In Mold Decorating of Injection Molded Parts - Esterline

In Mold Decorating of Injection Molded Parts - Esterline

In Mold Decorating of Injection Molded Parts - Esterline

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

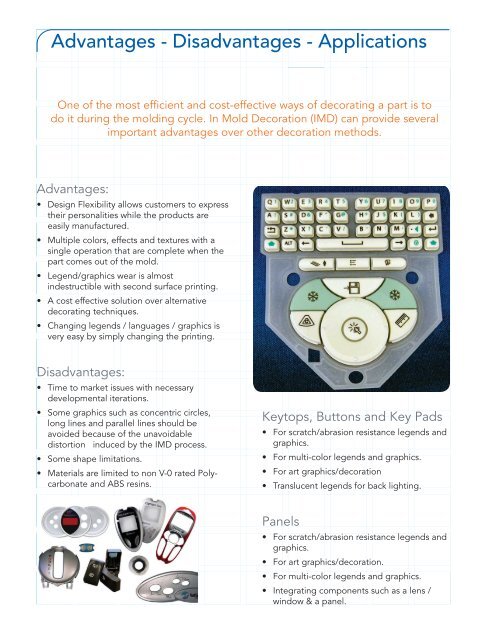

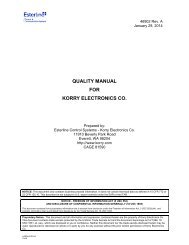

Advantages - Disadvantages - ApplicationsOne <strong>of</strong> the most efficient and cost-effective ways <strong>of</strong> decorating a part is todo it during the molding cycle. <strong>In</strong> <strong>Mold</strong> Decoration (IMD) can provide severalimportant advantages over other decoration methods.Advantages:• Design Flexibility allows customers to expresstheir personalities while the products areeasily manufactured.• Multiple colors, effects and textures with asingle operation that are complete when thepart comes out <strong>of</strong> the mold.• Legend/graphics wear is almostindestructible with second surface printing.• A cost effective solution over alternativedecorating techniques.• Changing legends / languages / graphics isvery easy by simply changing the printing.Disadvantages:• Time to market issues with necessarydevelopmental iterations.• Some graphics such as concentric circles,long lines and parallel lines should beavoided because <strong>of</strong> the unavoidabledistortion induced by the IMD process.• Some shape limitations.• Materials are limited to non V-0 rated Polycarbonateand ABS resins.Keytops, Buttons and Key Pads• For scratch/abrasion resistance legends andgraphics.• For multi-color legends and graphics.• For art graphics/decoration• Translucent legends for back lighting.Panels• For scratch/abrasion resistance legends andgraphics.• For art graphics/decoration.• For multi-color legends and graphics.• <strong>In</strong>tegrating components such as a lens /window & a panel.