T&K CONSTRUCTION LLC - TEC Tractor Times

T&K CONSTRUCTION LLC - TEC Tractor Times

T&K CONSTRUCTION LLC - TEC Tractor Times

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

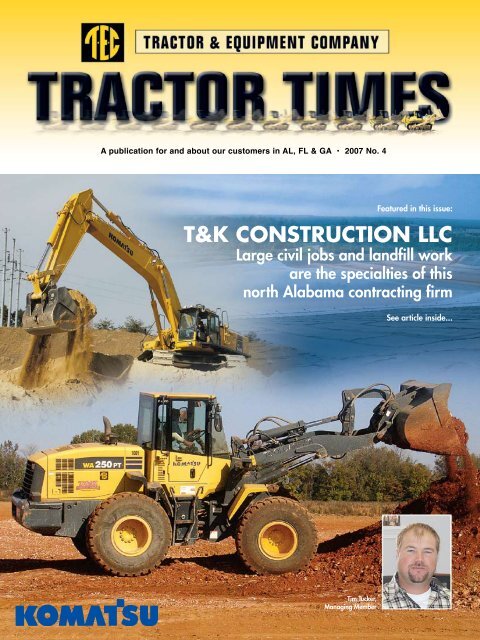

A publication for and about our customers in AL, FL & GA • 2007 No. 4Featured in this issue:T&K <strong>CONSTRUCTION</strong> <strong>LLC</strong>Large civil jobs and landfill workare the specialties of thisnorth Alabama contracting firmSee article inside...Tim Tucker,Managing Member

A MESSAGE FROMTHE PRESIDENTDan StracenerRELIABLEEQUIPMENTRESPONSIVESERVICEDear Equipment User:In slower times, it’s more important than ever to haveproductive, reliable equipment that works for you every day.The new Komatsu PC270LC-8 hydraulic excavator (featuredin this issue of your <strong>Tractor</strong> <strong>Times</strong>) is a good example of howKomatsu’s newest models outperform not only the previousgeneration, but competitive machines as well. In a Komatsufield test with two top competitors, the PC270LC-8 showedsignificant advantages in both trenching and truck loading.At <strong>TEC</strong>, providing productive and longlasting equipmentis just one way we can help you succeed. Another way is byproviding outstanding parts and service support that keepall your machines up and running. One service we offer is apreventive maintenance inspection (PMI), where one of ourtrained technicians will thoroughly inspect your machines.He’ll check all working parts and components to make surethere are no issues cropping up that may lead to potentiallycostly repairs, or worse yet, shut you down during a busy job.To schedule such an inspection, or to learn what elsewe can do to help you get the most out of your existingequipment fleet, feel free to contact your <strong>TEC</strong> product supportrepresentative or our service department. We’ll be happy toassist you in any way we can.Sincerely,Dan StracenerPresident

A SALUTE TO A <strong>TEC</strong> CUSTOMERRELIABLE EQUIPMENTRESPONSIVE SERVICET&K <strong>CONSTRUCTION</strong> <strong>LLC</strong>Large civil jobs and landfill work are the specialtiesof this north Alabama contracting firmTim Tucker,Managing MemberThis WA250PT wheelloader/parallel toolcarrier is one of thenumerous Komatsumachines in the T&Kequipment fleet.Although it’s less than 10 years old, T&KConstruction has become one of the leadingfull-service earthmoving and constructionmanagement firms in north Alabama. Basedin the small town of Vinemont, located inCullman County, T&K specializes in large, civilgrading projects in Alabama, as well as landfillconstruction throughout the mid-Atlantic andGulf Coast states.T&K’s civil grading division does clearing,mass earthwork, grading, and storm-drainwork for all types of commercial and industrialjobs, residential subdivisions, and streetand highway work throughout the region.In addition to all the work it self-performs,the company also offers a complete turnkeyconstruction-management service that willtake a project from concept to final acceptancefor an owner or developer.“We believe that’s what separates us frommany others in this business,” said T&KManaging Member Tim Tucker. “We have alot of engineering and project managementexpertise within our team. That enables us towork with clients right from the beginningto help them figure out the best and mostefficient way to get a job done. We do muchof the work ourselves and oversee the rest ofit to ensure that everything is done right andthat the project stays on schedule. We’re theon-site eyes and ears of the project owner andserve as a liaison to keep everything runningsmoothly.”In addition to its local civil work, T&Kis also one of the top landfill constructionfirms in the entire Southeast. The company islicensed to do landfill work in 12 states, fromPennsylvania to Mississippi, as well as inTexas. The scope of landfill work conductedby T&K is all-encompassing, ranging fromnew construction and expansion of existingfacilities, to closing cells that have reachedcapacity.“Again, we offer the complete packageto landfill operators, whether the facilityis privately or municipally owned,” saidTucker. “Regulations for landfill work are veryprecise and the work is closely monitoredby the EPA to ensure proper drainage thatprotects groundwater. They demand qualifiedengineers and contractors perform the work.We have those people and we have theexperience to deliver landfill projects on timeand on budget.”Large, complex jobsThe list of jobs performed by T&KConstruction is an impressive one. The civildivision, for example, did all the site work,including grading 3 million cubic yards ofmaterial, for the $22 million Grants Mill Auto

Landfill expertise is one of T&K’s calling cards. . . continuedLinda Stevens,Office ManagerLonnie Burgess,Construction Managerexcavators,” said Tucker. “I considered them tobe the best hoes on the market. When we wentinto business for ourselves, one of my prioritieswas to have good equipment that would allowus to get excellent production and Komatsuexcavators were at the top of my list.”Today, T&K owns a Komatsu PC600 and aKomatsu PC300, two Komatsu D61 dozers anda Komatsu WA250 wheel loader. The companyalso rents a considerable amount of Komatsuequipment from <strong>TEC</strong>, including HM400articulated trucks and a PC270 excavator.“The Komatsu dozers have been reallygood machines for us, and we think the wheelloaders, as well as the hoes, are the best outthere,” said Tucker. “But no matter how goodthe equipment is, it’s only as good as the servicebehind it and <strong>Tractor</strong> & Equipment providesreally good service. Our salesman, KevinBurgreen, takes excellent care of us and makessure we get whatever we need. We count on<strong>TEC</strong> and they’ve always been there for us.”Found their nicheAt its present size and capabilities, Tuckersays T&K is basically where he and Kent wantit to remain.“We’re able to do almost anything from asite-preparation standpoint, including projectmanagement, so I don’t see us expanding awhole lot from this point forward. We’re set upnow to where we can take on almost any sizeof job, yet we’re small enough that we can stilloffer clients personalized service and attention.“And management-wise, we’re verycomfortable with our current staff,” headded. “Finding good people is becomingincreasingly difficult, so it just doesn’t makemuch sense for us to try to get much biggerif we’re not going to be able to find the sametype of topnotch management people that wecurrently have in place.”Finding the right people, specifically Burgessand Jenkins, was what allowed T&K to enterand succeed in the landfill market.Nathaniel Hutchinson,Senior EstimatorWes Brokus,EstimatorMike Giddens,EstimatorThe T&K Construction staff includes (front row, L-R) Cheryl Cadle, Judy Smith,Charlotte Kirkland, (back row, L-R) Jamie Jenkins, Dennis Trogden and Tim Tucker,standing with <strong>TEC</strong> Sales Rep Kevin Burgreen.“Right now, landfill accounts for about 40percent of our business,” estimated Tucker.“That will fluctuate from year to year,depending on the local construction market.If residential and commercial constructionare booming around here, we’ll put most ofour people on those jobs because it allowsus to stay closer to home. But having thelandfill division is a real plus for us becauseit makes us much more diverse and givesus options. It’s a way to help us keep peopleand equipment busy when things slow downbecause even when the economy slows, there’salways a need for landfills.”Whether the company is doing civil orlandfill work, Tucker says a quality job willalways be T&K’s top priority. “That’s whatwe hang our hat on. We’re very proud thatcustomers who use us once, call us backfor their next job. As long as we continue todeliver quality work, on time and on budget,we are confident we’ll get our fair share of thework that’s out there.” n

A SALUTE TO A <strong>TEC</strong> CUSTOMERRELIABLE EQUIPMENTRESPONSIVE SERVICETURPIN BORINGCharacter counts for this Georgia horizontal-boringcompany that takes on the tough jobsThe Turpin Boringmanagement team includes(L-R) family members JohnTurpin, Keith Turpin, JudyTurpin and Ashley Turpin,along with Office ManagerPriscilla Berry.As metro Atlanta has grown considerably inthe last 20 years, so has the horizontal-boringindustry.“In a nutshell, boring is what you do whenyou need to get utilities, typically water andsewer, from one side of the road to the other,”said John Turpin, who along with his wife,Judy, and sons, Keith and Ashley, own andoperate Turpin Boring. “Of course, we boreunder more than just roads. We also bore toget to the other side of railroads, rivers andstreams, and environmentally sensitive areas.”Turpin Boring has grown right alongwith Atlanta’s increased demand for boringservices. The company was formed in 2000from a predecessor firm, Turpin Contracting,which specialized in sewer and water work.Today, Forest Park-based Turpin Boringemploys about 25 people on four to sixcrews, and has done significant boring jobsthroughout the greater Atlanta area. Thecompany has also begun to work elsewhere inGeorgia, as well as neighboring states.“We’ve probably gone under everyInterstate, every major highway and many ofthe minor roadways in the Atlanta area sincestarting the company a little more than sevenyears ago,” said Vice President Keith Turpin.“We specialize in cased bores 12 inches andlarger. The most common bore is probably a16- or 24-inch casing, but in recent years we’vedone a lot more 36-, 48- and 60-inch casings,even a 110-inch bore. We’ve successfullycompleted bores of more than 450 lineal feet,bores that were 30 feet underground anddeeper, and bores through solid rock.”“We can handle just about any jack andbore job that comes along,” said VP AshleyTurpin, who oversees field activities. “We prideourselves on doing the tough jobs. In fact, we’vedone some bores that people said couldn’t bedone. We have experienced and skilled fieldpersonnel, and Keith and I fill in whereverwe’re needed most on a given day. Our goal isto complete every job safely and quickly so thatthe contractor, developer or municipality we’reworking for can complete the project sooner.”Whatever it takesThere are a number of goodhorizontal-boring firms in the region. TurpinBoring President Judy Turpin knows mostof them. That’s because Turpin Boring isa longtime member of the Georgia UtilityContractor’s Association and Judy is currentlySecond Vice President of the organization.“We have good competitors,” said Judy.“What our company tries to emphasize ischaracter and trustworthiness. When we saywe’re going to do something, we do it — and

you can count on that. We don’t make excuses.We just get the job done, whatever that takes.As a result, we have many loyal clients whoturn to us first for their boring needs.”“Something that’s been drilled into bothAshley and me by our mom and dad is thata man is only as good as his word — and thesame goes for a company,” said Keith Turpin.“At Turpin Boring, we hate change orders asmuch as the project owner does, so we keepthem to an absolute minimum. We take a lotof pride in meeting the needs of our customersand that means starting and finishing jobs ontime and on budget.”“Another thing that’s important to us iscommunication,” said Ashley. “If you call usand we’re not here, we’re going to call you back,and it’s almost always going to be the same day— not three or four days later. Plus, we shootstraight with our customers. We’re not going totell you something to get a job, then not be ableto perform. If it’s going to be two weeks beforewe can start, we’ll tell you that up front.”Turnkey operationTurpin Boring has done some large jobsand some unusual ones through the years.The company recently completed a 400-footbore under I-75 south of Atlanta to carryrunoff from a future MARTA Park & Rideto a retention pond on the other side ofthe Interstate. They also have gone underpear and oak trees as part of “green space”properties, and did a 110-inch bore on a golfcourse that was divided by a roadway sogolfers could drive carts from one side to theother.“One thing our clients appreciate is that we’rea turnkey operation,” said John Turpin. “Weprovide engineering expertise and we do ourown excavation of the bore pits. Doing everythingin-house means we’re the only call they have tomake, and it’s one of the reasons we’re able toconsistently meet and beat schedules.”In addition to family members, TurpinBoring relies on key employees throughoutits work force. “We have excellent foremenand our field people are very important.”John acknowledged. “Several have been withus basically since we started the company.Turpin Boring got this Komatsu PC300LC-7 to help the company handle the larger jobsit’s been taking on in recent years. “We’re going deeper, we’re moving dirt and our boringrigs have gotten bigger, so we needed a beefier excavator,” said President Judy Turpin.“The PC300 has been a good fit for us, and like all our Komatsus, has given us excellentperformance.”Having people who understand the work andunderstand our company is a big plus.”Productive equipment/reliable serviceTurpin Boring turns to <strong>Tractor</strong> & EquipmentCompany in Forest Park for Komatsuexcavators to dig its bore pits, as well as tounload and set the boring equipment. Thecompany has four Komatsu excavators — twoPC200s, a PC220 and a PC300.Continued . . .Turpin Boring crewsrecently installed 200linear feet of 54-inchpipe at the AugustaRegional Airport. “Itwas a deep, difficult job,but we pride ourselveson completing the toughjobs that many boringfirms prefer to avoid,”said VP Keith Turpin.RELIABLEEQUIPMENTRESPONSIVESERVICE

Komatsu equipment is good fit for boring operation. . . continuedKeith Turpin (left) visitswith <strong>TEC</strong> VP/GeneralManager-Georgia SteveMcCondichie.“I had some previous experience with aKomatsu PC200, as well as a top competitivebrand,” said Keith Turpin. “There simply wasno comparison in terms of performance. TheKomatsu was rock-solid, whereas the othermachine was like being on a rocking horse. Andduring the time we had the Komatsu, we neverspent a dime on it for repairs. So when the timecame for us to get our first excavator, it was aneasy decision. I was familiar with Komatsu andwas confident it would do a great job for us —and that’s certainly been the case.”“The Komatsu PC300LC-7 is our newestexcavator and we got it to keep pace with ourown growth and to better handle the biggerjobs we’re doing today,” said Judy. “We’re goingdeeper, we’re moving more dirt and the boringrigs we’re using have gotten bigger and heavier,so we needed a beefier excavator to handle theselarger jobs. The PC300 has been a good fit for us,and like all our Komatsus, has given us excellentperformance and has been very reliable.”The Turpin family enjoys all types of motorcycle activities, from pleasure riding to competitivenational motocross events. John (left) rides a Harley, and according to Keith, “is a greatmechanic who knows everything about engines, both bikes and heavy equipment.” Ashleyshows off his five-year-old son Jackson’s bike. “Both our boys were very competitive dirtbike riders,” said Judy. “Keith was a factory-sponsored national champion and we think ourgrandson Bryan could be headed in that direction too.”The Turpins also appreciate the service theyget from <strong>Tractor</strong> & Equipment Company.“We let <strong>TEC</strong> handle all our routinemaintenance and service items,” said Judy.“They keep track of our machines, they give usa call when a service is due and they come toour jobsite and take care of it. The fact that theyhave convenient branch locations throughoutthe state is also a plus for us. The bottom line isthat <strong>TEC</strong> takes good care of us and keeps ourequipment running, which allows us to focuson what we do best, which is the boring.”“<strong>TEC</strong> treats us the way we try to treat all ourcustomers,” added Keith. “They give us fairprices, they’re responsive to our needs andthey have character — they follow through bydoing what they say they’re going to do.”Still growingDespite a slowdown in the housing marketin the region, Turpin Boring has remainedbusy and is optimistic about the future.“The amount of municipal and commercialwork we’re doing has picked up as theresidential has slowed down,” said Ashley.“We still have plenty of work and we’relooking into diversifying a little bit. In the past,we did sewer and water work and there’s alikelihood we’ll do a little bit more of it as away to stay busy and continue growing.”“Ashley and I have also talked about thepossibility of doing our own development work,maybe some small residential or commercialprojects,” said Keith. “But our core business willcontinue to be the horizontal boring. We’ve madea name for ourselves in that field in a relativelyshort time and we’re not about to abandon ourgood customers. For as long as they want us, weplan to be there to help them.”“We understand that there are alwaysgoing to be cycles in the economy and inconstruction,” said Judy. “But we’re confidentthat overall, Atlanta and Georgia are goingto be growth areas for many years to come.We believe as long as we continue to offercustomers quality work, excellent service and afair price — and most of all, continue to exhibitthe character they’ve come to expect fromTurpin Boring — we’ll be able to get our shareof the work that comes from that growth.” n

AVAILABLE THROUGH TRACTOR & EQUIPMENT COMPANY

INDUSTRY EVENTCONEXPO COMING SOONIndustry event will be the largest everwith more than 2 million square feet of exhibit spaceIIf you’ve ever been to CONEXPO-CON/AGGyou know the size and scope of the show ismassive. If you haven’t been before and aregoing this time around, you’re in for a hugetreat that features more types of equipment,educational opportunities and technology thanyou can possibly imagine in one location.The largest show of its kind inthe construction industry, the nextCONEXPO-CON/AGG will be held March11-15, 2008, at the Las Vegas ConventionCenter, the largest such facility in the world.You can get information on the event andregister for it online at www.conexpoconagg.com.You can also map out your visit ahead of timeusing the show’s Virtual Trade Show, whichincludes an interactive floor plan of exhibits, aswell as make a personalized list of companiesand products you may want to see.CONEXPO is the largest show of its kind in the construction industry. Held inside andoutside the Las Vegas Convention Center every three years, the 2008 show, to be heldMarch 11-15, will have more than 2 million square feet of exhibit space.“We are proud to be known as a show runby and for the construction industries, andour primary goal is to create a positive showexperience for all attendees and exhibitors,”said CONEXPO-CON/AGG Director MeganTanel. “The show continues to grow, but wereally don’t want the show just to be aboutbeing the biggest in the industry. We wantattendees to see that the show is a place to findinformation, education and solutions to issuesthey may face in their businesses. It’s a place tobring the user, the owner, the distributor andmanufacturer together in one place where theycan all work together.”Every three years when CONEXPO rollsaround, the show is bigger than the last, and2008 will be no exception as the triennialevent features more exhibit space than everbefore. For the first time ever, the show willtop 2 million square feet, breaking 2005’srecord-setting mark of 1.88 million. More than2,000 exhibits from leading manufacturers,such as Komatsu, and service providerswill display wares, with more than 125,000industry professionals expected to be on hand.Komatsu will display 24 products, includingseveral new Dash-8 excavator and Dash-6wheel loader models which feature ecot3 Tier 3engines that offer more productivity with lessfuel consumption and lower emissions. Alsoin its 30,000 square feet of display area will bedozers, motor graders, trucks, compact trackloaders, backhoe loaders and skid steer loaders.Products grouped togetherEvent organizers are grouping similarproducts and companies together, makingit easier to navigate your way around theshow. For instance, if you’re interested in

earthmoving equipment it can all be foundin the North Hall, part of the Central Hall,the Riviera Pavilion and the Gold, Blue andRiviera lots outside the convention center.If your interests lie in other types ofequipment, there are product concentrationareas for lifting equipment, asphalt paving andproduction, concrete paving and production,aggregate processing and heavy-duty trucksand mixers. Other sub-specialties such asengines, hydraulics, lubricants, tires andcomponents have their designated areas aswell.Information stands will be set up throughoutthe show, and interactive product locators,searchable by company and product, willbe on the show floor. These will also haveinformation regarding seminars and meetings.Other show services will include an expanded,free, shuttle system to transport visitors fromhotels to and from the convention center, andan intra-show shuttle-bus system.Several new items on the agendaAttendees may be directed to several newitems on the expo’s massive list of things tosee and do, including the free educationalprogram “Best Practices for Small FleetManagement” to be held on March 15. Theprogram will provide practical solutions forfleet management needs of small businessowners specializing in commercial, industrialand public construction. Topics includebudgeting and staffing, productivity and workscheduling, among others.Other new features are an InternationalDriver Mixer Championship, the first everinternational competition of concrete mixertruck drivers; an IPAF Safety Zone thatfeatures live demonstrations and safetyeducation; and “Construction Challenge,” acompetition with students competing in threechallenges related to the construction industry.“We’re very excited about the new features,and we believe that attendees will find theminformative and helpful,” said Tanel. “TheConstruction Challenge is one area we’reparticularly looking forward to as it showcasesyoung people involved in the constructionKomatsu always has one of the largest displays at CONEXPO. Twenty-four products willbe available for attendees to check out at the 2008 event.CONEXPO is more than just an equipment showcase. Attendees can learn more aboutthe construction industry through educational programs in such areas as aggregates,asphalt, project management, equipment management, personal development and safety.industry. We see this as a way to generateinterest among youth and highlight for themthe careers available in construction.”An Innovation and Solutions Center willalso be new. Experts in the field will bepresenting sessions that highlight research anddevelopments in Fluid Power Solutions, GreenSolutions, Motion Control Solutions Now andin the Future, and Innovative Applications inthe Entertainment Industry.Educational opportunitiesaboundWhile CONEXPO continues to add newitems, one thing that hasn’t changed fromprevious expositions is the chance to take Continued . . .

Educational opportunities abound at CONEXPO. . . continuedin some educational opportunities thatwill benefit you and your business. Thereare 10 seminar tracks organized by specificindustries and issues: aggregates, asphalt,concrete, construction project management,earthmoving, environmental/recycling,equipment management, management,personal development and safety. Sessions are90 minutes in length and include materials youcan take with you for future reference.Seminars in the earthmoving categoryinclude Introduction to Adopting PositioningTechnology for Construction; Paydirt: MassExcavating Alternatives for Mass Profit;Introduction to Design Data & EarthmovingConstruction Projects; Costs to Own & OperateHeavy Equipment; and The AmazinglyVersatile Backhoe.Equipment management educationalopportunities include An Introduction toBiodiesel Fuel, Equipment Management: Takingit to the Next Level; Getting the Most Out ofYour Equipment at Disposal; Are Fuel CostsCutting Into Your Profits?; The EquipmentTriangle View of Asset Management BestPractices for Fleet Management; and RealizingCost Return (or Cost Savings) Through EffectiveOil Analysis. For more details on these andother educational opportunities, you can visitthe CONEXPO-CON/AGG Web site.Attendees at the last CONEXPO got up close to machinery and looked at the inner workingsof equipment such as Komatsu’s ecot3, Tier 3 engines, now standard in numerous machines.“The educational opportunities are a greatway for attendees to learn new and creativeways to help increase their productivity, lowercosts and become better at what they do,”said Tanel. “Because the show is so large, it’snot always feasible to attend every seminar.We’re working this year on ways to bring theseminars to the attendee by putting them liveon cable through the hotels, over the Internetand by podcast.”A great partnershipIndustry certification courses and examsare offered, including a Certified EquipmentManager Exam and Study Course of theAssociation of Equipment ManagementProfessionals, and Crane OperatorCertification Examinations of the NationalCommission for the Certification of CraneOperators.CONEXPO is produced and sponsored bythe Association of Equipment Manufacturers,the National Stone, Sand & Gravel Association,the National Ready Mix Concrete Association,and the Associated General Contractors ofAmerica.“The success of CONEXPO-CON/AGGhas always been because of the partnershipof these organizations,” Tanel noted. “Severalof them hold their annual meetings duringCONEXPO. They are all committed tohelping everyone involved in the constructionindustry succeed. That’s why each has astrong commitment to making the show asinformative and insightful as possible.”Tanel pointed out that the ultimate goal forthose attending the 2008 CONEXPO is to takeaway something that they can use in theirbusiness to make it better.“The show is really about ways tohighlight the industry and what it can doto help businesses and individuals be moresuccessful,” she said. “We hope they findsolutions to everyday challenges, makecontacts and learn more about the industryin general. We want them to go home seeingthat the show had value to them and lookingforward to coming back in 2011 to findsomething else that will help them.” n

EQUIPMENT FOCUSRELIABLE EQUIPMENTRESPONSIVE SERVICEREDISCOVER THE PC270LC-8Field tests demonstrate how Komatsu’s new excavatordelivers superior performanceIIf you’re an equipment user in the market fora 28- to 33-ton excavator, the newly designedand upgraded Komatsu PC270LC-8 needs tobe at the top of your “check-it-out” list.“We’ve believed for some time that wehad a very competitive machine in this sizeclass,” said Komatsu Excavator Senior ProductManager Peter Robson. “Compared to the otherleading brands, we suspected that we werebetter in terms of fuel consumption, and thateverything else was fairly similar. But in takinganother look at the machine, we concludedthat by increasing counterweight mass, thePC270LC-8 would not just be competitive or alittle bit better than the competition, but wouldbe much better. So that’s what we did.”As part of a running design change,Komatsu increased counterweight mass onthe PC270LC-8 by 17 percent compared to thePC270LC-7.“The change was remarkable,” said KomatsuExcavator Product Manager Trenton Glore.“With the additional counterweight, lift capacityincreased significantly. Just as important,if not more so, machine stability improveddramatically. It gives the new unit a much better‘firm footedness.’ With that solid base, operatorsare more comfortable digging and loading at afaster speed, and in more difficult material, soproductivity is now much improved.”Field tests confirm PC270LC-8superiorityHow much improved? To find out, Komatsuput the machine to a field test against two topcompetitors. Here’s what they found.In a trenching test, the Komatsu PC270LC-8averaged 216 feet per hour, compared to 196feet and 192 feet for the competitive units.That’s 9 percent better than one machine and11 percent better than the other. “More than 20feet per hour adds up quickly over the course ofa day, a week, a month or a year of trenching,”pointed out Glore.“The difference between machines waseven more pronounced when we included theamount of fuel required to do the work,” hecontinued. “In terms of fuel efficiency (whichmeasures how many feet of trench are being dugper gallon of gas), the Komatsu PC270LC-8 was9 percent better than one of the competitors, anda whopping 17 percent better than the other.”Trenching TestContinued . . .Model Production Fuel EfficiencyKomatsu PC270LC-8 216 ft./hr. 26.8 ft./gallonCompetitor 196 ft./hr. 22.2 ft./gallonCompetitor 192 ft./hr. 24.5 ft./gallonPeter Robson,Senior Product ManagerTrenton Glore,Product ManagerIn a recent trenching field test, the new Komatsu PC270LC-8 dug more trench per hourand was significantly more fuel-efficient than two top competitive machines.

Tests confirm outstanding fuel efficiency for PC270LC-8. . . continuedFor more informationon how the KomatsuPC270LC-8 can be avaluable addition to yourexcavator fleet, contactyour sales representativeor our branch locationnearest you.The result was similar in a truck-loadingtest. An analysis of cycle times showed thePC270LC-8 took slightly more than 14.5seconds to load, swing, dump and return. Onecompetitor’s cycle time was about a half secondslower, while the other was more than a fullsecond slower. And not only did the Komatsuunit load trucks faster, it was also morefuel-efficient, moving 7 percent to 10 percentmore cubic yards of material per gallon of fuel.Fuel efficientAccording to Komatsu, the PC270LC-8’simpressive fuel consumption and efficiencyfigures (roughly 10 percent better than theprevious model and about 11 percent better thanTruck-Loading TestModel Cycle time Fuel EfficiencyKomatsu PC270LC-8 14.54 sec. 66.6 cu. yd./gallonCompetitor 14.97 sec. 60.0 cu. yd./gallonCompetitor 15.59 sec. 62.0 cu. yd./gallonBrief Specs on Komatsu PC270LC-8Model Horsepower Operating weight Blade capacityPC270LC-8 187 hp (net) 65,336-67,393 lbs. 0.76-2.13 cu. yd.The Komatsu-sponsored field test also showed a truck-loading advantage (faster cycletime and up to 10 percent more fuel efficient) for the PC270LC-8 compared to twocompetitive models.the competition) are achieved by total control ofthe engine, hydraulic and electronic systems.“Each component and machine system wasdesigned, engineered and manufactured tocomplement the other components and systemsto achieve maximum performance,” saidRobson. “The way they work together is one ofthe primary factors in the fuel efficiency we’vebeen able to achieve with the PC270LC-8.”Other factors include the overall efficiencyof Komatsu’s Tier 3 engine, combined withoptions and reporting tools that allow anoperator to significantly lessen the amount offuel being used to achieve the same amountof work. These include an economy (E) workmode; an “eco-gauge” that displays to theoperator whether he’s operating efficiently orwastefully; and an “idling caution” displaythat alerts the operator when he’s been idlingfor five minutes or more (extended idling isconsidered to be an unnecessary and wastefuluse of fuel).Design featuresIn addition to overall performance andfuel efficiency, the new PC270LC-8 hasnumerous other features designed to improveproductivity, including:• Work equipment structures with largecastings;• Boom and arm plates thicker than thecompetition;• Easy-to-access service and maintenancepoints;• A quieter, more comfortable cab that’s thelargest among top competitors and loadedwith user-friendly technology;• KOMTRAX, Komatsu’s FREE wirelessmonitoring system, as standard equipment.Demo will prove its worth“Obviously, we believe the PC270LC-8 isa superior excavator,” said Robson. “Ourhope is that equipment users who are in themarket for this size of excavator will demo thePC270LC-8 against any comparable machine. Ifthey do, we’re confident they will come to thesame conclusion we did — that it’s the mostproductive and efficient machine in its class.” n

NEW PRODUCTSRELIABLE EQUIPMENTRESPONSIVE SERVICE“RUGGED AND EFFICIENT”New landfill dozers reduce cost per yard withTier 3 engines that push more material with less fuelWith its new landfill dozers, Komatsucombined the best of its standard dozer features— which were designed to provide increasedproductivity and efficiency — with uniquefeatures that make them perfect for the ruggedconditions of a landfill operation. New landfilldozer sizes range from the nearly 53,000-poundD65EX-15SL to the 116,528-pound D275AX-5SL.Like Komatsu’s latest line of standarddozers, the landfill dozers are poweredby turbocharged, after-cooled, ecot3 Tier3-compliant diesel engines designed to providemore horsepower with less fuel consumptionand lower emissions than previous models.The combination provides the best-ever costper yard of material moved.Komatsu engineered each landfill dozer’shydraulics, power train, frame and all othermajor components in an integrated designthat works together for higher production,greater reliability and versatility. Add thefactory-installed Landfill Package withguarding specifically designed for harshlandfill conditions, and the result is machinesthat operate longer for increased production.“Our landfill dozers start off with standarddozer features — Hydrostatic SteeringSystem, Palm Command Control System,hydraulic-driven radiator fan, wet-disc brakes,Tier 3 engines and others — and have addedfeatures, such as gap seal guards, remote A/Cand oil cooler and guarding packages, amongothers, that make them stand out,” said MikeMilostan, Komatsu America Product Manager,Working Gear. “They really are purpose-builtmachines that will benefit landfill operations byproviding the productivity those customers needbecause Komatsu designed them to stand up tothe challenges of working in that environment.”Blades on the dozers are larger withintegrated trash racks that provide morematerial capacity without restricting visibility.A semi-U blade is available on all models,while a full-U blade is available on allmodels except the D65EX-15SL. The landfillcounterweight is designed to optimize themachine balance in landfill applications. Continued . . .Brief Specs on Komatsu Landfill DozersModel Operating Weight Net hp Blade CapacityD65EX-15SL 52,097 lbs.* 205 14.8 cu. yds.*D85EX-15SL 62,245 lbs.* 240 22.5 cu. yds.**D155AX-6SL 96,709 lbs.* 354 33.2 cu. yds.**D275AX-5SL 116,528 lbs.** 410 44.3 cu. yds.***With semi-U blade**With full-U bladeKomatsu’s new landfill dozers feature Tier 3 engines for greater production and fueleconomy. Each model has a factory-installed Landfill Package with guarding specificallydesigned for harsh landfill conditions.

Unique features stand up to landfill challenges. . . continuedKomatsu engineeredeach of its new landfilldozers with hydraulics,power train, frameand all other majorcomponents that worktogether in an integrateddesign for higherproduction, greaterreliability and versatility.Komatsu’s landfill package includes alarge number of unique features built into thedozers to make them stand up in challengingconditions. Among them is a chassis-sealpackage that helps close the gaps around thechassis where material could enter the enginecompartment. Final drive, pivot shaft and idlerseal guards help prevent debris from enteringoil-seal areas, extending component life.Extended component lifeExtending the component life of the tracksis a priority, so Komatsu landfill dozers usetrapezoidal track shoe holes to minimize debrispacking. Bolt-on front and rear striker bars helpprevent debris from riding up onto the tracksand damaging fenders and chassis. Chassisdeflector bars and bolt guards protect and helpkeep debris away from components as well.The machines are further protected fromdebris with additional guarding that’s availableonly on landfill dozers, such as the fuel andhydraulic tank guard. Hinged covers allow easyaccess for cleaning and maintenance.Keeping the working parts clean foroptimal production is necessary, and Komatsumakes it easier than ever with features suchas perforated hood and side doors thatincrease cooling airflow to the radiator whileminimizing the size of airborne particlesentering the engine compartment. Theperforated hood reduces air velocity passingthrough the screens, reducing debris stickingagainst the screens.A standard, reversible, hydraulically drivenfan is mounted in front of the radiator core sothe blades pull air through the core rather thanpush it, virtually eliminating debris blastingon the core surface and increasing the life ofthe heat exchangers. Thermally controlled,the fan turns at maximum speed only whenmaximum cooling is required, reducing thedebris collection on the engine inlet screensduring normal daily operations.Computer-controlled forward and reverseintervals clean the radiator regularly, allowingthe operator to concentrate on productivity.The computer timer is easily adjusted forvarying conditions and also has a manualoverride switch.Fine controlA turbine precleaner helps removeparticulates from the engine air before theyreach the filter elements. Quick-opening,two-piece doors allow easy access to theradiator and fan for cleaning. An enginebottom guard with electric winch simplifiescleaning of the engine compartment. Theengine compartment features two fewer items,as Komatsu relocated the hydraulic cooler andfan, as well as the air conditioner condenser.Both were moved to increase cooling efficiency.Efficiency is enhanced with Komatsu’sTorqflow Transmission that offers single-levercontrol of speed and directional changes. Ahydrostatic steering system makes for smooth,quick and powerful control of tracks. Palmcontrolsteering and blade joysticks providefine control. Operators will also appreciatethe hexagonal-designed pressurized cab,which offers greater visibility and comfort.Cab dampen mountings increase ride comfortwhile decreasing noise and vibration.“Lock-up torque converters and automaticshifting, available on our D155 and D275models, make these even more powerful andefficient to operate,” pointed out Milostan.“Production is terrific with these machines,and that’s really the bottom line.” n

UTILITY EQUIPMENTRELIABLE EQUIPMENTRESPONSIVE SERVICEFILLING THE GAPAs larger “compact ” excavators,Komatsu PC78 models offer many advantagesThe Komatsu PC78US-6 and PC78MR-6 seriesexcavators are the largest of the Komatsu utilityrange but they can hardly be called “compact.”These machines weigh in at more than sevenand eight metric tons respectively — about thesame as a full-size backhoe loader. They featureoutstanding performance, superior operatorcomfort and they fill the product gap betweencompact and construction-size excavators.• Two product types allow contractorsto choose between a fixed-boom machine(PC78US-6), like a full-size constructionexcavator, or an offsetting boom unit(PC78MR-6), like a compact excavator.• A full-featured cab is standard equipmenton these models. Every low-noise cabfeatures a spacious operator station with adigital monitor panel, air conditioning, aradio and a suspension seat.• Hydraulics on the PC78MR-6 andPC78US-6 are of the same pedigree asKomatsu construction excavators. Loadsensing,pilot proportional joystick controlsprovide low-effort precise control andenable the operator to perform taskssmoothly and productively.• A choice of three track shoe systems allowscontractors to choose what’s right for theiroperations: steel, rubber and KomatsuRoad Liner track shoes. The RoadLiner track shoes allow the operator totravel on hard surfaces, such as asphalt andconcrete, without damaging them like asteel grouser can.• A great alternative to a backhoe loader, thePC78s offer digging depth, dump height,bucket power, arm power, lifting capacity,better range of motion when working nextto an object, and better productivity becausethey don’t have to be repositioned like abackhoe loader.• Maintenance is easy with a wide-openingengine cover that provides great accessto daily checkpoints. The wide-opening sidecover provides access to the hydraulictank, air cleaner and main hydraulic valve.There’s also ground-level fueling witha sight gauge. Sealed pins allow Komatsuto extend the lubrication intervals to 100hours on the arm tip and 250 hours on thearm, boom, and swing pins, rather than thedaily or weekly lubrication required ofsome other brands. nBrief Specs on Komatsu PC78 compact excavatorsFor more informationon the PC78 compactexcavator, contact yoursales representative, orcall our nearest branchlocation.Model Power Dig Depth Dump Ht. Bkt. Force Arm Force Operating Wt.PC78MR-6 54 hp 15'7" 15'8" 13,780 lbs. 9,330 lbs. 18,230 lbs.PC78US-6 54 hp 15'5" 18'0" 13,780 lbs. 9,330 lbs. 15,850 lbs.Komatsu engineered its larger, PC78 compact excavator models to fill the gap betweencompact and construction-size excavators.

KOMATSU & YOURELIABLE EQUIPMENTRESPONSIVE SERVICEREMANUFACTURED PRODUCTSGeneral Manager says ISO certification ofKomatsu reman plant ensures product qualityQUESTION: One of your emphases, uponjoining Komatsu Remanufactured Products,was to earn ISO 9001 certification from theInternational Standards Organization. Haveyou achieved that, and why is it an importantdesignation?ANSWER: We became an ISO-certified planta little more than two years ago and webelieve it’s a very significant designation for amanufacturing plant like ours. For one thing,ISO certification, which includes regular,ongoing field audits of our operations, ensuresthat we’re following our own standardizedprocesses. These standardized processes leadto a consistently high-quality product that ourcustomers can count on.Equally important, ISO certification requiresus to continuously improve our operations.They check quality measurements, warrantyratios and customer complaints to see thatwe’re taking appropriate action and fixingany problems that arise. So yes, for us, ISOcertification is a very big deal because it’s thefoundation for the quality of product that we’renow producing at Komatsu Remanufacturing.QUESTION: Why is standardization soimportant in manufacturing?ANSWER: It’s important because, with astandardized process, in which the samejob is done the same way every time, whena problem crops up, we can locate whathappened. Without it, you have one persondoing the job one way and another persondoing it another way, so you may never beable to figure out why a failure occurred. It’sbecause of our standardized processes thatwe’re able to produce replacement parts andcomponents that are essentially the same asnew and are warrantied as such.Continued . . .This is one of a seriesof articles based oninterviews with key peopleat Komatsu discussing thecompany’s commitmentto its customers in theconstruction and miningindustries — and theirvisions for the future.Rob Shear,General Manager,Komatsu Remanufactured ProductsAs the son of a financial controller for the Department of theArmy, Rob Shear grew up in many places. Born at Fort LeonardWood in Missouri, Rob and his family moved to Korea for a time,then to Virginia, then to Oklahoma for his high school years.Following high school, Rob earned a spot at the U.S. MilitaryAcademy at West Point, and after graduation, spent time in theArmy leading a tank platoon.After his army service, Rob went into manufacturing. Whileworking for Cardinal Health as a plant manager, he earned anMBA at Northwestern University, where a classmate recruitedhim to Komatsu.Rob joined Komatsu America as General Manager of thecompany’s remanufacturing operations in Lexington, Ky., in late2003. In his capacity as GM, Rob oversees the efforts of about 140employees and has been responsible for numerous improvementinitiatives at the plant.“Our goal at Komatsu Remanufactured Products is to produceparts and components for Komatsu equipment that conformto the standards and specifications of brand-new parts andcomponents. We think remanufactured products make sense forthe end-using Komatsu customer as a way to save both time andmoney, and get the peace of mind of a factory warranty at thesame time.”

Komatsu Reman emphasizes “value”. . continuedIndividual parts are carefullyinspected to ensure they meet OEMstandards prior to being used in areman component. Here, technicianTony Johnson measures a camshaftfor a mining dozer as part of theinspection process.QUESTION: What Komatsu remanufacturedproducts are available?ANSWER: We reman all major componentsincluding engines, transmissions, torqueconverters, final drives, turbochargers,hydraulic cylinders, hydraulic pumps,alternators — nearly everything forconstruction equipment up through the largestmining machines. We’ve hired a marketingdirector to work with our Komatsu distributorsto make sure we’re meeting their needs anddon’t have gaps in our product offerings.QUESTION: What advancements have youmade recently?ANSWER: We’ve started inspecting and reusingvalve springs for use on cylinder heads. Before,we would have used a new valve spring if wewere reman’ing a cylinder head. We’re especiallyproud of this because it was initiated by ouremployees. They determined they could do it andthought it would be a good, cost-saving measure.QUESTION: It sounds like KomatsuRemanufacturing values its employees.Located in Lexington, Ky., KomatsuRemanufactured Products employsabout 140 people, includingtechnician Paul Carrico, shown hereassembling a reman engine for aD375 dozer. All reman engines aredyno-tested after final assembly.ANSWER: Certainly. We have a lot of experiencein our work force and very little turnover, andwe rely on our employees to help make us better.Some assembly teams have formed what wecall “quality circles,” consisting of three to fivemembers. The quality circles provide input fromthe floor on how we can improve. It was one ofthese quality circles that came up with the ideaof reman’ing the valve springs.QUESTION: How do your products comparewith new components?ANSWER: Our target is to produce a productthat costs 60 percent to 65 percent of what anew component costs, and that provides 80percent of the life of a new product. Somepeople may be wondering why, if it’s builtto the same standards as a new component,we only expect to get 80 percent of the life.They’ve got to understand that if a remanengine goes into a machine that has 10,000hours on the frame and 10,000 hours on thetransmission, it may not run as long as the firstengine did. A new engine put in the same usedmachine may not run as long either.QUESTION: How does a reman productcompare with a “job shop” rebuild?ANSWER: The main differences between us anda “job shop” are our standardized processes andthe number of units we build. We’re specialists.This is all we do.As for a “will-fit” or “job shop” mechanic,they’re not going to get the support from theOEM that we do. For example, we’re in weeklycontact with the factory, getting the latest criticalupdates on products and how to improveperformance. Another big difference is thattypically, a “job shop” warranty covers only thelabor.QUESTION: Why should Komatsuequipment users look to KomatsuRemanufactured Products for replacementparts and components?ANSWER: Komatsu is all about providingvalue for customers, and we’re an importantpart of that value equation. The combination ofprice, availability and quality make Komatsuremanufactured products not only a viablealternative to new and rebuilt components, butan excellent value as well. n

Ricky Mathis256/338-4574Brian Hagood205/335-3160Rich Trucks205/563-0811Matt Manning205/259-3756Barry Thornburg205/365-4546Edwin Murray770/608-6525Mickey Brooks770/654-3969Delane Brown205/337-6083Hugh Brown404/406-5985Rhett Autrey205/337-2980Terry Shepherd770/757-0547Marcus Hitt205/242-8567Jim Saunders678/596-5988Shane Marquis205/331-8641Sean Mehaffey205/453-2337Troy Cleckler334/312-2351Don Oliver706/474-1430Mark Hadley251/422-8356Nick Smith850/567-1076Mike Douglas850/554-3234Joey Majors850/527-1840Tony Kennedy877/384-4845Tony Bertino404/217-7883Doug Haas229/349-3383Ross Schweitzer770/714-1311Bob Raley478/952-5266Reed Jackson912/675-5826WE’LL ALWAYS BE THERE! Call your local PSSR for all your heavy equipment needs.BIRMINGHAM, AL MONTGOMERY, AL(205) 591-2131 (334) 288-6580Parts (205) 592-7276Service (205) 592-7378TUSCALOOSA, AL(205) 752-0621DECATUR, AL(256) 355-0305ANNISTON, AL(256) 831-2440ALABASTER, AL(205) 621-2489MOBILE, AL(251) 457-8991DOTHAN, AL(334) 678-1832GROVE HILL, AL(251) 275-4158SHOALS AREA, AL(256) 383-5666FOREST PARK, GA(Atlanta)(404) 366-0693HOSCHTON, GA(706) 654-9850KENNESAW, GA(678) 354-5533CALHOUN, GA(706) 879-6200MACON, GA(478) 745-6891AUGUSTA, GA(706) 798-7777COLUMBUS, GA(706) 562-1801SAVANNAH, GA(912) 330-7500ALBANY, GA(229) 435-0982PANAMA CITY, FL(850) 763-4654PENSACOLA, FL(850) 505-0550

UPPING UPTIMERELIABLE EQUIPMENTRESPONSIVE SERVICEUNDERCARRIAGE MANAGEMENTHow machine owners and operators can helpprevent unnecessary undercarriage wearWith undercarriage costs consuming asignificant portion of the average operatingcost-per-hour of your track-type equipment— 50 percent in most cases — properlymaintaining your undercarriage system isessential. Use the following recommendationsto maximize the hours of service life built intoyour Komatsu undercarriage components,keeping in mind that the undercarriage worksand wears as a system. A worn component canhave an adverse effect on the entire system,greatly reducing your total undercarriage life.Understand the System. Undercarriage is oftenthe least-understood system on the track-typemachines. If you are experiencing acceleratedundercarriage wear, the problem may not be thefault of the components. Operation, application,maintenance and component selection canoften be contributing factors in undercarriagewear. Wear cannot be eliminated, but it can becontrolled. Invest the time to learn all you can andtake control of undercarriage costs.Manage the System. Begin with acomprehensive undercarriage managementprogram. Inspection is only the beginning.Evaluating the measurement data and followingthe recommendations of your factory-traineddistributor undercarriage specialist is paramountto achieving satisfactory service life. Managementis essential and continuous. One of the toolsavailable through your Komatsu distributor is thecomputer-assisted Track Management Systemor TMS. By taking advantage of this service,you will reduce unscheduled downtime andoperating expense.Ensure proper alignment. The quickest wayto detect an alignment problem is to look foranything shiny that normally should not beshiny. The inside of track links that are scuffedand shiny, roller and front idler flanges thatshow wear, and sides of sprockets that arecoming in contact with the inside of the tracklinks most often are indicators that the trackframe alignment system needs attention.Failing to heed alignment warning signs willcause accelerated parts wear and, in extremecases, LTS seal and/or bushing failure.Operate with the undercarriage in mind.Managing undercarriage wear and controllingoperating cost-per-hour come first from theoperator’s seat. Turning, speed and directionof travel are three of the most importantoperationally controlled wear factors. Whileyou can seldom build job operations aroundthese operating factors, you should give themongoing consideration.In short, undercarriage cost-per-hour controlstarts with understanding and managing thesystem. Then, operate the machine keeping inmind control of undercarriage wear factors. nDick Schaefer,Senior ProductManager -UndercarriagesInspection is a starting point to managing your undercarriage. One of the tools available throughyour Komatsu distributor is the computer-assisted Track Management System or TMS. By takingadvantage of this service, you will reduce unscheduled downtime and operating expense.

INDUSTRY NEWSAED launches campaign to boost highway investmentAssociated Equipment Distributors (AED)has launched an initiative to position theconstruction equipment distribution industryfor a leadership role in the looming nationaldebate over transportation infrastructureinvestment.In a recent speech, AED President TobyMack told equipment industry executivesthat the nation’s infrastructure needs aredire, that Congress would soon be forcedto make difficult decisions about how topay for much-needed additional highwayconstruction, and that AED would be playinga major role in that national dialogue. Thevehicle for AED’s involvement will be theassociation’s new Highway InfrastructureTaskforce (HIT).Mack pointed to government estimatespredicting that by the time SAFETEA-LU, thecurrent highway law, expires in September 2009,gas tax revenues will fall short of authorizationlevels by close to $5 billion. If Congress does notaddress the problem, highway funding in 2009could be cut by more than 30 percent, and suchcuts would continue into the future.“AED has seen this coming and we have nointention of sitting on our hands,” Mack said.“We’re gearing up to play a major leadershiprole beyond anything we’ve done before. Withthe mobilization of our membership to provideboth the resources and political activism, notonly can we turn this around, but we can laythe groundwork for major new investment inhighway capacity going forward.” ■<strong>Tractor</strong> & Equipment Company has moved into new state-of-the-art facilities in Pooler, Georgia, serving Savannah and 13 surrounding countiesThe new facility is conveniently located at 1200 Highway 80 East in Pooler.The 22,000-square-foot branch features a 10-bay service shop and track press andsupports complete field service. It has an expansive parts facility that includes one of themost complete hose fabrication facilities in the Southeast and a complete complement ofOEM and aftermarket parts.Located directly adjacent to the branch is Komatsu’s newest Regional Parts Depot.The 30,000-square-foot, high-density warehouse is one of eight regional depots inthe Komatsu system and is tied directly to Komatsu’s main warehouse in Ripley,Tennessee, through <strong>Tractor</strong> & Equipment Company’s Network Overnight DeliverySystem (N.O.D.S.). N.O.D.S. gets parts from Ripley all the way to <strong>Tractor</strong> & EquipmentCompany’s facilities overnight. This great combination ensures you the best parts supportin southeast Georgia.In addition to Komatsu, the Savannah branch also offers and supports<strong>TEC</strong>’s full line of products including Ingersoll Rand compaction andpaving systems, Gradall and Sennebogen.Come by for any needs or just drop in and visit.See our commitment to you.PHONE: 912-330-7500 | FAX: 912-330-7490 | www.tractor-equipment.com | www.tecusedparts.com

DISTRIBUTOR CERTIFIEDRELIABLE EQUIPMENTRESPONSIVE SERVICECERTIFIED USED MACHINESWhy used equipment buyers will want to check outKomatsu ReMarketing's CONEXPO displayDo you want to avoid making a potentiallycostly mistake in your next used equipmentpurchase? A good way to be safe in buyingused is to buy a Komatsu Distributor Certifiedused machine. A Distributor Certified machineis not your typical used machine. To illustratethe difference, the Komatsu ReMarketinggroup will have a unique “half-and-half”machine at its display area at the upcomingCONEXPO in Las Vegas.“We’re taking a used D61PX dozer andfixing half of it to the standard of a ‘B-level’Distributor Certified unit,” explained KomatsuReMarketing director Lee Haak. “The otherhalf, we’re leaving ‘as is.’ We believe thiswill strikingly demonstrate what separates aKomatsu Distributor Certified machine from aused machine you might buy at auction.”The big difference between the two,according to Haak, is that Komatsu certifieswhat you’re buying, both inside and out. “Thefirst thing we do is put the machine through arigorous inspection to determine if it’s worthrestoring. If it doesn’t pass, we don’t fix it. Wesell it ‘as is,’ with a full report on what’s wrongwith it — or we sell it for parts.”Looks good and runs wellIf the inspection reveals the machine isworth fixing, your Komatsu distributor willmake the repairs, including putting in new orremanufactured parts or components wherenecessary.“Unlike some used equipment sellers whoonly do cosmetic work like paint jobs, wemake sure the machine is going to run well,as well as look good,” said Haak. “We dotrack work, blade or bucket work, servicethe hydraulic system, repack the cylinders,overhaul the engine — whatever is required.The bottom line is, because of the work we’vedone, you can be sure the machine will dowhat you’re counting on it to do.”In addition to viewing the “half-and-half”machine at CONEXPO, and learning whatall goes into bringing it up to a higher level,Komatsu Remarketing will have informationon a new warranty program designedspecifically for Distributor Certified machines.“We invite all CONEXPO attendees to stopin and see us, and learn more about KomatsuDistributor Certified used equipment,” saidHaak. “It sometimes costs a little more, butwe’ll be happy to show you how the additionalmoney is put back into the Distributor Certifiedpieces to bring them to a higher standard thanother used equipment.” ■Lee Haak,Komatsu ReMarketingDirectorWhat’s the difference between Komatsu Distributor Certified used equipmentand other used machines? A unique “half-and-half” D61 dozer (half certifiedand half used) will be on display at CONEXPO to illustrate the starkdifferences. Komatsu ReMarketing officials will be on hand to explain whatgets done and what it means to you as a used equipment purchaser.

If it can be measured,we measure it!Whether you’re looking for a highqualitymachine that will become part ofyour fleet, or for a machine that will get youthrough the busy season, Komatsu Distributor Certified Used Equipment is your best alternative to buying new.If it can be measured, we measure it! Specially trained Komatsu Distributor Certified evaluators check, measure and diagnosevirtually every aspect of the machine. Once the machine meets Komatsu’s high performance standards, your local distributorcan tailor the machine for your site-specific needs. And to add to your peace of mind, most Komatsu Distributor Certified UsedEquipment is eligible for special financing and warranty.Purchasing Komatsu Distributor Certified Used Equipment makes sound business sense. You’ll receive good value foryour money and a reliable and productive machine that will get the job done for years to come — we guarantee it!To learn more about Komatsu ReMarketing’s Distributor Certified Used Equipment, contact your local Komatsu Distributoror go to our Web site at www.equipmentcentral.com and click on “used equipment.”

Call Skip Walker404-366-0693Fax: 404-366-9688swalker@tractor-equipment.comCall Rick Mathis205-591-2131Fax: 205-592-7581rmathis@tractor-equipment.comKOMATSU D61EX-12, S/N B3188. .................$ 95,500 KOMATSU PC600LC-7, S/N 20082. ...............$ 350,000EXCAVATORSKOMATSU PC50MR-2, S/N 6028, 2005 ...................$ 35,000KOMATSU PC78MR-6, S/N 001468, 2004 .................$ 57,000KOMATSU PC95R-2, S/N R20395, 2005 ..................$ 74,000KOMATSU PC220LC-5, S/N A35447, 1989 ................$ 25,000KOMATSU PC270LC-7L, S/N A86156, 2004 ..............$ 155,000KOMATSU PC300HD-6, S/N A83004, 1999 ................$ 60,000KOMATSU PC300LC-6, S/N A84198, 2000 ................$ 75,000KOMATSU PC300LC-6, S/N A84711, 2001. ................$ 75,000KOMATSU PC300LC-6, S/N A84775, 2002 ............... $ 110,000KOMATSU PC300LC-6, S/N A84872, 2002 ............... $ 110,000KOMATSU PC300LC-7, S/N A85285, 2003 ...............$ 155,000KOMATSU PC300LC-7L, S/N A85994, 2004 ..............$ 149,500KOMATSU PC400HD-6, S/N A85020, 2002 ...............$ 135,000KOMATSU PC400LC-6LM, S/N A85333, 2003 .............$ 250,000KOMATSU PC600LC-7, S/N 20082, 2005. ................ $ 350,000KOMATSU PC750LC-7, S/N 020011, 2004. ...............$ 425,000DOZERSKOMATSU D31PX-21A, S/N 050897, 2005 ................$ 65,000KOMATSU D31PX-21A, S/N 50691, 2005 .................$ 47,500KOMATSU D31PX-21A, S/N 50780, 2004 .................$ 49,000KOMATSU D38P-1, S/N 86414, 2002 .....................$ 35,000KOMATSU D41E-6C, S/N B40042, 2004 ..................$ 82,500KOMATSU D41P-6C, S/N B40150, 2003 ..................$ 80,000KOMATSU D41P-6C, S/N B40225, 2004 ..................$ 75,000KOMATSU D61EX-12, S/N 0B1589, 2001. .................$ 60,000KOMATSU D61EX-12, S/N B1823, 2003. ..................$ 85,000KOMATSU D61EX-12, S/N B3188, 2004. ..................$ 95,500KOMATSU D61PX-12, S/N 1043, 2000 ....................$ 60,000KOMATSU D65EX-12, S/N 61587, 1996 ...................$ 48,500WHEEL LOADERSKOMATSU WA150L-5, S/N 71908, 2006 ..................$ 79,500KOMATSU WA250-5L, S/N A73333, 2004 .................$ 72,500KOMATSU WA250-5L, S/N A73337, 2004 .................$ 72,500COMPACTIONDYNAPAC CA150PD, S/N 73320445, 2004 ................$ 52,500www.tractor-equipment.com

C.P.I.P.O. Box 1689C.R., IA 52406-1689Change Service RequestedPresorted StandardUS Postage PaidC.P.I.THE PEOPLETHE PRODUCTSTHE SERVICE...WHERE YOU NEED US....WHEN YOU NEED US.TRACTOR & EQUIPMENTCO. LOCATIONS:BIRMINGHAM, AL(205) 591-2131MONTGOMERY, AL(334) 288-6580(800) 832-9563TUSCALOOSA, AL(205) 752-0621(800) 582-4625DECATUR, AL(256) 355-0305(800) 321-6865ANNISTON, AL(256) 831-2440MOBILE, AL(251) 457-8991(800) 233-7213DOTHAN, AL(334) 678-1832GROVE HILL, AL(251) 275-4158SHOALS AREA, AL(256) 383-5666ALABASTER, AL(205) 621-2489FOREST PARK, GA(Atlanta)(404) 366-0693(800) 488-0693HOSCHTON, GA(706) 654-9850(888) 334-9850KENNESAW, GA(678) 354-5533CALHOUN, GA(706) 879-6200(800) 827-3072MACON, GA(478) 745-6891(800) 786-3120AUGUSTA, GA(706) 798-7777(800) 659-3090COLUMBUS, GA(706) 562-1801SAVANNAH, GA(912) 330-7500(800) 827-1405ALBANY, GA(229) 435-0982(800) 733-0982Pantone 072 blueCRUZ-AIRD R E S S TATRASHMASTERSD R E S S TA®PANAMA CITY, FL(850) 763-4654(800) 342-2055PENSACOLA, FL(850) 505-0550P&H®*Prentice, Hydro-Ax CTR, Fabtek* In Alabama & Florida, Blount is only available through the Dothan,Pensacola & Panama City branches.P&H®AL-FL