON, ALTodd Bigbee, Branch ManagerMarlin Harrell, Service ManagerBuck Brown, Parts ManagerDOTHAN, ALRodney Maltbie, Parts ManagerTony House, Service ManagerSHOALS AREA, ALRandall Brown, Parts ManagerALABASTER, ALGreg Riggs, Parts ManagerALABAMAMONTGOMERY, ALDoug Stone, V.P./Branch ManagerRob Boroughs, Service ManagerLarry Long, Parts ManagerDECATUR, ALDon Burgreen,V.P./Branch ManagerTim Kohlenberg,Service ManagerGary Hall, Parts ManagerMOBILE, ALDanny Wright, Service ManagerLarry Cook, Parts ManagerGROVE HILL, ALKeith Hood, Parts ManagerRENEW CENTER, ALDave Hawker,Branch ManagerBenny Cusimano, Parts ManagerFLORIDAPANAMA CITY, FL PENSACOLA, FLChuck Tibbets,Branch ManagerTravis Howell, Service ManagerKelly Myers, Parts ManagerDave Niesen, Branch ManagerBilly Dees, Service ManagerChad Glass, Parts ManagerBIRMINGHAM, AL(205) 591-2131TUSCALOOSA, AL(205) 752-0621(800) 582-4625ANNISTON, AL(256) 831-2440ALABASTER, AL(205) 621-2489DOTHAN, AL(334) 678-1832SHOALS AREA, AL(256) 383-5666www.tractor-equipment.comMONTGOMERY, AL(334) 288-6580(800) 832-9563DECATUR, AL(256) 355-0305(800) 321-6865MOBILE, AL(251) 457-8991(800) 233-7213GROVE HILL, AL(251) 275-4158PANAMA CITY, FL(850) 763-4654(800) 342-2055FOREST PARK, GA(Atlanta)(404) 366-0693(800) 488-0693CALHOUN, GA(706) 879-6200(800) 827-3072HOSCHTON, GA(706) 654-9850(888) 334-9850AUGUSTA, GA(706) 798-7777(800) 659-3090MACON, GA(478) 745-6891(800) 786-3120 SAVANNAH, GACOLUMBUS, GA(706) 562-1801PENSACOLA, FL(850) 505-0550Printed in U.S.A © 2009 Construction Publications, Inc.Kennesaw, GA(678) 354-5533(912) 330-7500(800) 827-1405ALBANY, GA(229) 435-0982(800) 733-0982FOREST PARK(ATLANTA), GAGreg Carroll,Service ManagerEpps Hewett,Parts ManagerCALHOUN, GAMike Kemmerer,Service ManagerAndy Worley,Parts ManagerMACON, GAFrank Hall, Service ManagerJoe Bechtel, Parts ManagerCOLUMBUS, GAKelly Freeman, Service ManagerJamie Horsley, Parts ManagerGEORGIAHOSCHTON, GATim Aiken, Branch ManagerMark Ingle, Service ManagerPhillip Timms, Parts ManagerKENNESAW, GAMike Kemmerer, Service ManagerCurt Cook, Parts ManagerAUGUSTA, GARon Wallace, Service ManagerMark Anderson, Parts ManagerSAVANNAH, GAFrank Dabbs, Branch ManagerTim Stone, Service ManagerBrad Formby, Parts ManagerALBANY, GAHeath Odom, Service ManagerCharles Smith, Parts Manager

A SALUTE TO ACUSTOMER<strong>TRITT</strong> <strong>CONTRACTING</strong>This full-service Georgia site-development contractorcame to the business naturallyColt Tritt,OwnerTritt Contractingcrews did all the sitework at BridgemillCommons, a retailcenter in Canton, Ga.There was never any question about whatColt Tritt would do with his life.“My dad had a grading company and Iworked for him while I was growing up,” Trittrecalled. “As soon as I graduated high schoolin 2000, I started my own grading company.Then I decided to go to college, so I more orless put the business on hold for a couple ofyears. After college, I started it back up againfull time and have never looked back.”When Tritt started the company, whichwas originally called Colt Tritt Enterprises, itconsisted of him, a single-axle dump truck anda small skid steer loader. “As I started gettingmore work, I bought a loader and hired oneguy,” he explained. “Then I got more work andbought another loader and hired another guy.It just grew from there.”Today Tritt Contracting, Inc. (Tritt changed thename of the company in 2005), based in Jasper,Ga., has about three dozen employees. Thecompany offers complete site-work packagesthroughout the Atlanta metro area and beyond.“We primarily do municipal pipe work andsewer and water for government agencies. Wealso do commercial sites, such as retail centersand strip malls,” Tritt noted. “We can do all theclearing, pipe work and grading in-house. Wealso take on the paving and concrete. AlthoughI sub out that work, it’s to companies that doa lot of jobs with us, so it’s like they’re part ofour company too.”Tritt Contracting also does public work, suchas sewer or water-line reconstruction or newinstallation.One-stop shopThe fact that Tritt Contracting handles allaspects of a job for the owner or developer isdefinitely one of its strengths.“We do everything for our customer and do itall, basically, under one roof as a one-stop shop,”said Tritt. “I think that’s one of the big reasonsdevelopers want us to work for them. They onlyhave to deal with one person, which is me, andI’m pretty easy to get along with.“Also, if a problem does crop up, I’m easy toreach and willing to do whatever it takes to getthings moving again,” he added. “For example,on a job earlier this year there was an issue overa traffic lane, so I called the inspectors and somecounty officials and got everybody together atthe job. We drew up the changes right there onsite, got them approved by the engineer andthe county, and we were able to keep workingrather than shutting down the job for a periodof time. That’s the type of value we routinely tryto bring to the job for our clients.”Valued employeesWhile Tritt always knew he’d have aconstruction company, he didn’t expect to haveas much early success as he’s had.

Tritt Contracting owns four Komatsu hydraulic excavators including this PC270LC-7. “My introduction to Komatsu equipment was when I demo’d aused PC270 a few years ago,” said Owner Colt Tritt. “I’ve been sold on them ever since. I think they’re faster and smoother than other excavators.”“I can’t say I expected to have 36 employeesand even more pieces of equipment after beingin business just four years,” he admits. “Wejust try to take good care of our customers —give them a good job at a fair price with nohassles. I guess they appreciate that becauseit’s paid off with many repeat customers.”Tritt credits his employees for much of thecompany’s success.“We definitely have some good hands, guyswho know what they’re doing and are willing towork hard. I try to keep at least five jobs goingmost of the time, and they could be from northGeorgia, to Alabama, to south of Atlanta, so weneed a lot of good people when we get spreadout like that. I try to get to all the jobs every day,but I definitely need people I can count on in myabsence and I believe we have those people.”Tritt’s brother Troy works with him as anestimator. Greg Bowen is a key foreman.Randy Stanley is a mechanic who handlesminor repairs and maintenance.Fast, powerful equipmentAbout three years ago, Tritt was doing a jobfor a church in his hometown of Jasper andneeded about a 30-ton hydraulic excavator. Hehad never run a Komatsu, but he knew about<strong>Tractor</strong> & Equipment Company in nearbyCalhoun, so he called and asked if he coulddemo a PC270.“They brought me out a used one and I ran itfor a few days and really liked it, but I decidedI wanted a brand-new one instead. That wasmy introduction to Komatsu equipment and<strong>TEC</strong> and I’ve been pretty much sold on themever since.”Today, in addition to the PC270LC-7, TrittContracting also has two PC300LC-7s, threeD41 dozers, a PC50 compact excavator, and aWA250PT wheel loader from <strong>TEC</strong> and PSSRGreg Farr.Continued . . .This Tritt Contractingoperator used one of thecompany’s D41 dozersto walk an incline,compacting soil at theBridgemill Commonsjob in Canton.

Road work may be next for Tritt Contracting. . . continuedColt Tritt (left) worksclosely with <strong>TEC</strong> PSSRGreg Farr. “The serviceI get from <strong>TEC</strong> is thebest — period,” saidTritt. “All I have todo is call the Calhounbranch or call Greg andthey’re on it right away.<strong>TEC</strong> goes above andbeyond for me, and Iappreciate it.”“I think Komatsu machines are great,” saidTritt. “The excavators are fast and I think they’resmoother than other excavators. And I reallylike our D41 dozers. They’re very powerful andcan really push a lot for their size.”A dealer he can count onWhile Tritt is sold on Komatsu equipment,he’s also very pleased with the support he getsfrom <strong>Tractor</strong> & Equipment Company.“The service from <strong>TEC</strong> is the best — period,”said Tritt. “If I need something, all I have todo is call the Calhoun branch or call Greg,and they’re on it. If it’s important and I needit right away, they take care of me right away.If I need a part and they don’t have it rightThis Tritt Contracting operator used a Komatsu PC300 to lower a piece of pipe to tie intoan existing sewer manhole at Bridgemill Commons in Canton.at that moment, they’ll take it off one of theirmachines to put it on mine so I can get backup and running. That kind of service meanseverything to me.”Beyond the rapid response, Tritt says hisrelationship with <strong>TEC</strong> brings him peace of mind.“Just knowing that they’re going to support meif I need it is worth a lot to me. I probably talk toGreg every couple of days, and their parts manin Calhoun, Andy Worley, stops by the officeor jobsite periodically just to see how things aregoing — to make sure everything’s okay.“Some of the other companies I’ve dealt witharound here, their attitude seems to be, we’llget to you when we can — and it may well bea couple of days,” Tritt added. “<strong>TEC</strong>, on theother hand, jumps on any problem right away.When your dealer has your back like that, it’s abig relief. <strong>TEC</strong> goes above and beyond for me,and I appreciate it.”Still growingTritt says he’s proud of all the jobs hiscompany has done. He singled out its workfor the Pickens County High School addition,which included clearing about six acres andmoving about 60,000 yards of dirt, addinga third lane to a mile and a half of road, anddoing paving, curb work and retaining walls.He also cited the Preston Ridge Medical Centerin Alpharetta as a recent signature job.“I love driving by jobs that we’ve done afterthey’re completed,” said Tritt. “We take a pieceof raw ground and turn it into somethinguseful that people appreciate. There’s thegreen grass, the white stripes on the parkinglot, the curbs are clean and pretty. There’s justa tremendous amount of satisfaction for medoing this type of work.”Despite the success he’s already had,Tritt says he’s not done. His goal is to keepgrowing, and he has big aspirations.“I would love to be a large road builder. Atlantahas several of the leading highway contractors inthe south. If we could someday join their ranks,that would be a major accomplishment. We’realready starting to do some small road jobs. We’llsee where that leads us.” n

100%(the LOGICAL CHOICEfor your next excavator)LCKomatsu excavators have set the standards for productivity, operator comfort and reliability over theyears. And, with the introduction of our mid-sized –8 series, the standards have been raised yet again.• Tier-3 engines deliver reduced emissions without sacrificing power or productivity.• Electronics, engine and hydraulics are optimized for maximum efficiency andminimum fuel consumption (10% reduction compared to –7 models).• Multi-function LCD monitor provides critical operating information at a glance(and it can do this in 10 languages).From enhanced safety features to extended maintenance intervals, the PC200LC-8, PC220LC-8and PC270LC-8 show what happens when the best engineers put the latest technology to work.The results are always…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA03

A SALUTE TO ACUSTOMERVANTAGE CONSTRUCTIONLongtime Alabama builder Fyffe Constructionforms Vantage as a site-prep companyThis VantageConstruction operatoruses a KomatsuWA250PZ at a job inFt. Payne, Ala.Vantage Construction is the site-developmentarm of the longtime northeastern Alabamabuilder, Fyffe Construction. Located in Fyffe,Ala., Fyffe Construction was founded in 1971by Lowell Barron Sr., who in 1983 becamestate Sen. Barron by waging the first successfulwrite-in campaign in the history of the Alabamalegislature.After Sen. Barron’s election, Fyffe Constructionslowed its construction activities considerably,focusing instead on property management. Butin the mid-’90s, Sen. Barron’s son, Lowell RayBarron II, took over the company and began toonce again emphasize construction, specificallybuilding affordable housing and hotels. Lastyear, the younger Barron formed VantageConstruction to do earthwork and utilities,not just for Fyffe projects, but also for othercontractors and developers.Today, Vantage employs about 15 peopleduring its busy season and does jobsthroughout Alabama, Georgia and SouthCarolina. In addition to Lowell Ray BarronII, key personnel include Fyffe ConstructionVice President Coy Murray and OperationsManager Kevin Sawyer.“One of Fyffe’s specialties is providingaffordable housing — much of it for seniorcitizens,” said Vantage’s Sawyer. “At Vantage,we do most, if not all, of Fyffe’s site work,which includes a lot of apartment complexesand subdivisions, as well as commercialproperties such as hotels and restaurants.“Our goal is complete customer satisfactionwhich earns us repeat business, whetherit’s from Fyffe or any other company we’reworking for,” he added. “We don’t mindtraveling. We’ve worked throughout theSoutheast. Thus far, all of our work has beenon the private side, but down the road, I thinkwe’re also going to begin bidding municipalwater and sewer jobs in the public sector.”A quality job at a fair priceWhether it’s a hotel in Huntsville, Ala., amultistory senior-living facility in Milledgeville,Ga., or renovation of an apartment complex inDuncan, S.C., — all of which are recent Fyffejobs — the company emphasizes doing qualitywork, on time and on budget.“Fyffe Construction has built its business onejob at a time and has earned an outstandingreputation that has kept it very busy in recentyears,” said Sawyer. “At Vantage, we intendto operate the same way, which means givingcustomers value — a good job at a fair price.”Fyffe and Vantage rely on a talentedand trusted work force to deliver suchcost-effective projects.“Because we’re on the road a lot, we counton our guys to be able to work without much

supervision,” said Sawyer. “Overall, our team isvery self-motivated and our crews do a great jobof taking care of business at home or on the road.”Reliable equipment and supportTo help Vantage do its site work packages in anefficient and cost-effective manner, the companyhas turned to <strong>Tractor</strong> & Equipment Companyfor several machines. Among the most recentare two Komatsu units — a WA250PZ-6 wheelloader and a D51PX-22 dozer — as well as aPC200LC-7 hydraulic excavator.“Komatsu makes good equipment,” saidSawyer. “We’ve been pleased with all ourKomatsu units. The D51 dozer is truly in aclass by itself. We familiarized ourselves withthe D51 and the WA250 during a trip to theKomatsu Training Center in Georgia. Being ableto get on the machines and operate them at theproving grounds was very beneficial. It wasthere that our operators discovered they reallyliked some of the Komatsu features.”Equally important to Sawyer is the supportVantage gets from <strong>TEC</strong> and Decatur branchSales Representative Dwight Swaim.“Dwight and everybody at <strong>Tractor</strong> &Equipment are great to work with. They puttogether an excellent financial package thatallowed us to acquire the equipment. Theyservice us well. And because we do a lot ofwork throughout Alabama and Georgia, it’snice to know that <strong>TEC</strong> has branches all acrossthe two states. If we have any issues, theycome whenever and wherever we need them.”Optimistic about the futureLooking to the future, Sawyer says he’soptimistic that Vantage Construction will beable to grow, despite some concerns about thegeneral economy.“The government seems to understandthat economic stimulus is needed andthat infrastructure construction can be animportant part of that. If we slow down withprivate site work, we hope to more than makeup for that in municipal sewer and waterwork. We have very talented crews who canstep right in and do that work successfully sowe’re looking forward to it.A D51 dozer (above) and PC200LC-7 hydraulic excavator (below) work to clear a site.“The Komatsu D51 dozer is in a class by itself,” said Vantage Construction’s KevinSawyer. “We’ve been pleased with all of our Komatsu machines.”“There are always going to be challengesinvolved in construction work,” he added. “Aslong as we continue to work with our clientsand consistently deliver on-time, on-budget,quality projects for them, we believe we’ll staystrong and be in a good position to grow whenthe economy turns up again.” n<strong>Tractor</strong> & EquipmentCompany Sales Rep DwightSwaim (left) works closelywith Vantage Construction’sKevin Sawyer. “Dwightand everybody at <strong>Tractor</strong> &Equipment are great to workwith,” said Sawyer. “They’vetaken very good care of us.”

FIELD NOTESTEST DRIVEDemo Days attendees operate Komatsu equipment,take advantage of CMO tourDemo Days attendees listento a brief presentation atthe Komatsu Training andDemonstration Center inCartersville, Ga.Many of those attendingDemo Days also took a guidedtour of Komatsu’s ChattanoogaManufacturing Operation,where excavators andarticulated trucks are made.Equipment users from around the countrygot a close look and a chance to demonstratemachinery at Komatsu’s most recent Demo Daysat the Komatsu Training and DemonstrationCenter in Cartersville, Ga. Among the unitshighlighted were the PC200LC-8 excavator withthumb spec and the new D275AX-5 dozer withthe patented Sigma blade.Additional machinery included theaward-winning D51-22 dozer and its smallercounterparts, the D39-22, D37-22 and the D31-22.All are available with KOMTRAX, Komatsu’sremote machine-monitoring system, whichcustomers could learn more about duringthe event. They also had the opportunity totour Komatsu’s Chattanooga ManufacturingOperation (CMO), where some of the excavatorsand articulated dump trucks on display at DemoDays are made.Also on site were a wide range of the latestexcavator and wheel loader models, as wellarticulated and rigid-frame trucks, rubber-tireskid steers and compact track loaders, a GD655-3motor grader and a BR580JG mobile crusher.For more information on Komatsuequipment, call your sales representative orvisit our nearest branch location. In manycases, if you’d like to try something out, we’llbe able to set up a demo for you. nDemo Days featured a wide array of Komatsu equipment.Komatsu personnel were on hand to answer questionsabout all the machinery, which equipment users coulddemonstrate.

(L-R) <strong>TEC</strong> Savannah Branch Manager Frank Dabbs, Ellis WoodContracting Owner Ellis Wood and <strong>TEC</strong> Sales Rep Autrey McMillan(L-R) Blair Construction Co-Owners Roy Mutmer and William Mutmerare with <strong>TEC</strong> Sales Rep John McMahon(L-R) KC Sanders, Ricky Isbell and Darren Isbell, all of Isbell ConstructionU.S. Steel Mobile Equipment Fleet Maintenance Manager Scott Naugher(left) and engineering employee Rick Shrader<strong>TEC</strong> Sales Rep Robert Boehme (left) and Baxter Company ConsultantDavid MuncherCherokee Pipeline VP Paul Bowman (left) and Operator RichardEmmettEasterwood Excavating Owner Craig Easterwood (left) and <strong>TEC</strong> Sales RepTodd BigbeeChemical Lime Production Supervisor James Brasher (left) and <strong>TEC</strong>Sales Rep Mike Holloman

INVESTING IN THE PRESENT AND THE FUTURESTIMULUS PASSEDInfrastructure spending is a crucial elementof the recovery planThe American Recovery and ReinvestmentAct, more commonly known as the economicstimulus package, was passed and signedinto law in mid-February. The total cost of thepackage is estimated at $787 billion dollars.“The goal at the heart of this plan is to createjobs,” said President Barack Obama. “Not justany jobs, but jobs doing the work Americaneeds done: repairing our infrastructure,modernizing our schools and hospitals,and promoting the clean, alternative energyInfrastructure spending for items such as new utilities is a centerpiece of the neweconomic stimulus package.sources that will help us finally declareindependence from foreign oil.”Of course, the $64,000 question about thisthree-quarters-of-a-trillion-dollar plan is, willit succeed in its job-creation goal?Where the money will go?The stimulus package is a combinationof direct spending, tax breaks andappropriations. Direct spending,which includes items such as higherunemployment benefits and food stamps,accounts for $267 billion or about 34 percentof the total. Tax breaks for individualsand businesses total $212 billion, about 27percent of the total. The largest piece of thepie is appropriations spending, which comesin at more than $308 billion or 39 percent ofthe total.It’s the appropriations spending thatincludes the infrastructure investmentsthat are crucial to the construction industry.Total infrastructure spending will be about$135 billion. If you’re wondering whatmight be in it for you, take a look at how theAssociated General Contractors of America(AGC) breaks down the act’s infrastructureand public building investment provisions(see chart on next page).According to the Congressional BudgetOffice (CBO), only about $35 billion worthof stimulus appropriations will be spent bybefore Sept. 30, which is the end of FY 2009.The CBO estimates nearly $111 billion will bespent in FY 2010.The Obama administration estimates thestimulus package will create or save at least 3million jobs. n

TransportationInfrastructure (in billions) $49.3 billionHighway and bridge construction $27.5Surface transportation grants $1.5Transit capital assistance $8.4AMTRAK and intercity rail $1.3High-speed rail corridors $8.0Airport improvement grants $1.1Facilities and equipment $0.2TSA explosive detection systems $1.0Coast Guard bridges $0.24Assistance to small shipyards $0.1Buildinginfrastructure (in billions) $29.5 billionGSA federal buildings and facilities $5.6Military construction $2.8DOD facilities renovations $4.2DOD energy efficiency upgrades $0.12VA major construction $1.0Community Development Block Grants $1.0Public housing capital fund $4.0HOME investment partnerships $2.3Native American housing $0.51Lead paint removal $0.1Rural community facilities $0.13National Science Foundation facilities $0.4USDA facilities $0.2U.S. Geological Survey facilities $0.14Social Security Administration facilities $0.5BLM maint. and construction (M&C) $0.32U.S. Fish & Wildlife (M&C) $0.28National Park Service (M&C) $0.75Forest Service maint. and facilities $0.65Bureau of Indian Affairs facilities $0.5Indian Health Service facilities $0.5Community health centers $2.0FEMA infrastructure grants $0.3Fire station construction $0.21State Department facilities $0.09DHS headquarters consolidation $0.2Ports of Entry construction $0.7Water & environmentalinfrastructure (in billions) $21.4 billionClean water State Revolving Fund (SRF) $4.0Drinking water SRF $2.0USDA rural water and waste disposal $1.4Corps of Engineers $4.6Bureau of Reclamation $1.0Watershed infrastructure $0.34Int’l Boundary and Water Commission $0.22Superfund hazardous waste cleanup $0.7Leaking underground storage tanks $0.2Nuclear waste cleanup $6.0NOAA Environmental R and I $0.83Brownfields cleanup $0.1Other infrastructure$0.15 billionWorkforce develop./safety $4.7 billionEnergy &technology (in billions) $29.8 billionWireless and broadband grants $7.2Electricity grid $11.0Weatherization assistance $5.0State and local gov’t energy grants $6.3Diesel emissions reduction $0.3Total infrastructure investment:$134.9 billion

GUEST OPINIONPOTENTIAL GOOD NEWSFormer NAHB Chief Economist says there may be lightat the end of the housing tunnel soonCongress should consider providingfurther “sorely needed” economic stimulusto encourage home ownership and limitforeclosure in order to pull the U.S. economyout of recession, according to David Seiders,who recently stepped down as ChiefEconomist for the National Association ofHome Builders (NAHB). He spoke at theNAHB’s Construction Forecast Conference.The steep decline in sales of newsingle-family homes should be coming to anend in 2009, Seiders said, setting the stagefor “tepid” improvement in new residentialconstruction later this year. However, hewarned, that outcome has grown increasinglyuncertain in light of the turmoil that hasgripped world financial markets.“Things are a lot worse than any of us hadanticipated six months ago,” Seiders said, andthe national housing market — which is theroot cause of the collapse in confidence amonglenders — has continued to spiral downward.“Risks are piling up on the down side. Theseare tough times, no question,” he said.While remaining reasonably optimisticthat a housing recovery is beginning totake shape, “The uncertainties out there areunprecedented,” Seiders observed, “and thereis a growing risk that today’s major housingcontraction could get even worse.”On the brighter side, Seiders said thathousing in the first half of 2009 should behelped by the $7,500 tax credit available tofirst-time home buyers; legislative effortsto address foreclosures; the continuation ofaffordable mortgage rates; and the availabilityof fixed-rate mortgage financing throughFannie Mae, Freddie Mac, the Federal HousingAdministration and the Department ofVeterans Affairs.Restoring affordabilityCiting an increase in pent-up demand forhousing, he added that declines in home pricesand increases in personal income have helpedto restore housing affordability to the morenormal levels that existed prior to the peak ofthe housing boom.However, even as the demand for housingbegins to grow, housing production will beconstrained by tighter credit for the loansbuilders and developers need to break groundon new residential projects, he said. ■David Seiders,former NAHBChief EconomistFormer NAHB Chief Economist David Seiders said the steep decline in sales of newhomes should be coming to an end in 2009, setting the stage for “tepid” improvement innew residential construction later this year.

100%(productivity runs in this family)controlYou’re committed to getting things done on time and on budget, and you need dependable,hard-working machines to meet your deadlines day after day. The Komatsu D31, D37and D39 dozers all feature the reliability and versatility that have made Komatsu thechoice of owners and operators for years:• KomStat II Hydrostatic Transmission (HST) for superb accuracy and smooth control• Excellent blade visibility that minimizes operator guesswork and reduces cycle times• All the daily maintenance items centralized in one location for convenient accessWhether you’re looking for a 75, 85 or 95 horsepower machine, you can be confidentyou’ll get a full day’s work—and then some—from dozers that are…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA06

DESIGN INNOVATIONNEW DOZERSAward-winning super-slant design amongimprovements in D31, D37 modelsThe revolutionary design that madeKomatsu’s first super-slant dozer, the D51EX-22,an award winner is now available in the newD31 and D37 models. They are ideal for ownersand operators looking for better visibility andperformance in smaller-dozer applications.Both new models, available instandard-track EX and wide-track PX versions,feature Komatsu’s super-slant nose coupledwith a new cab-forward design that puts theoperator closer to the blade, while improvingmachine balance, ride and stability.“Slanting the nose and moving operatorsforward allows them a better view all around,and especially gives them a great view of thematerial they’re pushing,” said Bruce Boebel,Komatsu Dozer Product Manager. “Cabs arelarger than their predecessors, with more glassto enhance visibility, making the operator moreefficient. Owners could put a new operator inthese machines and be confident they’ll learnhow to run a dozer faster so they’re productivemore quickly.“We didn’t stop with improving the cab,”he added. “The dozers are more durable withthick plate steel and rigid frames, and tracks arewelded onto the frame, unlike most competitors,which have bolt-on track frames. Both have morehorsepower than their predecessors, increasingpushing capabilities for better productionand cost per yard. Couple that with new Tier3 engines that reduce fuel consumption, andmaintenance time, and they’re among the mostefficient dozers on the market.”Those attributes are helped by largepower-angle-tilt blades that hold morematerial, especially useful in mass dozing.Each hydrostatic dozer has a steering systemthat provides smooth movement duringdozing, even in gradual turns. That also allowsthe operator to approach objects accurately incorner and sidewall operations.By simply pushing a button, operators canselect between variable and quick-shift speedcontrol for maximum efficiency during fine orrough grading with optimal travel speeds tomatch job conditions and operator preferences.With variable speed, travel speed is adjustedthrough a range of 20 incremental speeds,while quick-shift allows operators to selectthree predetermined speed settings to matchjob conditions.“All models come standard with KOMTRAXto help track utilization and maintenance,”noted Boebel. “The D31 is great in residentialapplications and tight places for generalfinish work, and the D37 is a step up for thosewanting a little bigger machine, but can’tjustify going to a larger D39. They’re both greatinvestments that will pay big dividends.” nBrief Specs on Komatsu D31 and D37 DozersModel Output Operating weight Blade capacityD31EX-22 78 hp 18,056 lbs. 2.11 cu. yd.D31PX-22 78 hp 18,827 lbs. 2.11 cu. yd.D37EX-22 89 hp 18,298 lbs. 2.32 cu. yd.D37PX-22 89 hp 19,070 lbs. 2.55 cu. yd.Bruce Boebel,Komatsu DozerProduct ManagerKomatsu’s award-winning,super-slant nose design, isnow available in its newD31 and D37 models. Alsoavailable in D39 and D51models, it allows operatorsa better view of the bladefor increased efficiency.

PRODUCT NEWSADDED VALUEPC200LC-8 Thumb Spec excavator offersgreater lift capacity and stabilityArmando Najera,Product ManagerExcavatorsKomatsu’s PC200LC-8Thumb Spec excavator hasthe innovative features of itsstandard counterpart, plusa reinforced mainframe andadditional counterweightfor increased liftingcapacity and stability whenworking with heavy loads atmaximum reach.When Komatsu designed its PC200LC-8Thumb Spec excavator, it kept all the sameinnovative attributes of its PC200LC-8 counterpartand beefed up the counterweight to 11,113pounds. The result was a 20-percent increasein lifting capacity compared to the standardPC200LC-8 and increased stability when workingwith heavy loads at maximum reach.“This is really a great machine for anyonewho’s working in conditions that warrant thatextra lift and stability needed in applicationssuch as digging trenches or setting pipe andstructures,” said Armando Najera, ProductManager Excavators. “The thumb and bucket,as well as attachment piping, can be factoryinstalled. The PC200LC-8 Thumb Spec also hasa heavy-duty arm for improved durability andincreased support for thumb installation.”Also available for customers who requirefactory piping is an HD Spec (Heavy Duty) thatincludes an HD boom, HD revolving frameunder covers and HD decals. The HD Spec is asetup that is suited for demolition-type work.Other major production numbers remain theBrief Specs on Komatsu PC200LC-8 Thumb Spec ExcavatorModel Operating weight Net hp Bucket capacityPC200LC Thumb Spec 51,199-53,115 lbs. 148 hp 0.66-1.57 cu. yd.same for both the Thumb Spec and the HD Spec,with bucket capacity between 0.66 and 1.57 cubicyards and 148 net horsepower.“Keeping those numbers consistent meansthe Thumb Spec machine will continue tobe productive and fuel efficient, even whilehandling heavier work loads,” said Najera.“The PC200LC-8 Thumb Spec has increased inpopularity because of that. Contractors are seeingthe benefit and asking for this machine.”Efficient featuresPart of its popularity comes from the standardfeatures, similar to its counterpart, that makeit among the most productive in its size class,including low fuel consumption and emissionsfrom a Komatsu turbocharged, aftercooled Tier 3engine. Operators can maximize fuel efficiencyby using the Economy mode (one of fiveavailable modes), and using the Eco-gauge forenergy-saving operations. An extended idlingcaution helps operators remember to shut themachine down for fuel conservation.Operators can set the modes using aneasy-to-view, seven-inch LCD color monitorin the large, comfortable cab that has dampermounting for low noise and vibration. Extendedreplacement intervals for engine oil and filter andhydraulic filters means less downtime. Like allnew Komatsu excavators, the PC200LC-8 ThumbSpec comes with Komatsu’s KOMTRAX remotemachine-monitoring system.“Like the standard PC200LC-8, this is truly agreat machine that can benefit almost anyonedoing mass excavation, site preparation or utilityinstallation. The Thumb Spec is not just forcustomers with machines that will use a thumb,”said Najera. “If they need a little extra kick oradditional stability, they should consider thismachine. They’ll definitely see the difference.” n

UTILITY PRODUCTSEXPERIENCE PAYS OFFKomatsu designs the ultimateeight-ton size class excavatorKomatsu recently introduced its newPC88MR-8 excavator to the North Americanmarket to much critical acclaim. There are anumber of competitive units in its eight-tonsize class, but the comparison ends there asside-by-side tests show that the PC88MR-8offers more value from the start and cansave more money throughout the life of themachine.Before the test was conducted, Komatsulooked at 13 obvious areas of comparison,such as the manufacturer’s own hydraulicsand engine, short tail swing, fuel managementfeatures and number of working modes. Ineach case, the PC88MR-8 was equal to orbetter than the competitive model. Majorareas where Komatsu stood out were workingmodes — the PC88MR-8 has five to maximizeproduction and fuel economy — and fuelmanagement features, such as auto-idle, ecogauge, Economy mode and excess idle alarm.The competition had only one mode, auto-idle.After comparing the models, they wereput to the test under controlled conditionsat Komatsu’s Training and DemonstrationCenter in Cartersville, Ga. Komatsu was theclear winner in several categories, including 15percent faster cycle time in Production modeand nearly the same cycle time in Economymode. The PC88MR-8 moved 6 percent morespoil per hour in the Working mode.While the Komatsu PC88MR-8 moved morematerial, it used less fuel — 8 percent lessin Power mode and a whopping 45 percentless in Economy mode. In the same mode,Komatsu was 22 percent more efficient interms of cubic yards per gallon.Continued . . .In a side-by-side comparison, Komatsu’s PC88MR-8 showed faster cycle times, moving 6percent more spoil per hour in the Working Mode. In addition, it used less fuel, making itmore efficient and productive than the competition.

PC88MR-8 offers higher productivity, lower cost. . . continuedAdding to the PC88MR-8’s productivitynumbers is a quiet cab that’s more comfortablefor the operator. During the comparison,operators noted they could better hear thestandard radio in the Komatsu, making for amore pleasant operating environment.Komatsu PC88MR-8 Field Test ResultsP ModeE ModeCycle timein secondsPC88MR-8Competitor12.31 14.1714.2714.17Komatsu had a 15% faster cycle time in Production Mode and nearly thesame cycle time in Economy Mode.P ModeKomatsu moved 6.2% more spoil.P ModeE ModeGallons per hourGallons per hourPC88MR-8Komatsu used 8.1% less fuel in P Mode and 45.1% less in E Mode.P ModeE ModeTruck LoadingFuel ConsumptionFuel EfficiencyCycle timein secondsLoading AmountPC88MR-8Competitor2.74 2.962.04CompetitorCubic yards per hour 114.6 107.4Cubic yards per gallonCubic yards per gallonKomatsu was more efficient by as much as 22.6%.PC88MR-82.96Competitor41.9 36.346.9has onlyone modeKOMTRAX saves moneyIn today’s competitive environment, theavailability of accurate operating information canimprove the bottom line. Helping provide thataccurate information is Komatsu’s KOMTRAXsystem, standard on every new machine withfive years of free communications. To put such asystem on a machine using existing aftermarketofferings would cost well in excess of $2,000.Komatsu sampled the KOMTRAXinformation on several of its first PC88 modelssold, and found the following information:• Six of eight machines analyzed idled 50percent of the time. That excessive idlingwastes fuel, increases engine wear andadds unnecessary hours to the enginehour meter, which may affect machineresale value at trade-in time. The excesshours require more frequent maintenanceresulting in higher costs. By knowingand managing engine idling time, ownerscan reduce maintenance costs and increaseuseful life and resale value.• Those operators who idled the machineless, also used the Economy modetwo-thirds of the time. Using the E modeand idling less saved nearly 60 percent infuel consumption. Assuming a fuel priceof $3 per gallon, that equates to more than$3,300 savings over the course of 1,000hours of operation.Higher resale value,peace of mindThe conclusion from Komatsu’s testing andmonitoring is that the PC88MR-8 is truly theultimate eight-ton excavator. It gives ownersmore up-front at time of purchase and it keepson giving with exclusive fuel-managementfeatures, five working modes to match machineperformance to demand and the exclusiveKOMTRAX machine-monitoring system thatcan enhance efficient, money-saving operation.Komatsu believes that the KOMTRAX historyrecord will pay dividends at trade-in time withhigher resale values.For additional peace of mind, the PC88MR-8comes with a standard three-year/3,000-hourwarranty. n

100%precisionKomatsu compact excavators are right at home working in tight spaces. With advanced ProportionalPressure Control (PPC) joysticks, these machines give you precise handling without sacrificingspeed, reach or capacity. Plus, they have all the features that make Komatsu excavators the choiceof owners and operators across the country.• Low-effort Proportional Pressure Control (PPC) joysticks• Spacious, ergonomically designed operator platform• Industry-leading 360-degree visibility• Tilt-forward operator cab structure for ease of service access• Switchable excavator control pattern without tools (ISO/SAE)When there’s no room for error, the choice is 100% clear. Put our compact excavators to worktoday and enjoy the confidence that comes from machines that are…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA10

100%compatible(it’s the perfect working relationship)“Synergy” isn’t a word often associated with construction equipment, but it’s the perfectword to describe the Komatsu PC600LC-8 and HM300-2 working together… especiallywhen the terrain is less than perfect. Both of these hard-working machines deliver:• Rugged, dependable, go-anywhere productivity• Tier-3 certified engines to meet emissions standards• Advanced hydraulics for faster cycle timesIf you want maximum efficiency—no matter how rough the terrain might be—put thispair to work. At the end of the day, you’ll see the results from machines that are…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA02

MINING MACHINESMINExpo REPORTKomatsu showcases how equipment and technologywork together for better production, managementWhen it comes to mining machines, Komatsubelieves in “inventing the future” with innovativeproducts designed to make the user moreefficient, productive and profitable. It showcasedthe present and future of some of its largestproduction machinery with one of the show’sbiggest displays at MINExpo in Las Vegas.Highlighting the Komatsu display were twonew electric mining trucks — the massive 960E-1and the 860E-1KT — that provide optimalproductivity and fuel efficiency. Topping 1 millionpounds when fully loaded, the 960E-1 is now thelargest in Komatsu’s full line of mining truckswith a 360-ton payload. Hauling that massiveamount of material is no problem for the 960E-1and its 3,346-horsepower Komatsu engine, whichuses a unique dual-stage, turbo air-handlingsystem. It has the lowest brake-specific fuelconsumption at rated horsepower for its size class.“More than a decade ago, Komatsu wasthe first to introduce an AC drive system forultra-class mining trucks,” said Don Lindell,Product Manager for Mining Trucks. “Thatexperience, along with the more than 100 millionoperating hours logged overall for our electrictrucks, clearly puts us in the lead with these newmachines. Customer feedback was also a biginfluence driving our design criteria for these twonew models. The result is a truck that’s unrivaledfor productivity, efficiency and comfort in thissize class. We took great care in manufacturingthe truck to be rugged and dependable, evenin the most demanding applications. Thereare significantly fewer bearings than on othertrucks, so there are fewer wear components.We ultrasonically test every weld. It’s a veryinnovative product.”Komatsu drive and the T for Trolley) as well.The 2,700-horsepower, 16-cylinder, two-stageturbocharged diesel engine is not only powerful,but Tier 2 certified for lower environmentalimpact. With Komatsu’s factory-installed,trolley-capable option, the 860E-1KT can beutilized on either 1,600- or 1,800-volt linesfor faster propulsion uphill while the enginereduces rpm, saving fuel and extending the lifeof the engine compared to a non-trolley truck.Both trucks have ultra-quiet, dynamicretarding systems assisted by four-wheel,wet-disc brakes coupled with traction-controltechnology that provides excellent brakingforce, even in difficult road conditions.“One of the advantages is that the operator canmaintain a desired traveling speed,” said Lindell.“We also made the cabs in these machines largerwith better visibility. An integrated electronicdash display allows the driver to more easily seeand read the gauges as well as payload data.”D475ASD-5 Tier 2 pushes moreKomatsu displayed the latest D475ASD-5dozer with its Komatsu 890-horsepower Tier 2 Continued . . .Rich Smith,Product Manager,MechanicalDrive EquipmentDon Lindell,Product Manager,Mining TrucksKomatsu had one of the largest displays at MINExpo, including a WA1200-3 wheel loader.Komatsu added innovation to the280-ton-payload 860E-1KT (The K stands for

Innovation helps Komatsu remain a leader in mining machinery. . . continuedTom Stedman,Product MarketingManager forMechanical MiningEquipmentA Komatsu 860E-1KThas 2,700 horsepower formoving mass amountsof material faster.engine that works to help the 246,000-pound-plusmachine push nearly 60 cubic yards of materialwith its Super Dozer blade.“The D475ASD-5 Tier 2 is great for long,consistent pushes where operators can utilize allits horsepower,” pointed out Rich Smith, ProductManager for Mechanical Drive Equipment. “ItThe D475ASD-5 Tier 2 dozer pushes nearly 60 cubic yards of material with itsSuper Dozer blade.Komatsu’s newest mining truck, the 960E-1, is also its largest with a payload of 360 tons.uses a lockup torque converter that gets theengine’s power to the tracks and down to theground where it belongs. With the Super Dozerblade, it’s about 15 percent more effective than astandard blade.“That becomes even greater in uphillpushes,” he added. “For instance, on a12-percent or 15-percent grade, users may see20 percent to 25 percent greater productivityadvantages over a standard full-U blade.In addition, it offers greater travel speedwhile the engine kicks down in rpms, so ituses 3 percent to 5 percent less fuel than thecompetition. With today’s fuel prices, thatadds up significantly in a fleet of machines.”WA1200-3 leads the packRounding out Komatsu’s equipment offeringsat MINExpo was its largest wheel loader,the WA1200-3. This machine has a 1,560-nethorsepowerengine and a 26.2-cubic-yardbucket capacity in its standard configuration. Anoptional high-lift model provides an additionaltwo and a half feet of reach.The standard WA1200-3 is not onlyKomatsu’s largest loader, but one of theworld’s largest at more than 452,000 poundswith a dumping clearance higher than 20 feet.It has more than 286,000 pounds of breakoutforce and 253,000 pounds of traction force.Steering is controlled by the Advanced JoystickSteering System (AJSS) with light, short strokesfor perfect steering accuracy, and stopping issafe with closed, wet-disc brakes.“Of the world’s largest loaders, it gives thebest advantage in tractive effort and diggingpower,” said Tom Stedman, Product MarketingManager for Mechanical Mining Equipment.“Komatsu loaders are well-known throughoutthe range of sizes for their powerful digging,breakout force, stability and outstandingtipping load weight and ratio, and we believethe WA1200-3 is unmatched in all these areas.“The WA1200-3 has a wide range ofapplications,” he added. “They are in use in alltypes of mines around the globe because theymatch up very well with our electric miningtrucks. In addition, because of their stability,they make great load-and-carry machines forapplications such as charging a hopper.” n

Ricky Mathis256/338-4574Brian Hagood205/335-3160Rich Trucks205/563-0811Barry Thornburg205/365-4546Edwin Murray770/608-6525Delane Brown205/337-6083Hugh Brown404/406-5985Wesley Barrett334/451-2147Terry Shepherd770/757-0547Marcus Hitt205/242-8567Greg Farr404/245-2386Shane Marquis205/331-8641Troy Cleckler334/312-2351Sean Mehaffey706/836-6899Mark Hadley251/422-8356Bob Raley478/952-5266Mike Douglas850/554-3234Nick Smith850/567-1076Joey Majors850/527-1840Tony Kennedy229/389-1670Doug Haas229/349-3383Tony Bertino404/217-7883WE’LL ALWAYS BE THERE!Call your local PSSR forall your heavy equipment needs.BIRMINGHAM, AL MONTGOMERY, AL(205) 591-2131 (334) 288-6580Parts (205) 592-7276Service (205) 592-7378TUSCALOOSA, AL(205) 752-0621DECATUR, AL(256) 355-0305ANNISTON, AL(256) 831-2440ALABASTER, AL(205) 621-2489MOBILE, AL(251) 457-8991DOTHAN, AL(334) 678-1832GROVE HILL, AL(251) 275-4158SHOALS AREA, AL(256) 383-5666FOREST PARK, GA(Atlanta)(404) 366-0693HOSCHTON, GA(706) 654-9850KENNESAW, GA(678) 354-5533CALHOUN, GA(706) 879-6200MACON, GA(478) 745-6891AUGUSTA, GA(706) 798-7777COLUMBUS, GA(706) 562-1801SAVANNAH, GA(912) 330-7500ALBANY, GA(229) 435-0982PANAMA CITY, FL(850) 763-4654PENSACOLA, FL(850) 505-0550

KOMATSU & YOUKOMATSU’S “GREEN” COMMITMENTVP says the company’s efforts impact boththe environment and customers’ bottom lineErik Wilde,Vice President,Product MarketingThis is one of a series of articlesbased on interviews with keypeople at Komatsu discussingthe company’s commitment to itscustomers in the construction andmining industries — and theirvisions for the future.Erik Wilde has been with Komatsu more than a decade, the lastfive as Director and now Vice President of Product Marketing.“One of my primary missions is to help our product managersand distributors get the message out about how our products canmake our customers more efficient and productive at the sametime,” said Wilde. “Komatsu has done that in several ways that notonly improve machine and operator performance, but reduce fuelconsumption and harmful emissions. We believe we’re the mostenvironmentally friendly equipment company in the market.”Wilde has seen several of the changes that have led to betterowning and operating costs since he joined Komatsu in 1997 as aWarranty Coordinator and Assistant Service Engineer for miningdozers. He was with the Mining Division nearly four years beforemoving into the Construction Division as Product Manager ofhydraulic excavators. He completed an MBA in Marketing in 2003,which led to his position as Director of Product Marketing later thatyear.A San Francisco Bay-area native, Wilde has adapted well to theMidwest as he’s based at Komatsu’s Corporate Headquarters inRolling Meadows, Ill. He and his wife have three children under age10 who keep them busy with various activities.QUESTION: Komatsu has introduced a largenumber of new machines in the past fewyears. What’s changed and why?ANSWER: In the past three years, Komatsuhas redesigned or replaced nearly 95percent of its vast equipment offerings,some as a result of increased governmentalstandards, but just as importantly, becausewe’ve listened to our customers’ desiresfor improved technology, better partsavailability and other improvements thatbenefit their businesses’ bottom lines. Fromthe governmental standpoint, nearly everymachine in Komatsu’s lineup has a Tier 3 orEPA-compliant engine. With the Tier 3 engines,we not only meet governmental standardsfor reduced emissions, but we often exceedthem. At the same time, we reduced fuelconsumption and increased service intervals,both of which add up to more efficiency andcost savings. We simplified the machines forbetter operator efficiency and added itemssuch as lock-up torque converters for betterproductivity. We’re very proud of thoseachievements because they fit right in withour goal of being an environmentally friendlycompany with sustainable and “green”solutions as part of our corporate commitment.QUESTION: What else has Komatsu done togo “green?”ANSWER: Well in some sense, we believewe’ve always been the greenest equipmentcompany in the marketplace, stretching backdecades. All our equipment is designed andbuilt to last. That means fewer machinesbeing put out to pasture, so to speak. Anexample where we’ve extended life is inour new PLUS undercarriage on the D51,D61 and D65 machines, which doubles the

undercarriage life. But we all know that atsome point, every machine outlives its usefullife and will be taken out of service. Komatsudesigns machines that are virtually 100-percentrecyclable, from the steel to the plastic to theglass. We use recycled materials in their initialproduction. That way, there’s less waste andmore reusable material that can go into makingfuture products.Komatsu continues to implement greenpractices in its manufacturing operations.It’s adopted an Earth Environmental Charterthat lays out our principles and activities for agreen and sustainable company. All our plantsare near-zero-waste facilities, so that everymaterial that comes in is used or reused insome way. Waste oil is recaptured and used forheating. We’ve adopted new painting practicesthat cut waste and environmental impact,while making our paint jobs better. In addition,we’ve strategically located our parts depotsto be closer to our customers so less fuel isused to get parts to them quickly, and we’veteamed with suppliers and carriers who areclose to our manufacturing operations, so thereare shorter shipping distances and less fuelburned in getting materials in and productsout of our manufacturing facilities.QUESTION: What are some ways Komatsuis working with equipment users on greenpractices?ANSWER: Komatsu prides itself on beingahead of the technological curve. With ourKOMTRAX monitoring system, which isfree for five years and standard on most newmachines, users can see how a machine isperforming in various modes that Komatsuoffers. It’s widely believed that being inPower mode offers the best production. That’sunderstandable, but our data show that in70-plus percent of applications, they get thesame productivity in the Economy mode ata lower cost. The benefits are less fuel used,less engine wear and more profit. Komatsuis also introducing a “Green Guide,” whichoffers ways for equipment users to promoteand implement green practices into theircompanies and run their machinery moreefficiently. We’re encouraging users to checkit out online so they’re not using paper. IfUtility machines, such as the CK30 compact track loader, were required to meet Tier 4emission standards in 2008. Tier 4 is on the horizon for 175 horsepower and up machinesin 2011 and 75 to 175 horsepower must be Tier 4 in 2012.When Komatsu designed its Tier 3 engine machines, it not only lowered emissions, in manycases it increased horsepower and reduced fuel consumption, making them among the mostproductive and efficient machines in utility, construction and mining applications.they want a paper copy, it will be printed onrecycled paper using soy ink, which is muchmore environmentally friendly.QUESTION: What else is on the horizon forKomatsu?ANSWER: Our utility products already haveinterim Tier 4 engines and we’re working tomeet Tier 4 standards on time, or ahead oftime, like we did with Tier 3 on the balanceof the product line. Engines 175 horsepowerand up are required to be Tier 4 compliant by2011, 75 through 175 horsepower in 2012. Tier 4standards reduce emissions even more, whichfurther reduces environmental impact. As withour other products, we’re working to furtherimprove performance and efficiency on ourTier 4 machines, delivering more value for ourcustomers. n

SIDE TRACKSOn the light side“The good news is that we got the job . . . the bad news isthat they want us to loan them the money to pay for it.”“In local news, police seized 40 tons of smuggled asphaltworth an estimated street value of $1.5 million . . .”Did you know...• Recycling one aluminum can saves enough energyto run a television for three hours.• 80% of the earth’s surface is water.• A ‘jiffy’ is an actual unit of time for 1/100thof a second.• Ten inches of snow equals one inch of rain inwater content.• The WD in WD-40 stands for Water Displacement.It was invented on the 40th try for a formulathat worked.“Just between you and me, we were counting on a big stockmarket rally, so Wall Street could bail out the government.”Brain TeasersUnscramble the letters to reveal some commonconstruction-related words. Answers are on theright side of this page.1. M A M R H E __ __ __ __ __ __2. Z R O D E __ __ __ __ __3. M T C C O P A __ __ __ __ __ __ __4. I R P P A R __ __ __ __ __ __5. C R T E N H __ __ __ __ __ __6. R P O A T E R O __ __ __ __ __ __ __ __Brain Teaser answers: 1. hammer 2. dozer 3. compact 4. riprap 5. trench 6. operator

UNDER THE HOODSAVINGS SOLUTIONSKomatsu offers QuickEvac system designedto help reduce routine maintenance timeKomatsu has teamed up with RPM Industriesto offer its QuickEvac prelubrication and oilevacuation system, which is designed to reducethe time it takes to perform routine oil and filterchanges on equipment. The QuickEvac systemis available as a factory-installed item or a retrofitkit available for virtually any piece of Komatsuequipment.“It’s an on-board engine maintenancesystem that offers several advantages overconventional oil changes, especially the speedat which a service can be performed,” saidJohn Bagdonas, Product Marketing Managerfor Komatsu’s Working Gear Group. “In manycases, oil and filter changes can be performedin a half hour or less compared to multiplehours on some machines. That’s a significanttime savings that equals more profit becausethe machine and operator are producing more.Technicians and mechanics can perform moreservices in less time because they don’t have tocrawl under or over a machine to deal with oilspills from plug removal and installation.”Technicians simply follow these six easy stepsin the QuickEvac system:• Purge lube filters of oil;• Connect the service tool with quick-connectfittings and an electrical connection;• Empty the sump directly into a waste container;• Install dry oil filters;• Refill the sump and oil filters with new oil;• Disconnect the service tool and reconnect thePrelub line (technology that fullypressurizes the engine with oil before theengine cranks and prior to every start).Study shows reduced engine wearTime and money savings are only part of theequation. When coupled with Komatsu’s fuelsavings and lower emissions, the QuickEvacsystem further reduces environmental impact.There’s less chance of oil spills, and waste oilcan be transferred directly to final containmentwithout messy pans or cans. With the Prelubtechnology, there’s no need to prime the filterwith oil, reducing another contamination risk.“QuickEvac is a very ‘green’ technology,”said Bagdonas, who noted teaming up to offerQuickEvac is part of Komatsu’s commitmenttoward one-stop shopping. “Installing thefilters dry and using Prelub technology is notonly environmentally sound, it could help theengine last longer. A recent study by SouthwestResearch Institute showed that engineprelubrication reduced wear an average of 68percent. Of course, every situation is different,but increased component life and any savingson service costs and downtime mean moremoney in the owner’s pocket.”To learn more about QuickEvac, contactKomatsu, your sales representative or ournearest branch location. nQuickEvaccheck valvePrelubline back toengineOil to wastecontaineroil flowOperator electronicbutton to activate pumpJohn Bagdonas,Product MarketingManager,Working GearThe QuickEvac systemis designed to reduceroutine maintenancetime as well as potentialenvironmental impact.Electronic oil pressuresensoroil flowQuickEvacbracketQuickEvac Service Tool(sold separately)Operatorkey switchcontrolMagneticswitchQuickEvac/Prelub Pump and Motor

NEWS OF NOTESOUTHEAST CHEROKEECONSTRUCTIONPresident of Wetumpka, Ala., companywins prestigious national awardUnder Lynn Carter’s guidance, SoutheastCherokee Construction has grown from asmall 12-person road building firm into afull-service site development company withmore than 70 employees. The company todaydoes all types of heavy construction, as well asbuilding construction.Carter inherited Southeast CherokeeConstruction (SCC) upon her mother’s deathin 1987 and became sole owner in 1992. She hasoverseen almost all the growth that’s occurredat the company, which is headquartered inthe small town of Wetumpka, just north ofMontgomery. For her efforts, the U.S. SmallBusiness Administration named Carter the 2008Alabama Small Business Person of the Year.A <strong>Tractor</strong> & Equipment Company customer,Carter said she was “shocked, but honored” towin the award, which recognizes outstandingLynn Carter, Owner of Southeast Cherokee Construction in Wetumpka, Ala., was named U.S.Business Administration 2008 Alabama Small Business Person of the Year.achievement in community service as well asin the business community.“I love the construction industry and amvery proud to be awarded such an honor,”said Carter. “Of course, it’s not just me alone.I really can’t express my gratitude for thesupport and backing I’ve received from myfamily and from the entire SCC team. Our pathto where we are today has not been an easyone, and it did not occur overnight.”Regional contractorMuch of SCC’s work is in central Alabama,but the company also does a significantamount of federal work for the Department ofDefense and the EPA in Florida and Georgia.For succeeding in what is a male-dominatedindustry, Carter has earned the praise of many,including <strong>Tractor</strong> & Equipment CompanyRegional Manager Joe Patton. “I’ve workedwith her on many occasions, and I can vouchthat Lynn is the real deal,” said Patton.For her part, Carter says she’s most proud ofthe way in which her company has achievedits success. “For us, it’s important to do thingsthe right way, which means being persistent,being determined, being true to your work,and most of all, being true to your word.From the beginning, our goal has been todevelop long-term relationships by striving toconsistently provide the highest quality workand service to our customers — and to alwaysdo so with integrity and character.”Winning the 2008 Alabama Small BusinessPerson of the Year Award is a good indicationthat Carter and SCC have done just that. n

Used Equipment SpecialsFor more information, contact:Tim Thomas tthomas@tractor-equipment.comJon Lake jlake@tractor-equipment.com(205) 591-2131 • Fax: (205) 592-7581KOMATSU PC220LC-8, A88105, 2006, 2,085 hrs. . . . . . . . . . $130,000 KOMATSU PC300LC-7EO, A88585, 2006, 3,051 hrs. . . . . . . . $158,500EXCAVATORSKOMATSU PC160LC-7, K41365, 2006, 1,075 hrs. . . . . . . . . . . $92,000WHEEL LOADERSKOMATSU WA200-5, 68343, 2006, 7,167 hrs. . . . . . . . . . . . . . $45,000KOMATSU PC160LC-7K, K40418, 2004, 2,194 hrs. . . . . . . . . . $51,000KOMATSU WA200-5, 68409, 2007, 5,959 hrs. . . . . . . . . . . . . . . $49,000KOMATSU PC220LC-8, A88246, 2006, 1,904 hrs. . . . . . . . . . $101,000KOMATSU PC300LC-6, A84775, 2002, 9,858 hrs. . . . . . . . . . . $75,000DOZERSKOMATSU D31PX-21A, 50780, 2004, 2,243 hrs. . . . . . . . . . . . . $42,000KOMATSU PC300LC-6, A84872, 2002, 8,353 hrs. . . . . . . . . . . $79,000KOMATSU D31PX-21A, 50897, 2005, 1,214 hrs. . . . . . . . . . . . . $45,000KOMATSU PC600LC-7, 20079, 2004, 5,464 hrs. . . . . . . . . . . . $290,000KOMATSU D39PX-21A, 2132, 2006, 1,231 hrs. . . . . . . . . . . . . . $60,000KOMATSU PC750LC-7, 20011, 2004, 5,029 hrs. . . . . . . . . . . . $395,000KOMATSU D61EX-12, B1823, 2003, 3,327 hrs. . . . . . . . . . . . . . $85,000www.tractor-equipment.com

C.P.I.P.O. Box 1689C.R., IA 52406-1689Change Service RequestedPresorted StandardUS Postage PaidC.P.I.White logo is belowTRASHMASTERS®WALDONTRACTOR & EQUIPMENT CO. LOCATIONS:BIRMINGHAM, AL(205) 591-2131MONTGOMERY, AL(334) 288-6580(800) 832-9563TUSCALOOSA, AL(205) 752-0621(800) 582-4625DECATUR, AL(256) 355-0305(800) 321-6865ANNISTON, AL(256) 831-2440MOBILE, AL(251) 457-8991(800) 233-7213DOTHAN, AL(334) 678-1832GROVE HILL, AL(251) 275-4158SHOALS AREA, AL(256) 383-5666ALABASTER, AL(205) 621-2489FOREST PARK, GA(Atlanta)(404) 366-0693(800) 488-0693HOSCHTON, GA(706) 654-9850(888) 334-9850KENNESAW, GA(678) 354-5533CALHOUN, GA(706) 879-6200(800) 827-3072MACON, GA(478) 745-6891(800) 786-3120AUGUSTA, GA(706) 798-7777(800) 659-3090COLUMBUS, GA(706) 562-1801SAVANNAH, GA(912) 330-7500(800) 827-1405ALBANY, GA(229) 435-0982(800) 733-0982PANAMA CITY, FL(850) 763-4654(800) 342-2055PENSACOLA, FL(850) 505-0550GA